Thermodynamic Process Control LFC001TPCMVPMV Thermodynamic Controller User Manual 02

Thermodynamic Process Control, LLC Thermodynamic Controller 02

Contents

- 1. User manual 01

- 2. User manual 02

User manual 02

TPC-FI SoloNet O&M Page 36

TPC-FI SoloNet O&M Page 37

Appendix A

TPC-FI SoloNet O&M Page 38

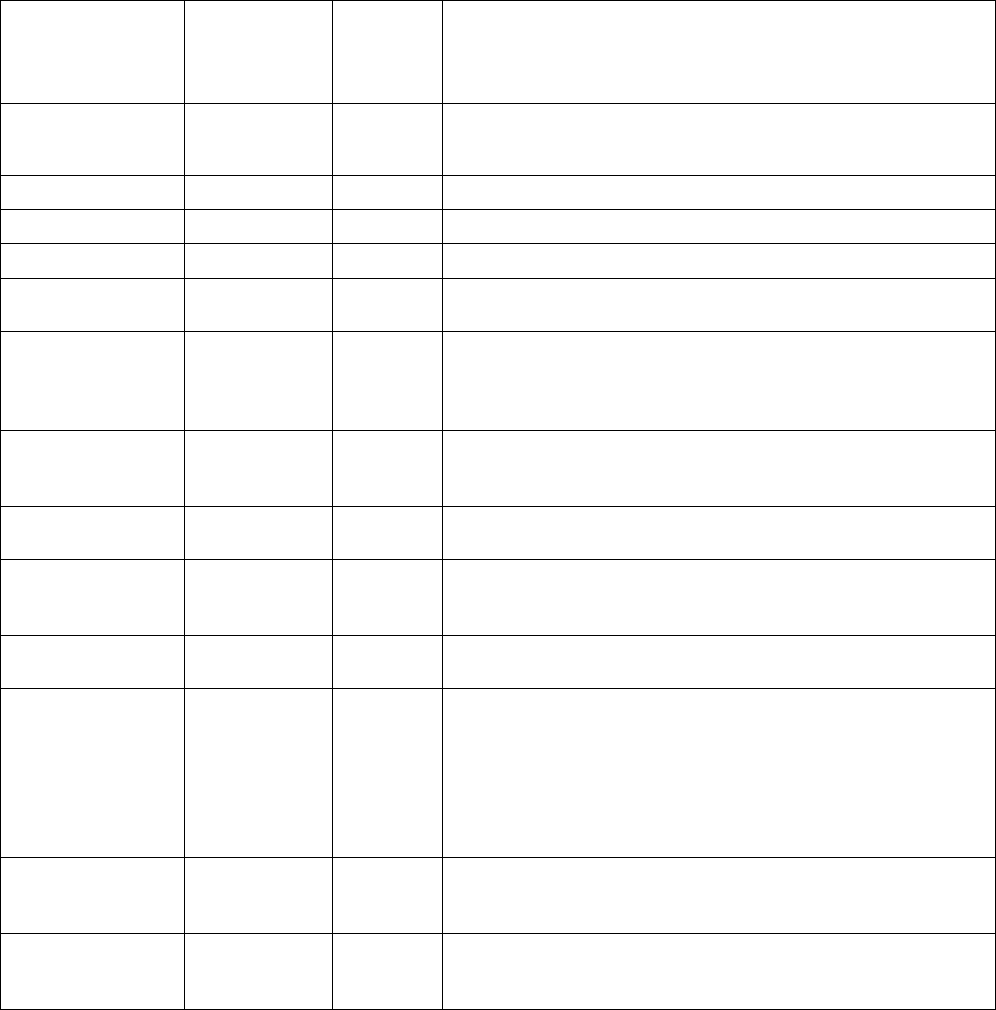

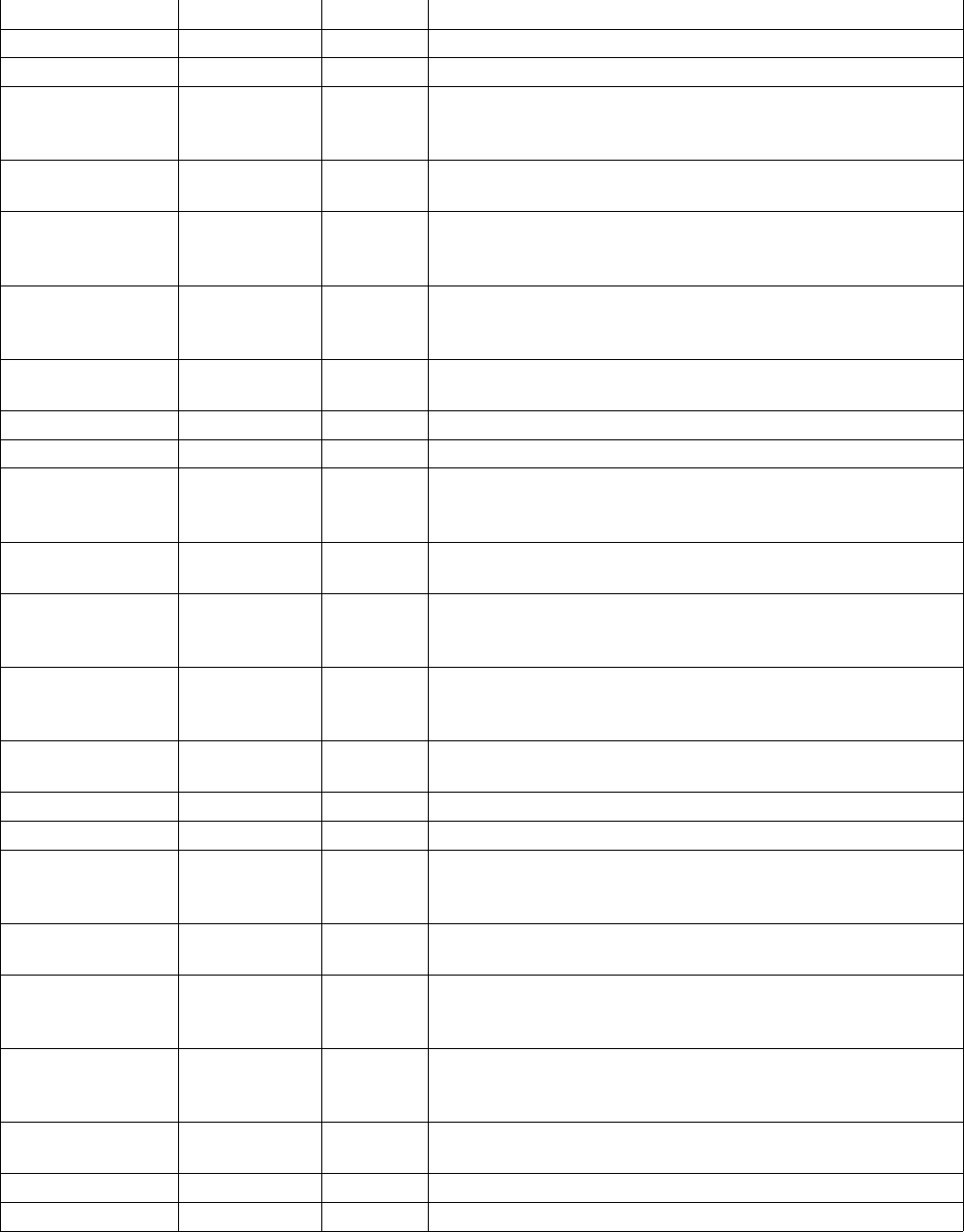

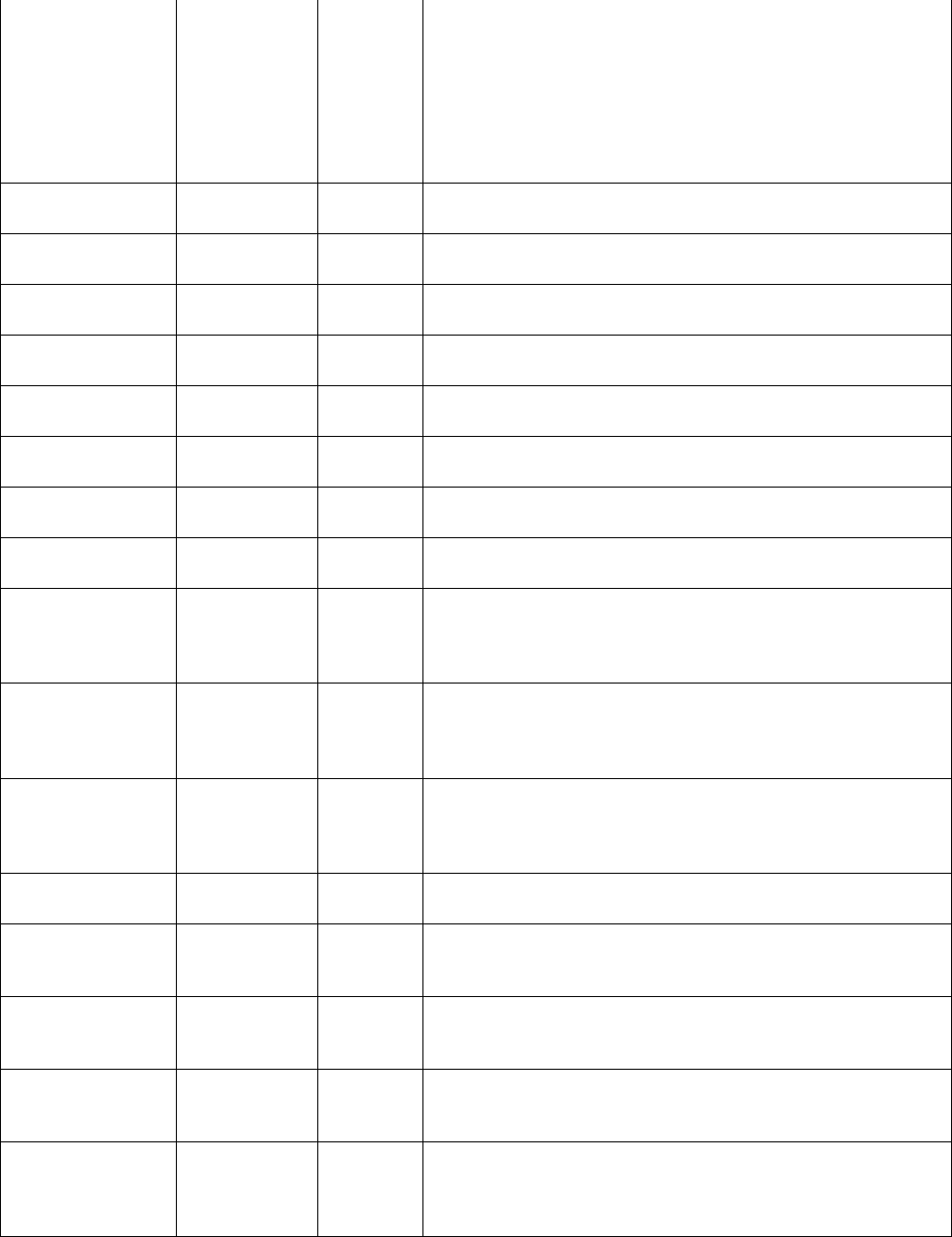

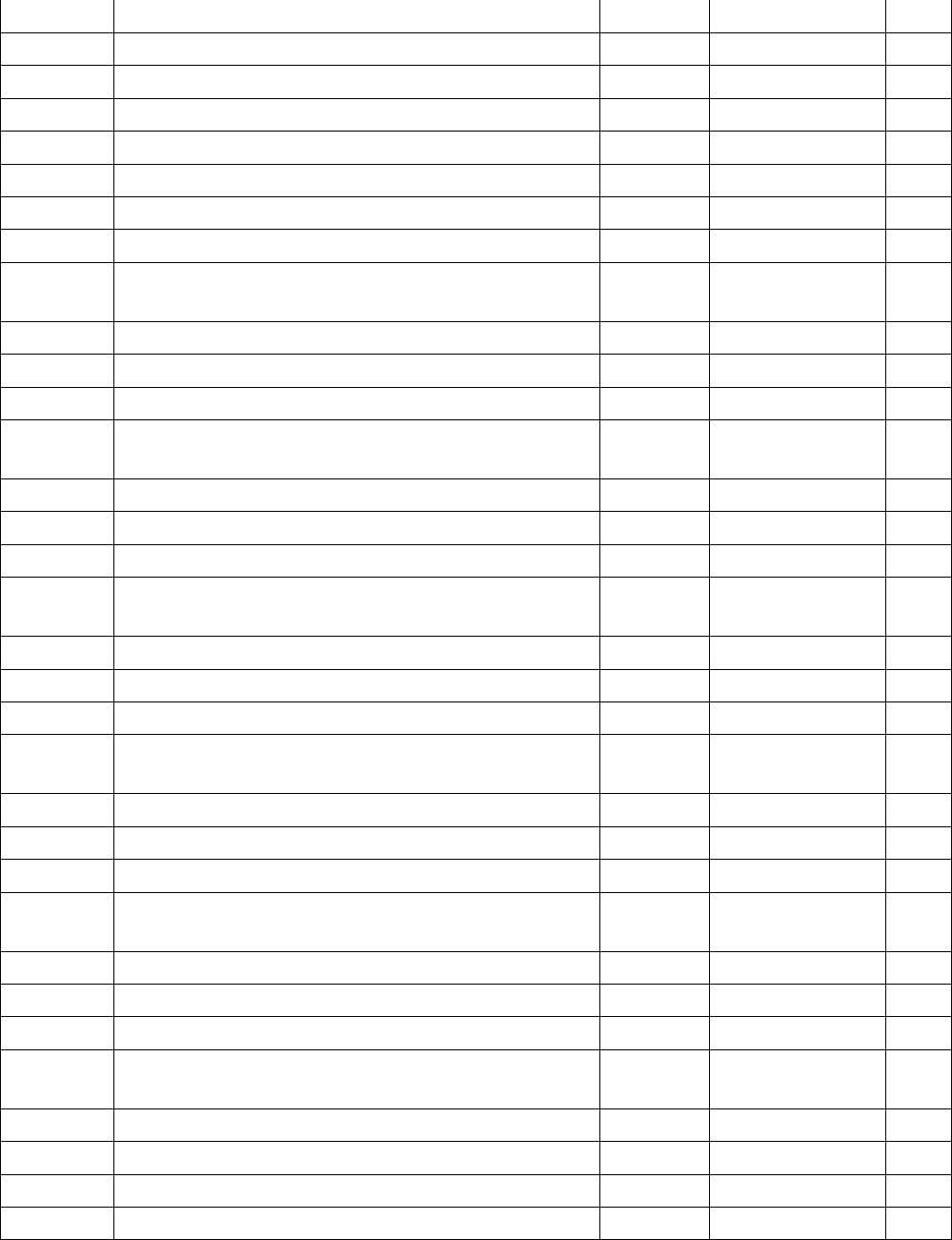

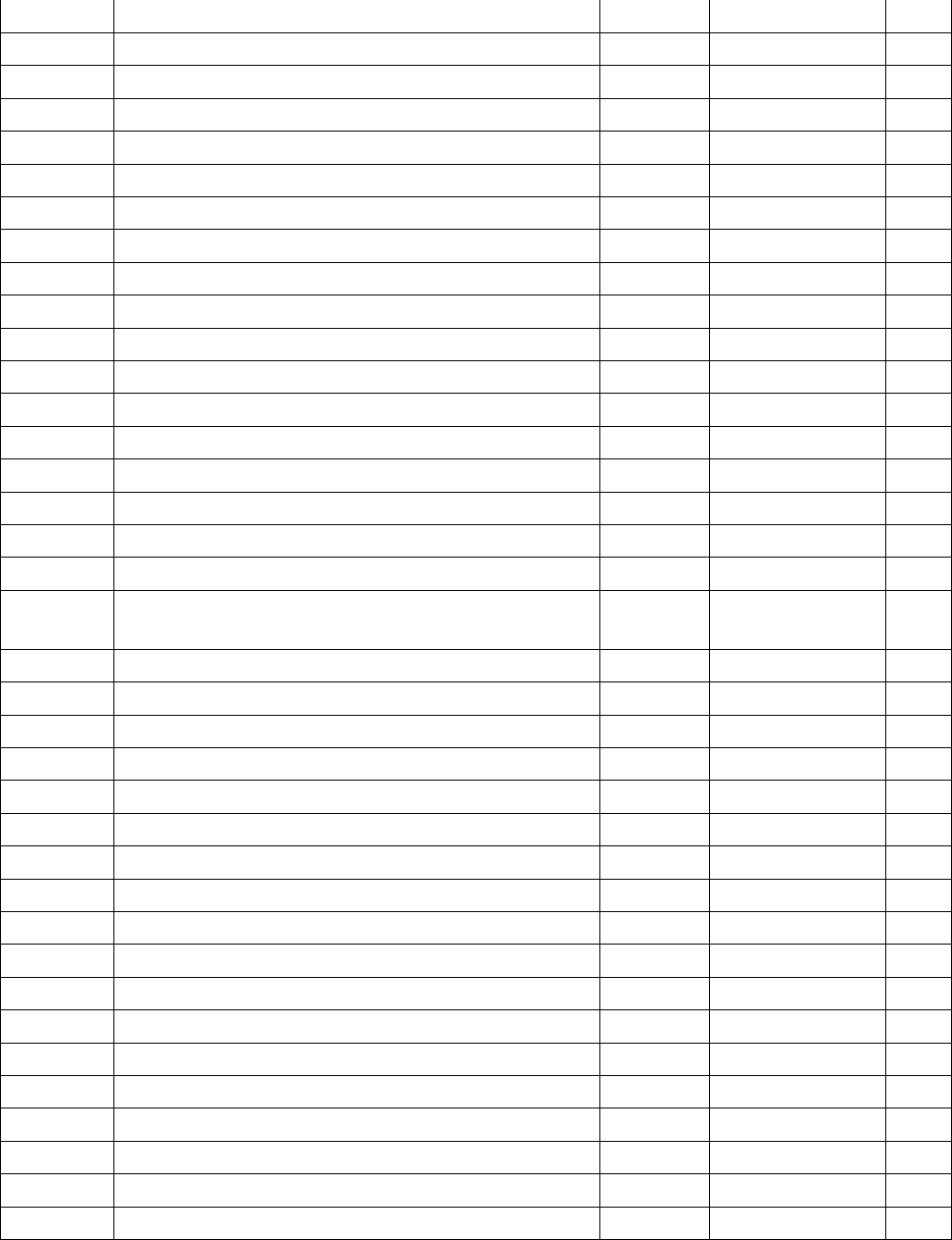

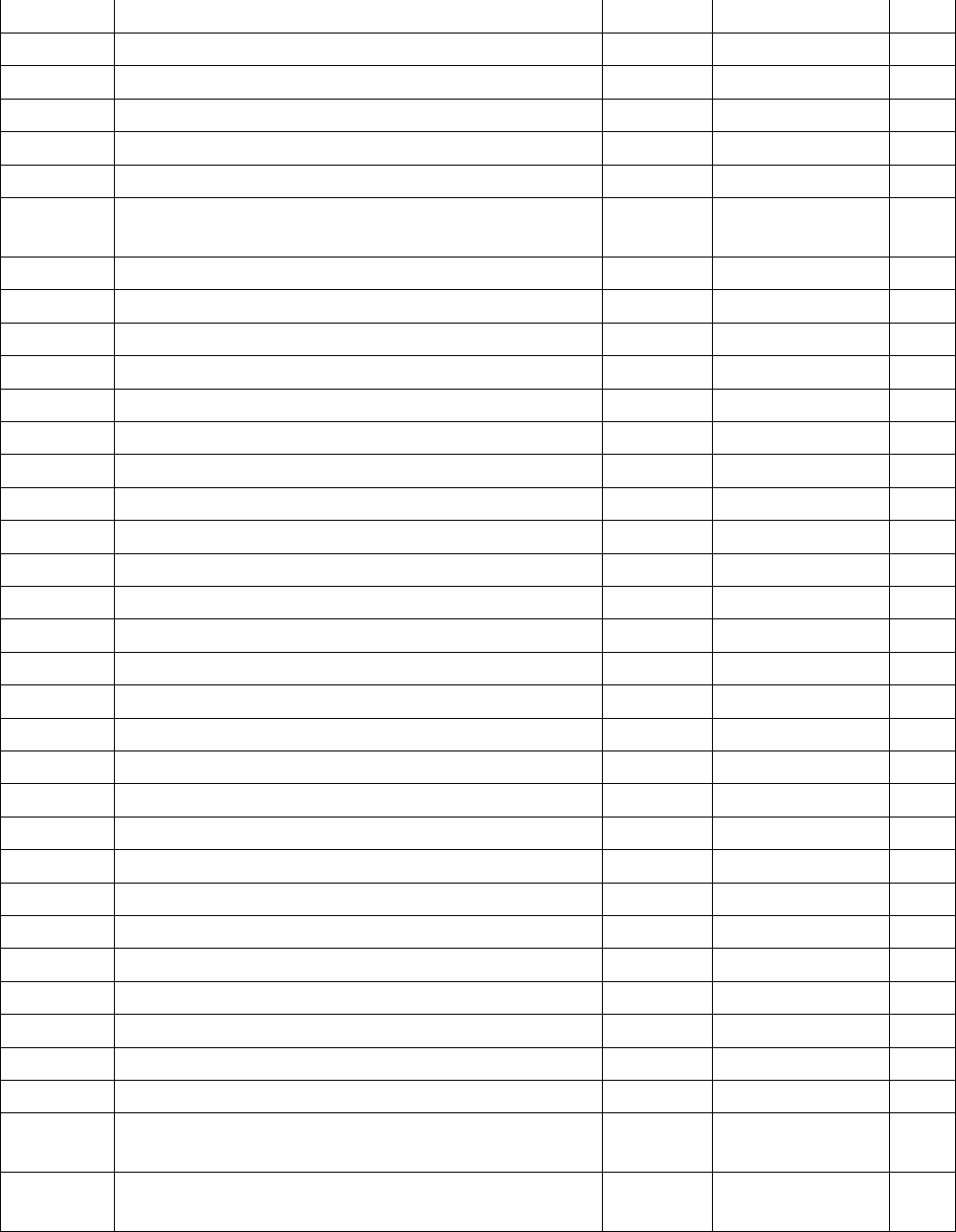

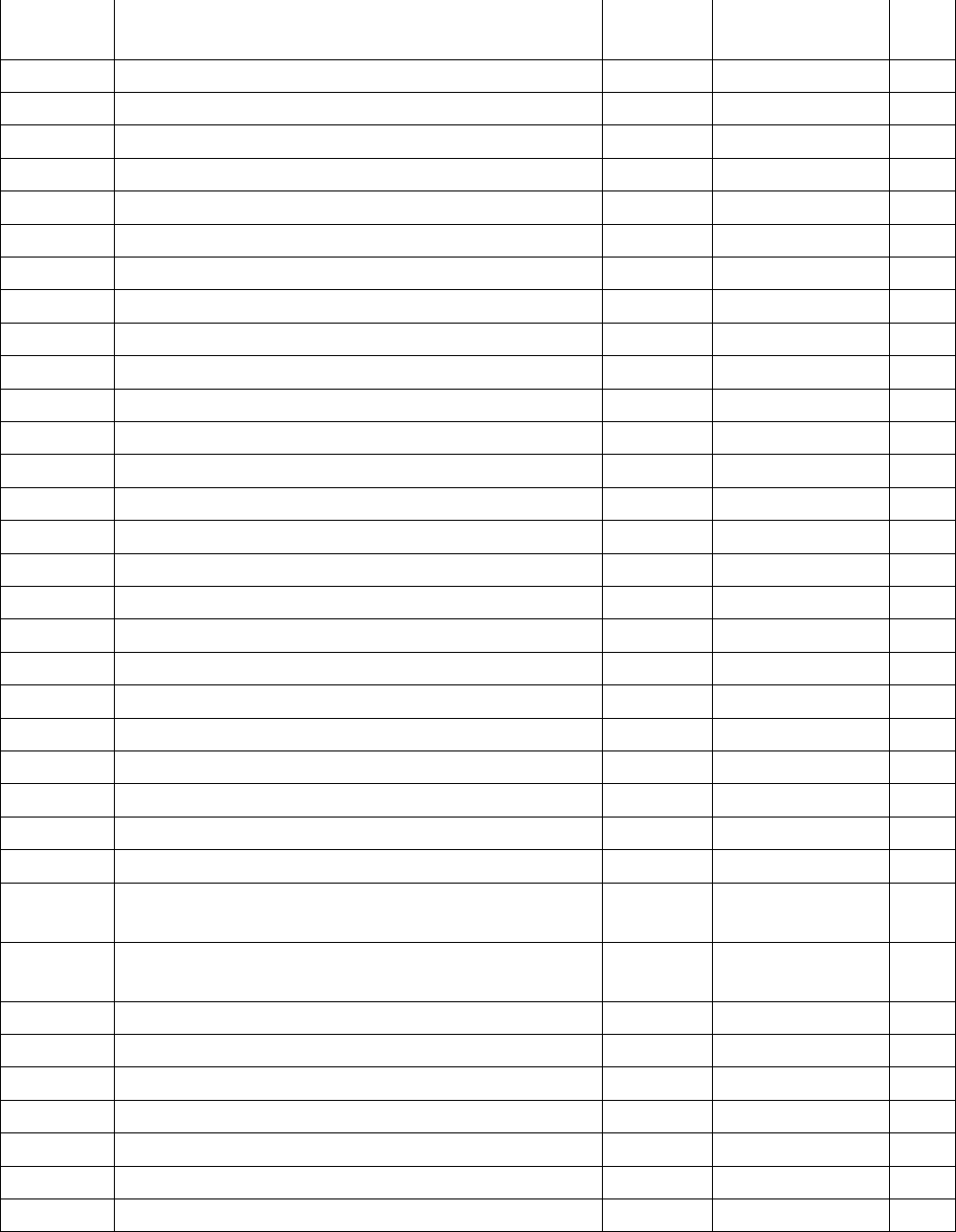

GUI

Parameters

TPC

Parameter

Ranges

TPC

Default

TPC Descriptions

System

Parameters

Design Inputs

Units Fahrenheit,

Celsius Fahrenheit Choose the convention in which you would like to display system

information.

Sum Reporting Zone

Loads Enable / Disable Disable

Choose "Enable" if you are using multiple flow meters attached to

"Zone Load Controllers" to report back loads in one or more zones.

Chose "Disable" if using single point flow measurement attached to

the "System Information Field Device"

Outdoor Design

Temperature -40 - 40 F 0

Choose the outdoor air temperature this system was designed to

overcome worst case. This will be the coldest temperatures you

would expect to see in this climate.

Indoor Design

Temperature 60 - 80 F 70 Choose the indoor temperature the building is designed to maintain

under full-load conditions.

Redundancy Factor 1.00 - 10.00 4

Choose the factor by which the design MBH input (sum of boiler

MBH inputs) is greater than the required MBH needed under

maximum load conditions.

System Circulation

Delay minutes 1 - 30 Min 10 Chose the delay time desired from the start of the system pumps

until the selection and start of the first boiler stage.

Initial Delay Minutes 10 - 240 Min 60

Choose the number of minutes you desire to delay an additional

boiler staging on when the outdoor air temperature has reached just

reached the "Winter Heat On Set-point". This delay is designed to

allow a single boiler stage to gradually warm the system during

light load times only. This delay is linked to the initial switching

from off to on of a call for heat and will not affect control action as

long as heat remains enabled.

Minimum Hysteresis 2 - 40 F 5

Chose the maximum number of degrees that you desire to allow the

system temperature to drop below set-point and sustain for the

"Stage Delay Time" before enabling another stage of heat.

Maximum Hysteresis 5 - 80 F 15

Chose the maximum number of degrees that you desire to allow the

system temperature to overshoot set-point before disabling all

boilers on the system.

