Park Air Systems B6525MDR Multimode VHF Ground to Air Transceiver User Manual MDR

Park Air Systems Limited Multimode VHF Ground to Air Transceiver MDR

User Manual

6525 Multimode Digital Radio

User Documentation

Draft

31-3MDR00HB Page 2

Draft

Handbook Title: 6525 Multimode Digital Radio User Documentation

Handbook Part Number: 31-3MDR00HB

Handbook Version: Draft

Date of Issue: June 2007

Published By: Park Air Systems

Northfields

Market Deeping

Peterborough PE6 8UE

England

Telephone: From UK, 01778 345434

From outside UK, 44 1778 345434

Fax: From UK, 01778 342877

From outside UK, 44 1778 342877

www.parkairsystems.com

Errata

Any errors found in this handbook are promulgated through the Park Air FTP network. Any

user can access this information by logging on to:

ftp.parkairsystems.com

When logged on, select the public (Pub) folder, then the Handbook Errata Sheets folder,

and then select the required equipment model.

[Adobe Acrobat™ must be loaded on your PC to use this facility]

31-3MDR00HB Page 3

Draft

Health and Safety

Warnings

A warning is used to indicate possible danger to personnel. Throughout Park Air handbooks, warnings

are indicated by the following symbols:

Cautions

A caution is used to indicate possible danger to the equipment.

Indicates electrical danger to personnel.WARNING

Indicates a hazardous material.

WARNING

Indicates a non-ionizing radiation hazard.

WARNING

Indicates a specified danger to personnel.

WARNING

Indicates the presence of electrostatic sensitive devices (ESSD). Caution

Indicates a specified danger to the equipment. Caution

31-3MDR00HB Page 4

Draft

Health and Safety (Continued)

Specific Warnings Applicable to the MDR

The instructions given in this documentation involve connecting dangerous voltage to the MDR.

Installation must be carried out only by suitably qualified personnel.

This equipment must be earthed. The earth terminal of the ac connector must be used as the safety

earth.

The antenna used with the MDR must be installed such that the resultant radiated field strength is

below 10 W/m² in areas normally accessible to personnel.

The RF field strength from the antenna can be predicted from the equation S=1.4PG/4πR2

[Where S = power density; P = power input to antenna; G = antenna gain; R = distance

to centre of radiation and 1.4 = multiplication factor for average power based on a

modulation index of 90%.]

Based on this formula a 2 dBi antenna, the predicted safe distance from the centre of radiation would

be approximately 0.75 m for a field strength of 10 W/m2 (1 mW/cm2).

This meets the requirements of Health Canada Safety Code 6 for RF and microwave exposed

workers. For persons not classed as RF and microwave workers and including the general public

the limit is 2 W/m2 (0.2 mW/cm2) which increases the minimum safe distance to 1.7 m.

Further information on calculating the field strengths and power levels can be found in Health

Canada Safety Code 6 'Limits of Human Exposure to Radiofrequency Electromagnetic Fields in the

Frequency Range 3 kHz to 300 GHz', and also in FCC document OET Bulletin 65.

Ensure an antenna, or dummy load, is connected before switching on the MDR. There is high RF

voltage present at the antenna connector when the radio is keyed.

Although no instructions in this documentation involve removing any equipment covers, users

should be aware that the RFPA output transistors contain Beryllium.

During installation an MDR may have to be lifted, possibly to head height, to fit onto telescopic slides.

At least two people should be used to lift the equipment. Failure to use sufficient people when lifting

equipment can result in personal injury.

WARNING Dangerous Voltage

WARNING Earth Connection

WARNING Antenna Radiation

WARNING Antenna Radiation

Beryllium Hazard

WARNING

WARNING Heavy Item

31-3MDR00HB Page 5

Draft

Disposal

This product is covered by the European Directive 2002/96/EC.

It must not be disposed of in domestic waste.

Disposal should be made using designated collection facilities

appointed by the government or local authority in your area.

31-3MDR00HB Page 6

Draft

List of Abbreviations

Aamp

ac alternating current

ACARS aircraft communications, addressing

and reporting system

AM amplitude modulation

BIT built-in test

C celsius

dB decibel

dBm power ratio in decibel (dB) referenced

to one milliwatt (mW)

dc direct current

ESD electrostatic sensitive devices

Fig figure

Hz hertz

kg kilogramme

kHz kilohertz

LCD liquid crystal display

mmetre

mA milliamp

MDR multimode digital radio

MHz megahertz

mm millimetre

ms milli-second

mW milliwatt

PA power amplifier

ppm parts per million

PTT press to transmit

RFPA radio frequency power amplifier

s second

Vvolt

VDL VHF data link

VHF very high frequency

VSWR voltage standing wave ratio

Wwatt

31-3MDR00HB Page 7

Draft

Approvals and Standards 6525 Multimode Digital Radio

The equipment is designed to meet the following requirements:

RoHS Directive 2002/95/EC

WEEE Directive 2002/96/EC

ICAO Annex 10 Vol lll Part 1 Chapter 6

EN 301 841-1 Electromagnetic compatibility and Radio spectrum Matters (ERM); VHF air-ground

Digital Link (VDL) Mode 2; Technical characteristics and methods of measurement for

ground-based equipment; Part 1: Physical layer and MAC sub-layer

EN 300 676 Electromagnetic compatibility and Radio spectrum Matters (ERM); Ground-based

VHF hand-held, mobile and fixed radio transmitters, receivers and transceivers for the VHF

aeronautical mobile service using amplitude modulation; Technical characteristics and methods

of measurement.

Approvals have been granted against the following:

Safety approval to EN60950-1, CAN/CSA-C22.2 No. 60950 and UL 60950

FCC Rules 47CFR Parts 15 and 87

Technical Acceptance under Industry Canada, reference Radio Standard Specification RSS141

CE approval under the R&TTE Directive 1999/5/EC.

0336

!

RoHS

2002/95/EC

FCC ID; C8L 6525MDR

FCC / Industry Canada Statement

This device has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used

in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Consult the supplier or an experienced radio/TV technician for help.

Operation on 8.33 kHz channel spacing is prohibited under the current regulations

of Industry Canada and the FCC.

31-3MDR00HB Page 8

Draft

Intentionally Blank

Contents

Page

31-3MDR00HB Page 9

Draft

Overview 11

Introduction 12

Operating Modes 12

MDR Applications 13

Hardware Configuration 13

Software Configuration 13

Specification 15

MDR Operating Characteristics 16

Dimensions and Weight 16

Input Supply Requirement 16

Environmental 16

Operation 17

Controls and Indicators 18

Introduction 18

Controls and Indicators 18

Ready Indicator 18

Alarm Indicator 18

Receive Indicator 18

Transmit Indicator 18

Scroll/Select Switch and LCD 19

Connectors 19

Reference Connector 19

Headset/Microphone/Diagnostics Connector 19

Switching On and Setting the Operating Parameters 21

Using the Scroll/Select Switch 21

Screen Protocol 21

Switching On 22

Selecting an Operating Mode 23

Selecting the Operating Frequency 24

Storing and Recalling Frequency Channels 25

Setting Band Edges 27

Setting Parameters 29

Downloading Software Fills 35

Installation 37

Introduction 38

Fuses and Connectors 39

Initial Inspection of the MDR 39

Fitting an MDR into an Equipment Cabinet 40

Rear Panel Interfaces 41

Ethernet Connector 42

Facilities Connector 43

Auxiliary Connector 45

Connecting the Chassis Stud 46

Connecting an Antenna 46

Checking the ac Input Fuse 47

AC Supply Connection 47

31-3MDR00HB Page 10

Contents (continued)

Page

Draft

Maintenance 49

Maintenance Policy 50

Unscheduled Maintenance 50

Scheduled Maintenance 50

Cleaning the Equipment 50

Security of External Connections 50

Checking the MDR’s Internal Reference Frequency 51

Initiating an Interruptive BIT Test 52

Removing and Refitting the Cooling Fan 54

Draft

Overview

31-3MDR00HB Page 12 Overview

Draft

Introduction

This documentation describes the Park Air 6525 Multimode Digital Radio (MDR). The MDR is a VHF

transceiver operating in the aeronautical frequency band between 118 and 136.975 MHz. The maximum

transmit output power is 25 watts.

The MDR can be used as a conventional AM-Voice transceiver, or can operate as a subsystem of the

Aircraft Communications, Addressing and Reporting System (ACARS) and the VHF Data Link (VDL)

air-ground communication systems.

Fig 1 6525 Multimode Digital Radio (MDR)

Operating Modes

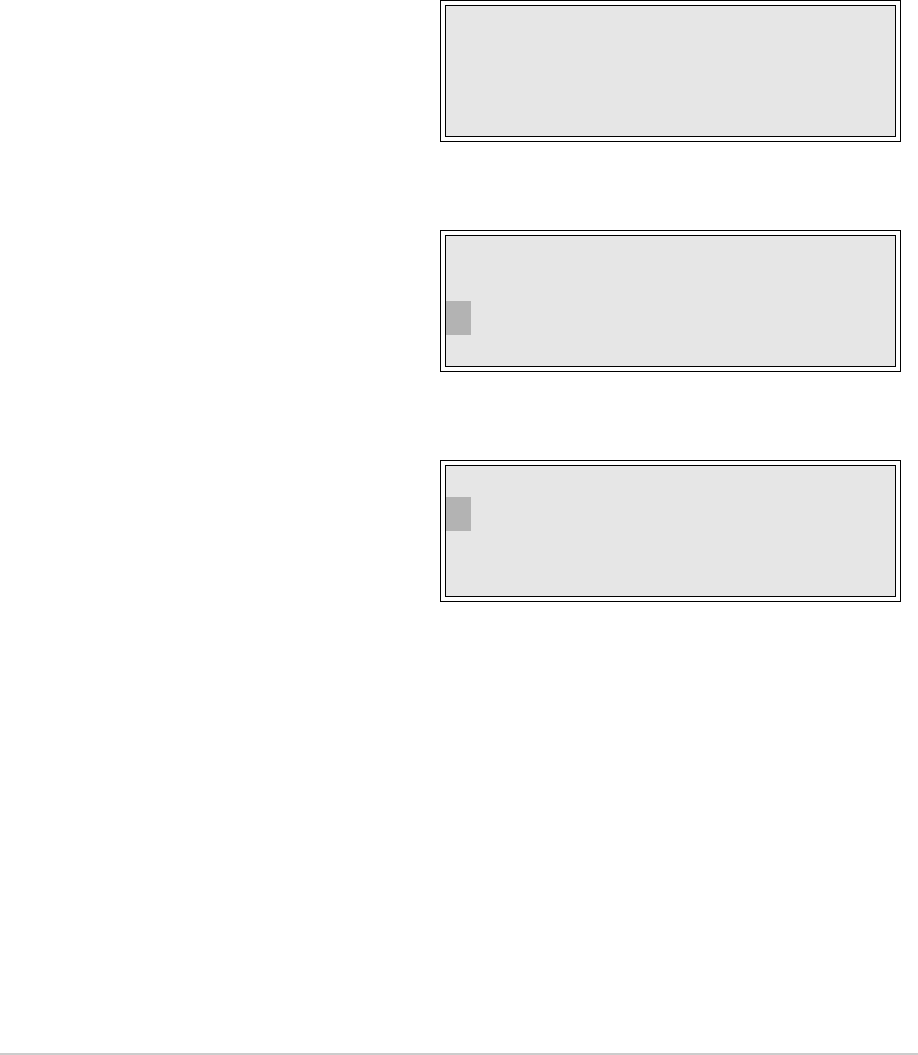

Operating modes are software controlled. A 6525 MDR can be loaded with any two of the four available

software fills shown in Fig 2. All four software fills are available to download through the user’s network.

Fig 2 Operating Modes

AM DigitalAM Analogue

ACARS ACARS

VDL

Mode 2

AM-Voice

6525 MDR

(requires an

external modem)

(uses modem

within the MDR)

31-3MDR00HB Page 13 Overview

Draft

MDR Applications

In addition to operating in a conventional AM-Voice mode, the MDR can operate in two VHF air-ground

data link services: ACARS and VDL mode 2.

ACARS is a low-speed data link in wide use throughout the world, operating at 2.4 kbits per second using

MSK modulation.

VDL mode 2 is a higher bandwidth, connection orientated service, operating at 31.5 kbits per second

using D8PSK modulation.

Hardware Configuration

The product model is: 6525 MDR.

The part number is: B6525.

