Park Air Systems B63100HS VHF Ground to air transmitter User Manual

Park Air Systems Limited VHF Ground to air transmitter Users Manual

User manual

T6T VHF 100 W Transmitter

User Documentation

Page ii T6T VHF 100 W Transmitter

Handbook Title: T6T VHF 100 W Transmitter User Documentation

Handbook Part Number: 31-3T6T100V

Handbook Version: 2.0

Date of Issue: February 2005

Equipment Modification Level 7

Published By: Park Air Systems

Northfields

Market Deeping

Peterborough PE6 8UE

England

Telephone: From UK, 01778 345434

From outside UK, 44 1778 345434

Fax: From UK, 01778 342877

From outside UK, 44 1778 342877

www.parkairsystems.com

Errata

Any errors found in this handbook are promulgated through the Park Air FTP network. Any

user can access this information by logging on to:

ftp.parkairsystems.com

When logged on, select the public (Pub) folder, then the Handbook Errata Sheets folder,

and then select the required equipment model.

[Adobe Acrobat™ must be loaded on your PC to use this facility]

T6T VHF 100 W Transmitter Page iii

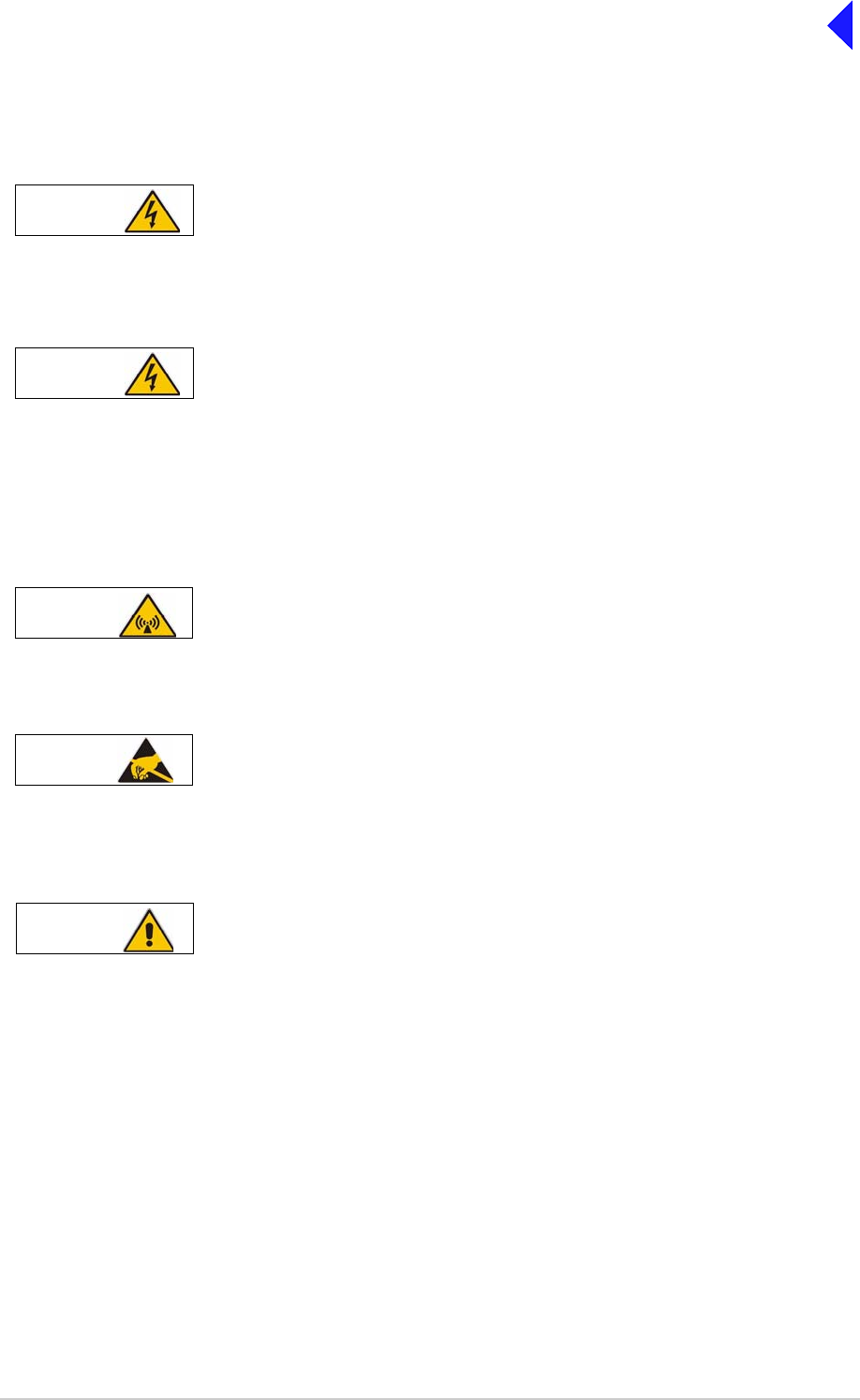

Health and Safety

Warnings

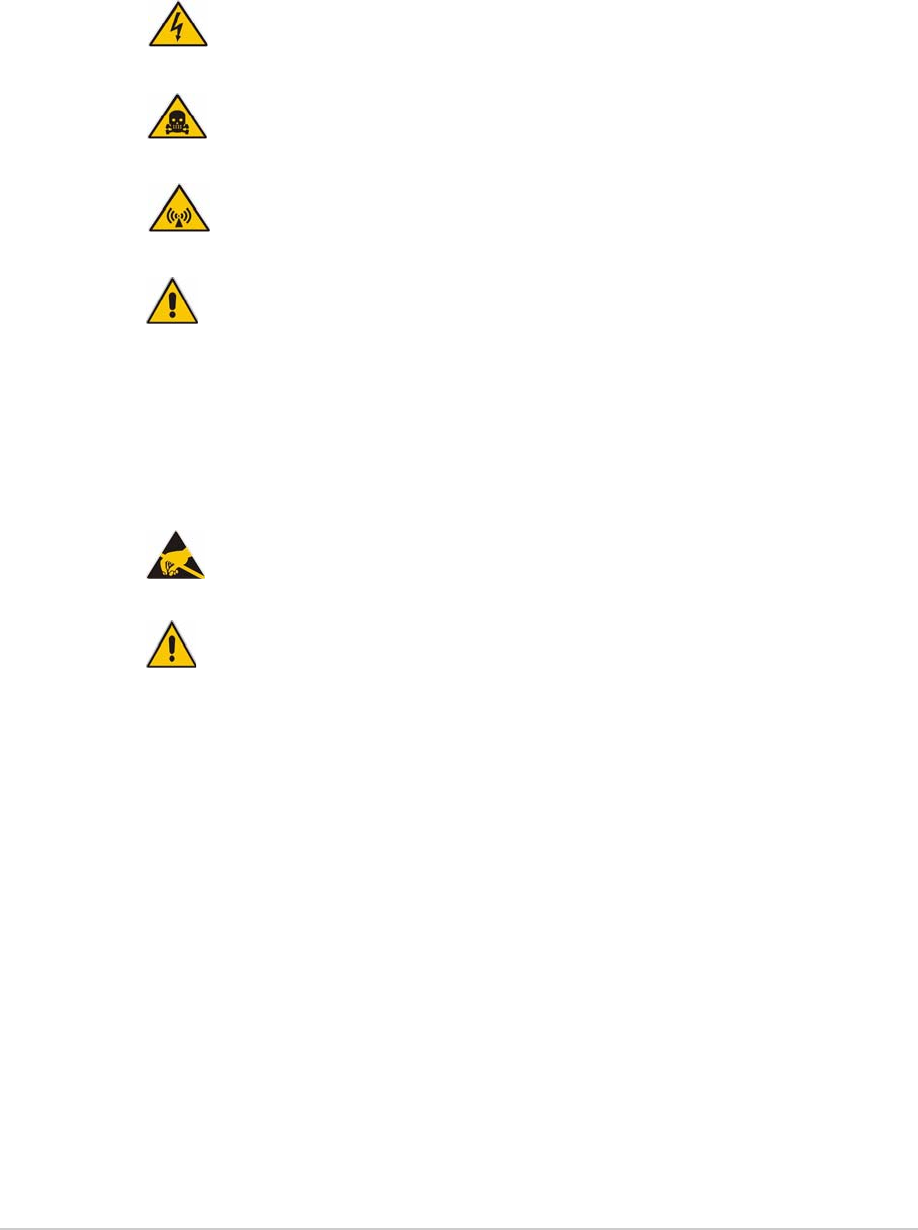

A warning is used to indicate possible danger to personnel. Throughout Park Air handbooks, warnings

are indicated by the following symbols:

Cautions

A caution is used to indicate possible danger to the equipment.

Trademarks

The following tradenames are used in this handbook.

IBM This is a registered trademark of International Business Machines.

Microsoft This is a registered trademark of Microsoft Corporation in the USA and other

countries.

Windows This is a registered trademark of Microsoft Corporation in the USA and other

countries.

Indicates electrical danger to personnel.WARNING

Indicates a hazardous material.

WARNING

Indicates a non-ionizing radiation hazard.

WARNING

Indicates a specified danger to personnel.

WARNING

Indicates the presence of electrostatic sensitive devices (ESSD). Caution

Indicates a specified danger to the equipment. Caution

Page iv T6T VHF 100 W Transmitter

List of Abbreviations

ac alternating current

AGC automatic gain control

AM amplitude modulation

ATC air traffic control

BER bit error rate

BIT built-in test

C celsius

CD compact disk

dB decibel

dc direct current

DSB double sideband

E-BIT external bit signal

ESSD electrostatic sensitive devices