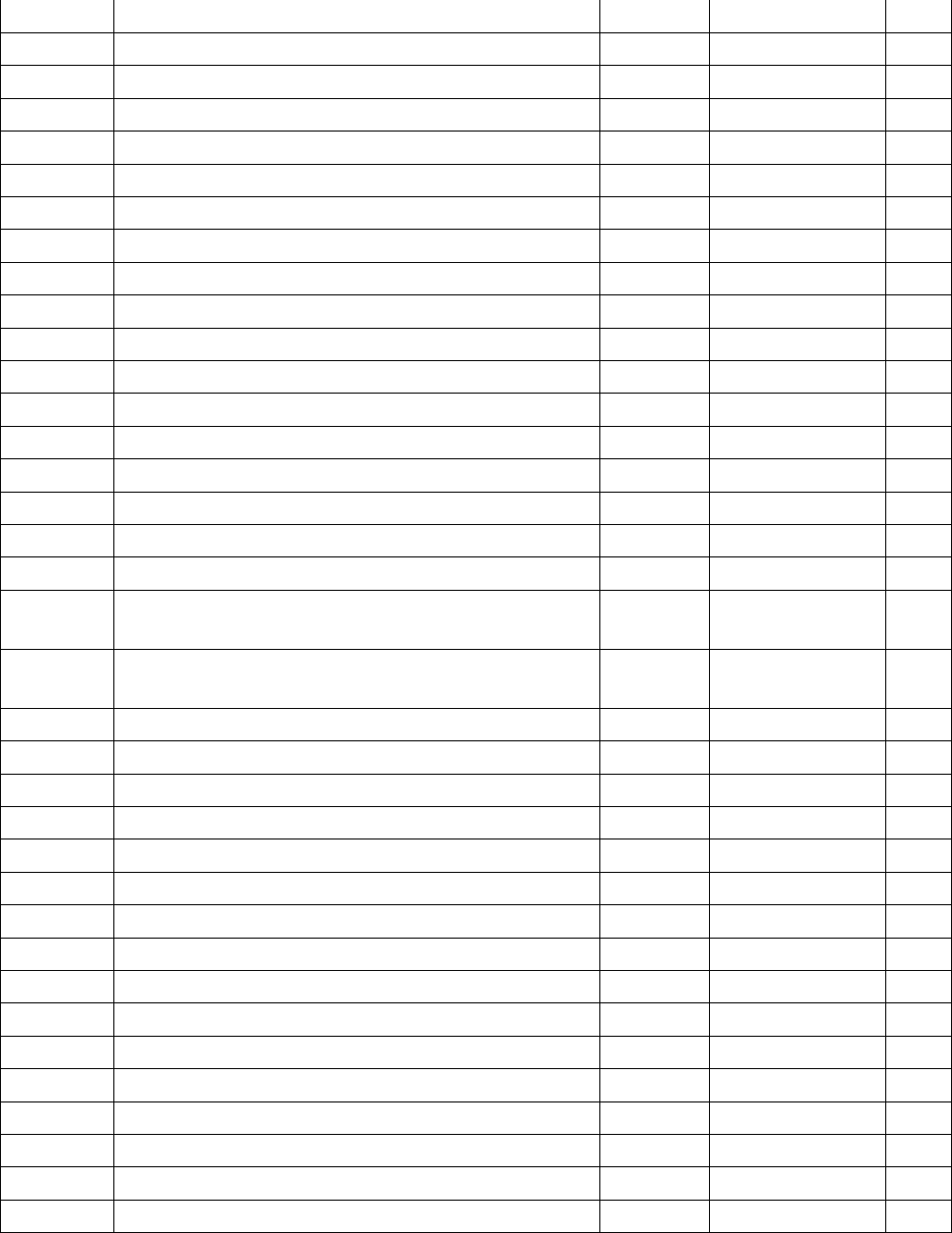

TPC-FI SoloNet O&M Page 39

Minimum Stage

Delay Minutes 1 - 60 Min 30

Choose the number of minutes conditions ( load deficit ) must

persist before activating the next stage of heat. This delay will

work between every stage selection except in the case of a heating

emergency as defined in the O&M manual

System Delta T Set-

point 0-50 F 10

Enter the Delta T you wish to keep across the system. To use this

feature you must also designate a system pump for Delta T

operation.

Pipe Type Steel, Copper,

CPVC- Steel Enter the type of pipe in which the flow meter is inserted

Pipe Schedule 20, 40, 80 40 Enter the code of construction of the pipe in which the flow meter

is inserted.

Pipe Size 2 - 48 In 8 Enter the diameter of the pipe in which the flow meter is inserted.

Default Flow Rate

GPM

10 - 150,000

GPM 500 Enter the estimated maximum flow rate of this system.

Manual Override of

System Flow Input Enable / Disable Disable

Choose to manually override the flow meter by enabling this

function. If you enable this function then the control will choose to

read the maximum flow rate. You will only want to enable this

function when you are servicing the flow meter or if it otherwise

not operating.

Heat Priority

Winter Heat On Set-

point 30 - 150 F 60 Choose the outdoor air temperature at which you desire to enable

the heating plant.

NonCondensing

Outdoor Set-point -20 - 80 F 0 Choose the outdoor air temperature at which you desire to begin

utilizing the non-condensing control loop Reset 2.

Heat Reset 1 -

Condensing

Maximum System

Supply Set-point 60 - 210 F 120 Choose the maximum supply temperature allowed on this system

while the condensing reset loop is active.

Minimum System

Supply Set-point 40 - 200 F 80 choose the minimum supply temperature allowed while the

condensing reset loop is active.

Maximum Outdoor

Temperature Set-

point

30 - 150 F 60

Choose the maximum outdoor air temperature which the

condensing reset loop will use to calculate the Supply water

temperature set-point.

Minimum Outdoor

Temperature Set-

point

-40 - 40 F 0

Choose the minimum outdoor air temperature which the condensing

reset loop will use to calculate the Supply water temperature set-

point.

Reset Shift Degrees 0 - 40 F 0

After the system has been in operation you may further fine tune

this reset loop by shifting the slope up or down. This is a linear

function which means the entire reset slope will shift.

Heat Reset 2 -

NonCondensing

Maximum System

Supply Set point 60 - 210 F 180 Choose the maximum supply temperature allowed on this system

while the Non-condensing reset slope is active.