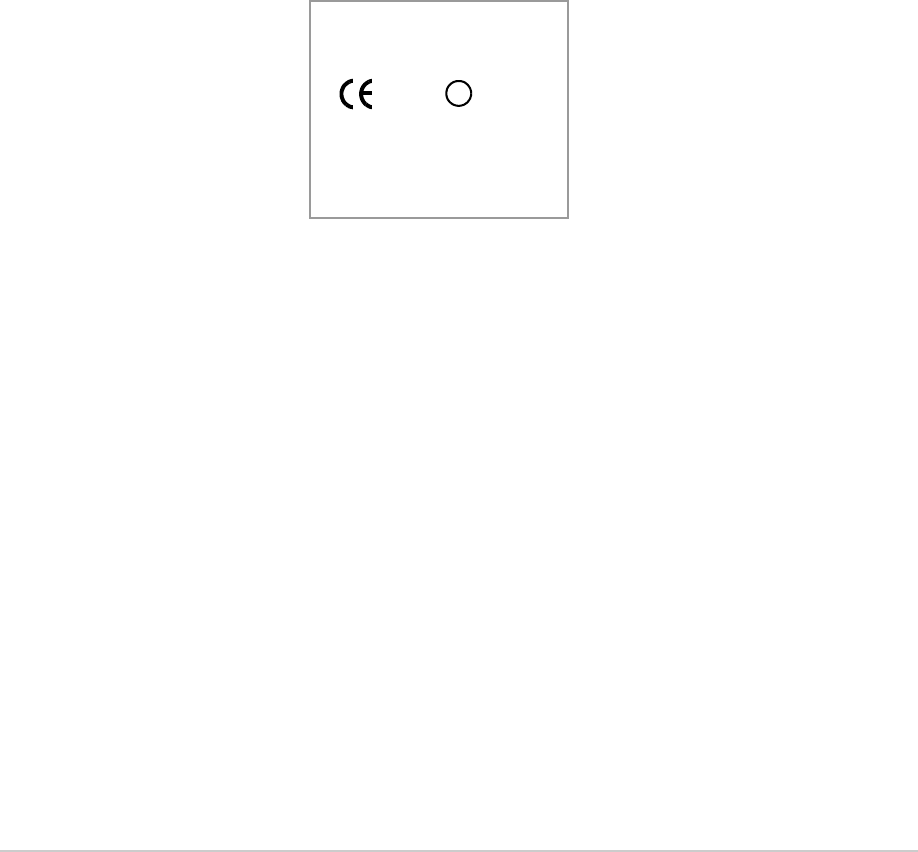

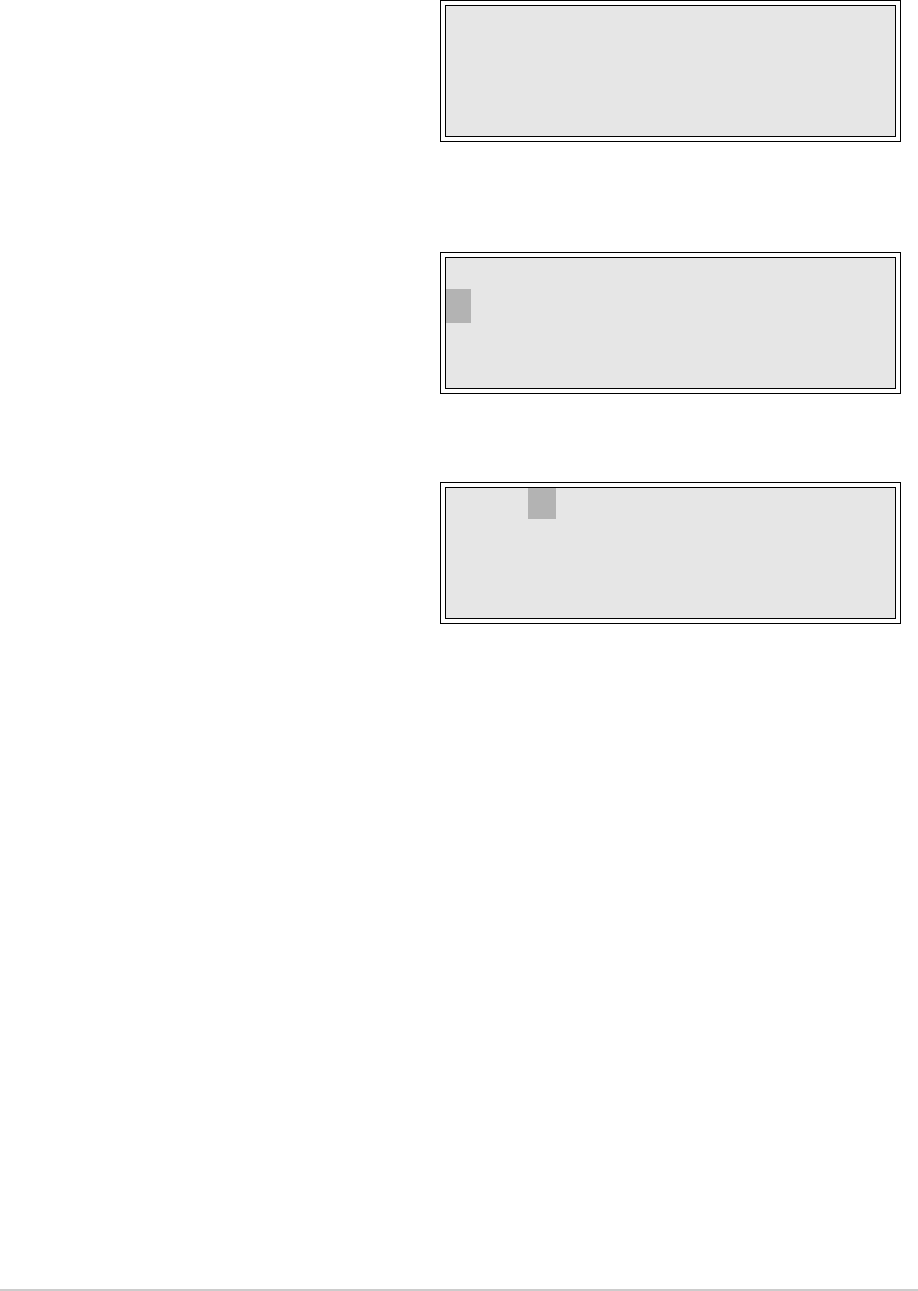

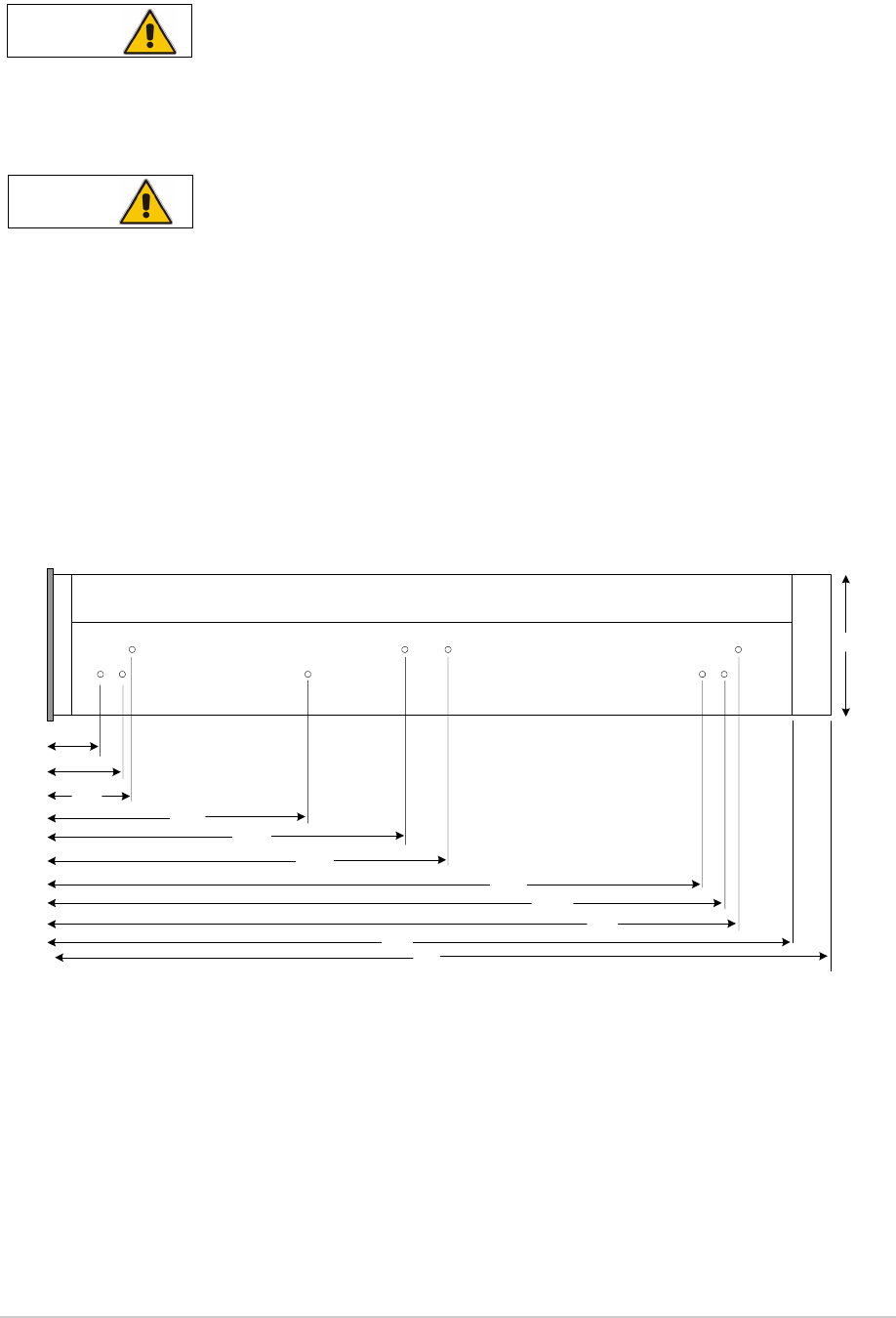

A hardware configuration label is fixed to the MDR’s rear panel. The label shows the model, part number,

serial number and modification status. An example label is shown in Fig 3.

Fig 3 Hardware Configuration Label

Software Configuration

The part order number is TBD (customer specific). This number encompasses the hardware part number

detailed above, fitted with the software detailed below.

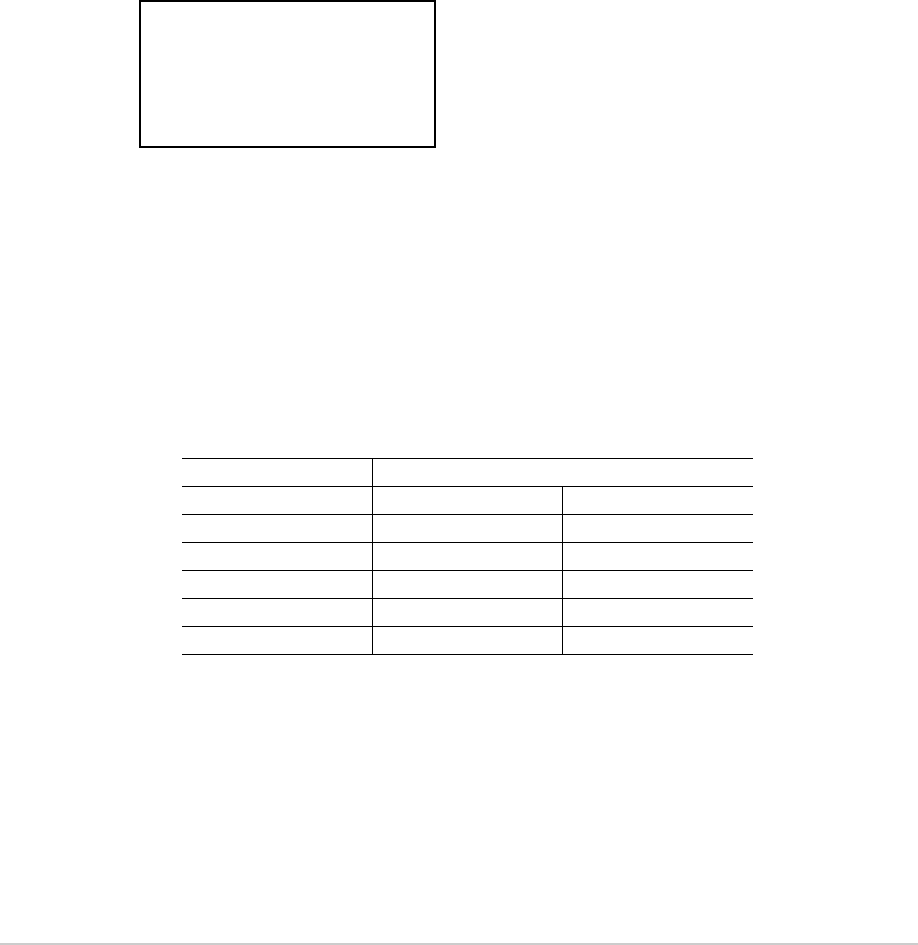

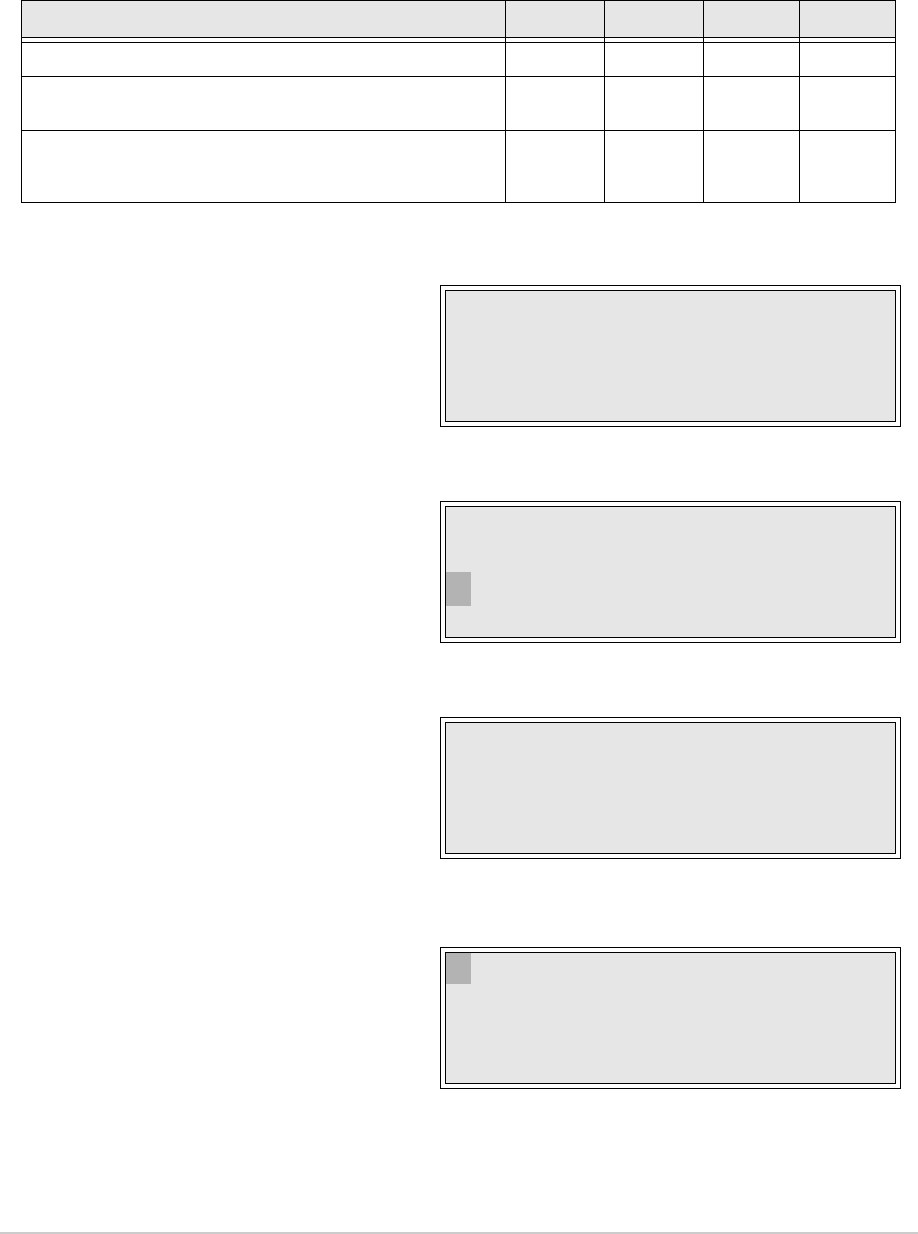

Any two of the four available software fills can be stored in the MDR at any one time. A software

configuration label, as shown in Fig 4, is fixed to the MDR’s top cover. This label details the part numbers

for the four mode software fills, and the permanently installed Ethernet software.