Fig figure

FM frequency modulation

Hz hertz

IF intermediate frequency

kg kilogramme

kHz kilohertz

LCD liquid crystal display

mmetre

mA milliamp

MARC multi-access remote control

mm millimetre

mW milliwatt

MHz megahertz

MSK minimum shift keying

PA power amplifier

PC personal computer

PCB printed circuit board

pk-pk peak-to-peak

ppm parts per million

PSU power supply unit

PTT press to transmit

RF radio frequency

ROM read-only memory

RSE2 remote site equipment

RSSI receiver signal strength indication

Vvolt

VFP virtual front panel

VHF very high frequency

VOGAD voice-operated gain adjusting device

VSWR voltage standing wave ratio

Wwatt

Approvals and Standards T6T VHF 100 Watt Transmitters

Approvals:

The equipment is designed to meet the essential requirements of Directives

1999/5/EC, 89/336EEC as amended by Directive 93/68/EEC, and 72/23/EEC.

Standards:

The following standards are applied:

EMC EN 301 489-1; EN 301 489-22.

Health & Safety, EN 60950, CAN/CSA-C22.2 No. 60950, UL 60950.

Radio EN 300 676, IC RSS141, FCC part 15 and 87.

Telecom CS-03.

FCC Statement:

This device has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and the receiver.

-Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

-Consult the supplier or an experienced radio/TV technician for help.

Operation on 8.33 kHz channel spacing is restricted to European customers.

This Class B digital apparatus complies with Canadian ICES-003

Page vi T6T VHF 100 W Transmitter

About This Hard Copy

This document, apart from the preface, is a hard copy of the files contained on the CD and comprises

the following parts:

Preface (not on CD)

Introduction

Specification

Operation

Installation

Maintenance.

Back to Transmitter

Main Page

Introduction

This topic gives a brief introduction to the T6T VHF 100 W Multimode Transmitter.

T6T VHF 100 W Transmitter Page 2 Introduction

Back to Transmitter

Main Page

Purpose

The T6T VHF multimode 100 W transmitter is intended for use in fixed ground environments such as

airports and en-route centres. The transmitter operates in voice and ICAO defined data modes at

frequencies between 118 and 136.975 MHz.

Dependent on the software loaded into the radio, the following operating modes can be selected:

❑AM-Voice. All transmitters have this mode

❑AM-MSK (optional)

❑Mode 2 (optional)

❑Mode 3 (optional).