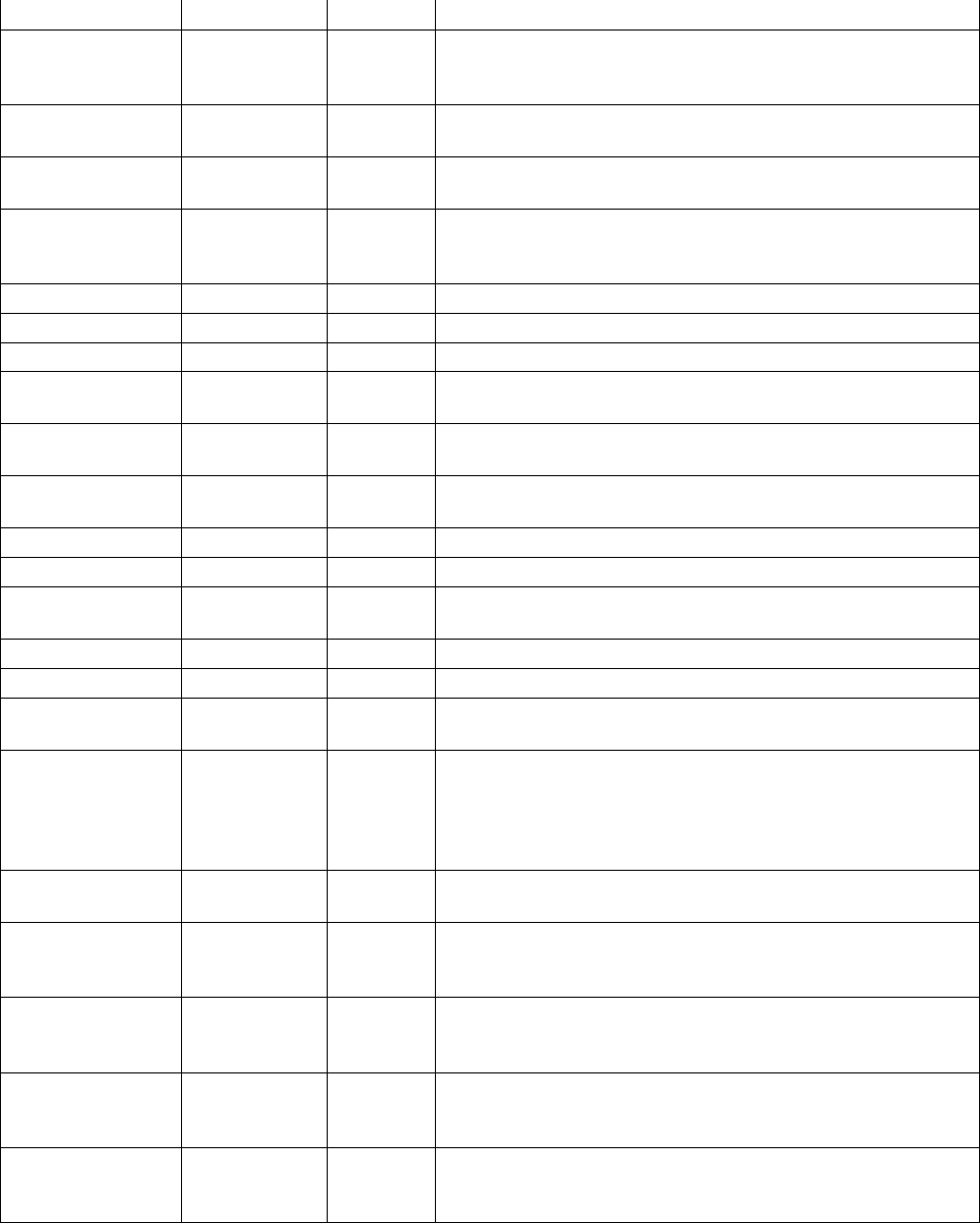

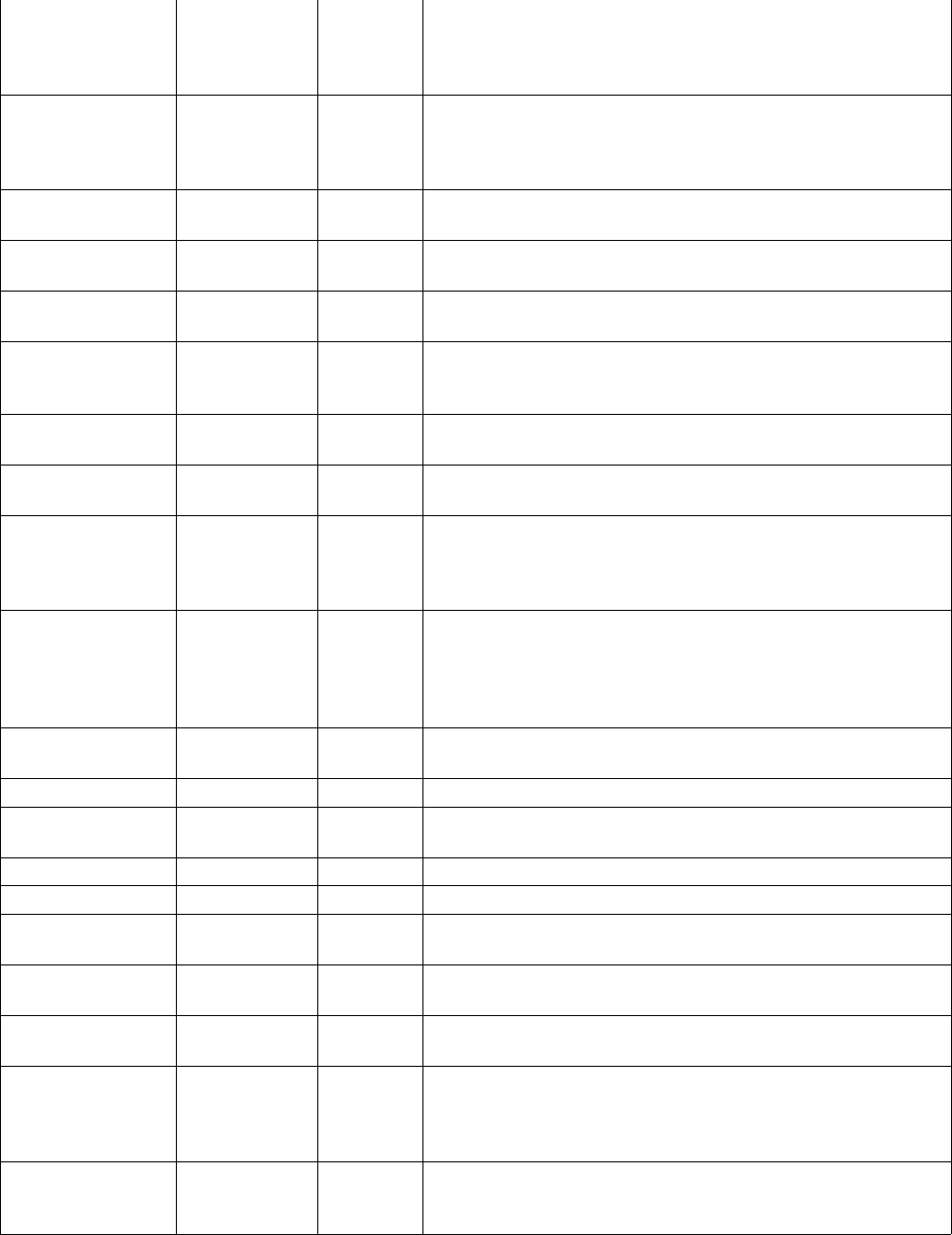

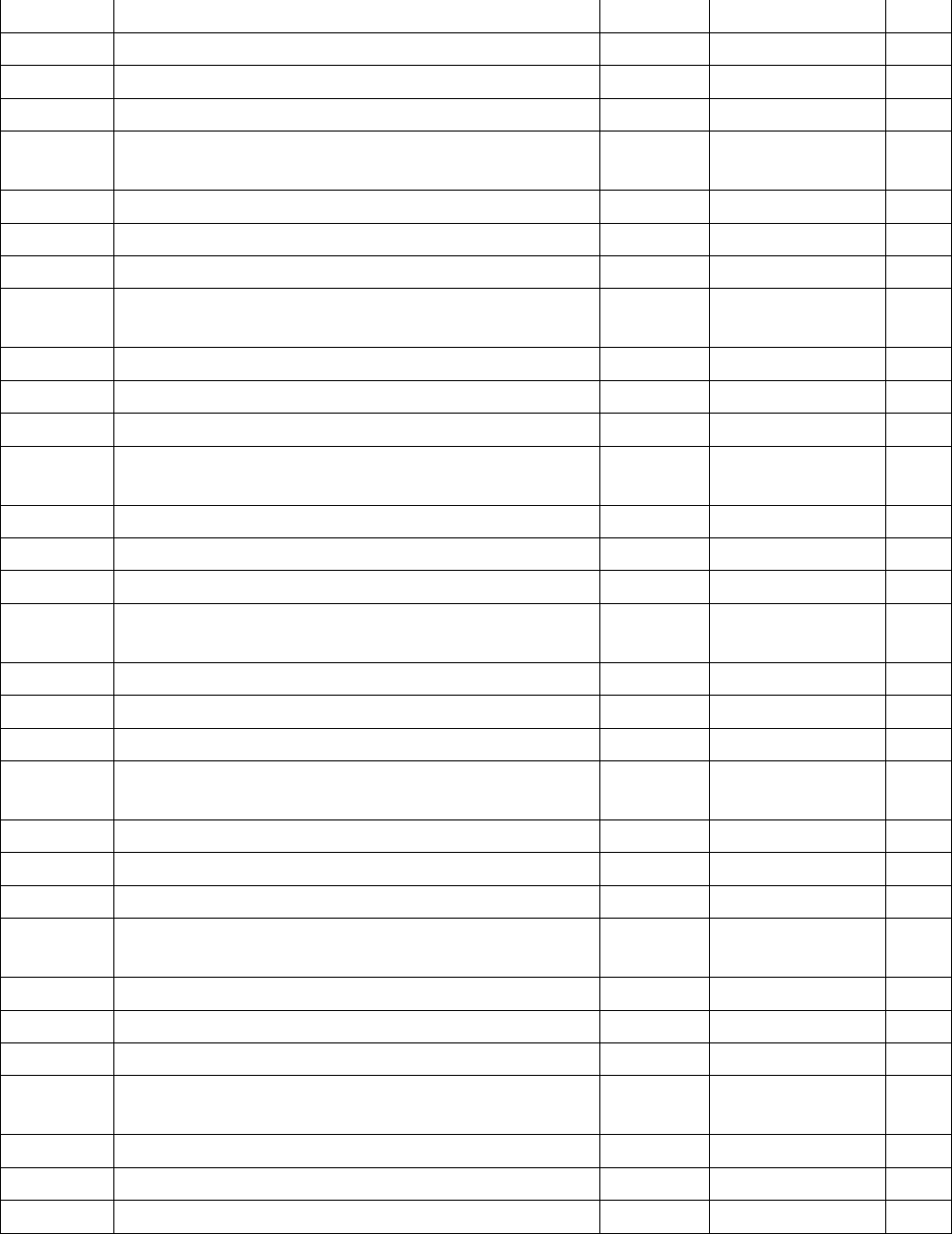

TPC-FI SoloNet O&M Page 40

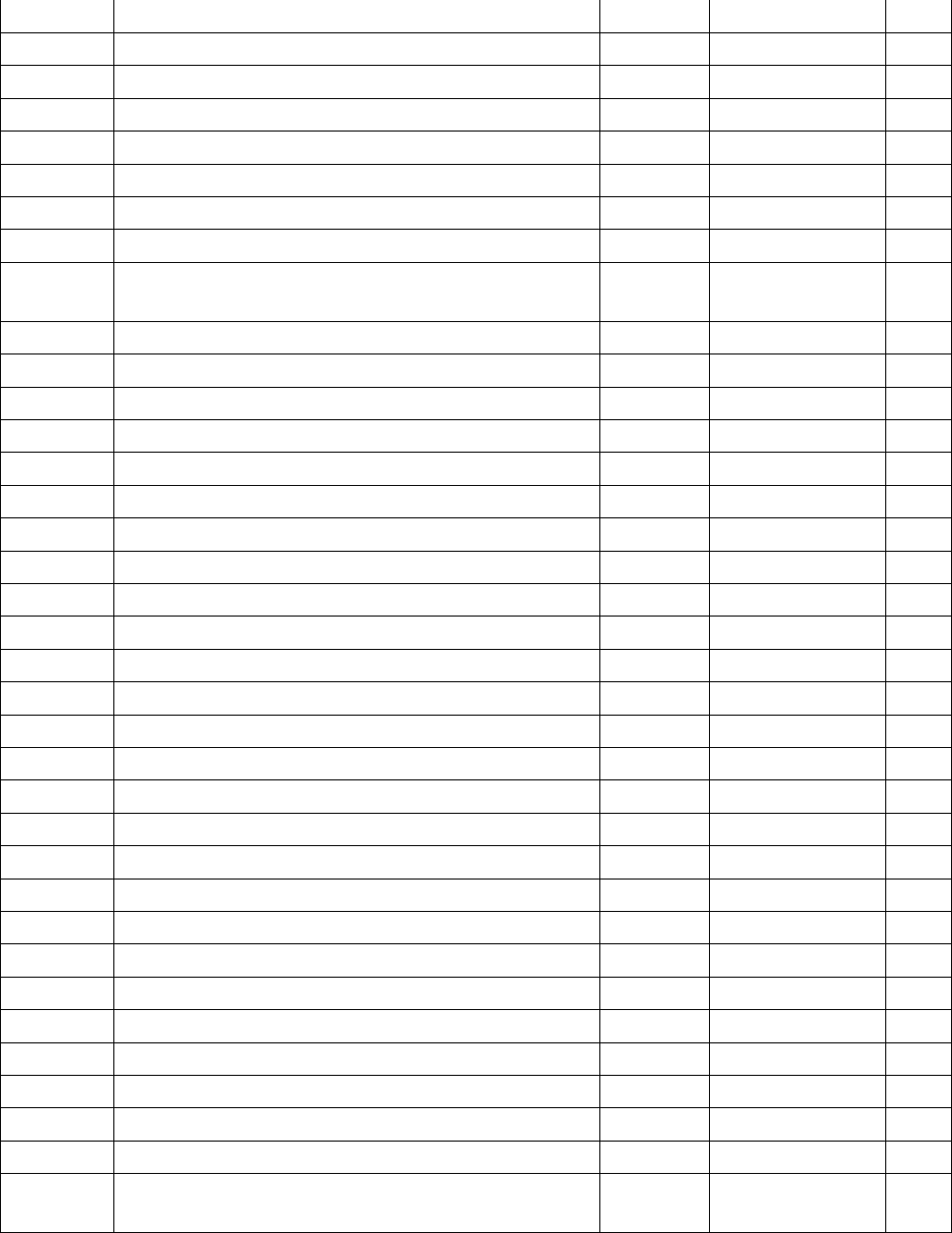

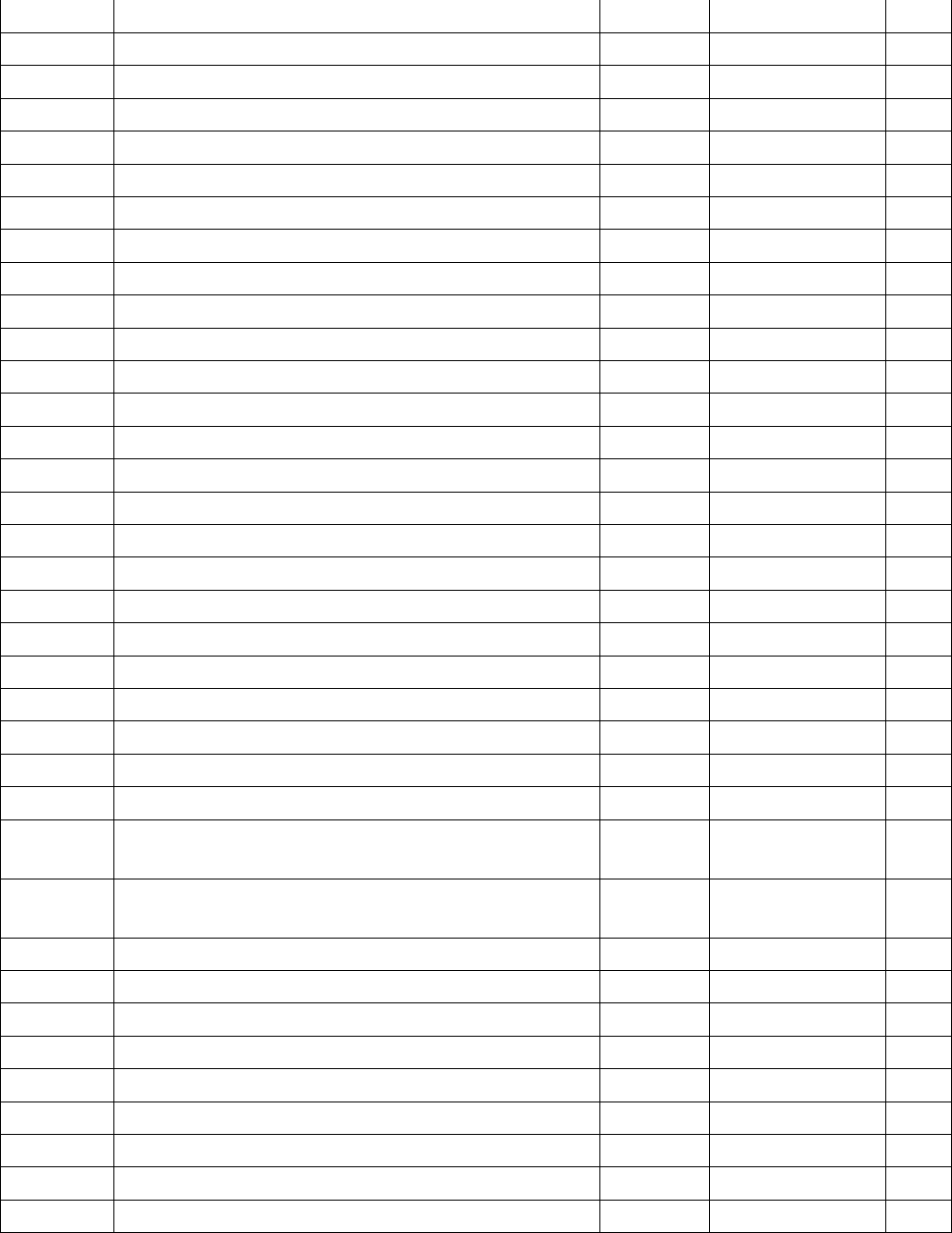

Minimum System

Supply Set point 40 - 200 F 140 Choose the minimum supply temperature allowed while the Non-

condensing reset slope is active.

Maximum Outdoor

Temperature Set

point

30 - 150 F 60

Choose the maximum outdoor air temperature which the Non-

condensing reset loop will use to calculate the Supply water

temperature set-point.

Minimum Outdoor

Temperature Set

point

-40 - 40 F 0

Choose the minimum outdoor air temperature which the Non-

condensing reset loop will use to calculate the Supply water

temperature set-point.

Reset Shift Degrees 0 - 40 F 0

After the system has been in operation you may further fine tune

this reset loop by shifting the slope up or down. This is a linear

function which means the entire reset slope will shift.

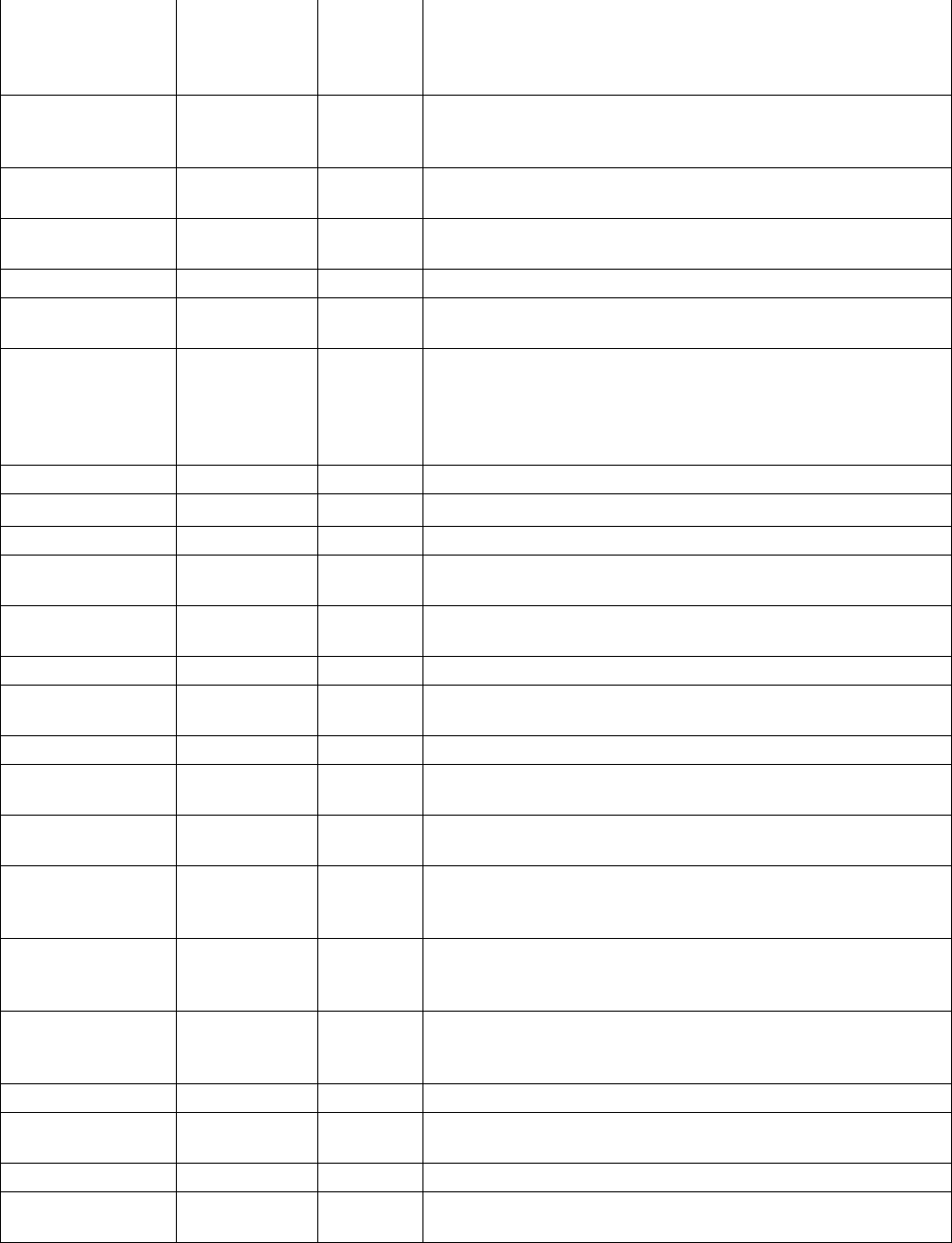

Heat Reset 3 - Reheat

Maximum System

Supply Set point 60 - 210 F 120 Choose the maximum supply temperature allowed on this system

while the Reheat reset slope is active.

Minimum System

Supply Set point 40 - 200 F 100 Choose the minimum supply temperature allowed while the Reheat

reset slope is active.

Maximum Outdoor

Temperature Set

point

80 - 160 F 100

Choose the maximum outdoor air temperature which the Reheat

reset slope will use to calculate the Supply water temperature set-

point.

Minimum Outdoor

Temperature Set

point

40 - 100 F 70

Choose the minimum outdoor air temperature which the Reheat

reset slope will use to calculate the Supply water temperature set-

point.

Reset Shift Degrees 0 - 40 F 0

After the system has been in operation you may further fine tune

this reset slope by shifting the line up or down. This is a linear

function which means the entire reset slope will shift.

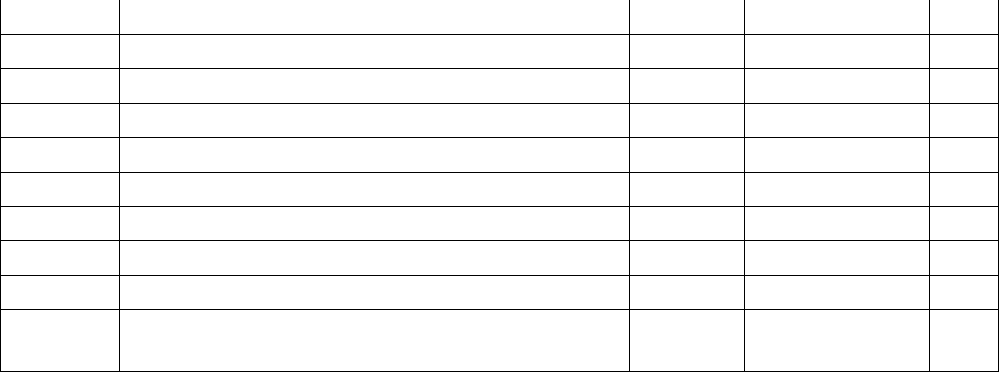

Optimum Stop / Start

Night Setback Value 0 - 40 F 10 Choose the number of degrees you wish to let the system fall to

under night setback conditions.