Fig 4 Software Label

Model:

Part No:

S / No:

Mod Record:

6525 MDR

B6525

1M2345

1 2 3 4 5 6 7 8 9

Park Air Systems Ltd England

PAE

Software Configuration

Part Order No. TBD (customer specific)

Software Mode Part No.

Fill * AM Voice TBD (customer specific)

Fill * AM Analogue ACARS TBD (customer specific)

Fill * AM Digital ACARS TBD (customer specific)

Fill * VDL Mode 2 TBD (customer specific)

Interface Ethernet TBD (customer specific)

*Only 2 are stored in the radio at any one time

Intentionally Blank

Draft

Specification

31-3MDR00HB Page 16 Specification

Draft

MDR Operating Characteristics

Frequency range Between 118 and 136.975 MHz

Number of channels 100

Channel spacing 25 kHz (all modes)

8.33 kHz (Am-Voice mode only)

Modulation modes ACARS 13K0A2D

VDL Mode 2 14K0G1D

AM-Voice (25 kHz) 6K00A3E

AM-Voice (8.33 kHz) 5K00A3E

Frequency stability Better than 1 ppm within permissible environmental conditions

Dimensions and Weight

The dimensions and weight of the MDR are:

Width 483 mm (19 inches)

Depth 450 mm (17.8 inches)

Height 88.9 mm (3.5 inches).

Weight 12.5 kg (27.5 pounds)

Input Supply Requirement

ac input supply Between 90 and 264 Vac, 47 to 63 Hz

ac power consumption Tx, less than 400 VA (250 VA typical)

Rx, less than 70 VA

Environmental

Temperature range 0 to +40°C operating

-20 to +60°C non-operating

Ventilation The MDR is cooled by a temperature controlled fan. When the MDR is

switched on, the fan runs at full speed for a short period before coming

under temperature control

Warm up time Less than 30 seconds

Draft

Operation

31-3MDR00HB Page 18 Operation

Draft

Controls and Indicators

Introduction

This topic describes the MDR’s front panel (see Fig 5) controls, indicators and connectors.

Fig 5 MDR Front Panel

Controls and Indicators

Ready Indicator

A green indicator that lights when the MDR is ready for use and no BIT faults have been detected.

Alarm Indicator

A red indicator that either flashes, or lights, when a BIT fault has been detected. BIT indications are

classified as either Alerts or Alarms.

If an ‘alert’ condition is detected, the Alarm indicator flashes, the Ready indicator remains lit, and the

MDR remains operational. A BIT ‘alert’ is indicated if:

The MDR’s RF output power has reduced from its setting by more than 1 dB but not more than

3dB

The supply volts falls below 21.6 V

The RF PA temperature has exceeded 80oC.

Any other BIT condition results in an alarm. When detected, the Alarm indicator lights and the Ready

indicator becomes unlit; the MDR cannot be used.

When the Alarm indicator flashes, or is lit, the front panel display indicates the nature of the Alert or Alarm

Receive Indicator

An amber indicator that lights as follows:

In AM-Voice mode When a signal above the squelch threshold is received, or when

the squelch is defeated.

In VDL 2 mode Lights on Sync and remains lit until the end of message.

In AM Analogue ACARS mode Lit when a signal is received.

In AM Digital ACARS mode Lights on Sync and remains lit until the end of message.

Transmit Indicator

An amber indicator that lights when the transmit circuit is keyed and producing output power.

31-3MDR00HB Page 19 Operation

Draft

Scroll/Select Switch and LCD

The Scroll/Select switch is used in conjunction with the LCD to select most of the MDR's operational

settings. During normal operation, the LCD displays the Main screen. Detailed information regarding the

Scroll/Select switch and LCD is given on page 21.

Connectors

Reference Connector

An SMB jack socket that allows a frequency counter to monitor the MDR's reference frequency. This

connector is used only for maintenance purposes. The instructions for checking and adjusting the

reference frequency are given in the Maintenance topic.

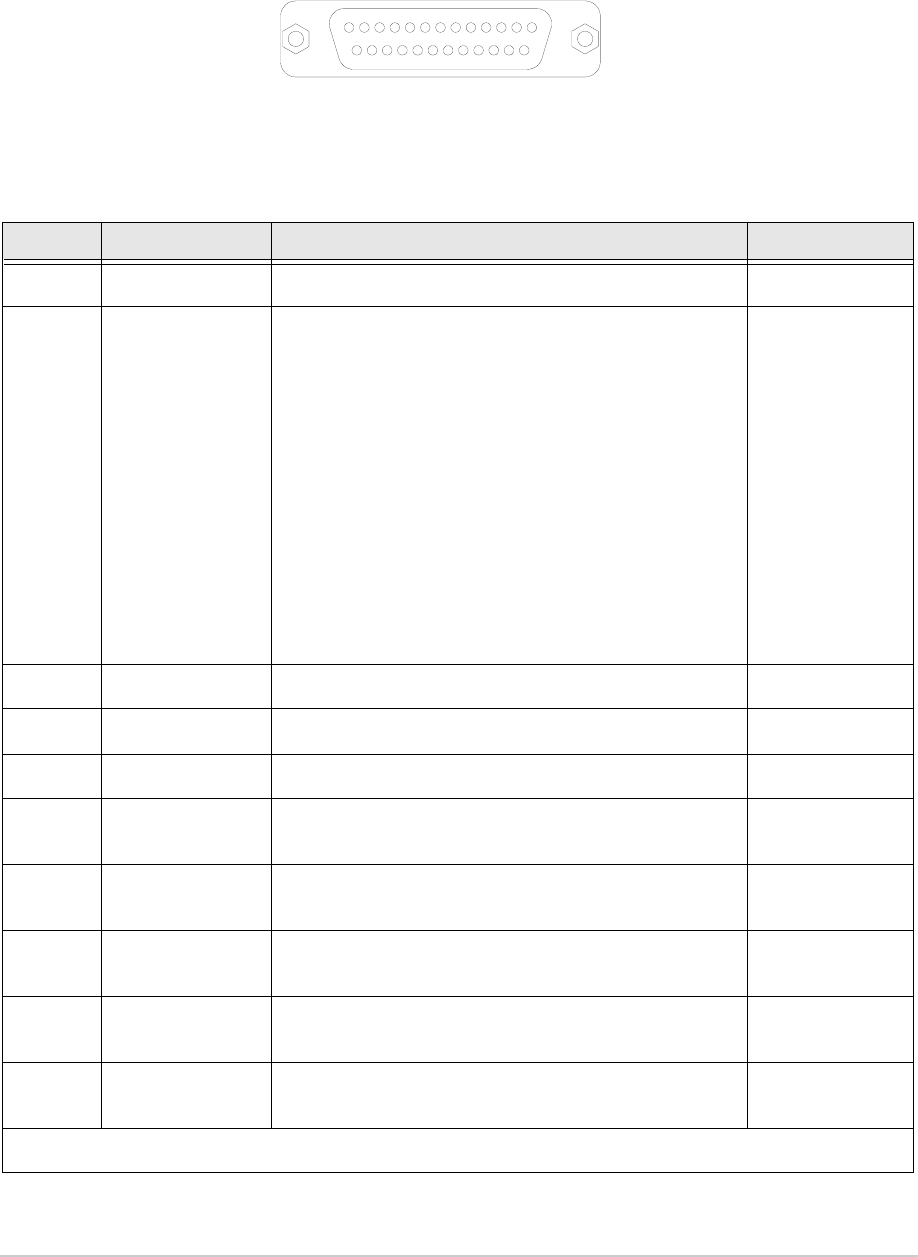

Headset/Microphone/Diagnostics Connector

A dual purpose connector that allows either a headset/microphone, or a PC, to be connected to the MDR.

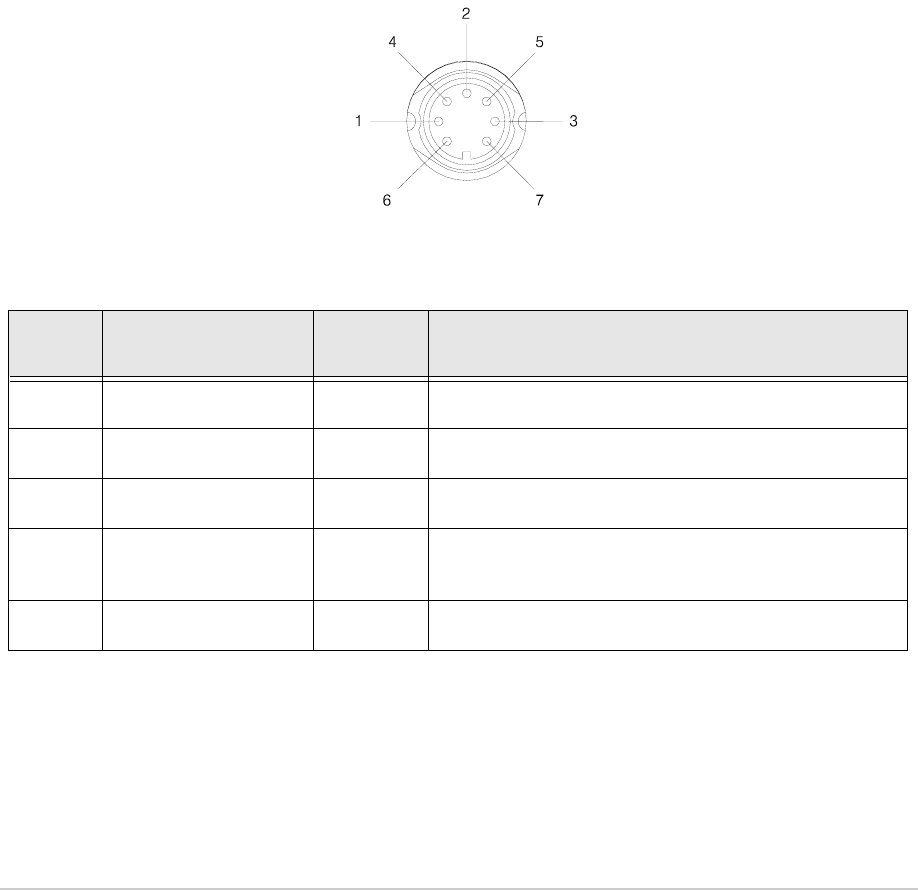

The connector is a 7-pin self-locking DIN socket; the pin-out is shown in Fig 6 and detailed in Table 1 for

the audio connections, and Table 2 for the PC connections.

A microphone/headset is used to enable the MDR to be operated from the front panel in AM-Voice mode.

Fig 6 Headset/Microphone/Diagnostics Connector Pin-Out

Table 1 Headset/Microphone/Diagnostics Connector - Audio Connections

Pin

Number Signal Input or

Output Description

1 Microphone ground - 0 V.

3 Microphone PTT Input 0 V to PTT.

5 Sidetone/headset drive Output 0 to 3 V pk-pk.

6 Microphone input Input 2 to 35 mV rms on Passive setting and 8 to 140 mV rms

on Active setting to remain in VOGAD range.

7 Ground - 0 V.

31-3MDR00HB Page 20 Operation

Draft

Note:

PC connections are used for maintenance at Park Air. No instructions in this documentation

require the use of this port.

Table 2 Headset/Microphone/Diagnostics Connector - PC Connections

Pin

Number Signal Input or

Output Description

2 Transmit data Output RS232, 115200 baud, 8 data bits, 1 stop bit, no parity, no

handshaking.

4 Receive data Input RS232, 115200 baud, 8 data bits, 1 stop bit, no parity, no

handshaking.

7 Ground - 0 V.

31-3MDR00HB Page 21 Operation

Draft

Switching On and Setting the Operating Parameters

Using the Scroll/Select Switch

The Scroll/Select switch (referred to throughout this topic as the ‘Switch’) is used to leave the Main

screen and display the Control screen. Further use of the Switch displays various selection menus and

allows the required parameters to be set. The switch has three actions: it can be turned clockwise, anti-

clockwise, or momentarily pushed in.

Screen Protocol

The following protocol is applicable to all screens described in this document.

Main Screen During normal MDR operation, the Main screen, an example of which is shown

below, is displayed.

Switch Refers to the front panel Scroll/Select switch. The switch is turned clockwise to scroll

through fields from left to right, and from top to bottom. The switch is turned

anticlockwise to scroll through fields from right to left, and from bottom to top. The

switch is pressed to make a selection.

Time out If during any setting up procedure the Scroll/Select switch is not operated for

30 seconds, the display returns to the Main screen. If editing any parameter has not

been completed, the MDR stays on the original setting.

>> Indicates more fields are available other than those currently displayed. To access

those fields, turn the switch clockwise through the last displayed field.

<< Indicates more fields are available other than those currently displayed. To access

those fields, turn the switch anti-clockwise through the first displayed field.

Back When Back is selected, you are returned to the previous menu.

Exit When Exit is selected, you are returned to the Main screen.

F r e q 1 1 8 . 0 0 0 M H z

M o d e V D L M O D E 2

31-3MDR00HB Page 22 Operation

Draft

Switching On

The MDR is switched on by setting the rear panel AC Supply switch to On. The LCD should light and

show the following displays.