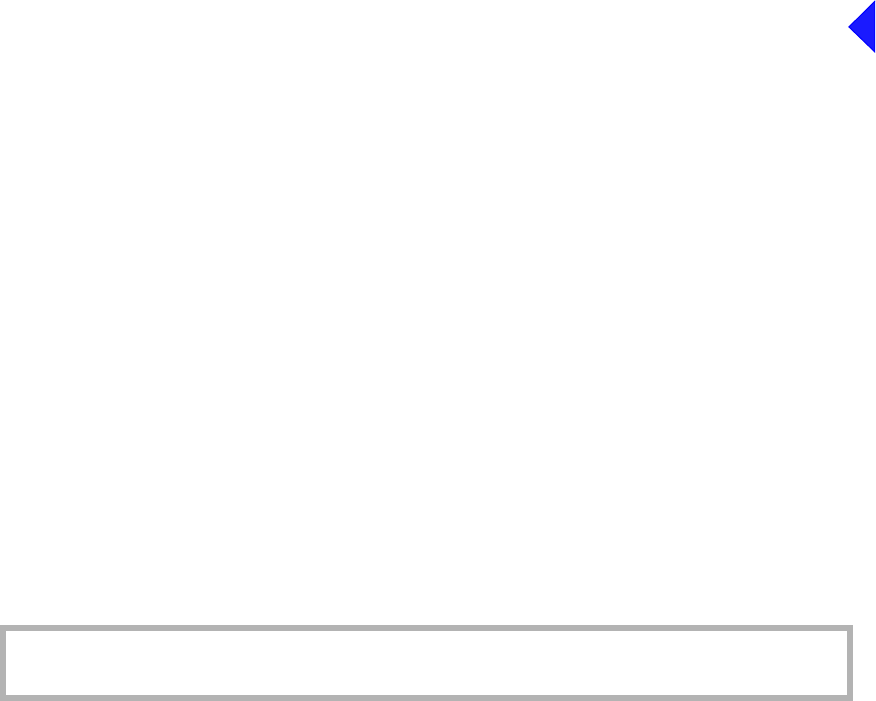

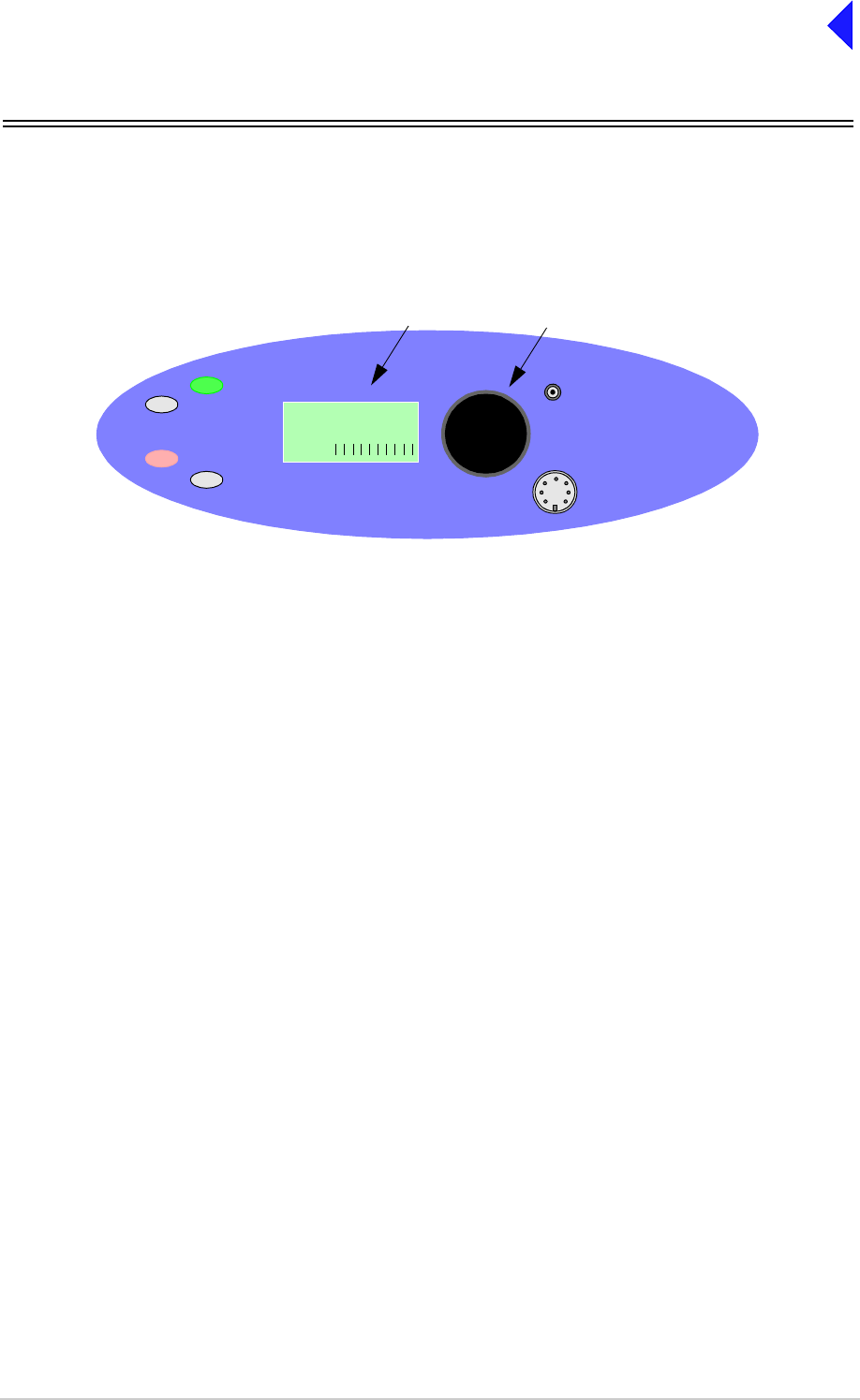