Boost Value 0 - 40 F 0

Choose the number of degrees you wish to allow the control to take

the system above the set point at morning warm up. A value

greater than zero may or may not be required for optimum start.

Boost Runtime

Minutes 0 - 120 Min 60 Choose the number of minutes you wish for boost above the active

reset to operate before returning to the calculated reset value.

Monday

Night Setback Enable / Disable Disable Choose to enable or disable this operation.

Begin Setback Hour /

Minute 0:00 - 23:59 1

Choose the time before the unoccupied period you wish to allow

the control to begin a "controlled descent" to the unoccupied

temperature.

Complete Setback

Hour / Minute 0:00 - 23:59 1 Enter the time you expect the building to be unoccupied for this day

of the week.

Day Return Enable / Disable Disable

Choose enable if you desire to bring the system back up to

temperature from the previous day. If you choose to designate this

day of the week as unoccupied simply disable day return.

TPC-FI SoloNet O&M Page 41

Begin Return Hour /

Minute 0:00 - 23:59 0

Choose the time before the building is occupied that you desire to

start a controlled ramp up to the calculated reset + Boost value

temperature.

Complete Return

Hour / Minute 0:00 - 23:59 0 Choose the time of day you expect the building to be occupied.

Tuesday

Night Setback Enable / Disable Disable Choose to enable or disable this operation.

Begin Setback Hour /

Minute 0:00 - 23:59 1

Choose the time before the unoccupied period you wish to allow

the control to begin a "controlled descent" to the unoccupied

temperature.

Complete Setback

Hour / Minute 0:00 - 23:59 1 Enter the time you expect the building to be unoccupied for this day

of the week.

Day Return Enable / Disable Disable

Choose enable if you desire to bring the system back up to

temperature from the previous day. If you choose to designate this

day of the week as unoccupied simply disable day return.

Begin Return Hour /

Minute 0:00 - 23:59 0

Choose the time before the building is occupied that you desire to

start a controlled ramp up to the calculated reset + Boost value

temperature.

Complete Return

Hour / Minute 0:00 - 23:59 0 Choose the time of day you expect the building to be occupied.

Wednesday

Night Setback Enable / Disable Disable Choose to enable or disable this operation.

Begin Setback Hour /

Minute 0:00 - 23:59 1

Choose the time before the unoccupied period you wish to allow

the control to begin a "controlled descent" to the unoccupied

temperature.

Complete Setback

Hour / Minute 0:00 - 23:59 1 Enter the time you expect the building to be unoccupied for this day

of the week.

Day Return Enable / Disable Disable

Choose enable if you desire to bring the system back up to

temperature from the previous day. If you choose to designate this

day of the week as unoccupied simply disable day return.

Begin Return Hour /

Minute 0:00 - 23:59 0

Choose the time before the building is occupied that you desire to

start a controlled ramp up to the calculated reset + Boost value

temperature.

Complete Return

Hour / Minute 0:00 - 23:59 0 Choose the time of day you expect the building to be occupied.

Thursday

Night Setback Enable / Disable Disable Choose to enable or disable this operation.

Begin Setback Hour /

Minute 0:00 - 23:59 1

Choose the time before the unoccupied period you wish to allow

the control to begin a "controlled descent" to the unoccupied

temperature.

Complete Setback

Hour / Minute 0:00 - 23:59 1 Enter the time you expect the building to be unoccupied for this day

of the week.

Day Return Enable / Disable Disable

Choose enable if you desire to bring the system back up to

temperature from the previous day. If you choose to designate this

day of the week as unoccupied simply disable day return.

Begin Return Hour /

Minute 0:00 - 23:59 0

Choose the time before the building is occupied that you desire to

start a controlled ramp up to the calculated reset + Boost value

temperature.

Complete Return 0:00 - 23:59 0 Choose the time of day you expect the building to be occupied.

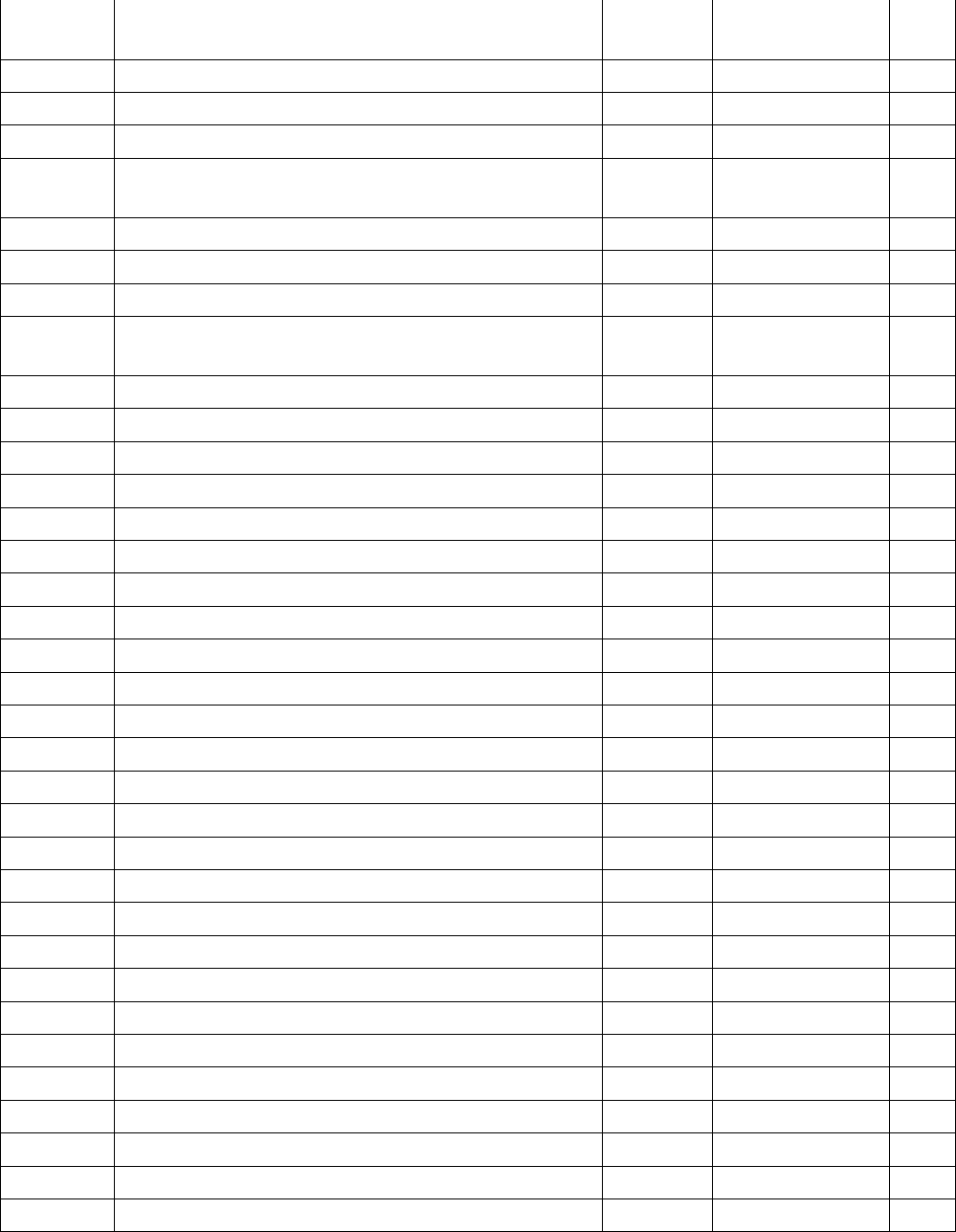

TPC-FI SoloNet O&M Page 42

Hour / Minute

Friday

Night Setback Enable / Disable Disable Choose to enable or disable this operation.

Begin Setback Hour /

Minute 0:00 - 23:59 1

Choose the time before the unoccupied period you wish to allow

the control to begin a "controlled descent" to the unoccupied

temperature.

Complete Setback

Hour / Minute 0:00 - 23:59 1 Enter the time you expect the building to be unoccupied for this day

of the week.

Day Return Enable / Disable Disable

Choose enable if you desire to bring the system back up to

temperature from the previous day. If you choose to designate this

day of the week as unoccupied simply disable day return.

Begin Return Hour /

Minute 0:00 - 23:59 0

Choose the time before the building is occupied that you desire to

start a controlled ramp up to the calculated reset + Boost value

temperature.

Complete Return

Hour / Minute 0:00 - 23:59 0 Choose the time of day you expect the building to be occupied.

Saturday

Night Setback Enable / Disable Disable Choose to enable or disable this operation.

Begin Setback Hour /

Minute 0:00 - 23:59 0:00

Choose the time before the unoccupied period you wish to allow

the control to begin a "controlled descent" to the unoccupied

temperature.

Complete Setback

Hour / Minute 0:00 - 23:59 0:00 Enter the time you expect the building to be unoccupied for this day

of the week.

Day Return Enable / Disable Disable

Choose enable if you desire to bring the system back up to

temperature from the previous day. If you choose to designate this

day of the week as unoccupied simply disable day return.

Begin Return Hour /

Minute 0:00 - 23:59 1

Choose the time before the building is occupied that you desire to

start a controlled ramp up to the calculated reset + Boost value

temperature.

Complete Return

Hour / Minute 0:00 - 23:59 1 Choose the time of day you expect the building to be occupied.

Sunday

Night Setback Enable / Disable Disable Choose to enable or disable this operation.

Begin Setback Hour /

Minute 0:00 - 23:59 0:00

Choose the time before the unoccupied period you wish to allow

the control to begin a "controlled descent" to the unoccupied

temperature.

Complete Setback

Hour / Minute 0:00 - 23:59 0:00 Enter the time you expect the building to be unoccupied for this day

of the week.

Day Return Enable / Disable Disable

Choose enable if you desire to bring the system back up to

temperature from the previous day. If you choose to designate this

day of the week as unoccupied simply disable day return.

Begin Return Hour /

Minute 0:00 - 23:59 1

Choose the time before the building is occupied that you desire to

start a controlled ramp up to the calculated reset + Boost value

temperature.

Complete Return

Hour / Minute 0:00 - 23:59 1 Choose the time of day you expect the building to be occupied.

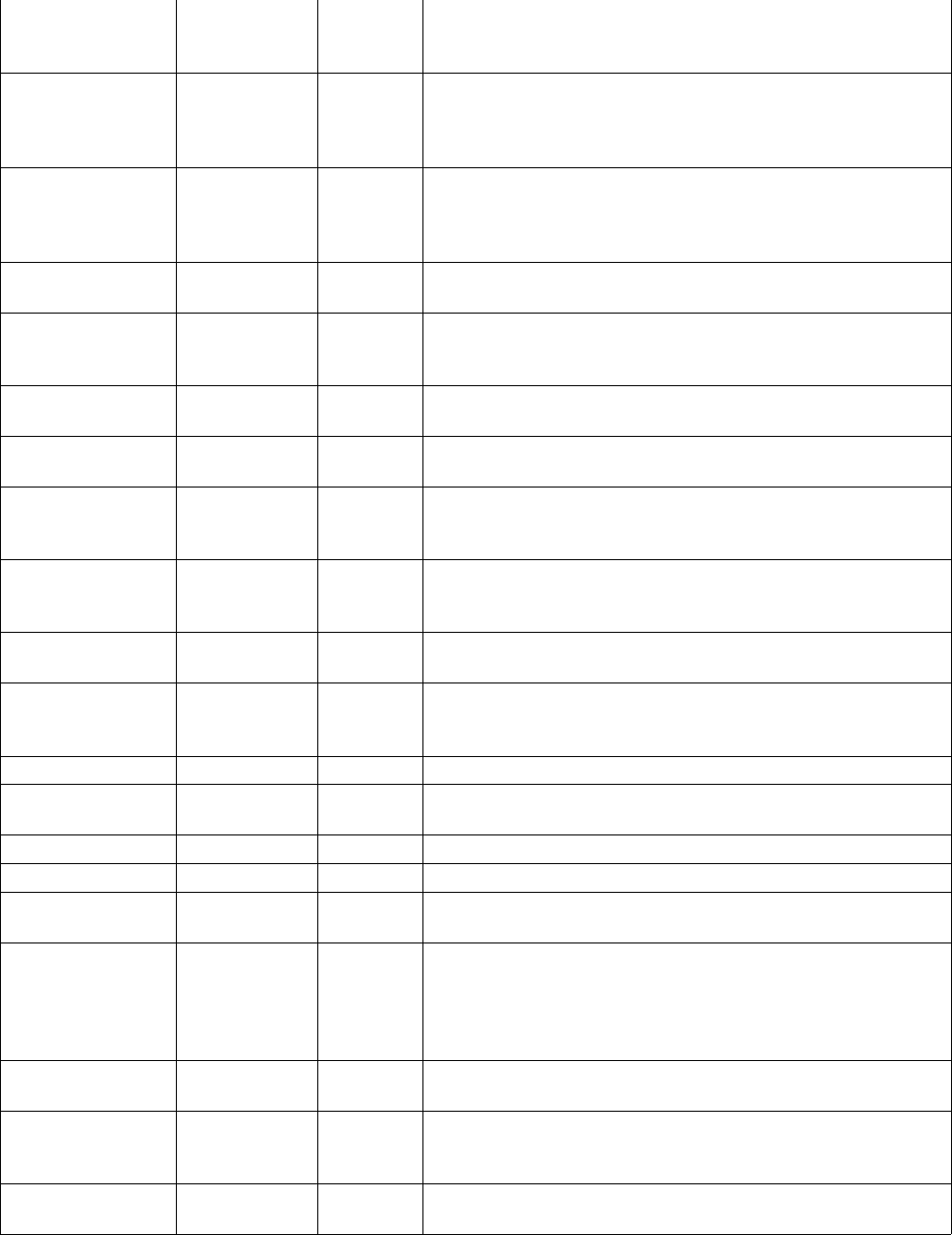

Winter Priority

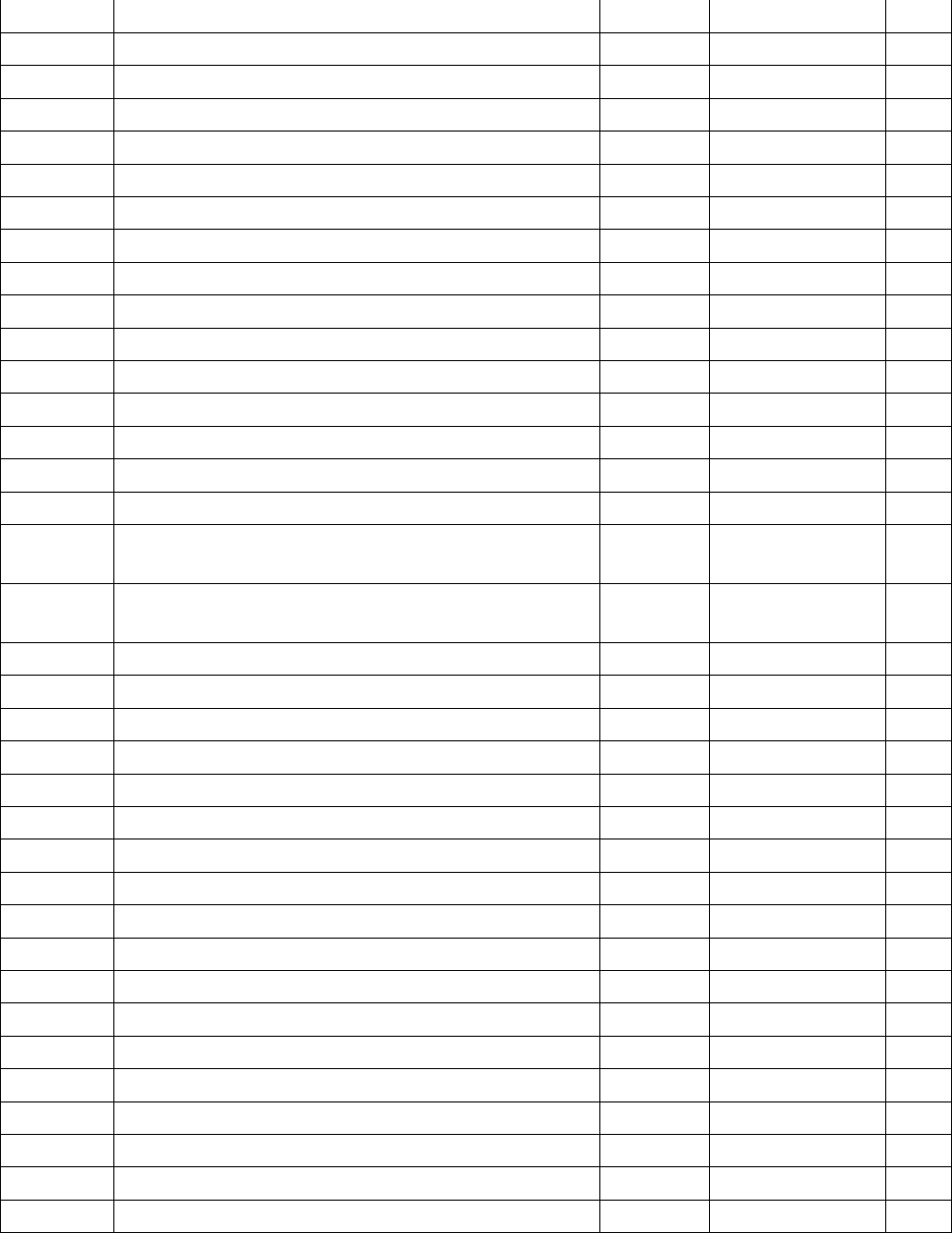

TPC-FI SoloNet O&M Page 43

Winter Priority

Staging Enable / Disable Disable

Choose to enable Winter Priority if you have a large mass boiler

that you desire to put into the lead position for a portion of the

heating season.

Winter Priority Start

Date mm/dd 12/25 Choose the date you would like to begin Winter Priority

Winter Priority Stop

Date mm/dd 2/14 Choose the date you would like to stop Winter Priority.

Winter Boilers

Rotation Hours 24 - 720 Hours 168

If you have more than one large mass boiler that will be designated

as Winter Priority choose the number of hours you would like for

each boiler to be in the lead position.