F r e q 1 1 8 . 0 0 0 M H z

M o d e A M V O I C E

V o l l l l l l l

Main Screen for AM-Voice Mode

F r e q 1 1 8 . 0 0 0 M H z

M o d e V D L M O D E 2

Main Screen for VDL Mode 2

F r e q 1 1 8 . 0 0 0 M H z

C h 4 2

M o d e A M A / A C A R S

V o l l l l l l l l l l l

Main Screen for AM Analogue ACARS

F r e q 1 1 8 . 0 0 0 M H z

M o d e A M D / A C A R S

P w r l l l l l l l l l l

Main Screen for AM Digital ACARS

When switched on, the MDR initialises which

takes approximately five seconds.

When the MDR is initialised a Main screen is

displayed.

Four Main screens are available that reflect

the MDR’s four possible operating modes.

The screen displayed after switch on reflects

the last selected operating mode.

Channel (Ch) information is shown only when

the MDR operates from a stored channel

frequency.

A power (Pwr) level indication is shown only

when the MDR is keyed.

A volume (Vol) level indication is shown only

when the MDR is not keyed.

31-3MDR00HB Page 23 Operation

Draft

Selecting an Operating Mode

To select the MDR’s operating mode, use the following procedure:

F r e q 1 1 8 . 0 0 0 M H z

M o d e V D L M O D E 2

Main Screen (example shown for VDL Mode 2)

F r e q u e n c y

C h a n n e l

S e t t i n g s

E x i t > >

Control Screen

M o d e A M V O I C E

M o d e S e t t i n g s

P o l a r i t i e s

E x i t > >

Settings Screen

With the Main screen displayed, press the

Switch to display the Control screen.

Turn the Switch until Settings is highlighted.

Then press the Switch to display the Settings

screen.

Turn the Switch until the current Mode is

highlighted; then press the Switch. Turn the

switch to alter the operating mode. When the

required mode is displayed, press the Switch.

After a delay of approximately 15 seconds the

Main screen, applicable to the selected

mode, is displayed.

The MDR can contain the software fills for two operating modes. If the

required operating mode cannot be selected during this procedure, the

required fill must be downloaded. See page 35.

31-3MDR00HB Page 24 Operation

Draft

Selecting the Operating Frequency

The MDR’s frequency can be changed in two ways: either from the frequency screen, or by recalling a

preset channel. This procedure details using the Frequency screen. Storing and recalling channel

frequencies is detailed on page 25.

F r e q 1 1 8 . 0 0 0 M H z

M o d e V D L M O D E 2

Main Screen (example shown for VDL Mode 2)

F r e q u e n c y

C h a n n e l

S e t t i n g s

E x i t > >

Control Screen

F r e q 1 1 8 . 0 0 0 M H z

C a n c e l O K

Frequency Screen

With the Main screen displayed, press the

Switch to display the Control screen.

Turn the Switch until Frequency is

highlighted. Then press the Switch to display

the Frequency screen.

Turn the Switch to highlight the digits to be

changed, then press the Switch. Turn the

Switch until the required digits are shown,

then press the Switch. Repeat until the

required frequency is shown, then highlight

OK and press the switch.

Only frequencies that fall between the band edge settings can be selected.

Setting Band Edges is described on page 27.

31-3MDR00HB Page 25 Operation

Draft

Storing and Recalling Frequency Channels

As an alternative to setting an individual operating frequency, up to 100 preset frequency channels can

be stored in the MDR; any stored channel can be recalled for immediate use.

To store a frequency channel:

F r e q 1 1 8 . 0 0 0 M H z

C h 2 3

M o d e A M A / A C A R S

V o l l l l l l l l l l l

Main Screen (example shown for

AM Analogue ACARS)

F r e q u e n c y

C h a n n e l

S e t t i n g s

E x i t > >

Control Screen

C h 2 4

F r e q 1 1 8 . 0 0 0 M H z

S t o r e

B a c k E x i t

Channel Screen

With the Main screen displayed, press the

Switch to display the Control screen.

Turn the Switch until Channel is highlighted.

Then press the Switch to display the Channel

screen.

Turn the Switch to highlight the channel

number and press the Switch. Turn the switch

to select the required channel number and

then press the switch again.

Turn the Switch to highlight the Frequency

digits to be changed, then press the Switch.

Turn the Switch until the required digits are

shown, then press the Switch. Repeat until

the required frequency is shown, then

highlight Store and press the switch.

Repeat for other channels as required.

Select Back to return to the Control screen, or

Exit to return to the Main screen.

Only channel frequencies that fall between the band edge settings can be

selected. If an attempt is made to store a frequency outside the band edges,

an error message is displayed.

Setting Band Edges is described on page 27.

31-3MDR00HB Page 26 Operation

Draft

To recall a previously stored channel:

F r e q 1 1 8 . 0 0 0 M H z

C h 2 3

M o d e A M A / A C A R S

V o l l l l l l l l l l l

Main Screen (example shown for

AM Analogue ACARS)

F r e q u e n c y

C h a n n e l

S e t t i n g s

E x i t > >

Control Screen

C h 2 4

F r e q 1 1 8 . 0 0 0 M H z

R e c a l l

B a c k E x i t

Channel Screen

With the Main screen displayed, press the

Switch to display the Control screen.

Turn the Switch until Channel is highlighted.

Then press the Switch to display the Channel

screen.

Turn the Switch to highlight the channel

number and press the Switch. Turn the switch

to select the required channel number/

frequency and then press the switch.

Highlight Recall and press the Switch. The

MDR now operates on the selected frequency

channel.

Select Back to return to the Control screen, or

Exit to return to the Main screen.

31-3MDR00HB Page 27 Operation

Draft

Setting Band Edges

The frequency range of the MDR is 118 to 136.975 MHz. If required, operation can be limited to either

one or two smaller parts of the frequency band by setting the band edges BE1 to BE4. Operation is

possible between BE1 and BE2 frequencies, and frequencies between BE3 and BE4. Examples are

shown in Table 3.

To set the band edges:

Table 3 Band Edge Values

BE1 BE2 BE3 BE4

MDR set so that the full frequency range can be received. 118.000 136.975 118.000 136.975

Example: MDR set to transmit and receive only those

frequencies in the range 120 to 130 MHz. 120.000 130.000 120.000 130.000

Example: MDR set to transmit and receive only those

frequencies in the ranges 120 to 125 MHz and 130 to

135 MHz.

120.000 125.000 130.000 135.000

F r e q 1 1 8 . 0 0 0 M H z

M o d e V D L M O D E 2

Main Screen (example shown for VDL Mode 2)

F r e q u e n c y

C h a n n e l

S e t t i n g s

E x i t > >

Control Screen

M o d e V D L M O D E 2

M o d e S e t t i n g s

P o l a r i t i e s

E X I T > >

Settings Screen (First Page)

B a n d E d g e s

I P S e t t i n g s

R e f F r e q 6 7 . 0 %

E x i t < < > >

Settings Screen (Second Page)

With the Main screen displayed, press the

Switch to display the Control screen.

Turn the Switch until Settings is highlighted.

Then press the Switch to display the Settings

screen.

Turn the Switch clockwise until the Settings

screen (second page) is displayed. Highlight

Band Edges and press the Switch to display

the Band Edge screen.

(continued ...)

31-3MDR00HB Page 28 Operation

Draft

B E 1 1 2 0 . 0 0 0 M H z

B E 2 1 2 5 . 0 0 0 M H z

B E 3 1 3 0 . 0 0 0 M H z

E x i t > >

Band Edge Screen (First Page)

B E 4 1 3 5 . 0 0 0 M H z

B a c k

E x i t

< <

Band Edge Screen (First Page)

Using the Switch, highlight the band edge

values to be altered, pressing the switch after

each alteration.

When all values are correct, select Exit to

return to the Main page.

Note that band edge frequencies can be set

only in increments of 25 kHz.

31-3MDR00HB Page 29 Operation

Draft

Setting Parameters

The MDR’s parameters listed in the following tables can be set by the user. Not all parameters can be

set from the MDR’s front panel.

The applicable tables are:

Analogue ACARS mode, Table 4

Digital ACARS mode, Table 5

VDL mode 2, Table 6

AM-Voice mode, Table 7.

Mode specific parameters are set by selecting Mode Settings as follows:

F r e q 1 1 8 . 0 0 0 M H z

M o d e V D L M O D E 2

Main Screen (example shown for VDL Mode 2)

F r e q u e n c y

C h a n n e l

S e t t i n g s

E x i t > >

Control Screen

M o d e A M V O I C E

M o d e S e t t i n g s

P o l a r i t i e s

E x i t > >

Settings Screen

With the Main screen displayed, press the

Switch to display the Control screen.

Turn the Switch until Settings is highlighted.

Then press the Switch to display the Settings

screen.

Turn the Switch until Mode Settings is

highlighted; then press the Switch. Turn the

switch to scroll through and set the applicable

parameters.