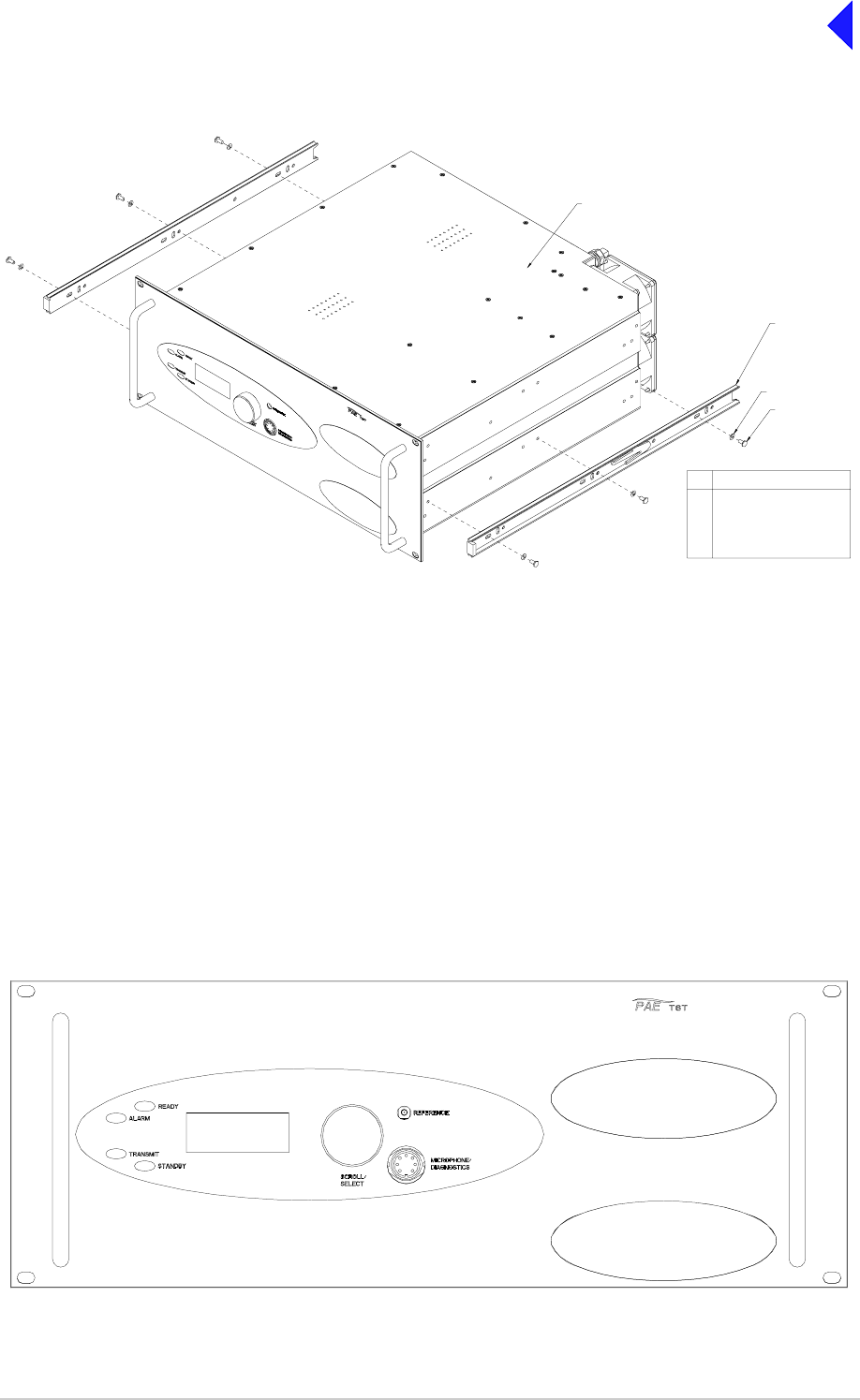

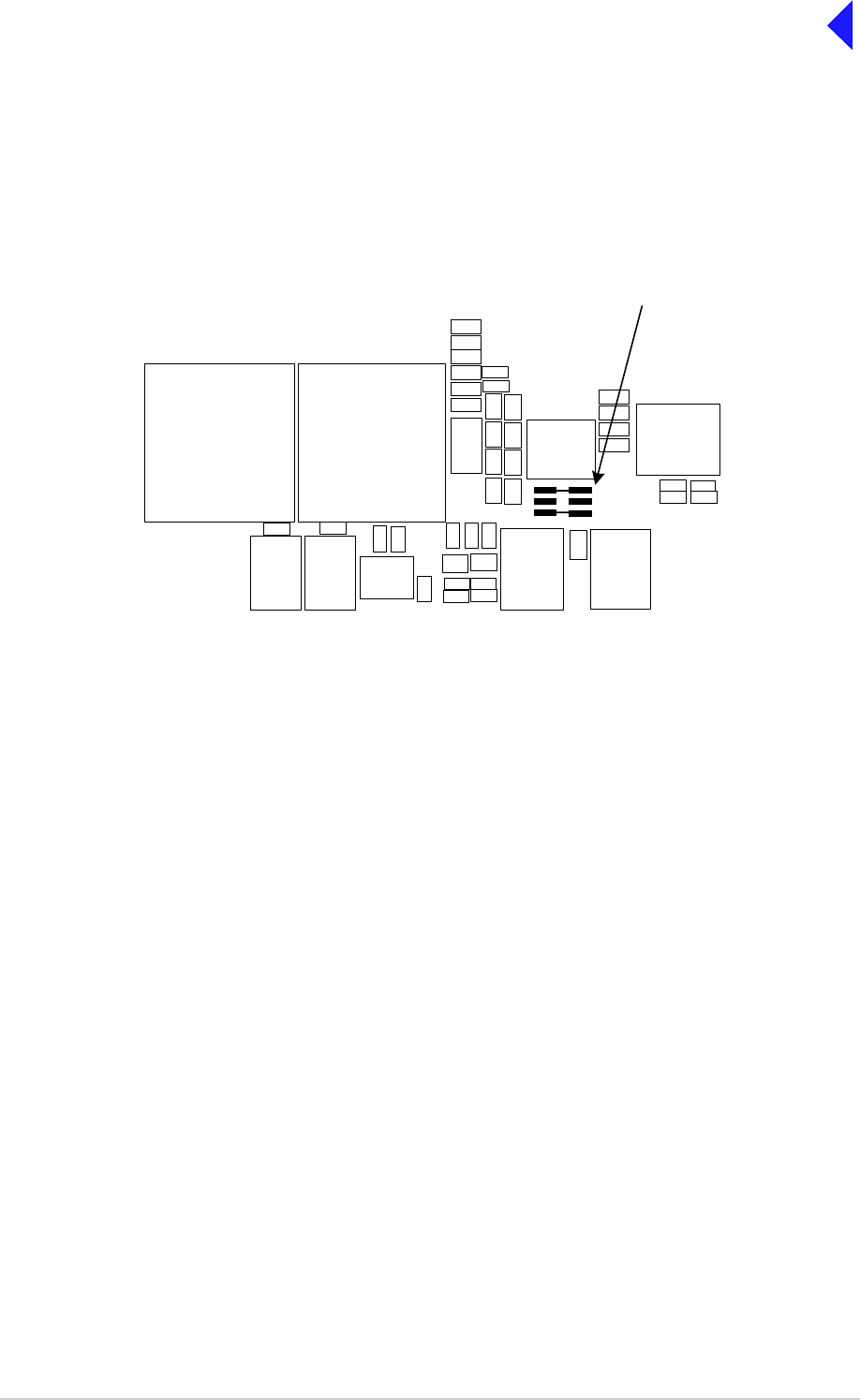