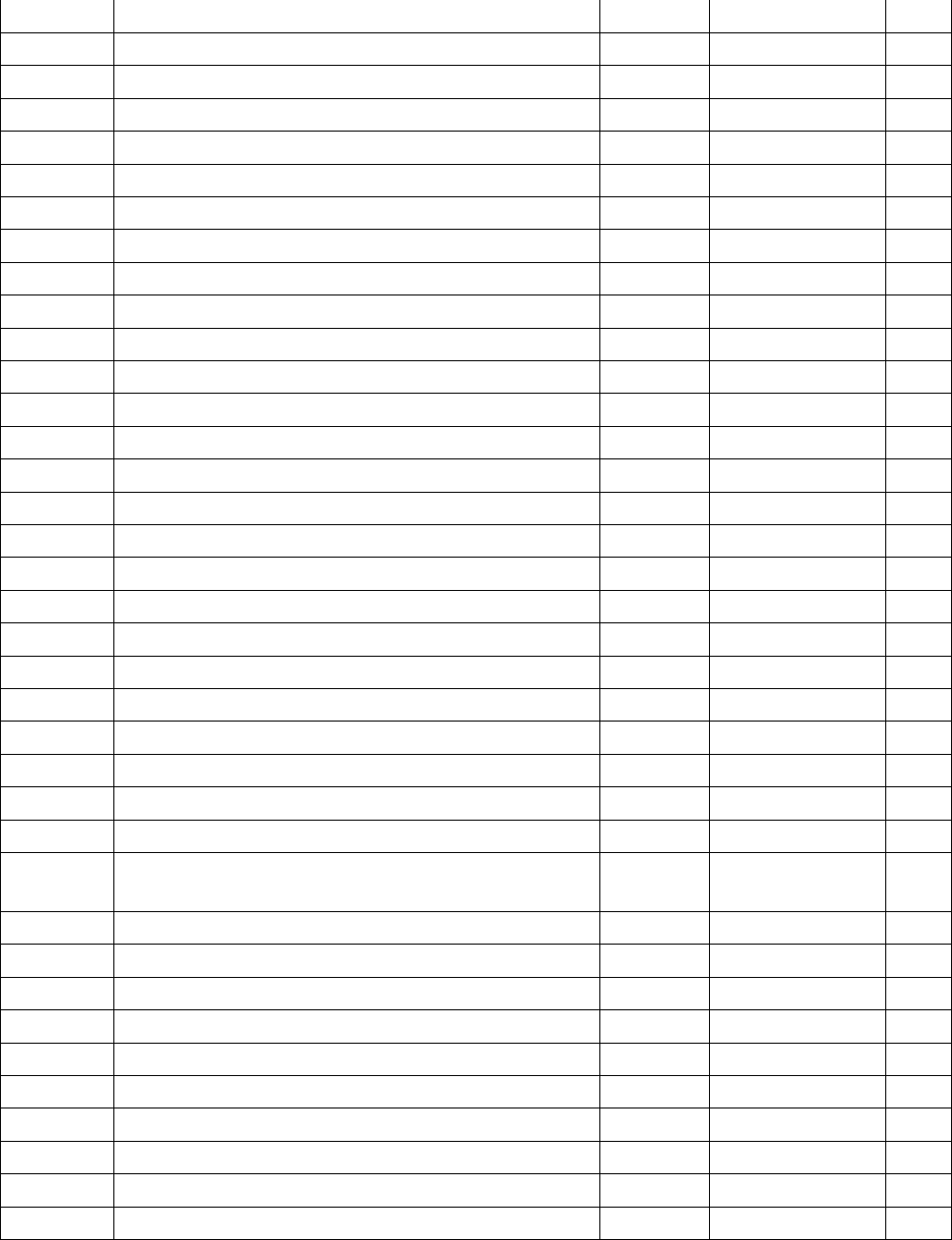

Reheat

Reheat Enable / Disable Disable Choose to enable the reheat reset slope if you are using reheat in

this application.

Reheat On Set point 60 - 90 F 70 Choose the outdoor air temperature at which you desire the reheat

reset slope to be enabled.

Reheat Warm

Weather Shutdown 80 - 160 F 100 Choose the outdoor air temperature at which you desire the reheat

to be disabled due to warm weather.

System Pump

Parameters

Activation Enable / Disable Enable Choose Enable to activate this pump to be used in this system.

Dedicated Lead Enable / Disable Enable Choose Enable to always use this pump as the lead pump in this

system. Pump = on when heating operations are on

Lead-Lag / Lead-

Help

Lead-Lag / Lead-

Help Lead-Lag

Choose "Lead/Lag" if this pump will be rotated into the lead

position as an either or pumping scenario. For lead/lag switching +

help when using variable speed pumping chose "Lead/Help" in

order to meet flow requirements of the system based on Delta P or

Delta T system needs.

Lead Shutdown

Delay (for Lead-Lag) 10 - 120 Sec 30 Choose the number of seconds you would like to delay the

shutdown of the lead pump in this system.

Lag Help Enable

Output % (for Lead-

Help)

51-100% 100 Choose the percentage of sustained pump output required to enable

the lag pump.

Lag Help Disable

Output % (for Lead-

Help)

1-50% 40 Choose the percentage of sustained pump output required to disable

the lag pump.

Lag Help Delay (for

Lead-Help) 1 - 60 Min 30

Choose the number of minutes the conditions (Output %) for lag

help Enable/Disable must be sustained before action is taken to

Enable or Disable the lag pump

Rotation Hours (for

Lead-Lag or Lead-

Help)

12 - 720 Hrs 168 Choose the number of hours you desire this pump to stay in the lead

position.

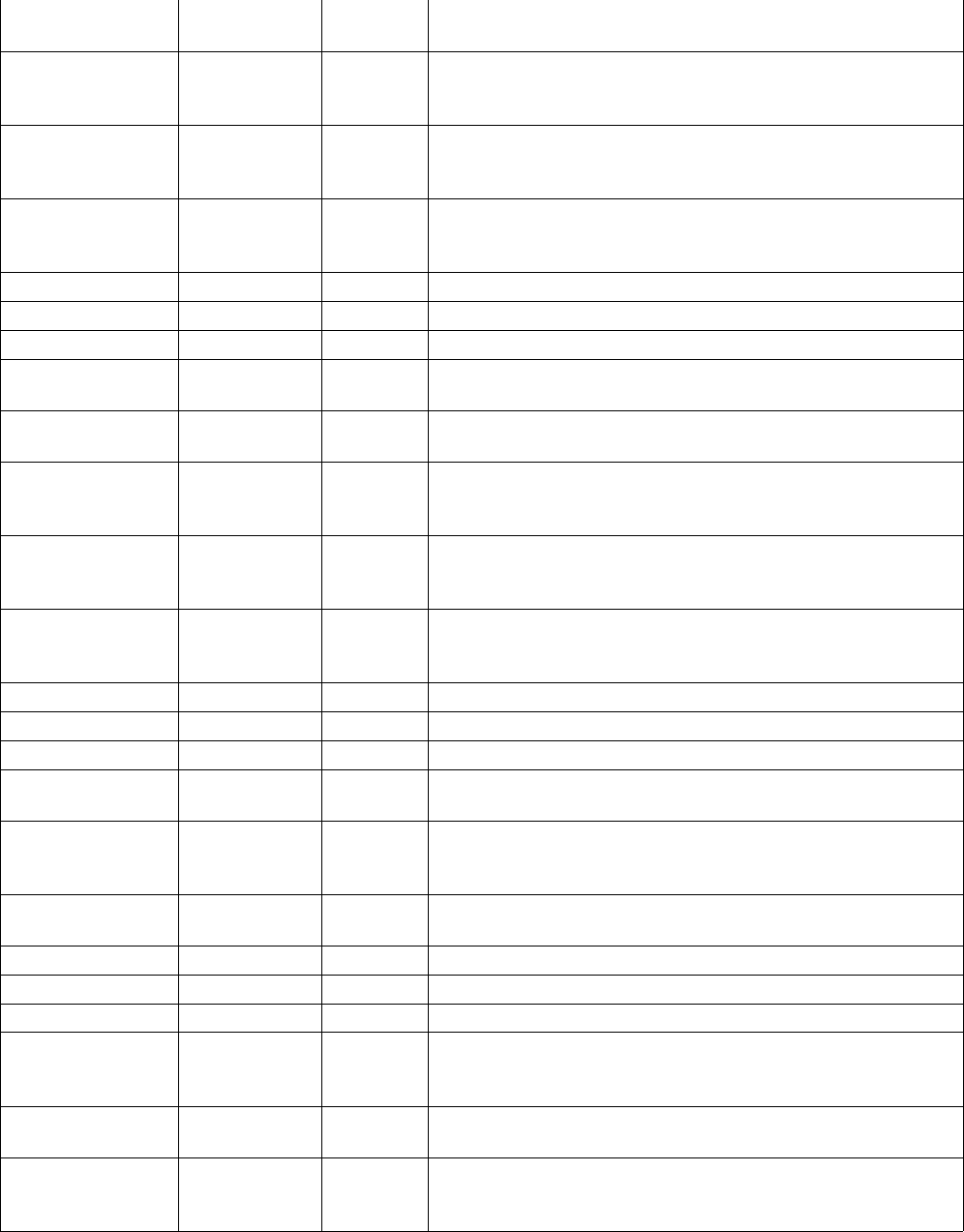

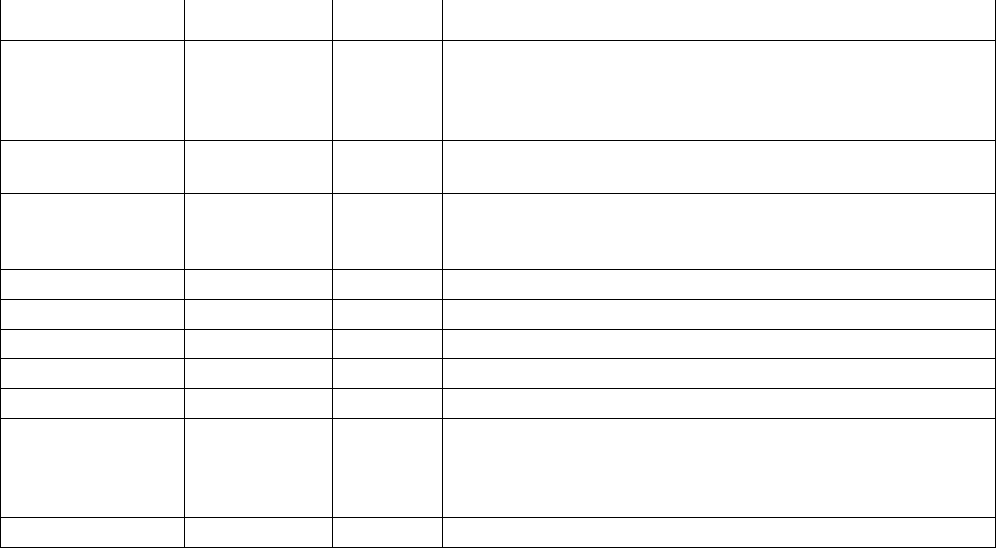

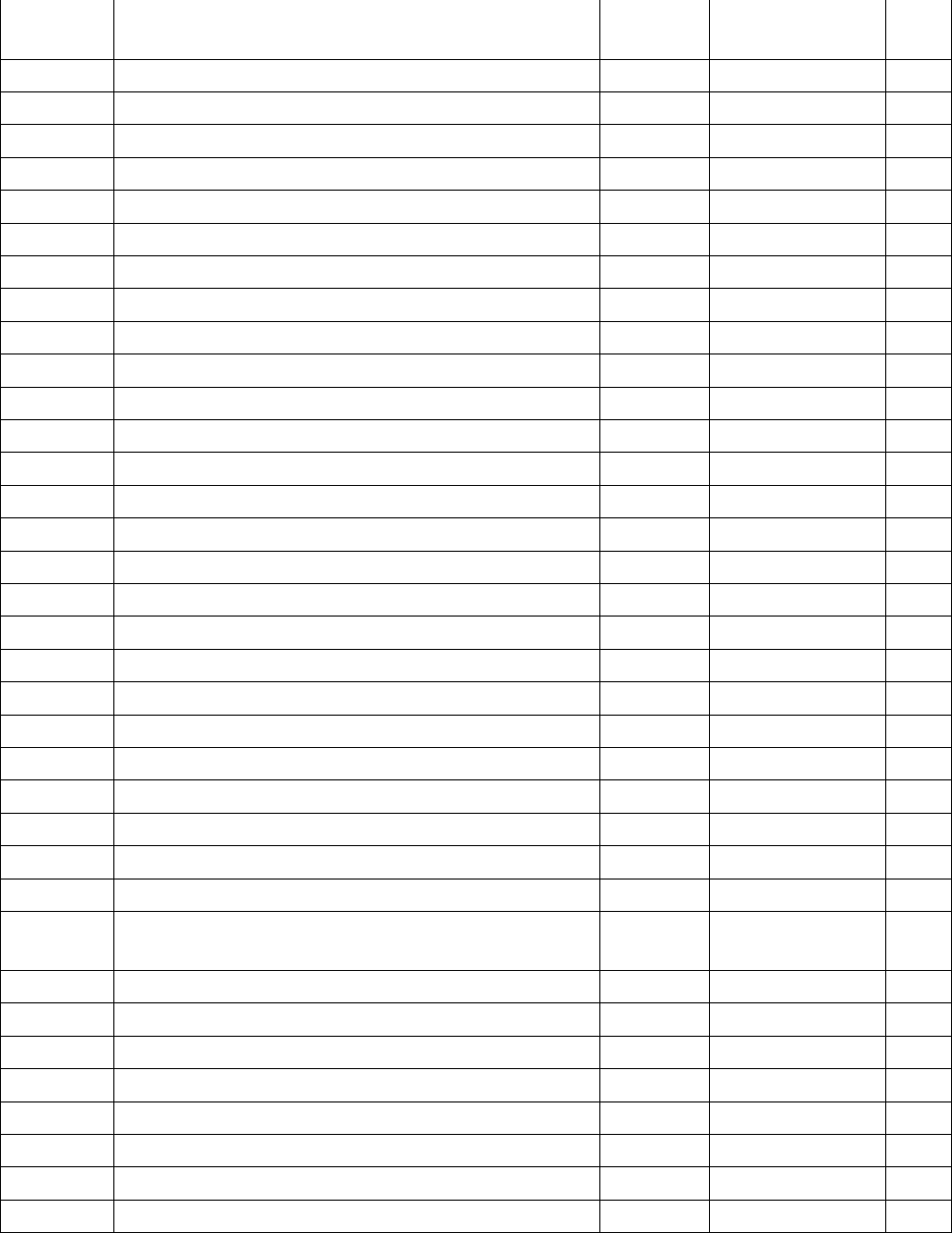

TPC-FI SoloNet O&M Page 44

Heat Enable

Shutdown Delay

Time

1 - 120 Min 60

Choose the number of minutes you would like the pumps to

continue to operate after the system has been shut down on outdoor

air temperature.

System Pump

Maximum

Modulation

Percentage

50 - 100 % 100 Choose the maximum modulation signal expressed as a percentage

you desire to be sent to this pump.

System Pump

Minimum

Modulation

Percentage

0 - 50 % 35 Choose the minimum modulation signal expressed as a percentage

you desire to be sent to this pump.

System Pump Process

Acceleration 0 - 100.0 20 Select the process acceleration speed. (Lower numbers cause faster

response to changes)

System Pump

Modulation Signal

0-10 Vdc,

4-20mA 0-10 Vdc

Choose the type of signal you desire to be sent to modulate this

pump, 0-10 Vdc or 4-20mA. (also requires wiring to the correct

terminal on the control)

System Pump Delta T

Operations Enable / Disable Disable Choose enable if you desire to modulate this pump based on the

system Delta T.

System Pump Delta P

Operations Enable / Disable Disable Choose enable if you desire to modulate this pump based on the

system Delta P.

Delta P Transducer

Pressure at 10Vdc

(20mA) Input

0-50 Psi 30 Input the value of the pressure (in Psig 0.0) the transducer will

experience at 20mA or 10Vdc

Delta P Transducer

Pressure at 0Vdc

(4mA) Input

0-10 Psi 0 Input the value of the pressure (in Psig 0.0) the transducer will

experience at 4mA or 0Vdc

Delta P Pressure Set

point 0-50 Psi 10 Choose the differential pressure the pump is modulated to maintain

Delta P Pressure

Transducer Input

Signal

0-10 Vdc,

4-20mA 0-10 Vdc Choose the input signal of the pressure transducer (0-10 Vdc or

4-20mA)

Zone Pump

Parameters

Activation Enable / Disable Enable Choose Enable to activate this pump to be used in this system.

Dedicated Lead Enable / Disable Enable Choose Enable to always use this pump as the lead pump in this

system. Pump = on when heating operations are on

Lead-Lag / Lead-

Help

Lead-Lag / Lead-

Help Lead-Lag

Choose "Lead/Lag" if this pump will be rotated into the lead

position as an either or pumping scenario. For lead/lag switching +

help when using variable speed pumping chose "Lead/Help" in

order to meet flow requirements of the system based on Delta P or

Delta T system needs.

Lead Shutdown

Delay (for Lead-Lag) 10 - 120 Sec 30 Choose the number of seconds you would like to delay the

shutdown of the lead pump in this system.

Lag Help Enable

Output % (for Lead-

Help)

51-100% 100 Choose the percentage of sustained pump output required to enable

the lag pump.

Lag Help Disable

Output % (for Lead-

1-50% 40 Choose the percentage of sustained pump output required to disable

the lag pump.

TPC-FI SoloNet O&M Page 45

Help)

Lag Help Delay (for

Lead-Help) 1 - 60 Min 30

Choose the number of minutes the conditions (Output %) for lag

help Enable/Disable must be sustained before action is taken to

Enable or Disable the lag pump

Rotation Hours (for

Lead-Lag or Lead-

Help)

12 - 720 Hrs 168 Choose the number of hours you desire this pump to stay in the lead

position.

Heat Enable

Shutdown Delay

Time

1 - 120 Min 60

Choose the number of minutes you would like the pumps to

continue to operate after the system has been shut down on outdoor

air temperature.

Zone Pump

Maximum

Modulation

Percentage

50 - 100 % 100 Choose the maximum modulation signal expressed as a percentage

you desire to be sent to this pump.

Zone Pump

Minimum

Modulation

Percentage

0 - 50 % 35 Choose the minimum modulation signal expressed as a percentage

you desire to be sent to this pump.

Zone Pump Process

Acceleration 0 - 100.0 20 Select the process acceleration speed. (Lower numbers cause faster

response to changes)

Zone Pump

Modulation Signal

0-10 Vdc,

4-20mA 0-10 Vdc

Choose the type of signal you desire to be sent to modulate this

pump, 0-10 Vdc or 4-20mA. (also requires wiring to the correct

terminal on the control)

Zone Pump Delta T

Operations Enable / Disable Disable Choose enable if you desire to modulate this pump based on the

Zone Delta T.

Zone Pump Delta T

Set-point 0 - 100 F 10 Choose the Delta T you desire to be kept across this zone.

Zone Pump Delta P

Operations Enable / Disable Disable Choose enable if you desire to modulate this pump based on the

system Delta P.