31-3MDR00HB Page 30 Operation

Draft

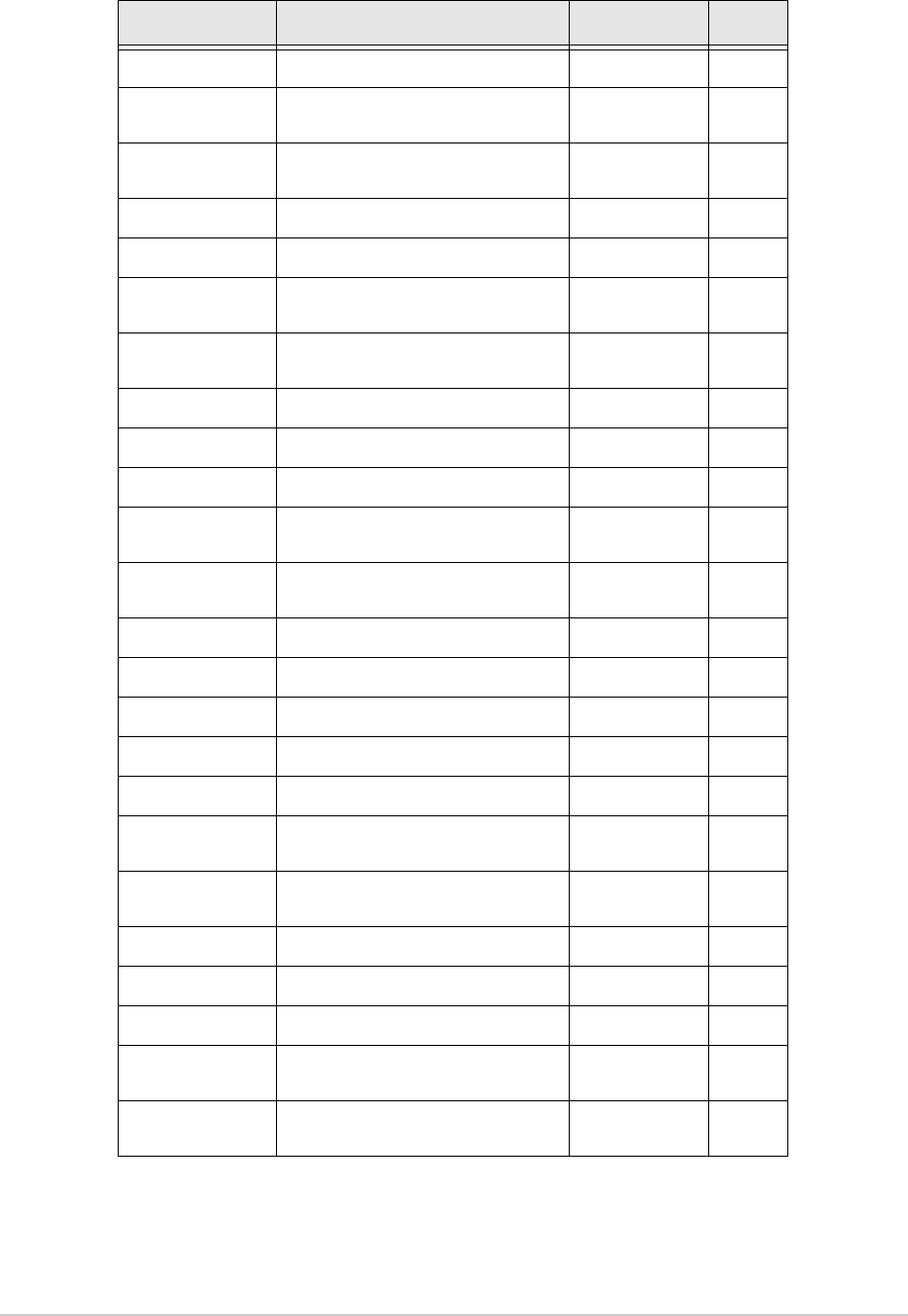

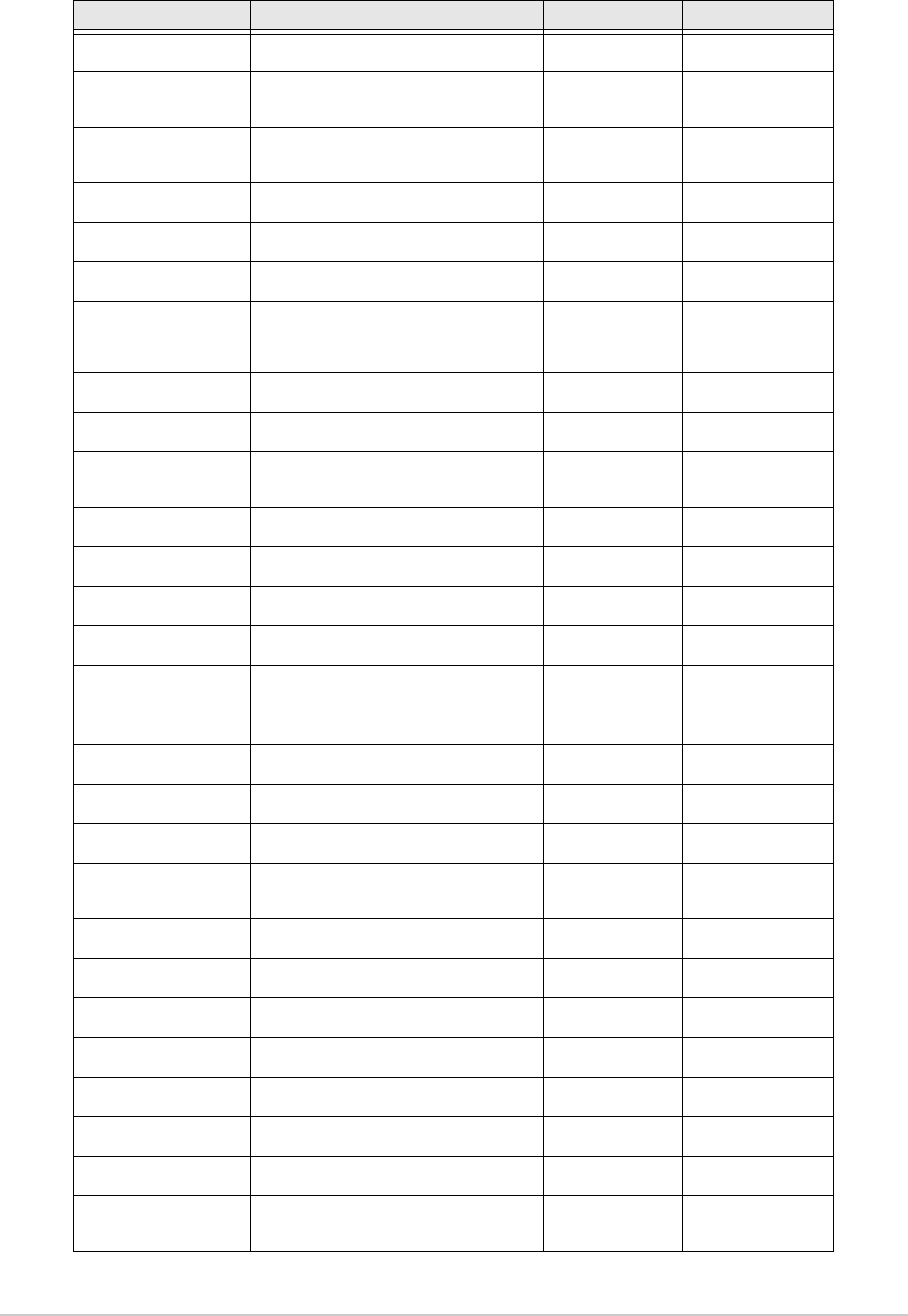

Table 4 Analogue ACARS Functions and Parameters

Function Adjustment Range Factory Default Step

Size

Frequency 118 to 136.975 MHz 118.000 MHz 25 kHz

Band edges BE1

and BE3 118 to 136.975 MHz 118.000 MHz 25 kHz

Band edges BE2

and BE4 118 to 136.975 MHz 136.975 MHz 25 kHz

Channel 1 to 100 – 1

RF power 3 to 25 W 25 W 1 W

Reference

frequency 0 to 100% – 0.4%

LCD display

backlight time-out 15 to 120 s, On or Off 30 s 15 s

Modulation depth 5 to 95% 90% 1%

PTT On (key) or Off (dekey) Off –

PTT Polarity STD (active low) or INV (active high) STD –

Phantom PTT

Polarity STD (active low) or INV (active high) STD –

PTT reference

voltage +14, 0, or -14 V +14 V –

Audio line input -20 to +10 dBm -13 dBm 1 dB

TX inhibit On or Off Off –

Transmit time-out 2 to 510 s, or Off 180 s 2 s

RF pre-attenuator On or Off Off –

Audio line output -20 to +10 dBm -13 dBm 1 dB

Loudspeaker/

Headset volume 0 to 100% 30% 5%

Initiate BIT

interruptive test On or Off – –

DHCP On or Off Off –

IP address 000.000.000.000 to 255.255.255.255 192.168.0.2 –

IP subnet mask 000.000.000.000 to 255.255.255.255 255.255.255.000 –

Default gateway

address 000.000.000.000 to 255.255.255.255 192.168.0.1 –

Control application

TCP port number 5001 to 65535 30000 –

31-3MDR00HB Page 31 Operation

Draft

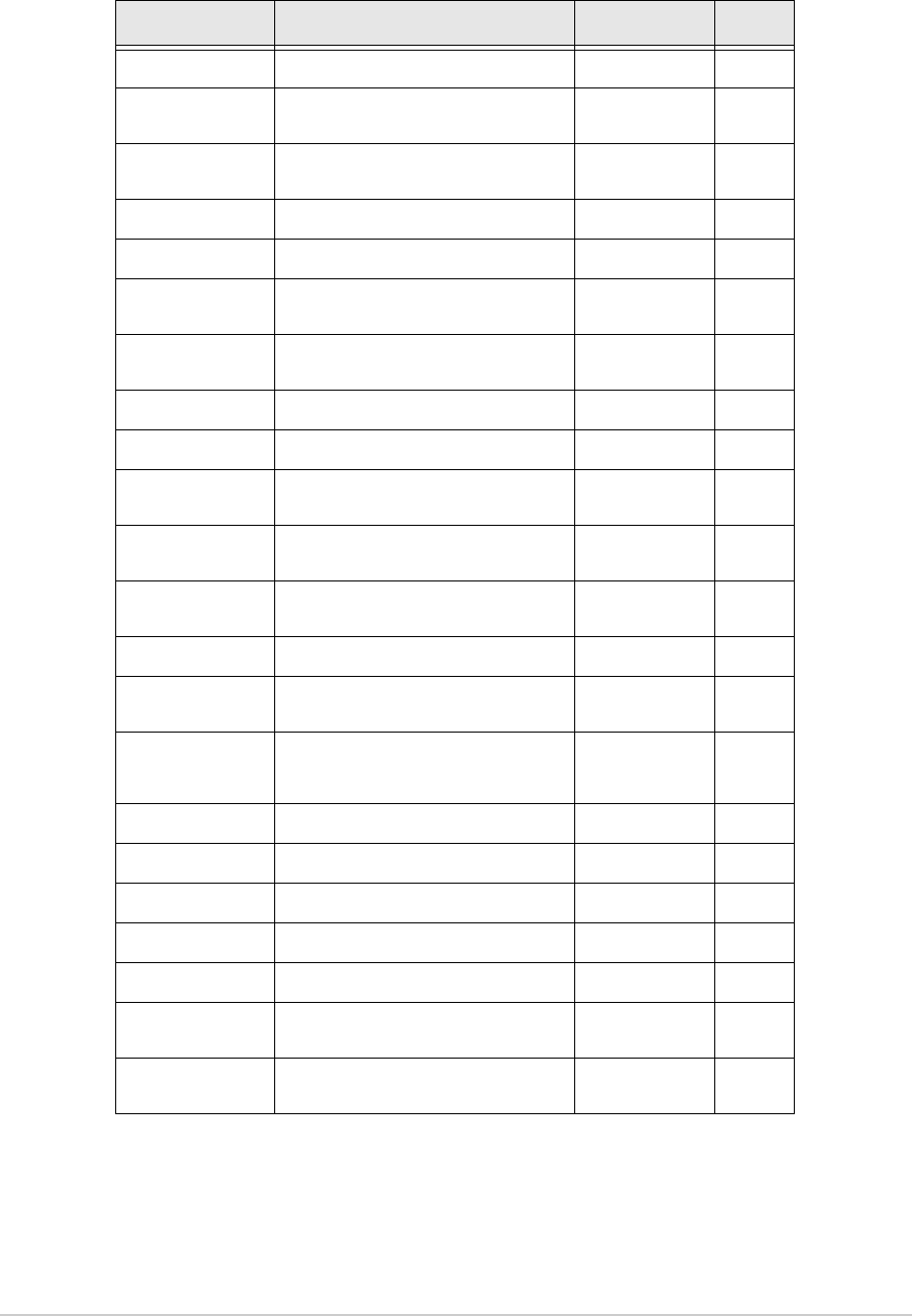

Table 5 Digital ACARS Functions and Parameters

Function Adjustment Range Factory Default Step

Size

Frequency 118 to 136.975 MHz 118.000 MHz 25 kHz

Band edges BE1

and BE3 118 to 136.975 MHz 118.000 MHz 25 kHz

Band edges BE2

and BE4 118 to 136.975 MHz 136.975 MHz 25 kHz

Channel 1 to 100 – 1

RF power 3 to 25 W 25 W 1 W

Reference

frequency 0 to 100% – 0.4%

LCD display

backlight time-out 15 to 120 s, On or Off 30 s 15 s

Modulation depth 5 to 95% 90% 1%

RF pre-attenuator On or Off Off –

Loudspeaker/

Headset volume 0 to 100% 30% 5%

MAC TM1

(Inter-access delay) 0.5 to 125 ms 75.5 ms 0.5 ms

MAC TM2

(Channel busy) 1 to 120 s 60 s 1 s

MAC TM3 1 to 120 s 20 s 1 s

MAC p

(Persistance) 1/256 to 256/256 50/256 1/256

MAC M1

(maximum number

of access attempts)

2 to 9999 10 10

TX enable On or Off Off –

Loop back On or Off Off –

DHCP On or Off Off –

IP address 000.000.000.000 to 255.255.255.255 192.168.0.2 –

IP subnet mask 000.000.000.000 to 255.255.255.255 255.255.255.000 –

Default gateway

address 000.000.000.000 to 255.255.255.255 192.168.0.1 –

Control application

TCP port number 5001 to 65535 30000 –

31-3MDR00HB Page 32 Operation

Draft

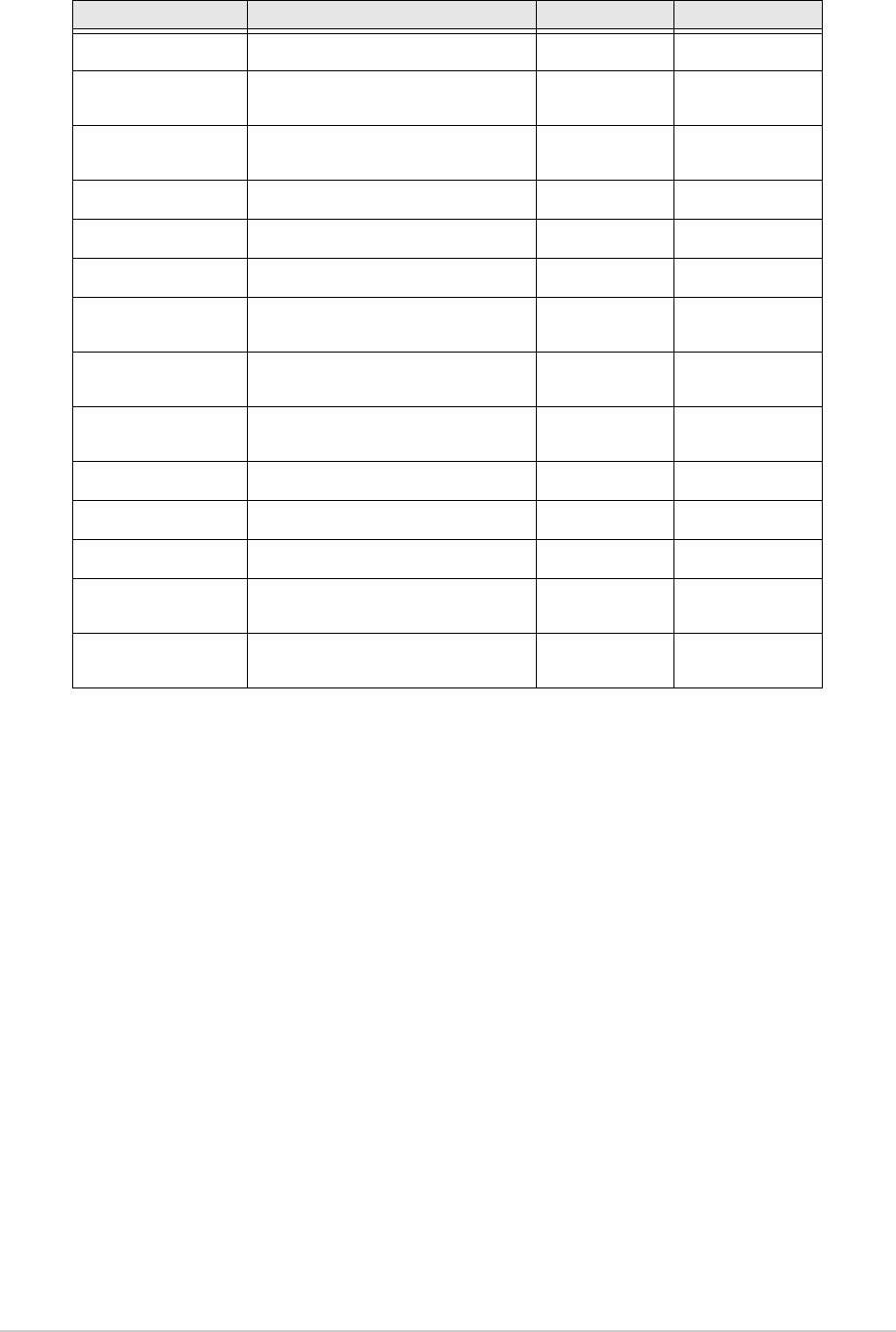

Table 6 VDL Mode 2 Functions and Parameters

Function Adjustment Range Factory Default Step

Size

Frequency 118 to 136.975 MHz 118.000 MHz 25 kHz

Band edges BE1

and BE3 118 to 136.975 MHz 118.000 MHz 25 kHz

Band edges BE2

and BE4 118 to 136.975 MHz 136.975 MHz 25 kHz

Channel 1 to 100 – 1

RF power 3 to 25 W 25 W 1 W

Reference

frequency 0 to 100% – 0.4%

LCD display

backlight time-out 15 to 120 s, On or Off 30 s 15 s

RF pre-attenuator On or Off Off –

MAC TM1

(Inter-access delay) 0.5 to 125 ms 4.5 ms 0.5 ms

MAC TM2

(Channel busy) 6 to 120 s 60 s 1 s

MAC p

(Persistance) 1/256 to 256/256 13/256 1/256

MAC M1

(maximum number

of access attempts)