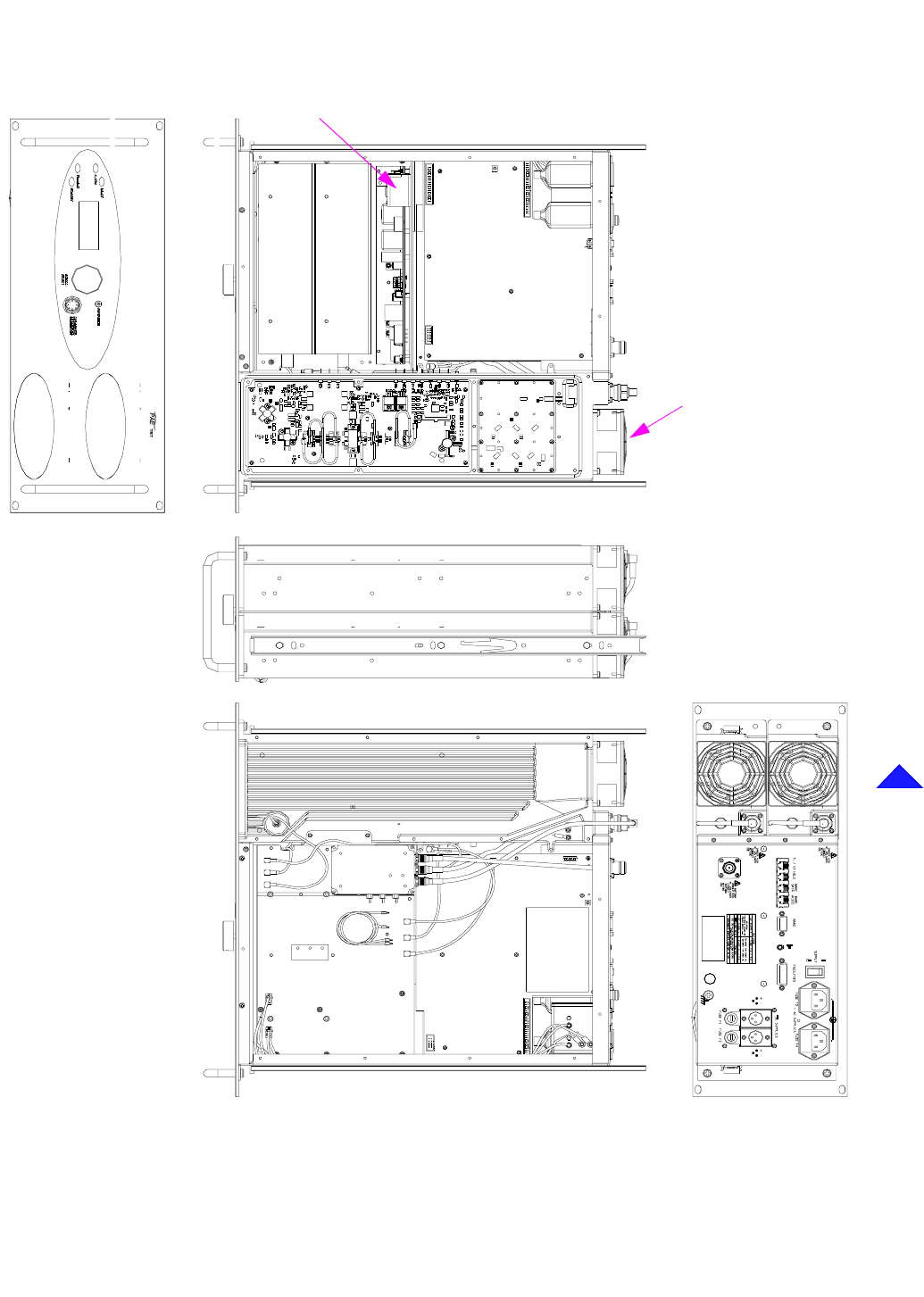

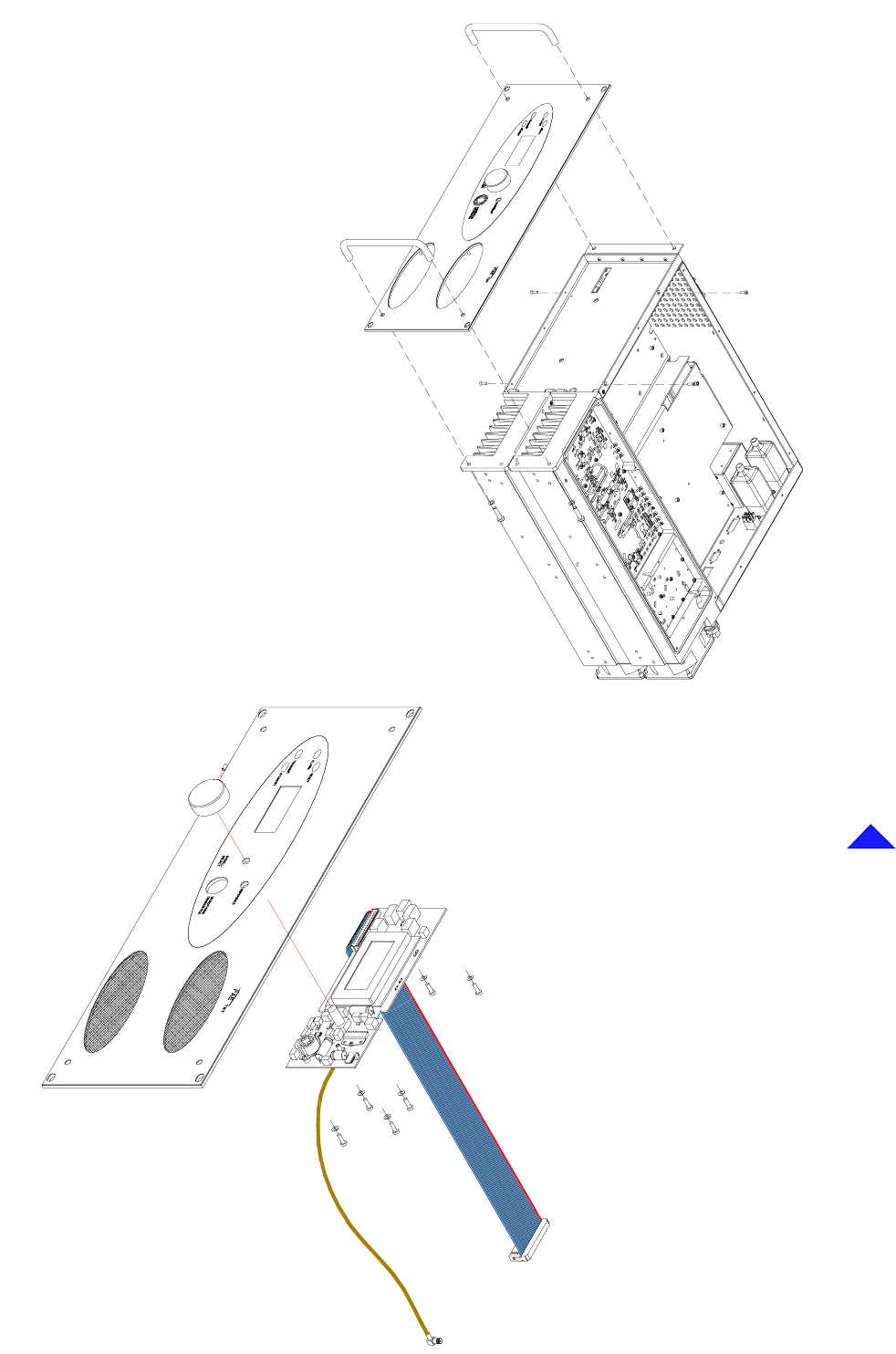