Delta P Transducer

Pressure at 10Vdc

(20mA) Input

0-50 Psi 30 Input the value of the pressure (in Psig 0.0) the transducer will

experience at 20mA or 10Vdc

Delta P Transducer

Pressure at 0Vdc

(4mA) Input

0-10 Psi 0 Input the value of the pressure (in Psig 0.0) the transducer will

experience at 4mA or 0Vdc

Delta P Pressure Set

point 0-50 Psi 10 Choose the differential pressure the pump is modulated to maintain

Delta P Pressure

Transducer Input

Signal

0-10 Vdc,

4-20mA 0-10 Vdc Choose the input signal of the pressure transducer (0-10 Vdc or

4-20mA)

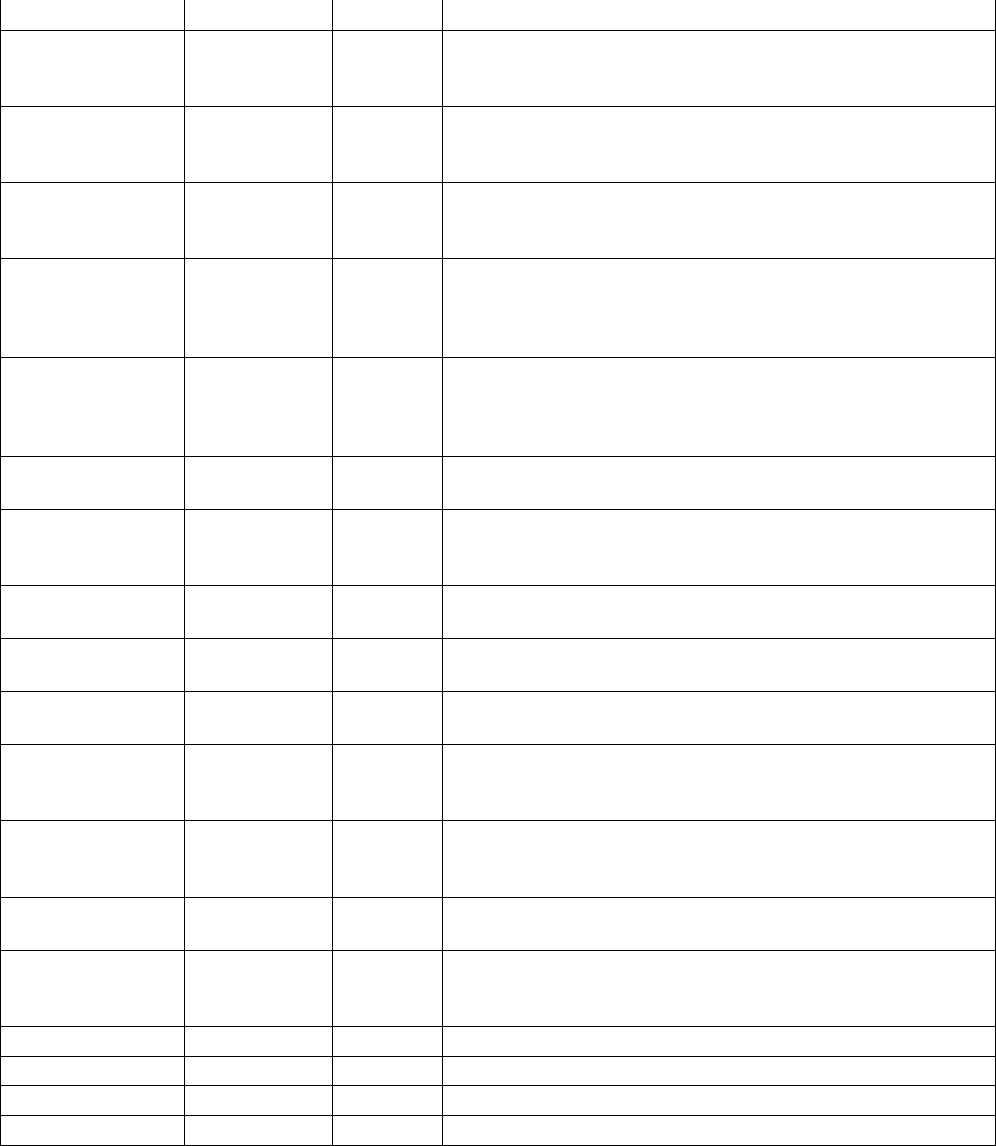

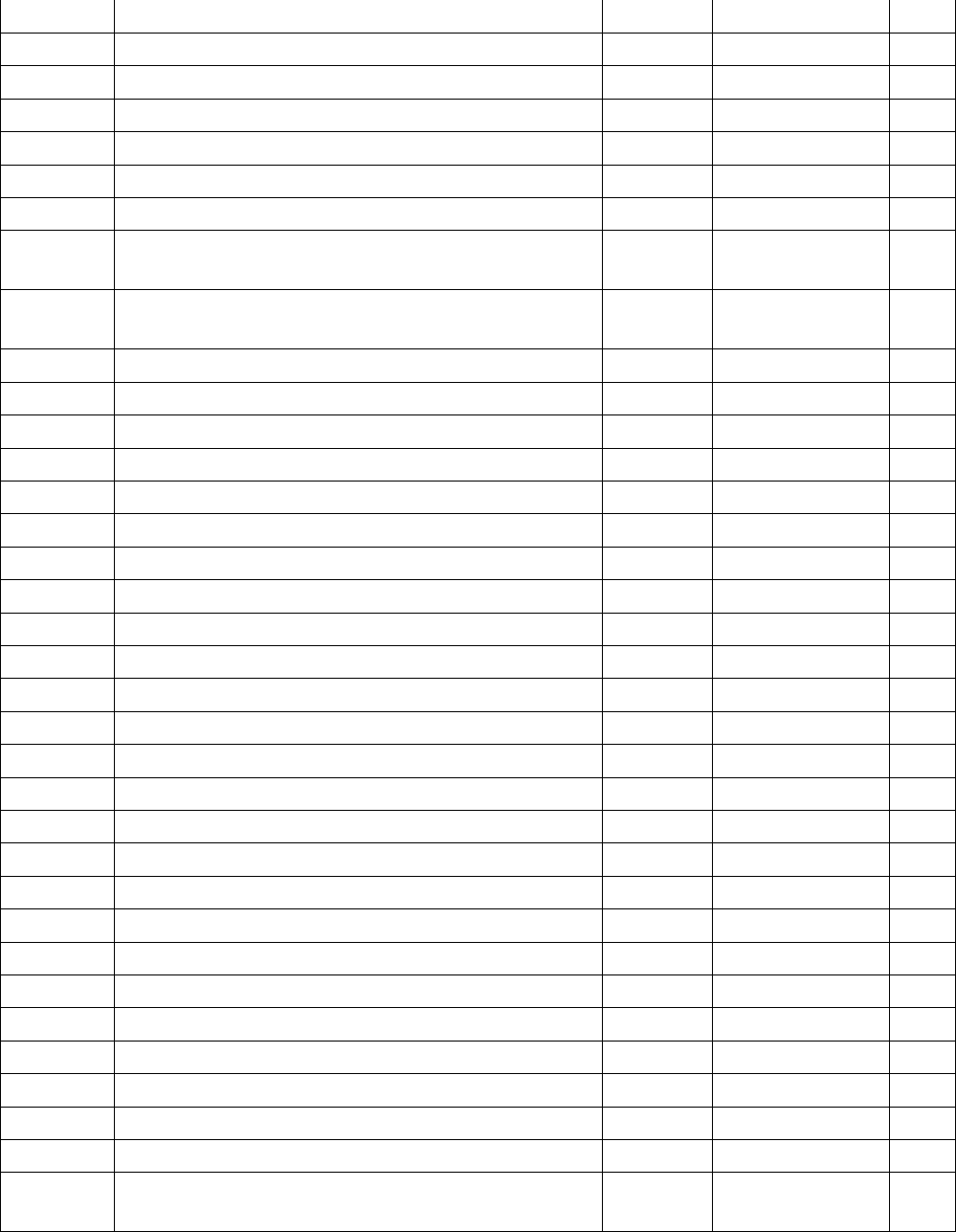

Boiler Parameters

Activation Enable / Disable Enable Choose enable to activate this boiler for use in this system.

TPC-FI SoloNet O&M Page 46

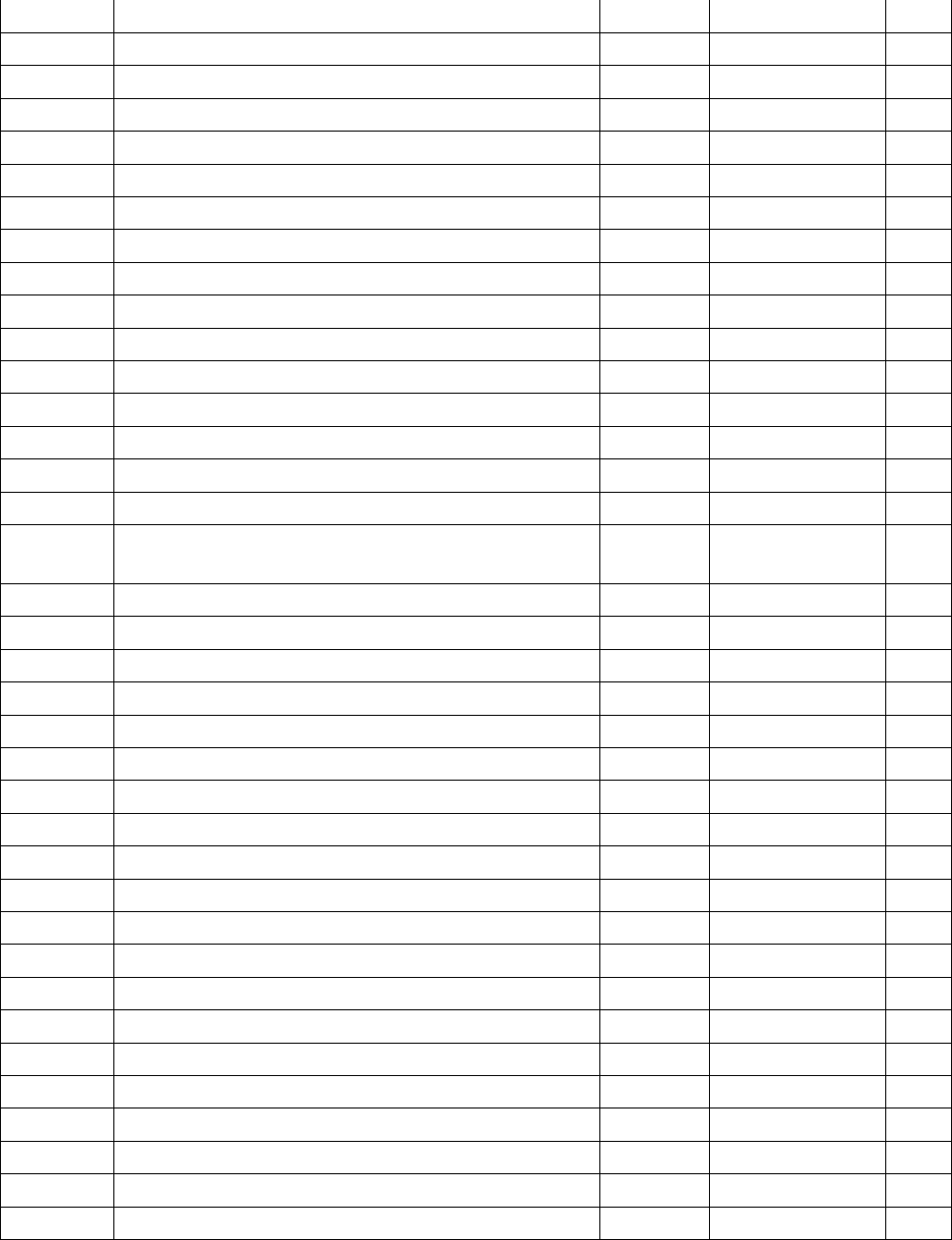

Flow Sensitive Yes/No Yes

Choose Yes unless the boiler you are configuring is rated by its

manufacturer as having no minimum flow requirements. Choosing

"No" allows boiler secondary pump modulation off the boiler

device. It allows another Field Device dedicated to boiler

secondary pumping to control boiler pump modulation through

wireless network traffic of boiler inlet and outlet temperatures.

Choosing "Yes" forces boiler secondary pump modulation to occur

local on the Boiler Field Device only.

Boiler Type - Cond /

NonCond Cond / NonCond Cond Choose Cond. For condensing boilers, Choose NonCond for non-

condensing boilers

Boiler Fire Delay

Seconds 30 - 300 Sec 90 Choose the number of seconds between when this boiler is enabled

until it has established main flame.

Boiler Low Fire Hold

Minutes 5 - 60 Min 15 Choose the number of minutes you desire for the control to keep

this boiler in low fire at the beginning of every cycle

Boiler Maximum

Runtime Hours 1 - 24 Hrs 12 Choose the maximum number of hours you desire for this boiler to

run in any single cycle.

Maximum Boiler

MBH Output 1 - 52,000 MBH 3000 Enter in MBH the maximum output of this boiler. (Mbh =

Btu/1000)

Minimum Boiler

MBH Output 1 - 26,000 MBH 1500 Enter in MBH the minimum output of this boiler. (Mbh =

Btu/1000)

Maximum Boiler

Outlet Temperature 160 - 210 F 180 Enter the maximum outlet water temperature allowed to be supplied

by this boiler.

Minimum Boiler Inlet

Temperature 20 - 150 F 130 Enter the minimum inlet water temperature allowed to be returned

to this boiler.

Maximum Boiler

Output Percentage 50 - 100 % 100

Enter the maximum output percentage signal that you would like to

send this boiler. This is used to help establish the relationship

between output signal and Mbh output value of the boiler. ( If 9.00

Vdc = maximum boiler output then enter 90%)

Minimum Boiler

Output Percentage 0 - 50 % 18

Enter the minimum output percentage signal that you would like to

send this boiler. This is used to help establish the relationship

between output signal and Mbh output value of the boiler. ( If 1.80

Vdc = minimum boiler output then enter 18%)

Boiler Ignition

Output Percentage 0 - 50 % 0

Enter the output percentage at which main flame is ignited. Some

boilers light off at greater than minimum signal. If light off of the

boiler is 50% of output then enter 50%. This modulation signal

will be sent to the boiler during the entire fire delay.

Boiler Next Stage

Percentage 10 - 100 % 85 This is the percentage of boiler output that must be sustained for the

entire "Stage Delay Time" before another boiler is enabled.

Boiler Turn Down 2:1-10:1 0

Enter the turn-down of this boiler. For turn-down's greater than 5:1

check with the start-up technician to confirm the field configured

turn-down for the boiler.

Boiler Maximum

Output Manual Limit 10 - 100 % 100

This is the maximum output signal to the boiler. It is not linked to

the load calculation. It is used to limit a boilers output. Suggested

use is a limit for output during start up and combustion analization.

Boiler Maximum

Allowable Delta T. 2 - 160 F 20

Enter the maximum allowable Delta T for this boiler. This is the

manufacturers maximum allowable Delta T the boiler is allowed to

achieve.

Boiler Maximum

operating Delta T. 0 - 158 F 15

Enter the maximum operating Delta T for this boiler. This is the

set-point for the user to choose a number at least 2 degrees

Fahrenheit below maximum allowable boiler Delta T. This number

shall be used for modulation limits and error calculations

TPC-FI SoloNet O&M Page 47

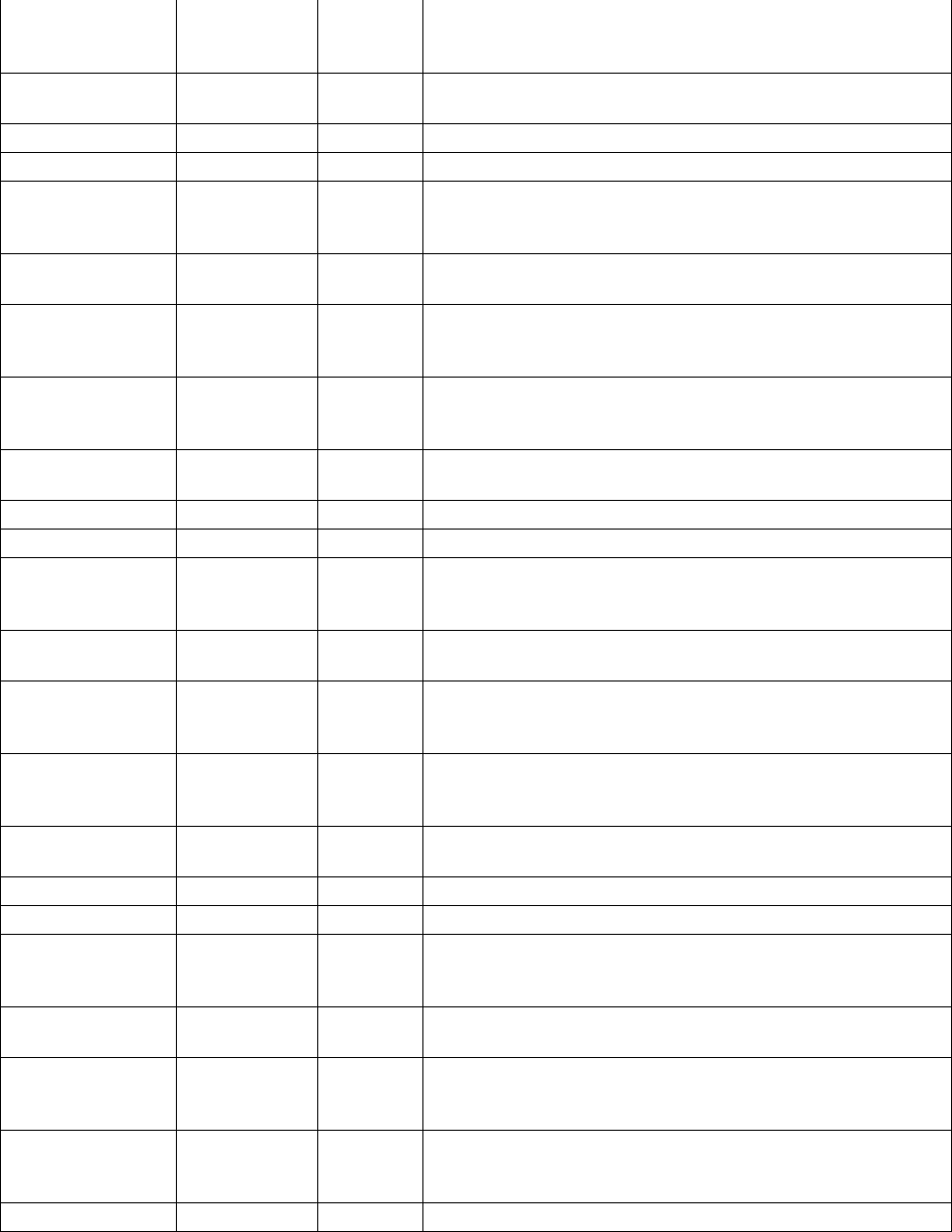

Standby Mode Enable / Disable Disable

Choose enable if you desire this boiler to be used as a standby

boiler. A standby boiler is the lowest priority for operation and will

be selected if all other boilers on the network are failing to meet the

load requirements

Winter Priority Mode Enable / Disable Disable

Choose enable if you desire this boiler to be a "Winter Priority"

boiler. Note: You must have activated winter priority under system

settings and chosen a date to put this boiler into priority to use this

feature.

Boiler Water Volume

Gallons 1 - 12,000 Gal 100 Enter the volume of water in this boiler.

Maximum Rated

Efficiency 65 - 99 % 85 Enter the maximum rated efficiency for this boiler

Process Output

Acceleration 1 - 100.0 30 Select the process acceleration speed. (Lower numbers cause faster

response to changes)

Boiler Modulation

Signal

0-10 Vdc,

4-20mA 0-10 Vdc

Choose the type of signal you desire to be sent to modulate this

boiler, 0-10 Vdc or 4-20mA. (also requires wiring to the correct

terminal on the control)

DHWP (on-board or

Network) Enable / Disable Disable Select to enable this boiler for DHWP operations. This must be

selected of either on board priority or Network priority

DHWP Set-point (on-

board only) 110-240F 140F Provide the outlet water temperature this boiler will be asked to

provide when producing domestic hot water.

DHWP Maximum

Hysteresis (on-board

only)

5-30F 10F

This is the maximum allowable overshoot of the DHWP set-point

for boiler water temperature. Outlet temperatures exceeding this

value will cause the boiler to disable until the DHWP Minimum

Hysteresis value has been reached

DHWP Minimum

Hysteresis (on-board

only)

3-20F 3F

This is the minimum allowable under-shoot of the DHWP set-point

for boiler water temperature. Outlet temperatures less than or equal

to this value will cause the boiler in priority to enable until the

DHWP Maximum Hysteresis value has been reached or until the

priority has ended

DHWP Override (on-

board only) 15 - 181 Min 30 Choose the maximum number of minutes this boiler can be used to

provide DHW when there is simultaneously a call for comfort heat.