1 to 65535 135 1

Scramble vector 0000 to 7FFF (hex)

0 to 32767 (decimal)

4D4B (hex)

19787 (decimal) 1

TX enable On or Off Off –

Loop back On or Off Off –

Reed Solomon

Decoding On or Off On –

DHCP On or Off Off –

IP address 000.000.000.000 to 255.255.255.255 192.168.0.2 –

IP subnet mask 000.000.000.000 to 255.255.255.255 255.255.255.000 –

Default gateway

address 000.000.000.000 to 255.255.255.255 192.168.0.1 –

Control application

TCP port number 5001 to 65535 30000 –

31-3MDR00HB Page 33 Operation

Draft

Table 7 AM-Voice Functions and Parameters

Function Adjustment Range Factory Default Step Size

Frequency 118 to 136.975 MHz 118.000 MHz 25 or 8.33 kHz

Band edges BE1 and

BE3 118 to 136.975 MHz 118.000 MHz 25 kHz

Band edges BE2 and

BE4 118 to 136.975 MHz 136.975 MHz 25 kHz

Front panel step size 25, 8.33 kHz, or both 25 kHz 25 or 8.33 kHz

Channel 1 to 100 – 1

Channel spacing 25 or 8.33 kHz 25 kHz -

Offset carrier

2 offset, ±5 kHz

3 offset, 0 and ±7.5 kHz

4 offset, ±2.5 kHz and ±7.5 kHz

--

RF power 3 to 25 W 25 W 1 W

Reference frequency 0 to 100% – 0.4%

LCD display backlight

time-out 15 to 120 s, On or Off 30 s 15 s

Modulation depth 5 to 95% 90% 1%

VOGAD On or Off On -

Mute On or Off On -

PTT On (key) or Off (dekey) Off –

Tone keying 2175, 2300 Hz, or Off Off -

Microphone type Active or passive Passive -

Keying priority Local-remote, or remote-local Local-remote -

Local PTT enable Enabled or disabled Enabled -

Remote PTT enable Enabled or disabled Enabled -

Remote phantom PTT

enable Enabled or disabled Disabled -

PTT Polarity STD (active low) or INV (active high) STD –

Phantom PTT Polarity STD (active low) or INV (active high) STD –

PTT reference voltage +14, 0, or -14 V +14 V –

Audio line input -20 to +10 dBm -13 dBm 1 dB

TX inhibit On or Off Off –

Transmit time-out 2 to 510 s, or Off 180 s 2 s

Audio AGC On or Off On -

Squelch -110 to -60 dBm (-104 to -54 dBm with

RF pre-attenuator selected) -110 dBm 1 dB

31-3MDR00HB Page 34 Operation

Draft

Squelch polarity STD (n/o) or INV (n/c) STD -

Squelch noise

compensation On or Off On -

Squelch carrier

override On or Off Off -

Squelch defeat On or Off Off -

RF pre-attenuator On or Off Off –

Audio line output -20 to +10 dBm -13dBm 1 dB

Loudspeaker/Headset

volume 0 to 100% 30% 5%

Self-receive transmit

audio on line output On or Off Off

Initiate BIT interruptive

test On or Off – –

DHCP On or Off Off –

IP address 000.000.000.000 to 255.255.255.255 192.168.0.2 –

IP subnet mask 000.000.000.000 to 255.255.255.255 255.255.255.000 –

Default gateway

address 000.000.000.000 to 255.255.255.255 192.168.0.1 –

Control application

TCP port number 5001 to 65535 30000 –

Table 7 AM-Voice Functions and Parameters (Continued)

Function Adjustment Range Factory Default Step Size

Intentionally Blank

Installation

31-3MDR00HB Page 38 Installation

Draft

Introduction

The instructions given in this topic involve connecting dangerous voltage to the MDR.

Installation must be carried out only by suitably qualified personnel.

The antenna used with the MDR must be installed such that the resultant radiated field

strength is below 10 W/m² in areas normally accessible to personnel.

The RF field strength from the antenna can be predicted from the equation S=1.4PG/4πR2

[Where S = power density; P = power input to antenna; G = antenna gain; R = distance

to centre of radiation and 1.4 = multiplication factor for average power based on a

modulation index of 90%.]

Based on this formula a 2 dBi antenna, the predicted safe distance from the centre of radiation would

be approximately 0.75 m for a field strength of 10 W/m2 (1 mW/cm2).

This meets the requirements of Health Canada Safety Code 6 for RF and microwave exposed

workers. For persons not classed as RF and microwave workers and including the general public

the limit is 2 W/m2 (0.2 mW/cm2) which increases the minimum safe distance to 1.7 m.

Further information on calculating the field strengths and power levels can be found in Health

Canada Safety Code 6 'Limits of Human Exposure to Radiofrequency Electromagnetic Fields in the

Frequency Range 3 kHz to 300 GHz', and also in FCC document OET Bulletin 65.

Ensure an antenna, or dummy load, is connected before switching on the MDR. There is high

RF voltage present at the antenna connector when the radio is keyed.

During installation an MDR may have to be lifted, possibly to head height, to fit onto

telescopic slides. At least two people should be used to lift the equipment. Failure to use

sufficient people when lifting equipment can result in personal injury.

The MDR's circuitry contains Electrostatic Sensitive Devices (ESDs). Personnel must be

aware of the precautions necessary to prevent damage to such devices. During installation

all precautions necessary to prevent ESSD damage must be taken.

Changes or modifications made to this equipment that are not expressly approved by

Park Air, or parties authorized by Park Air, could void the user’s authority to operate the

equipment.

WARNING Dangerous Voltage

WARNING Antenna Radiation

WARNING Antenna Radiation

WARNING Heavy Item

Caution ESDs

Caution Unauthorized Modifications

31-3MDR00HB Page 39 Installation

Draft

The procedures in this document describe how to install an MDR. The procedures necessary during

installation are listed in Table 8.

Fuses and Connectors

Table 9 lists the radio’s supply fuse and the connectors. Some of the connectors (depending on your

particular configuration) are required during installation.

Initial Inspection of the MDR

On receipt of the MDR from Park Air, remove all transit packaging and check that there is no damage. If

damage is evident, contact Park Air immediately and retain the original transit packaging. It is helpful if

photographs of any damage can be taken and then forwarded to Park Air in support of any claim.

Table 8 Installation Procedures

Procedure Reference

1 Perform an initial inspection of the MDR. page 39

3 Fit the MDR into an equipment cabinet. page 40

4 Connect the remote signals (as required). page 41

5 Connect the chassis stud to the cabinet or system earth. page 46

6 Connect an antenna page 46

7 Checking the ac input fuse page 47

8 Connect the ac supply. page 47

Table 9 Fuses and Connectors

Component Type Park Air Part Number

Fuse:

AC input fuse T4AH 250V IEC 29E01120108S

Connectors:

AC supply connector IEC 20-02030102

Antenna connector N-type plug (straight)

or,

N-type plug (right-angle)

19-01030301

19-01030401

Ethernet connector RJ45 plug 20K01080100

Facilities connector 25-way D-type plug Plug: 20-01250100

Cover: 20-09250101

Auxiliary connector 9-way D-type plug Plug: 20-01090100

Cover: 20-09090101

Reference connector BNC to SMB 2 metre long lead 17K11000004

Diagnostics connector 7-pin DIN plug to 9-way D-type, radio

to PC interconnection lead

17E12600001

31-3MDR00HB Page 40 Installation

Draft

Fitting an MDR into an Equipment Cabinet

During installation an MDR may have to be lifted, possibly to head height, to fit onto

telescopic slides. At least two people should be used to lift the equipment. Failure to use

sufficient people when lifting equipment can result in personal injury.

It is essential that the chosen mechanical installation provides adequate support along the

depth (front to rear) of the unit. The MDR must not be supported by the front panel; doing so

can cause damage.

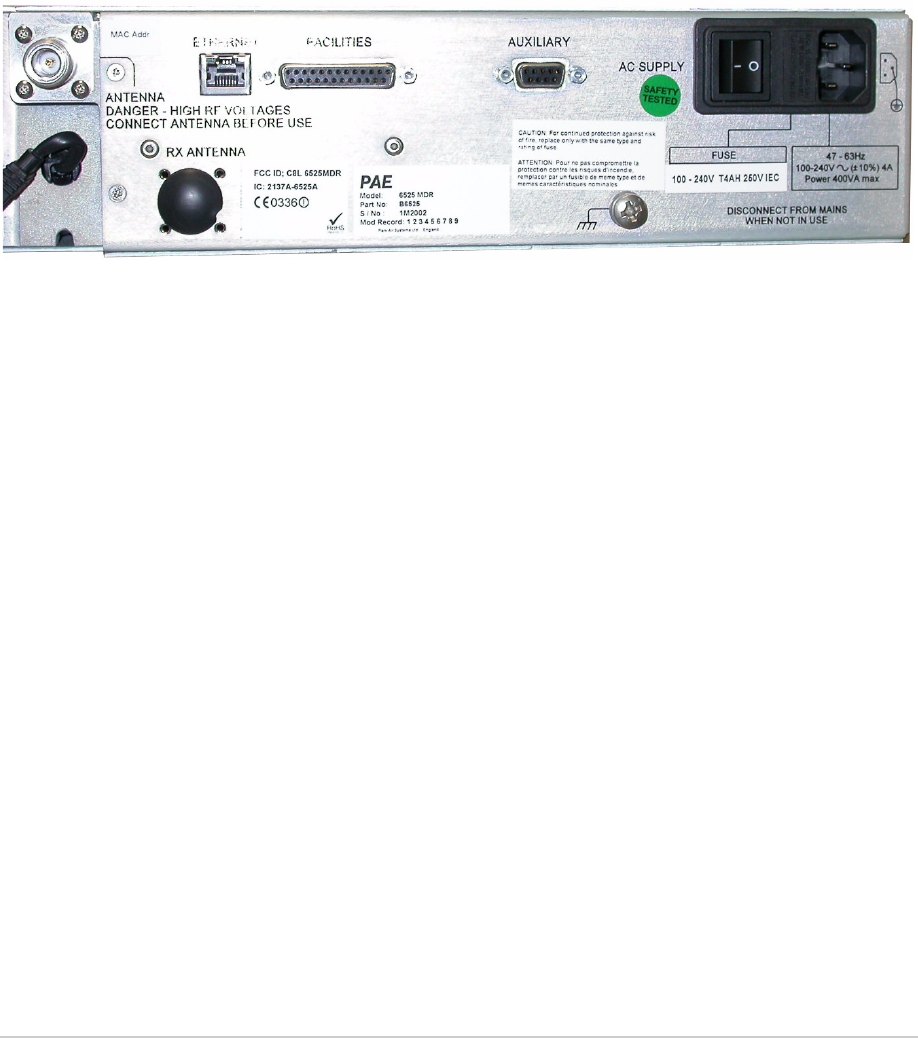

The MDR can be installed on telescopic slides, or on fixed runners, within a standard 483 mm (19 inch)

equipment rack. M4 tapped holes, each 10 mm deep (see Fig 7) are provided on each side of the

equipment to accept the slides. Details of suitable telescopic slides are available from Park Air.

When fitted in the rack, the MDR's front panel must be secured to the cabinet’s chassis using four

M6 x 16 mm screws and plastic washers.

Fig 1 Slide Fittings

Fig 7 Slide Fittings

WARNING Heavy Item

Caution Mechanical Support

Front

Panel

399

390.9

378.2

232.2

207.5

152.8

47.0

29.0

41.7

430

88.9

450

All measurements in mm

31-3MDR00HB Page 41 Installation

Draft

Rear Panel Interfaces

The rear panel Ethernet, Facilities and Auxiliary interfaces (Fig 8) are used to connect remote signals as

follows:

For AM-Voice The line, PTT and squelch inputs and outputs connect via the Facilities

interface.

For AM Analogue ACARS The analogue ACARS waveform connects between an external

modem and the line inputs and outputs via the Facilities interface.

For AM Digital ACARS The digital ACARS data connects via the Ethernet interface.

For VDL Mode 2 All control information and data to be transmitted and received is

transferred via the Facilities (HDLC connections) and Ethernet

interfaces.