Fig 1 T6T VHF 100 W Transmitter

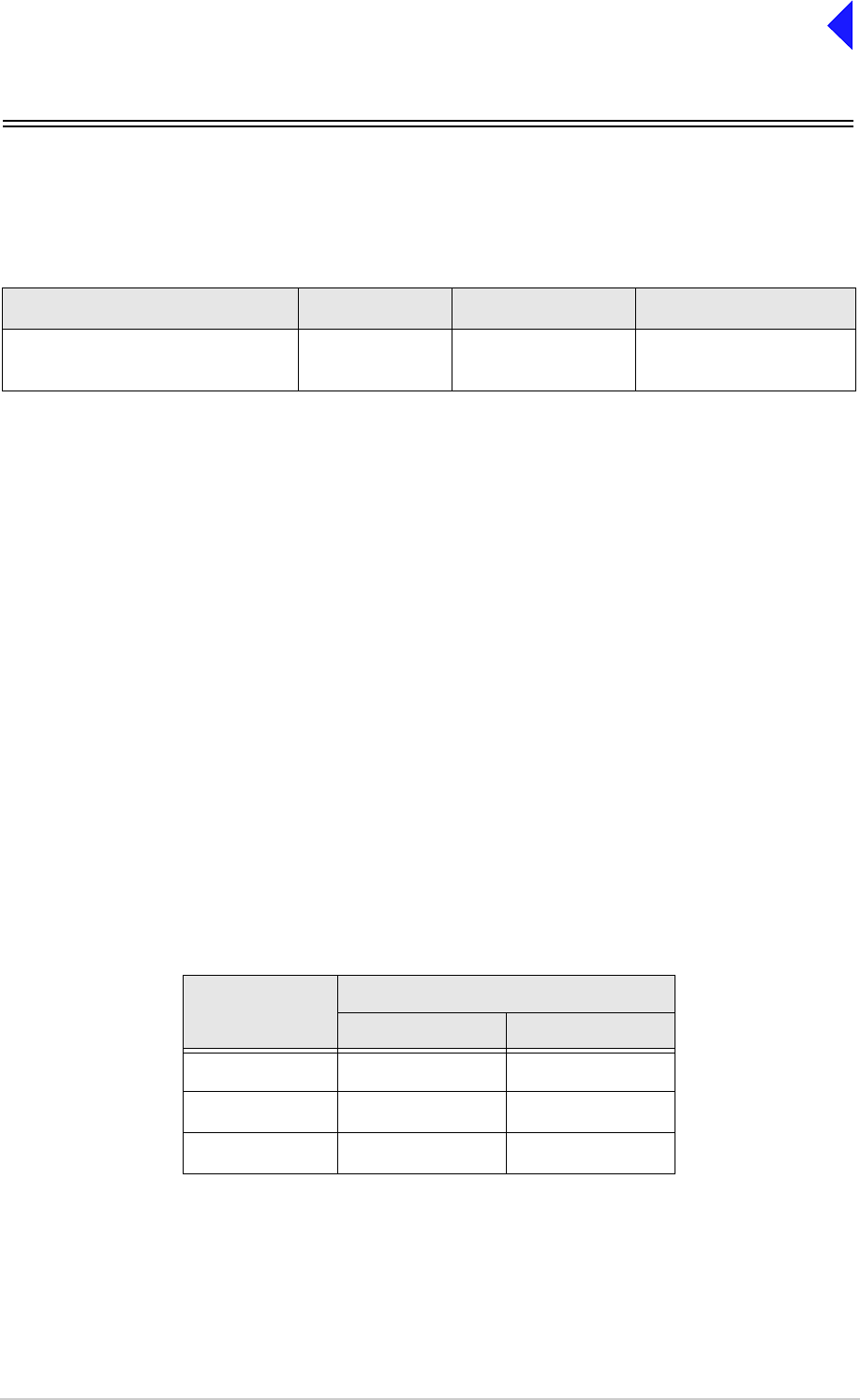