Boiler Pump

Parameters

Activation Enable / Disable Enable Choose enable to activate this boiler pump for use in this system.

Pump control / Valve

control Pump / Valve Pump Choose the device that is being controlled

Boiler Pump Off

Delay 1 - 15 Min 10 Enter the number of minutes you would like this pump to run after

the boiler has finished a cycle.

Boiler Pump

Modulation Enable / Disable Disable Enter "enable" if this pump is connected to a frequency drive and

you wish to modulate that drive based on boiler Delta T

Boiler Delta T Set

point 0 - 158 F 20

Enter the Delta T that you desire across this boiler. This number

needs to be less than or equal to the value chosen as the maximum

operating Delta chosen under Boiler Parameters for the boiler

assigned to this pump.

Boiler Pump

Maximum

Modulation

50 - 100 % 100 Choose the maximum modulation signal expressed as a percentage

you desire to be sent to this pump.

TPC-FI SoloNet O&M Page 48

Percentage

Boiler Pump

Minimum

Modulation

Percentage

0 - 50 % 30 Choose the minimum modulation signal expressed as a percentage

you desire to be sent to this pump.

Boiler Pump Process

Acceleration 1 - 100.0 30 Select the process acceleration speed. (Lower numbers cause faster

response to changes)

Boiler Pump

Modulation Signal

0-10 Vdc,

4-20mA 0-10 Vdc

Choose the type of signal you desire to be sent to modulate this

pump, 0-10 Vdc or 4-20mA. (also requires wiring to the correct

terminal on the control)

Damper Parameters

Activation Enable / Disable Enable Choose enable to allow this damper to be used in this system.

Boiler Association 1-1, 1-16 Range (1 - 1)

Identify the boiler(s) that this damper will work with. Boilers must

be in sequential order. For example: Inputting 1-3 will not enable

the damper on just 1 and 3. If 1-3 is chosen then boiler 1,2 & 3 will

enable this damper if any or all of these boilers are enabled.

TPC-FI SoloNet O&M Page 49

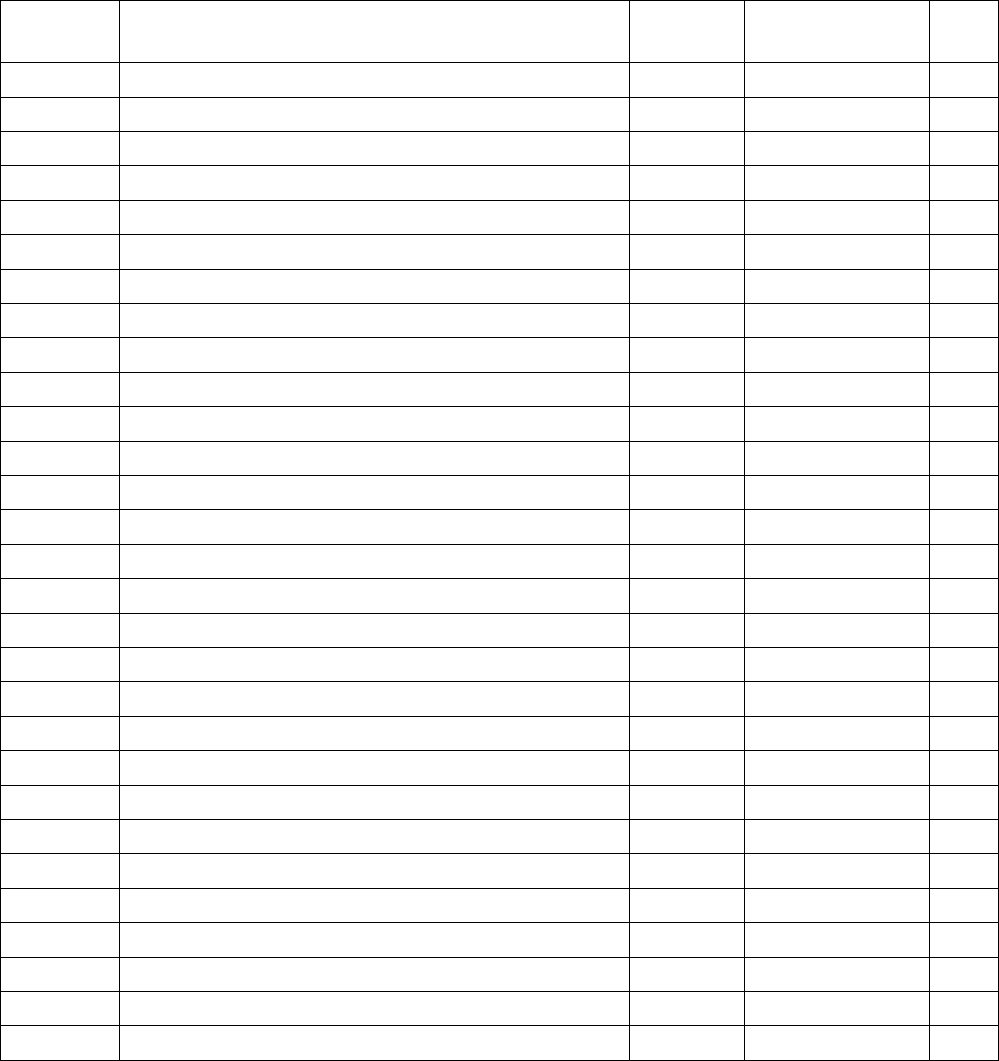

Appendix B

TPC-FI SoloNet O&M Page 50

ADDRESS TAG NAME TAG

DATATYPE

NOD

E

405000 MODBUS_ON_OFF_WRITE UNSIGNED_16 PLC1

405001 BMS_ENABLE_CONTROL_WRITE UNSIGNED_16 PLC1

405002 SYSTEM_SETPOINT_WRITE UNSIGNED_16 PLC1

405003 REMOTE_ENABLE UNSIGNED_16 PLC1

405004 SYSTEM_SETPOINT_READ UNSIGNED_16 PLC1

405005 CONDENSING UNSIGNED_16 PLC1

405006 OPTIMUM_STOP UNSIGNED_16 PLC1

405007 OPTIMUM_START UNSIGNED_16 PLC1

405008 OCCUPIED_OPERATIONS UNSIGNED_16 PLC1

405009 UNOCCUPIED_OPERATIONS UNSIGNED_16 PLC1

405010 WINTER_HEAT UNSIGNED_16 PLC1

405011 SUMMER_HEAT UNSIGNED_16 PLC1

405012 WINTER_PRIO UNSIGNED_16 PLC1

405013 SYSTEM_SUPPLY_TEMP SIGNED_16 PLC1

405014 SYSTEM_RETURN_TEMPERATURE SIGNED_16 PLC1

405015 OUTDOOR_AIR_TEMPERATURE SIGNED_16 PLC1

405016 SYSTEM_GPM_FLOW UNSIGNED_16 PLC1

405017 SYSTEM_MBH_LOAD UNSIGNED_32 PLC1

405018 PLC1

405019 MBREG_MAX_HYST SIGNED_16 PLC1

405020 MBREG_MIN_HYST SIGNED_16 PLC1

405021 SYSTEM_DELTA_T SIGNED_16 PLC1

405022 WINTER_HEAT_ON_SP SIGNED_16 PLC1

405023 WINTER_HEAT_OFF_SP SIGNED_16 PLC1

405024 REHEAT_ON_SETPOINT SIGNED_16 PLC1

405025 REHEAT_OFF_SETPOINT SIGNED_16 PLC1

405026 DATE UNSIGNED_16 PLC1

405027 24HR_TIME UNSIGNED_16 PLC1

TPC-FI SoloNet O&M Page 51

405028 SYS_7 UNSIGNED_16 PLC1

405029 SYS_8 UNSIGNED_16 PLC1

405030 SYS_9 UNSIGNED_16 PLC1

405031 MBREG_TPCMODBUS_VERSION UNSIGNED_16 PLC1

405032 MBREG_NUM_MAIN_PUMPS UNSIGNED_16 PLC1

405033 MBREG_FIRST_MAIN_PUMP_ADDR UNSIGNED_16 PLC1

405034 MBREG_NUM_BOILERS UNSIGNED_16 PLC1

405035 MBREG_FIRST_BOILER_ADDR UNSIGNED_16 PLC1

405036-40

5099 Reserved PLC1

405100 MP_EXISTING PUMP1 UNSIGNED_16 PLC1

405101 MP_ON UNSIGNED_16 PLC1

405102 MP_LEAD UNSIGNED_16 PLC1

405103-40

5105 Reserved PLC1

405106 MP_EXISTING PUMP2 UNSIGNED_16 PLC1

405107 MP_ON UNSIGNED_16 PLC1

405108 MP_LEAD UNSIGNED_16 PLC1

405109-40

5111 Reserved PLC1

405112 MP_EXISTING PUMP3 UNSIGNED_16 PLC1

405113 MP_ON UNSIGNED_16 PLC1

405114 MP_LEAD UNSIGNED_16 PLC1

405115-40

5117 Reserved PLC1

405118 MP_EXISTING PUMP4 UNSIGNED_16 PLC1

405119 MP_ON UNSIGNED_16 PLC1

405120 MP_LEAD UNSIGNED_16 PLC1

405121-40

5123 Reserved PLC1

405124 MP_EXISTING PUMP5 UNSIGNED_16 PLC1

405125 MP_ON UNSIGNED_16 PLC1

405126 MP_LEAD UNSIGNED_16 PLC1

405127-40

5129 Reserved PLC1

405130 MP_EXISTING PUMP6 UNSIGNED_16 PLC1

405131 MP_ON UNSIGNED_16 PLC1

405132 MP_LEAD UNSIGNED_16 PLC1

405133-40 Reserved PLC1

TPC-FI SoloNet O&M Page 52

5135

405136 MP_EXISTING PUMP7 UNSIGNED_16 PLC1

405137 MP_ON UNSIGNED_16 PLC1

405138 MP_LEAD UNSIGNED_16 PLC1

405139-40

5141 Reserved PLC1

405142 MP_EXISTING PUMP8 UNSIGNED_16 PLC1

405143 MP_ON UNSIGNED_16 PLC1

405144 MP_LEAD UNSIGNED_16 PLC1

405145-40

5147 Reserved PLC1

405148 MP_EXISTING PUMP9 UNSIGNED_16 PLC1

405149 MP_ON UNSIGNED_16 PLC1

405150 MP_LEAD UNSIGNED_16 PLC1

405151-40

5153 Reserved PLC1

405154 MP_EXISTING PUMP10 UNSIGNED_16 PLC1

405155 MP_ON UNSIGNED_16 PLC1

405156 MP_LEAD UNSIGNED_16 PLC1

405157-40

5159 Reserved PLC1

405160 MP_EXISTING PUMP11 UNSIGNED_16 PLC1

405161 MP_ON UNSIGNED_16 PLC1

405162 MP_LEAD UNSIGNED_16 PLC1

405163-40

5165 Reserved PLC1

405166 MP_EXISTING PUMP12 UNSIGNED_16 PLC1

405167 MP_ON UNSIGNED_16 PLC1

405168 MP_LEAD UNSIGNED_16 PLC1

405169-40

5171 Reserved PLC1

405172 MP_EXISTING PUMP13 UNSIGNED_16 PLC1

405173 MP_ON UNSIGNED_16 PLC1

405174 MP_LEAD UNSIGNED_16 PLC1

405175-40

5177 Reserved PLC1

405178 MP_EXISTING PUMP14 UNSIGNED_16 PLC1

405179 MP_ON UNSIGNED_16 PLC1

405180 MP_LEAD UNSIGNED_16 PLC1

TPC-FI SoloNet O&M Page 53

405181-40

5183 Reserved PLC1

405184 MP_EXISTING PUMP15 UNSIGNED_16 PLC1

405185 MP_ON UNSIGNED_16 PLC1

405186 MP_LEAD UNSIGNED_16 PLC1

405187-40

5189 Reserved PLC1

405190 MP_EXISTING PUMP16 UNSIGNED_16 PLC1

405191 MP_ON UNSIGNED_16 PLC1

405192 MP_LEAD UNSIGNED_16 PLC1

405193-40

5199 Reserved PLC1

405200 B_EXISTING BOILER1 UNSIGNED_16 PLC1

405201 B_ACTIVE UNSIGNED_16 PLC1

405202 B_ALARM UNSIGNED_16 PLC1

405203 B_CON_NON UNSIGNED_16 PLC1

405204 B_WINTER UNSIGNED_16 PLC1

405205 B_DHWP UNSIGNED_16 PLC1

405206 B_ON UNSIGNED_16 PLC1

405207 B_PUMP_EXISTING UNSIGNED_16 PLC1

405208 B_PUMP_ON UNSIGNED_16 PLC1

405209 B_VALVE_EXISTING UNSIGNED_16 PLC1

405210 B_VALVE_ON UNSIGNED_16 PLC1

405211 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405212 B_DAMPER_ON UNSIGNED_16 PLC1

405213 B_DAMPER_PROVE UNSIGNED_16 PLC1

405214 B_OUTLET_TEMP SIGNED_16 PLC1

405215 B_INLET_TEMP SIGNED_16 PLC1

405216 B_STACK_TEMP SIGNED_16 PLC1

405217 B_CYCLE_TIME UNSIGNED_16 PLC1

405218 B_CYCLE_COUNT UNSIGNED_32 PLC1

405219 PLC1

405220 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405221 PLC1

405222 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405223 PLC1

405224 B_MBH_OUTPUT UNSIGNED_32 PLC1

405225 PLC1

TPC-FI SoloNet O&M Page 54

405226-40

5249 Reserved PLC1

405250 B_EXISTING BOILER2 UNSIGNED_16 PLC1

405251 B_ACTIVE UNSIGNED_16 PLC1

405252 B_ALARM UNSIGNED_16 PLC1

405253 B_CON_NON UNSIGNED_16 PLC1

405254 B_WINTER UNSIGNED_16 PLC1

405255 B_DHWP UNSIGNED_16 PLC1

405256 B_ON UNSIGNED_16 PLC1

405257 B_PUMP_EXISTING UNSIGNED_16 PLC1

405258 B_PUMP_ON UNSIGNED_16 PLC1

405259 B_VALVE_EXISTING UNSIGNED_16 PLC1

405260 B_VALVE_ON UNSIGNED_16 PLC1

405261 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405262 B_DAMPER_ON UNSIGNED_16 PLC1

405263 B_DAMPER_PROVE UNSIGNED_16 PLC1

405264 B_OUTLET_TEMP SIGNED_16 PLC1

405265 B_INLET_TEMP SIGNED_16 PLC1

405266 B_STACK_TEMP SIGNED_16 PLC1

405267 B_CYCLE_TIME UNSIGNED_16 PLC1

405268 B_CYCLE_COUNT UNSIGNED_32 PLC1

405269 PLC1

405270 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405271 PLC1

405272 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405273 PLC1

405274 B_MBH_OUTPUT UNSIGNED_32 PLC1

405275 PLC1

405276-40

5299 Reserved PLC1

405300 B_EXISTING BOILER3 UNSIGNED_16 PLC1

405301 B_ACTIVE UNSIGNED_16 PLC1

405302 B_ALARM UNSIGNED_16 PLC1

405303 B_CON_NON UNSIGNED_16 PLC1

405304 B_WINTER UNSIGNED_16 PLC1

405305 B_DHWP UNSIGNED_16 PLC1

405306 B_ON UNSIGNED_16 PLC1

405307 B_PUMP_EXISTING UNSIGNED_16 PLC1

TPC-FI SoloNet O&M Page 55

405308 B_PUMP_ON UNSIGNED_16 PLC1

405309 B_VALVE_EXISTING UNSIGNED_16 PLC1

405310 B_VALVE_ON UNSIGNED_16 PLC1

405311 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405312 B_DAMPER_ON UNSIGNED_16 PLC1

405313 B_DAMPER_PROVE UNSIGNED_16 PLC1

405314 B_OUTLET_TEMP SIGNED_16 PLC1

405315 B_INLET_TEMP SIGNED_16 PLC1

405316 B_STACK_TEMP SIGNED_16 PLC1

405317 B_CYCLE_TIME UNSIGNED_16 PLC1

405318 B_CYCLE_COUNT UNSIGNED_32 PLC1

405319 PLC1

405320 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405321 PLC1

405322 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405323 PLC1

405324 B_MBH_OUTPUT UNSIGNED_32 PLC1

405325 PLC1

405326-40

5349 Reserved PLC1

405350 B_EXISTING BOILER4 UNSIGNED_16 PLC1

405351 B_ACTIVE UNSIGNED_16 PLC1

405352 B_ALARM UNSIGNED_16 PLC1

405353 B_CON_NON UNSIGNED_16 PLC1

405354 B_WINTER UNSIGNED_16 PLC1

405355 B_DHWP UNSIGNED_16 PLC1

405356 B_ON UNSIGNED_16 PLC1

405357 B_PUMP_EXISTING UNSIGNED_16 PLC1

405358 B_PUMP_ON UNSIGNED_16 PLC1

405359 B_VALVE_EXISTING UNSIGNED_16 PLC1

405360 B_VALVE_ON UNSIGNED_16 PLC1

405361 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405362 B_DAMPER_ON UNSIGNED_16 PLC1

405363 B_DAMPER_PROVE UNSIGNED_16 PLC1

405364 B_OUTLET_TEMP SIGNED_16 PLC1

405365 B_INLET_TEMP SIGNED_16 PLC1

405366 B_STACK_TEMP SIGNED_16 PLC1

405367 B_CYCLE_TIME UNSIGNED_16 PLC1

TPC-FI SoloNet O&M Page 56

405368 B_CYCLE_COUNT UNSIGNED_32 PLC1

405369 PLC1

405370 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405371 PLC1

405372 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405373 PLC1

405374 B_MBH_OUTPUT UNSIGNED_32 PLC1

405375 PLC1

405376-40

5399 Reserved PLC1

405400 B_EXISTING BOILER5 UNSIGNED_16 PLC1

405401 B_ACTIVE UNSIGNED_16 PLC1

405402 B_ALARM UNSIGNED_16 PLC1

405403 B_CON_NON UNSIGNED_16 PLC1

405404 B_WINTER UNSIGNED_16 PLC1

405405 B_DHWP UNSIGNED_16 PLC1

405406 B_ON UNSIGNED_16 PLC1

405407 B_PUMP_EXISTING UNSIGNED_16 PLC1

405408 B_PUMP_ON UNSIGNED_16 PLC1

405409 B_VALVE_EXISTING UNSIGNED_16 PLC1

405410 B_VALVE_ON UNSIGNED_16 PLC1

405411 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405412 B_DAMPER_ON UNSIGNED_16 PLC1

405413 B_DAMPER_PROVE UNSIGNED_16 PLC1

405414 B_OUTLET_TEMP SIGNED_16 PLC1

405415 B_INLET_TEMP SIGNED_16 PLC1

405416 B_STACK_TEMP SIGNED_16 PLC1

405417 B_CYCLE_TIME UNSIGNED_16 PLC1

405418 B_CYCLE_COUNT UNSIGNED_32 PLC1

405419 PLC1

405420 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405421 PLC1

405422 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405423 PLC1

405424 B_MBH_OUTPUT UNSIGNED_32 PLC1

405425 PLC1

405426-40

5449 Reserved PLC1

TPC-FI SoloNet O&M Page 57

405450 B_EXISTING BOILER6 UNSIGNED_16 PLC1

405451 B_ACTIVE UNSIGNED_16 PLC1

405452 B_ALARM UNSIGNED_16 PLC1

405453 B_CON_NON UNSIGNED_16 PLC1

405454 B_WINTER UNSIGNED_16 PLC1

405455 B_DHWP UNSIGNED_16 PLC1

405456 B_ON UNSIGNED_16 PLC1

405457 B_PUMP_EXISTING UNSIGNED_16 PLC1

405458 B_PUMP_ON UNSIGNED_16 PLC1

405459 B_VALVE_EXISTING UNSIGNED_16 PLC1

405460 B_VALVE_ON UNSIGNED_16 PLC1

405461 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405462 B_DAMPER_ON UNSIGNED_16 PLC1