Fig 8 Rear Panel Connectors

31-3MDR00HB Page 42 Installation

Draft

Ethernet Connector

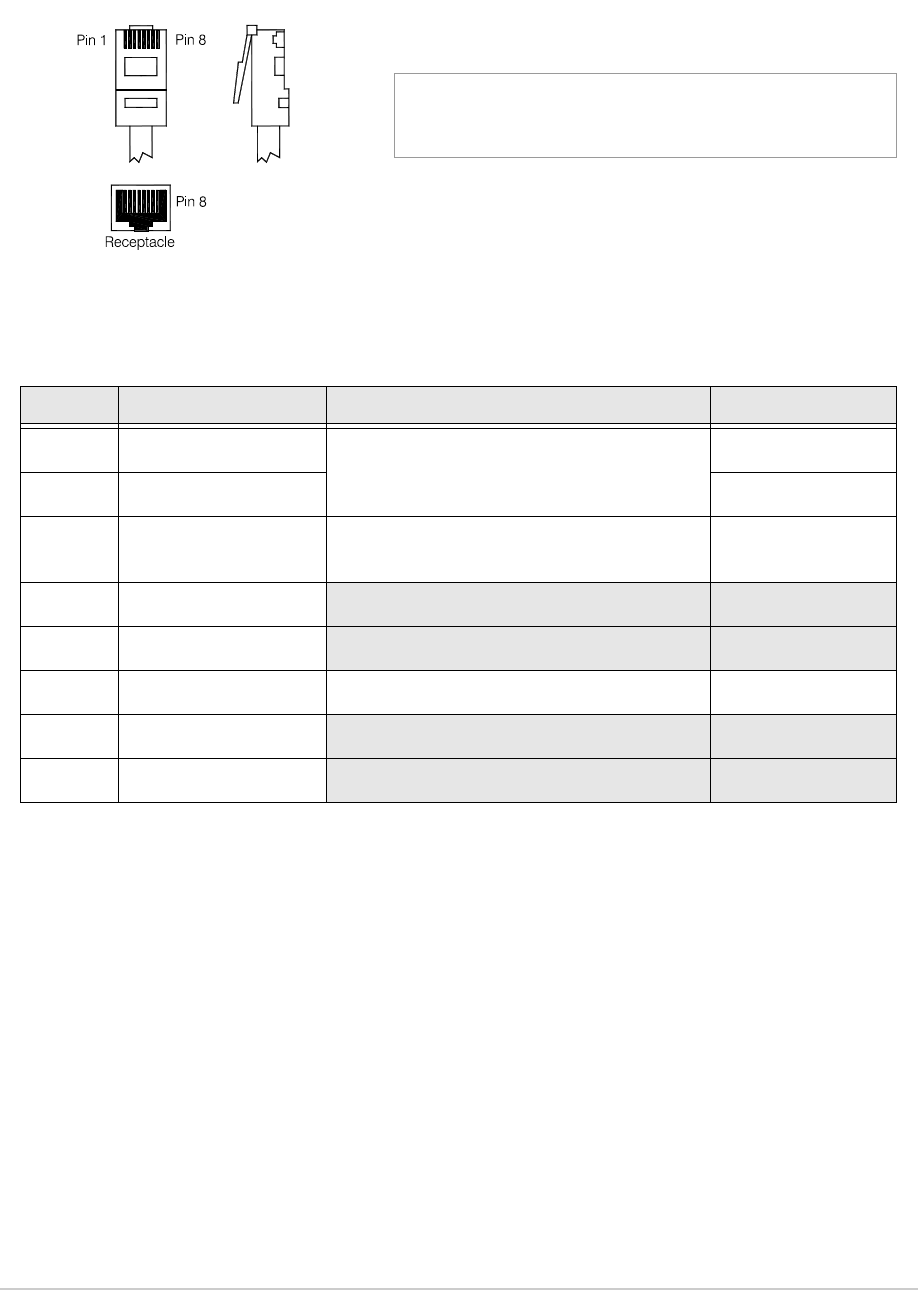

The Ethernet RJ socket connects to a 10/100Base-T Ethernet network. The connector is shown in Fig 9

and the pin-out listed in Table 10.

Fig 9 Ethernet Connector Pin-out

Table 10 Ethernet Connector Pin-out

Pin Signal Name Characteristic Input or Output

1TD +

Balanced 100 ohm ±10%, 10/100 Mbps

Output

2 TD – Output

3RD +Balanced 100 ohm differs from the reference

by more than 10%, 10/100 Mbps Input

4 Not connected

5 Not connected

6 RD – Pair with pin 3 Input

7 Not connected

8 Not connected

Pin 1

Numbering is shown looking from the top of the connector.

The top is being viewed with the lever at the bottom.

RJ45 Plug

31-3MDR00HB Page 43 Installation

Draft

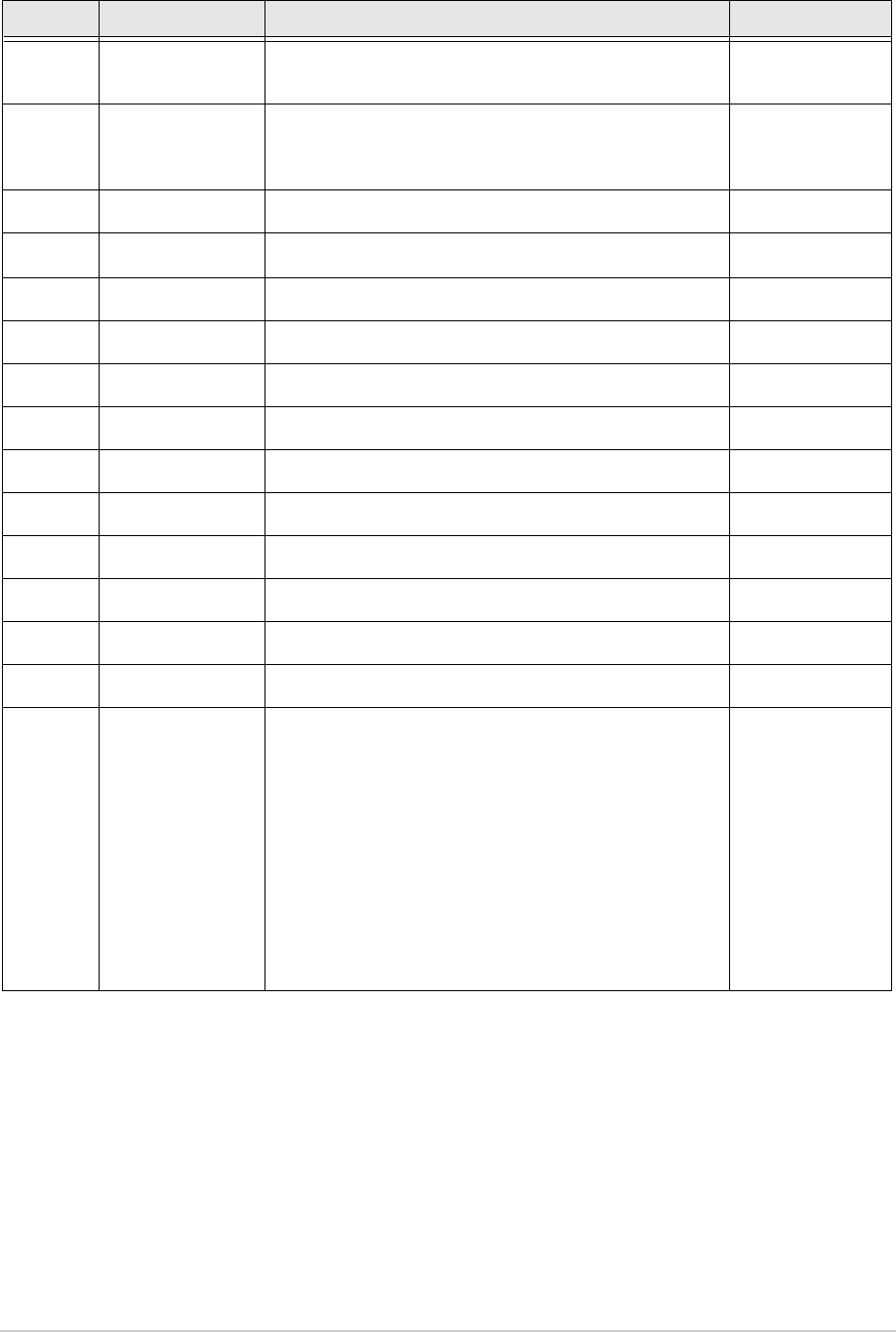

Facilities Connector

A 25-way D-type filtered socket providing analogue and HDLC interfaces. The connector is shown in

Fig 10 and the pin-out listed in Table 11. A suitable 25-way D-type plug to connect to this interface is

listed in Table 9 on page 39.

Fig 10 Facilities Connector Pin-out

Table 11 Facilities Connector

Pin Signal Name Characteristic Input or Output

1Ground 0 V.

2 Line in – Balanced 600 ohm, -20 to +10 dBm.

Phantom Keying:

Phantom PTT active when the input differs from the

reference by more than 10 V. Reference voltage

(common to PTT input on pin 25) is programmable to

+14, 0 or -14 V (all ±1 V).

Phantom PTT inactive when the input differs from the

reference by less than 1 V

Maximum input level ±60 V with respect to reference.

Input requires at least 1 mA to operate and draws no

more that 6 mA.

Configurable active high or low.

Input

3 Signal strength Between 0 and 5 V. Output

4Line out +Balanced 600 ohm, -20 to +10 dBm. Output

5Ground 0V.

6 HDLC 0 TX B RS422 differential synchronous data at 128 kbits per

second.

Output

7 HDLC 0 RX B RS422 differential synchronous data at 128 kbits per

second.

Input

8 HDLC 0 CL B RS422 differential synchronous data at 128 kbits per

second.

Output

9 HDLC 1 TX B RS422 differential synchronous data at 128 kbits per

second.

Output

10 HDLC 1 RX B RS422 differential synchronous data at 128 kbits per

second.

Input

continued ...

13 1

25 14

31-3MDR00HB Page 44 Installation

Draft

Note:

HDLC 0 is used for VDL Mode 2 operation.

HDLC 1 is reserved.

11 HDLC 1 CL B RS422 differential synchronous data at 128 kbits per

second.

Output

12 Squelch Solid state relay configurable to be normally open or

normally closed. Between +60 and -60 V ac or dc may be

applied drawing 100 mA maximum.

Output

13 Ground 0 V.

14 Line in +Pair to pin 2. Input

15 Ground 0 V.

16 Ground 0 V. –

17 Line out – Pair to pin 4. Output

18 HDLC 0 TX A Pair to pin 6. Output

19 HDLC 0 RX A Pair to pin 7. Input

20 HDLC 0 CL A Pair to pin 8. Output

21 HDLC 1 TX A Pair to pin 9. Output

22 HDLC 1 RX A Pair to pin 10. Input

23 HDLC 1 CL A Pair to pin 11. Output

24 Time 0 5 V CMOS Input

25 PTT Active when the input differs from the reference by more

than 10 V. Reference voltage (common to phantom PTT

input on pin 2) is programmable to be +14, 0 or -14 V (all

±1 V).

Inactive when the input differs from the reference by less

than 1 V

Maximum input level ±60 V with respect to reference.

Input requires at least 1 mA to operate and draws no

more that 6 mA.

Configurable active high or low.

Input

Table 11 Facilities Connector (Continued)

Pin Signal Name Characteristic Input or Output

31-3MDR00HB Page 45 Installation

Draft

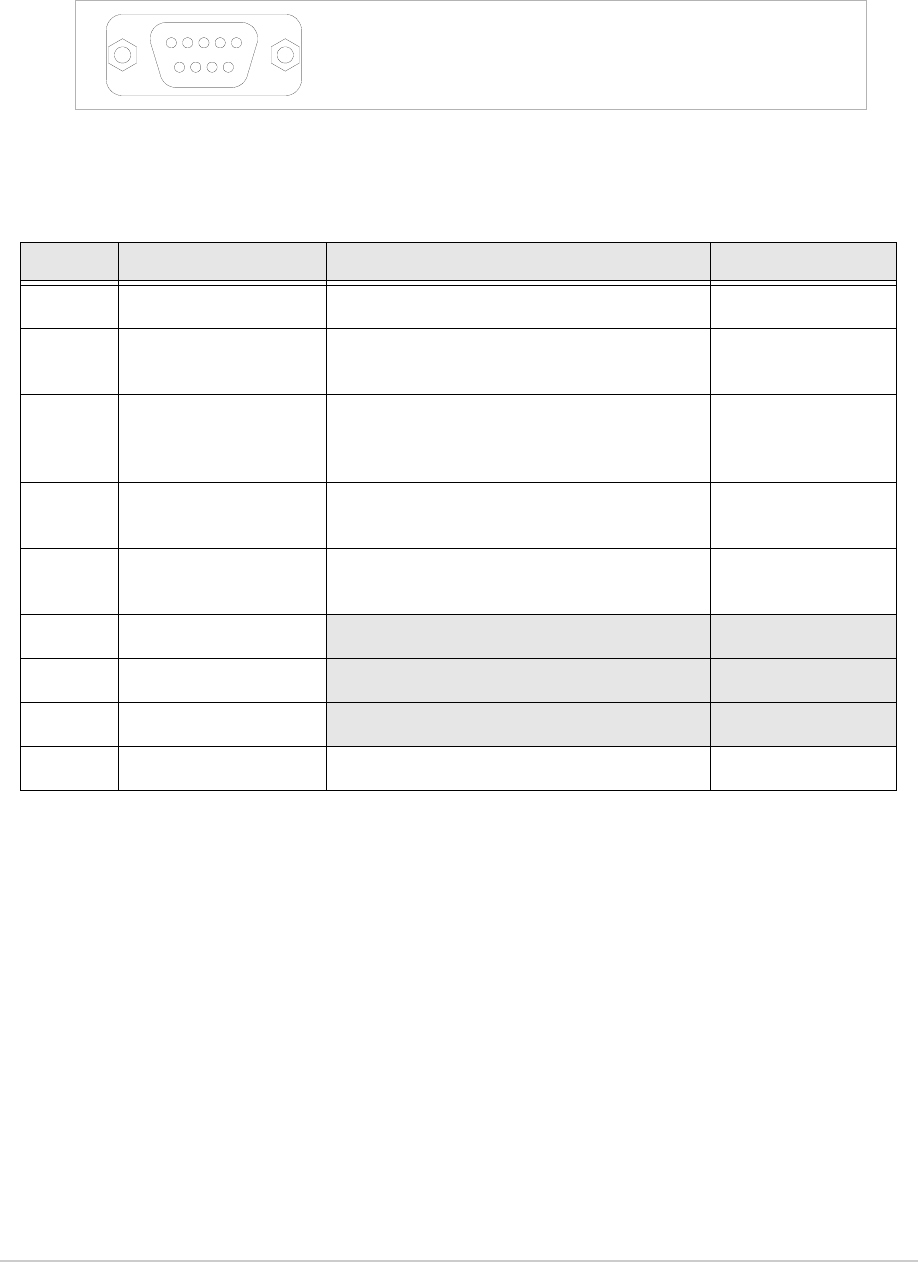

Auxiliary Connector

A 9-way D-type filtered socket for future interface expansion. The connector is shown in Fig 11 and the

pin-out listed in Table 12. A suitable 25-way D-type plug to connect to this interface is listed in Table 9

on page 39.

Fig 11 Auxiliary Connector Pin-out

Table 12 Auxiliary Connector Pin-out

Pin Signal Name Characteristic Input or Output

1Ground 0 V –

2 Antenna change-over Open collector NPN transistor grounding

output, normally open, 200 mA maximum. Output

3Reserved

Open collector NPN transistor grounding

output, configurable to be normally open or

normally closed, 200 mA maximum.

Output

4Reserved TTL with 4.7 kohm pull-up to 5 V.

Configurable to be active high or low. Input

5Reserved TTL with 4.7 kohm pull-up to 5 V.

Configurable to be active high or low. Input

6 Not connected

7 Not connected

8 Not connected

9 dc supply Between 21.6 and 32 Vdc. Fused at 500 mA. Output

Pin-out of Auxiliary connector looking into the mating face of

the chassis mounted socket.