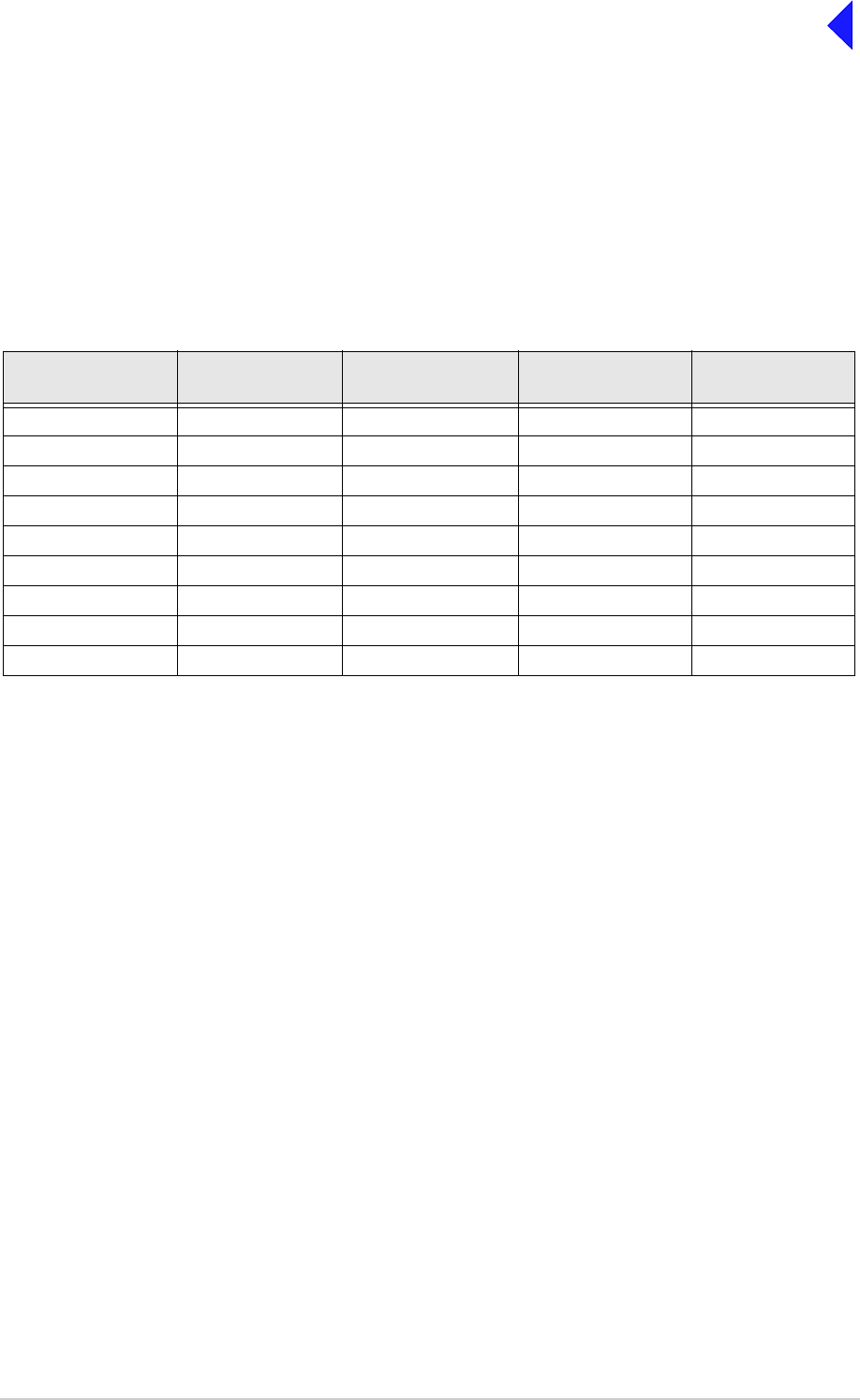

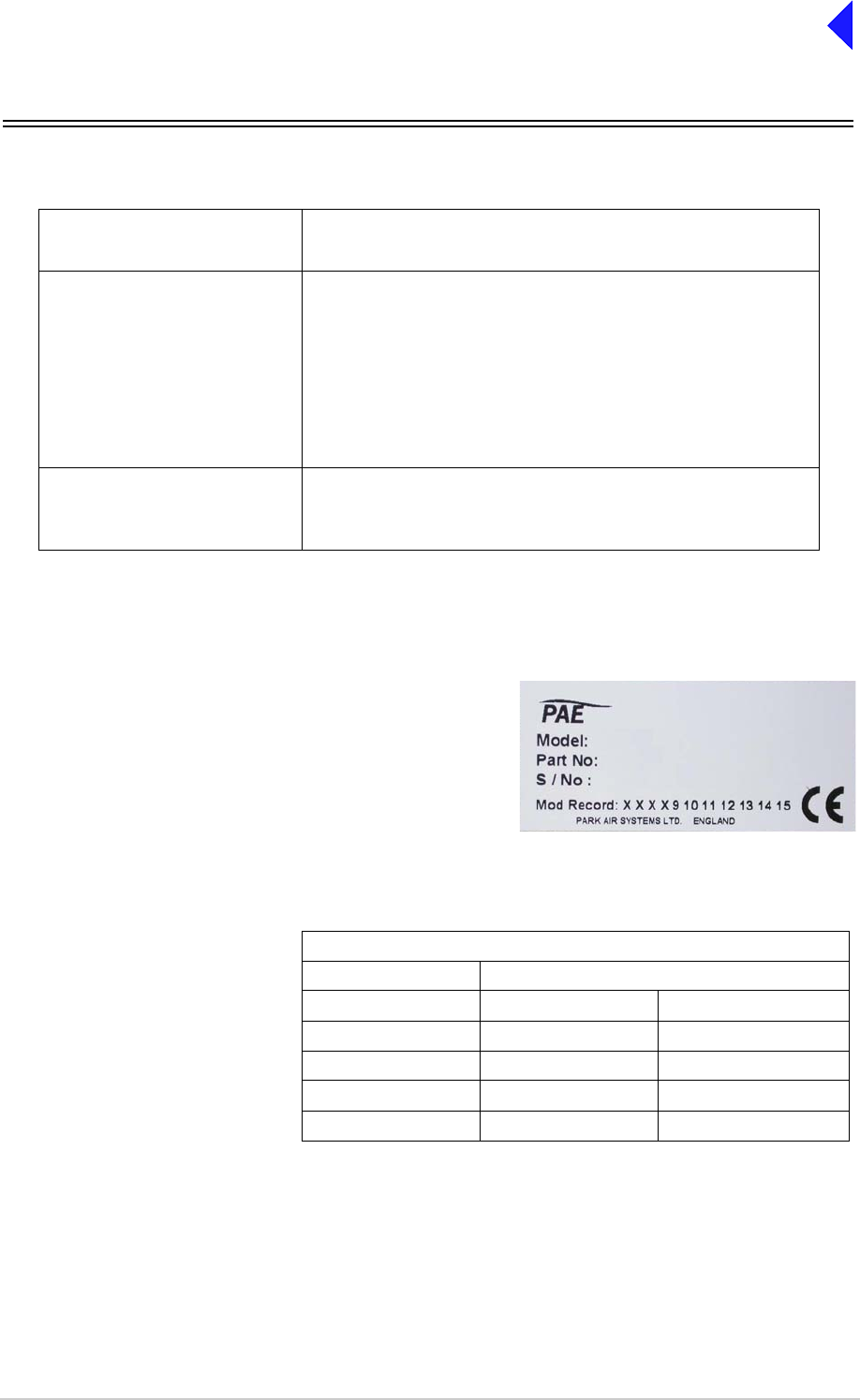

Models and Part Numbers