405463 B_DAMPER_PROVE UNSIGNED_16 PLC1

405464 B_OUTLET_TEMP SIGNED_16 PLC1

405465 B_INLET_TEMP SIGNED_16 PLC1

405466 B_STACK_TEMP SIGNED_16 PLC1

405467 B_CYCLE_TIME UNSIGNED_16 PLC1

405468 B_CYCLE_COUNT UNSIGNED_32 PLC1

405469 PLC1

405470 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405471 PLC1

405472 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405473 PLC1

405474 B_MBH_OUTPUT UNSIGNED_32 PLC1

405475 PLC1

405476-40

5499 Reserved PLC1

405500 B_EXISTING BOILER7 UNSIGNED_16 PLC1

405501 B_ACTIVE UNSIGNED_16 PLC1

405502 B_ALARM UNSIGNED_16 PLC1

405503 B_CON_NON UNSIGNED_16 PLC1

405504 B_WINTER UNSIGNED_16 PLC1

405505 B_DHWP UNSIGNED_16 PLC1

405506 B_ON UNSIGNED_16 PLC1

405507 B_PUMP_EXISTING UNSIGNED_16 PLC1

405508 B_PUMP_ON UNSIGNED_16 PLC1

405509 B_VALVE_EXISTING UNSIGNED_16 PLC1

TPC-FI SoloNet O&M Page 58

405510 B_VALVE_ON UNSIGNED_16 PLC1

405511 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405512 B_DAMPER_ON UNSIGNED_16 PLC1

405513 B_DAMPER_PROVE UNSIGNED_16 PLC1

405514 B_OUTLET_TEMP SIGNED_16 PLC1

405515 B_INLET_TEMP SIGNED_16 PLC1

405516 B_STACK_TEMP SIGNED_16 PLC1

405517 B_CYCLE_TIME UNSIGNED_16 PLC1

405518 B_CYCLE_COUNT UNSIGNED_32 PLC1

405519 PLC1

405520 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405521 PLC1

405522 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405523 PLC1

405524 B_MBH_OUTPUT UNSIGNED_32 PLC1

405525 PLC1

405526-40

5549 Reserved PLC1

405550 B_EXISTING BOILER8 UNSIGNED_16 PLC1

405551 B_ACTIVE UNSIGNED_16 PLC1

405552 B_ALARM UNSIGNED_16 PLC1

405553 B_CON_NON UNSIGNED_16 PLC1

405554 B_WINTER UNSIGNED_16 PLC1

405555 B_DHWP UNSIGNED_16 PLC1

405556 B_ON UNSIGNED_16 PLC1

405557 B_PUMP_EXISTING UNSIGNED_16 PLC1

405558 B_PUMP_ON UNSIGNED_16 PLC1

405559 B_VALVE_EXISTING UNSIGNED_16 PLC1

405560 B_VALVE_ON UNSIGNED_16 PLC1

405561 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405562 B_DAMPER_ON UNSIGNED_16 PLC1

405563 B_DAMPER_PROVE UNSIGNED_16 PLC1

405564 B_OUTLET_TEMP SIGNED_16 PLC1

405565 B_INLET_TEMP SIGNED_16 PLC1

405566 B_STACK_TEMP SIGNED_16 PLC1

405567 B_CYCLE_TIME UNSIGNED_16 PLC1

405568 B_CYCLE_COUNT UNSIGNED_32 PLC1

405569 PLC1

TPC-FI SoloNet O&M Page 59

405570 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405571 PLC1

405572 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405573 PLC1

405574 B_MBH_OUTPUT UNSIGNED_32 PLC1

405575 PLC1

405576-40

5599 Reserved PLC1

405600 B_EXISTING BOILER9 UNSIGNED_16 PLC1

405601 B_ACTIVE UNSIGNED_16 PLC1

405602 B_ALARM UNSIGNED_16 PLC1

405603 B_CON_NON UNSIGNED_16 PLC1

405604 B_WINTER UNSIGNED_16 PLC1

405605 B_DHWP UNSIGNED_16 PLC1

405606 B_ON UNSIGNED_16 PLC1

405607 B_PUMP_EXISTING UNSIGNED_16 PLC1

405608 B_PUMP_ON UNSIGNED_16 PLC1

405609 B_VALVE_EXISTING UNSIGNED_16 PLC1

405610 B_VALVE_ON UNSIGNED_16 PLC1

405611 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405612 B_DAMPER_ON UNSIGNED_16 PLC1

405613 B_DAMPER_PROVE UNSIGNED_16 PLC1

405614 B_OUTLET_TEMP SIGNED_16 PLC1

405615 B_INLET_TEMP SIGNED_16 PLC1

405616 B_STACK_TEMP SIGNED_16 PLC1

405617 B_CYCLE_TIME UNSIGNED_16 PLC1

405618 B_CYCLE_COUNT UNSIGNED_32 PLC1

405619 PLC1

405620 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405621 PLC1

405622 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405623 PLC1

405624 B_MBH_OUTPUT UNSIGNED_32 PLC1

405625 PLC1

405626-40

5649 Reserved PLC1

405650 B_EXISTING BOILER1

0UNSIGNED_16 PLC1

TPC-FI SoloNet O&M Page 60

405651 B_ACTIVE UNSIGNED_16 PLC1

405652 B_ALARM UNSIGNED_16 PLC1

405653 B_CON_NON UNSIGNED_16 PLC1

405654 B_WINTER UNSIGNED_16 PLC1

405655 B_DHWP UNSIGNED_16 PLC1

405656 B_ON UNSIGNED_16 PLC1

405657 B_PUMP_EXISTING UNSIGNED_16 PLC1

405658 B_PUMP_ON UNSIGNED_16 PLC1

405659 B_VALVE_EXISTING UNSIGNED_16 PLC1

405660 B_VALVE_ON UNSIGNED_16 PLC1

405661 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405662 B_DAMPER_ON UNSIGNED_16 PLC1

405663 B_DAMPER_PROVE UNSIGNED_16 PLC1

405664 B_OUTLET_TEMP SIGNED_16 PLC1

405665 B_INLET_TEMP SIGNED_16 PLC1

405666 B_STACK_TEMP SIGNED_16 PLC1

405667 B_CYCLE_TIME UNSIGNED_16 PLC1

405668 B_CYCLE_COUNT UNSIGNED_32 PLC1

405669 PLC1

405670 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405671 PLC1

405672 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405673 PLC1

405674 B_MBH_OUTPUT UNSIGNED_32 PLC1

405675 PLC1

405676-40

5699 Reserved PLC1

405700 B_EXISTING BOILER1

1UNSIGNED_16 PLC1

405701 B_ACTIVE UNSIGNED_16 PLC1

405702 B_ALARM UNSIGNED_16 PLC1

405703 B_CON_NON UNSIGNED_16 PLC1

405704 B_WINTER UNSIGNED_16 PLC1

405705 B_DHWP UNSIGNED_16 PLC1

405706 B_ON UNSIGNED_16 PLC1

405707 B_PUMP_EXISTING UNSIGNED_16 PLC1

405708 B_PUMP_ON UNSIGNED_16 PLC1

405709 B_VALVE_EXISTING UNSIGNED_16 PLC1

TPC-FI SoloNet O&M Page 61

405710 B_VALVE_ON UNSIGNED_16 PLC1

405711 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405712 B_DAMPER_ON UNSIGNED_16 PLC1

405713 B_DAMPER_PROVE UNSIGNED_16 PLC1

405714 B_OUTLET_TEMP SIGNED_16 PLC1

405715 B_INLET_TEMP SIGNED_16 PLC1

405716 B_STACK_TEMP SIGNED_16 PLC1

405717 B_CYCLE_TIME UNSIGNED_16 PLC1

405718 B_CYCLE_COUNT UNSIGNED_32 PLC1

405719 PLC1

405720 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405721 PLC1

405722 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405723 PLC1

405724 B_MBH_OUTPUT UNSIGNED_32 PLC1

405725 PLC1

405726-40

5749 Reserved PLC1

405750 B_EXISTING BOILER1

2UNSIGNED_16 PLC1

405751 B_ACTIVE UNSIGNED_16 PLC1

405752 B_ALARM UNSIGNED_16 PLC1

405753 B_CON_NON UNSIGNED_16 PLC1

405754 B_WINTER UNSIGNED_16 PLC1

405755 B_DHWP UNSIGNED_16 PLC1

405756 B_ON UNSIGNED_16 PLC1

405757 B_PUMP_EXISTING UNSIGNED_16 PLC1

405758 B_PUMP_ON UNSIGNED_16 PLC1

405759 B_VALVE_EXISTING UNSIGNED_16 PLC1

405760 B_VALVE_ON UNSIGNED_16 PLC1

405761 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405762 B_DAMPER_ON UNSIGNED_16 PLC1

405763 B_DAMPER_PROVE UNSIGNED_16 PLC1

405764 B_OUTLET_TEMP SIGNED_16 PLC1

405765 B_INLET_TEMP SIGNED_16 PLC1

405766 B_STACK_TEMP SIGNED_16 PLC1

405767 B_CYCLE_TIME UNSIGNED_16 PLC1

405768 B_CYCLE_COUNT UNSIGNED_32 PLC1

TPC-FI SoloNet O&M Page 62

405769 PLC1

405770 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405771 PLC1

405772 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405773 PLC1

405774 B_MBH_OUTPUT UNSIGNED_32 PLC1

405775 PLC1

405776-40

5799 Reserved PLC1

405800 B_EXISTING BOILER1

3UNSIGNED_16 PLC1

405801 B_ACTIVE UNSIGNED_16 PLC1

405802 B_ALARM UNSIGNED_16 PLC1

405803 B_CON_NON UNSIGNED_16 PLC1

405804 B_WINTER UNSIGNED_16 PLC1

405805 B_DHWP UNSIGNED_16 PLC1

405806 B_ON UNSIGNED_16 PLC1

405807 B_PUMP_EXISTING UNSIGNED_16 PLC1

405808 B_PUMP_ON UNSIGNED_16 PLC1

405809 B_VALVE_EXISTING UNSIGNED_16 PLC1

405810 B_VALVE_ON UNSIGNED_16 PLC1

405811 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405812 B_DAMPER_ON UNSIGNED_16 PLC1

405813 B_DAMPER_PROVE UNSIGNED_16 PLC1

405814 B_OUTLET_TEMP SIGNED_16 PLC1

405815 B_INLET_TEMP SIGNED_16 PLC1

405816 B_STACK_TEMP SIGNED_16 PLC1

405817 B_CYCLE_TIME UNSIGNED_16 PLC1

405818 B_CYCLE_COUNT UNSIGNED_32 PLC1

405819 PLC1

405820 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405821 PLC1

405822 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405823 PLC1

405824 B_MBH_OUTPUT UNSIGNED_32 PLC1

405825 PLC1

405826-40

5849 Reserved PLC1

TPC-FI SoloNet O&M Page 63

405850 B_EXISTING BOILER1

4UNSIGNED_16 PLC1

405851 B_ACTIVE UNSIGNED_16 PLC1

405852 B_ALARM UNSIGNED_16 PLC1

405853 B_CON_NON UNSIGNED_16 PLC1

405854 B_WINTER UNSIGNED_16 PLC1

405855 B_DHWP UNSIGNED_16 PLC1

405856 B_ON UNSIGNED_16 PLC1

405857 B_PUMP_EXISTING UNSIGNED_16 PLC1

405858 B_PUMP_ON UNSIGNED_16 PLC1

405859 B_VALVE_EXISTING UNSIGNED_16 PLC1

405860 B_VALVE_ON UNSIGNED_16 PLC1

405861 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405862 B_DAMPER_ON UNSIGNED_16 PLC1

405863 B_DAMPER_PROVE UNSIGNED_16 PLC1

405864 B_OUTLET_TEMP SIGNED_16 PLC1

405865 B_INLET_TEMP SIGNED_16 PLC1

405866 B_STACK_TEMP SIGNED_16 PLC1

405867 B_CYCLE_TIME UNSIGNED_16 PLC1

405868 B_CYCLE_COUNT UNSIGNED_32 PLC1

405869 PLC1

405870 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405871 PLC1

405872 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405873 PLC1

405874 B_MBH_OUTPUT UNSIGNED_32 PLC1

405875 PLC1

405876-40

5899 Reserved PLC1

405900 B_EXISTING BOILER1

5UNSIGNED_16 PLC1

405901 B_ACTIVE UNSIGNED_16 PLC1

405902 B_ALARM UNSIGNED_16 PLC1

405903 B_CON_NON UNSIGNED_16 PLC1

405904 B_WINTER UNSIGNED_16 PLC1

405905 B_DHWP UNSIGNED_16 PLC1

405906 B_ON UNSIGNED_16 PLC1

405907 B_PUMP_EXISTING UNSIGNED_16 PLC1

TPC-FI SoloNet O&M Page 64

405908 B_PUMP_ON UNSIGNED_16 PLC1

405909 B_VALVE_EXISTING UNSIGNED_16 PLC1

405910 B_VALVE_ON UNSIGNED_16 PLC1

405911 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405912 B_DAMPER_ON UNSIGNED_16 PLC1

405913 B_DAMPER_PROVE UNSIGNED_16 PLC1

405914 B_OUTLET_TEMP SIGNED_16 PLC1

405915 B_INLET_TEMP SIGNED_16 PLC1

405916 B_STACK_TEMP SIGNED_16 PLC1

405917 B_CYCLE_TIME UNSIGNED_16 PLC1

405918 B_CYCLE_COUNT UNSIGNED_32 PLC1

405919 PLC1

405920 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405921 PLC1

405922 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405923 PLC1

405924 B_MBH_OUTPUT UNSIGNED_32 PLC1

405925 PLC1

405926-40

5949 Reserved PLC1

405950 B_EXISTING BOILER1

6UNSIGNED_16 PLC1

405951 B_ACTIVE UNSIGNED_16 PLC1

405952 B_ALARM UNSIGNED_16 PLC1

405953 B_CON_NON UNSIGNED_16 PLC1

405954 B_WINTER UNSIGNED_16 PLC1

405955 B_DHWP UNSIGNED_16 PLC1

405956 B_ON UNSIGNED_16 PLC1

405957 B_PUMP_EXISTING UNSIGNED_16 PLC1

405958 B_PUMP_ON UNSIGNED_16 PLC1

405959 B_VALVE_EXISTING UNSIGNED_16 PLC1

405960 B_VALVE_ON UNSIGNED_16 PLC1

405961 B_DAMPER_EXISTING UNSIGNED_16 PLC1

405962 B_DAMPER_ON UNSIGNED_16 PLC1

405963 B_DAMPER_PROVE UNSIGNED_16 PLC1

405964 B_OUTLET_TEMP SIGNED_16 PLC1

405965 B_INLET_TEMP SIGNED_16 PLC1

405966 B_STACK_TEMP SIGNED_16 PLC1

TPC-FI SoloNet O&M Page 65

405967 B_CYCLE_TIME UNSIGNED_16 PLC1

405968 B_CYCLE_COUNT UNSIGNED_32 PLC1

405969 PLC1

405970 B_HOURS_OF_OPERATION UNSIGNED_32 PLC1

405971 PLC1

405972 B_MBH_LOAD_ASSIGNMENT UNSIGNED_32 PLC1

405973 PLC1

405974 B_MBH_OUTPUT UNSIGNED_32 PLC1

405975 PLC1

405975-40

9999 Reserved PLC1

TPC-FI SoloNet O&M Page 66

Appendix C

TPC-FI SoloNet O&M Page 67

TPC-FI SoloNet O&M Page 68

GROUP Parameter Logging Type Sample Size

Design Inputs Supply Temp Hourly Average >= 10 samples/hour

Design Inputs Return Temp Hourly Average >= 10 samples/hour

Design Inputs Outdoor Air Temp Hourly Average >= 10 samples/hour

Design Inputs GPM Flow Hourly Average >= 10 samples/hour

Design Inputs Set Point Hourly Average >= 10 samples/hour

Design Inputs Display Load (Supply – Return * GPM) Hourly Average >= 60 samples/hour

Heat Priority Event Driven On Delta

Heat Priority Event Driven On Delta

Operation in reset Event Driven On Delta

Operation in reset Event Driven On Delta

Heat Reset 3 (Reheat) Operation in reset Event Driven On Delta

Winter Priority Active / Inactive Event Driven On Delta

System Pumps Alarm Status Event Driven On Delta

System Pumps On/Off Status Event Driven On Delta

System Pumps Output Percentage (Modulation) Hourly Average >= 60 samples/hour

Zone Pump Alarm Status Event Driven On Delta

Zone Pump On/Off Status Event Driven On Delta

Zone Pump Output Percentage (Modulation) Hourly Average >= 60 samples/hour

Boiler Pump Alarm Status Event Driven On Delta

Boiler Pump On/Off Status Event Driven On Delta

Boiler Pump Output Percentage (Modulation) Hourly Average >= 60 samples/hour

Boilers Hours of Operation Event Driven To a minute

Boilers Alarm Status Event Driven On Delta

Boilers On/Off Status Event Driven On Delta

Boilers Output Percentage (Modulation) Hourly Average >= 60 samples/hour

Damper Alarm Status Event Driven On Delta

Winter Heat On Setpoint

NonCondensing Outdoor Setpoint

Heat Reset 1 (Condensign)

Heat Reset 2 (NonCondensing)

Notices of software licenses used in this product:

FreeRTOS(tm):

-------------

This product uses FreeRTOS.org, version 4.7.0. FreeRTOS is distributable under a modified version of

the GNU General Public License. Should you desire to obtain the version of FreeRTOS used in this

product, you may do so at http://www.thermodynamicprocesscontrol.com/software/oss. The full text

of the license governing the use of FreeRTOS.org may be found on the same page.

You may learn more about FreeRTOS.org from http://www.freertos.org.

FreeModbus:

------------

FreeModbus Libary: A portable Modbus implementation for Modbus ASCII/RTU.

Copyright (c) 2006 Christian Walter <wolti@sil.at>

All rights reserved.

Redistribution and use in source and binary forms, with or without

modification, are permitted provided that the following conditions

are met:

1. Redistributions of source code must retain the above copyright

notice, this list of conditions and the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright

notice, this list of conditions and the following disclaimer in the

documentation and/or other materials provided with the distribution.

3. The name of the author may not be used to endorse or promote products

derived from this software without specific prior written permission.

THIS SOFTWARE IS PROVIDED BY THE AUTHOR ``AS IS'' AND ANY EXPRESS OR

IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED.

IN NO EVENT SHALL THE AUTHOR BE LIABLE FOR ANY DIRECT, INDIRECT,

INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING,

BUT

NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE,

DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY

THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT

(INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF

THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Linux Kernel:

TPC-FI SoloNet O&M Page 69

---------------

The Linux kernel is used by this product. The kernel itself is

distributed under the GNU General Public License, Version 2. To obtain a copy of

the kernel source used in this product, please visit

http://www.thermodynamicprocesscontrol.com/software/oss.

Other Programs:

----------------

Other programs under the GPL or other open-source license terms may be distributed

with the product. To obtain the sources for these programs, please visit

http://www.thermodynamicprocesscontrol.com/software/oss.

Alternative source:

-------------------

If you prefer to obtain the sources for the open-source programs used by this product

by way of CD or DVD, you may do so for a cost of $9.99. Please contact Thermodynamic Process

Control for more details.

TPC-FI SoloNet O&M Page 70