A suitable free socket is detailed in Table 9 on page 39.

54321

9876

31-3MDR00HB Page 46 Installation

Draft

Connecting the Chassis Stud

A chassis stud is fitted to the MDR's rear panel. This stud is used to connect the equipment

to the equipment rack, or to the user's system earth point. The stud must not be used as the

safety earth.

In order not to compromise the MDR’s Electromagnetic Compatibility (EMC) the chassis stud, marked

and fitted to the rear panel must be connected to the equipment cabinet (if a cabinet is being used)

or to the user's system earth point. The connection should be made using a single tri-rated, green-and-

yellow cable having a cross-sectional area of 2.5 mm2. The cable should have CSA and UL1015

approval, and be connected to the chassis stud through an M6 eyelet (for example, Park Air part number

20-08010103).

Failure to comply with this instruction could result in non-compliance with the European

Commission EMC Directive 89/336/EEC.

Connecting an Antenna

The antenna used with the MDR must be installed such that the resultant radiated field

strength is below 10 W/m² in areas normally accessible to personnel.

The RF field strength from the antenna can be predicted from the equation S=1.4PG/4πR2

[Where S = power density; P = power input to antenna; G = antenna gain; R = distance

to centre of radiation and 1.4 = multiplication factor for average power based on a

modulation index of 90%.]

Based on this formula a 2 dBi antenna, the predicted safe distance from the centre of radiation would

be approximately 0.75 m for a field strength of 10 W/m2 (1 mW/cm2).

This meets the requirements of Health Canada Safety Code 6 for RF and microwave exposed

workers. For persons not classed as RF and microwave workers and including the general public

the limit is 2 W/m2 (0.2 mW/cm2) which increases the minimum safe distance to 1.7 m.

Further information on calculating the field strengths and power levels can be found in Health

Canada Safety Code 6 'Limits of Human Exposure to Radiofrequency Electromagnetic Fields in the

Frequency Range 3 kHz to 300 GHz', and also in FCC document OET Bulletin 65.

Ensure an antenna, or dummy load, is connected before switching on the MDR. There is high

RF voltage present at the antenna connector when the radio is keyed.

The MDR uses a common antenna for transmission and reception. The rear panel N-type (female)

antenna connector accepts a straight or right-angle N-type plug as listed in Table 9 on page 39. Park Air

recommends that RG214 1/2” flexible feeder cable, part number 10-05120610, be used for that part of

the feeder circuit that is within a building.

WARNING Chassis Earth

WARNING Antenna Radiation

WARNING Antenna Radiation

31-3MDR00HB Page 47 Installation

Draft

Checking the ac Input Fuse

For continued protection against risk of fire, replace only with the same type and rating of

fuse.

The ac input fuse is located in a pull-out holder that is an integral part of the ac connector. Check that the

fuse type is of the correct rating:

100 - 240V T4AH 250V IEC (Park Air part number, 29E01120108S)

AC Supply Connection

The equipment is permanently connected to the mains supply when the mains connector is

attached. Switching the rear panel Power switch to Off does not isolate all internal circuits

from the mains supply. For this reason, a mains isolating switch should be fitted close to,

and easily accessible from, the MDR's position. The isolation switch should isolate both live

and neutral supplies, be clearly labelled, and adequately rated to protect the equipment.

This equipment must be earthed. The earth terminal of the ac connector should be used as

the safety earth.

An ac input connector (see Fig 8 and Fig 12) is fitted to the equipment’s rear panel. The cable used to

connect between the equipment and the user’s ac power source should be 3-core (to IEC 227) rated

250 Vac at 8 amps, and have a minimum cross-sectional area of 1.0 mm2 per core. Park Air recommends

the use of polyvinyl chloride (PVC) insulated cable. The cable must be fitted with the IEC approved

equipment connector (Park Air part number 20-02030102) and conform to the following specification:

If PVC insulated, be not lighter than ordinary polyvinyl chloride sheathed flexible cord according

to IEC publication 227 (designation H05 VV-F, or H05 VVH2-F).

If rubber insulated, be of synthetic rubber and not lighter than ordinary tough rubber-sheathed

flexible cord according to IEC publication 245 titled ‘Rubber Insulated Cables of Rated Voltage up

to and Including 450/750 V (designation H05 RR-F)’.

Caution Fuse Rating

WARNING Dangerous Voltage

WARNING Earth Connection

31-3MDR00HB Page 48 Installation

Draft

The MDR is a Class 1 equipment. The ac supply cable should have a green-and-yellow protective

earthing conductor electrically connected to the protective earthing terminal of the equipment connector

and the mains plug. Park Air recommends the ac supply cable is colour coded in accordance with the

electrical appliance (colour code) regulations for the UK. That is:

The core coloured green-and-yellow must be connected to the terminal in the plug that is marked

with the letter E or by the earth symbol or coloured green-and-yellow.

The core coloured blue must be connected to the terminal that is marked with the letter N or

coloured black.

The core coloured brown must be connected to the terminal that is marked with the letter L or

coloured red.

Fig 12 ac Connector Pin-out

E

N

L

Draft

Maintenance

31-3MDR00HB Page 50 Maintenance

Draft

Maintenance Policy

Apart from the scheduled maintenance detailed in this topic, and replacing a faulty cooling fan, the

maintenance policy for the MDR is to return faulty units to Park Air.

Unscheduled Maintenance

Unscheduled maintenance is limited to replacing a faulty cooling fan (see page 54).

Scheduled Maintenance

Park Air recommends that scheduled maintenance be carried out at twelve-monthly intervals. Schedule

maintenance comprises:

(1) Ensuring the equipment is clean.

(2) Ensuring that the external connectors are securely fitted to the MDR.

(3) Checking and resetting (if required) the MDR's frequency standard (see page 51).

(4) Performing an interruptive BIT test (see page 52).

Cleaning the Equipment

Remove all dust and dirt from the equipment's exterior using cleaning cloths and a camel hair brush.

Clean the front panel indicators and LCD face.

Security of External Connections

Check all external connections are secure and free from damage.

There are no user serviceable parts within the MDR. Breaking the seals on the

top and bottom covers voids the MDR’s warranty.

31-3MDR00HB Page 51 Maintenance

Draft

Checking the MDR’s Internal Reference Frequency

To set the MDR’s internal reference frequency, use the following procedure. Note that references to the

switch in the procedure mean the Scroll/Select switch.

F r e q u e n c y

C h a n n e l

S e t t i n g s

E x i t > >

Control Screen

M o d e V D L M O D E 2

M o d e S e t t i n g s

P o l a r i t i e s

E X I T > >

Settings Screen (First Page)

B a n d E d g e s

I P S e t t i n g s

R e f F r e q 6 7 . 0 %

E x i t < < > >

Settings Screen (Second Page)

(1) If the MDR is used in AM-Voice mode

with a frequency offset, reset the offset

to 0 kHz.

(2) Connect a high impedance frequency

counter to the front panel Reference

connector.

(3) From the Main screen, press the switch

to display the Control screen. Turn the

switch until Settings is highlighted.

Press the switch.

(4) Ensure the Settings screen is displayed.

Turn the switch until Ref Freq is

highlighted, then press the switch.

(5) With Ref Freq selected turn the switch

clockwise or anti-clockwise until the

frequency counter reads 20.950000 MHz

±10 Hz, then press the switch.

(6) Turn the switch clockwise until Exit is

highlighted, then press the switch. You

are returned to the Main screen.

(7) Disconnect the frequency counter.

31-3MDR00HB Page 52 Maintenance

Draft

Initiating an Interruptive BIT Test

An interruptive BIT test is available only in AM-Voice and AM analogue ACARS modes.

Use the following procedure to initiate an interruptive BIT test from the MDR's front panel. A BIT test

cannot be initiated while the MDR is keyed.

During an interruptive BIT test, the MDR radiates modulated carrier waves at the set power.

Users should therefore obtain the necessary authority before initiating a test.

If the test is to be carried out with the antenna disconnected, ensure a load is fitted to the

MDR's Antenna connector.

In order to test the line input stages, an internally generated 1 kHz tone is injected into the

line input circuit. Any other audio present on the line input will cause the test to be

inaccurate. Therefore the MDR must not be keyed during the test.

F r e q u e n c y

C h a n n e l

S e t t i n g s

E x i t > >

Control Screen (Page 1)

B I T

S / W C o n f i g

E x i t < <

Control Screen (Page 2)

B I T I n i t i a t e

E T I 0 0 0 1 0 1 : 3 6 h r s

S u p p l y 2 5 v

E x i t > >

BIT Screen

(1) From the Main screen, press the switch

to display the Control screen. Turn the

switch until BIT is highlighted. Press the

switch.

(2) Ensure the BIT screen is displayed.

Turn the switch until BIT Initiate is

highlighted. Press the switch.

(continued)

31-3MDR00HB Page 53 Maintenance

Draft

T e s t i n g

P l e a s e W a i t

T e s t S t a t u s

P A S S

O K

T e s t S t a t u s

F A I L

O K

(3) During the test, which takes

approximately two seconds, the

Testing screen is displayed.

(4) When the test is complete, either Pass

or Fail is displayed.

31-3MDR00HB Page 54 Maintenance

Draft

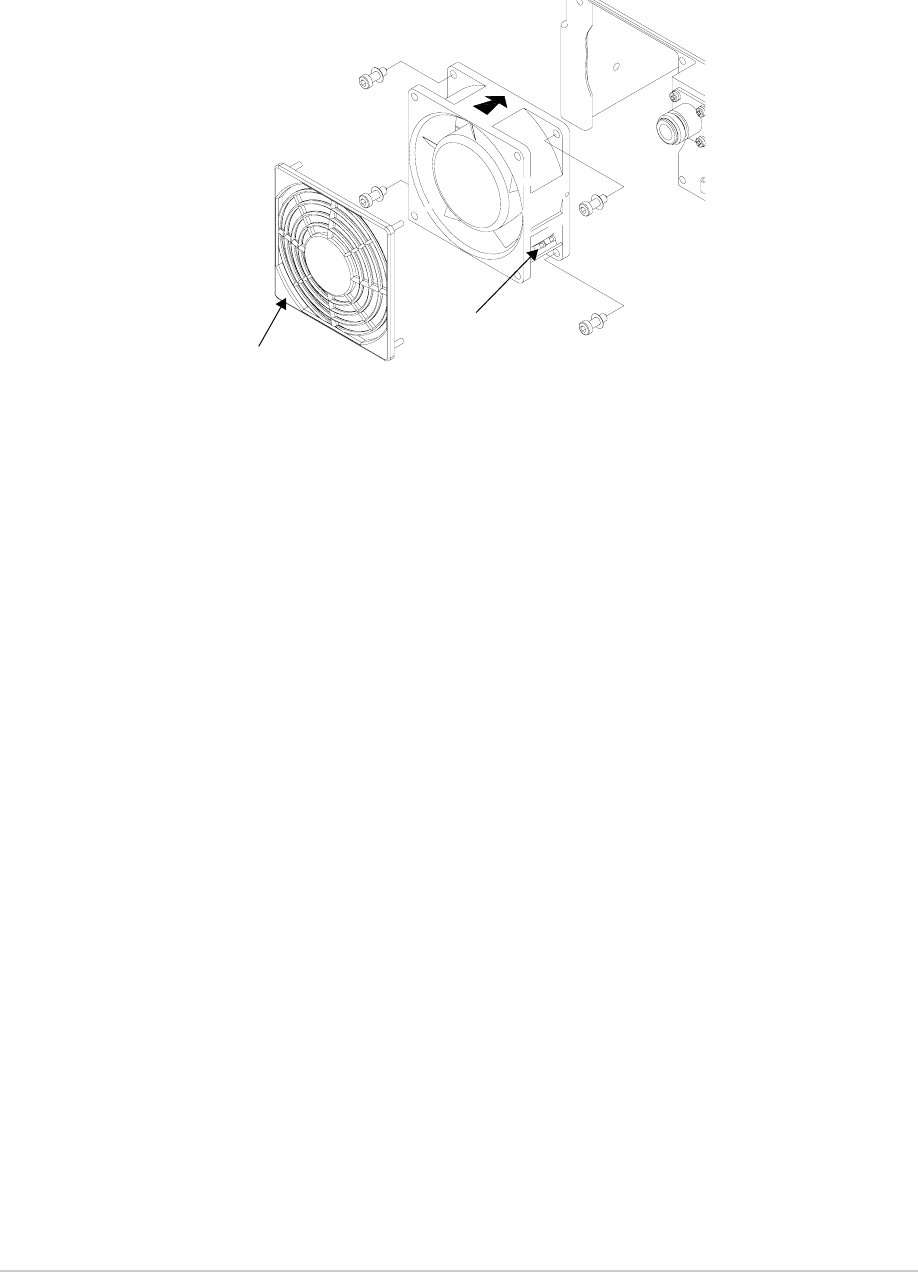

Removing and Refitting the Cooling Fan

The cooling fan is at the rear of the MDR as shown in Fig 13.

The part number of the fan is: 69J1208314H

Fig 13 Cooling Fan Removal

Removal

Before attempting to remove the fan, ensure that the MDR is isolated from the ac input supply. Then

proceed as follows:

(1) Disconnect the two-pin power connector.

(2) Remove the fan's finger guard.

(3) Using an Allen key, inserted through the holes in the fan exposed with the finger guard removed,

remove the four M4 x 12 mm caphead Allen screws that secure the fan to the PA module

heatsink.

(4) Remove the fan from the PA module.

Refitting

To refit the cooling fan, proceed as follows:

(1) Locate the fan in position and using a suitable Allen key inserted through the holes for the fan's

finger guard, secure using the four M4 x 12 mm caphead Allen screws.

(2) Secure the finger guard to the fan.

(3) Connect the 2-pin fan connector to the fan. Ensure the + marked socket mates with the + marked

plug on the fan.

(4) Re-establish the ac supply.

(5) Switch power on at the MDR using the rear mounted Power switch.

(6) Ensure the front panel Ready indicator is lit and the Alarm indicator is unlit.

Power

Connector

Finger

Guard