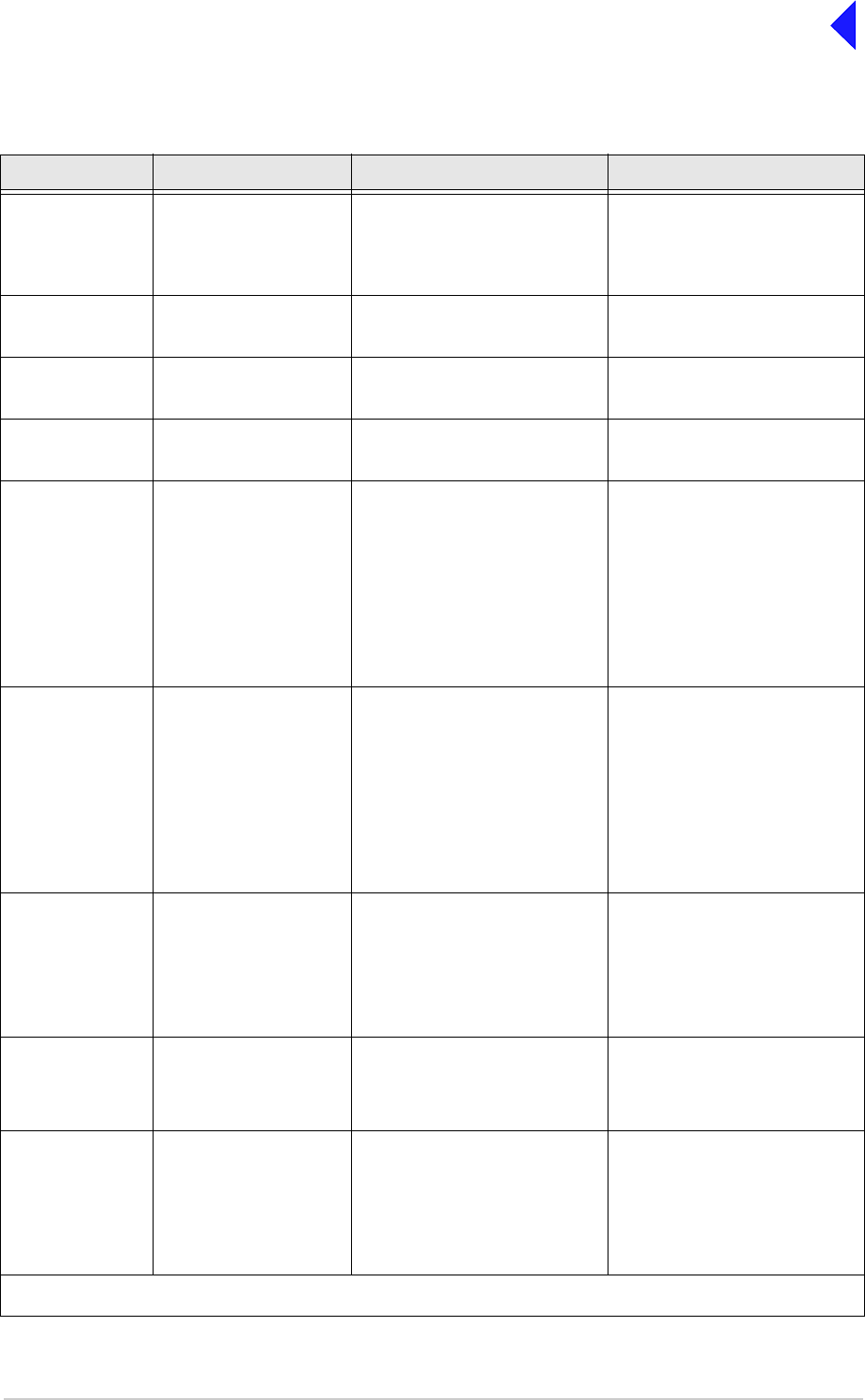

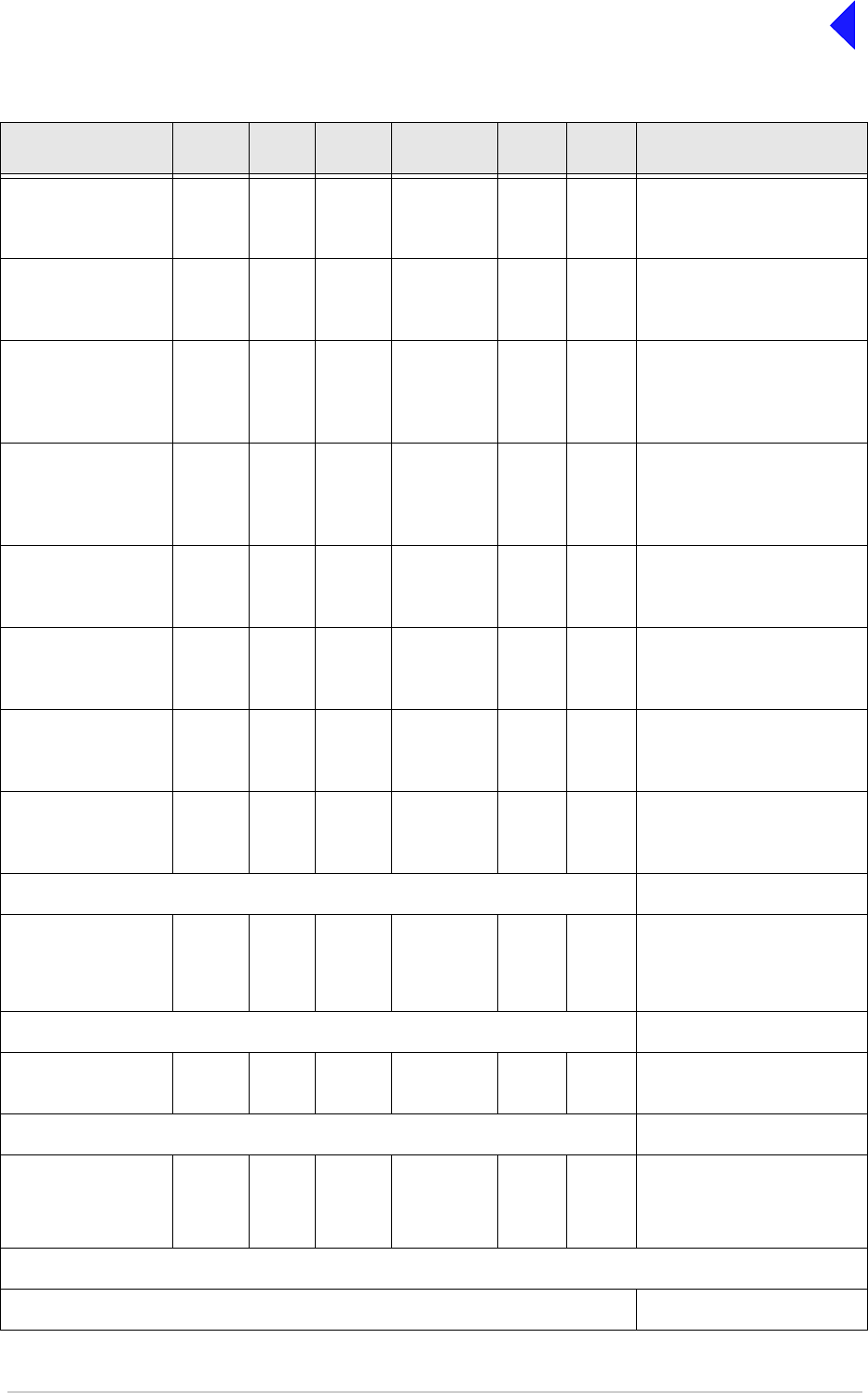

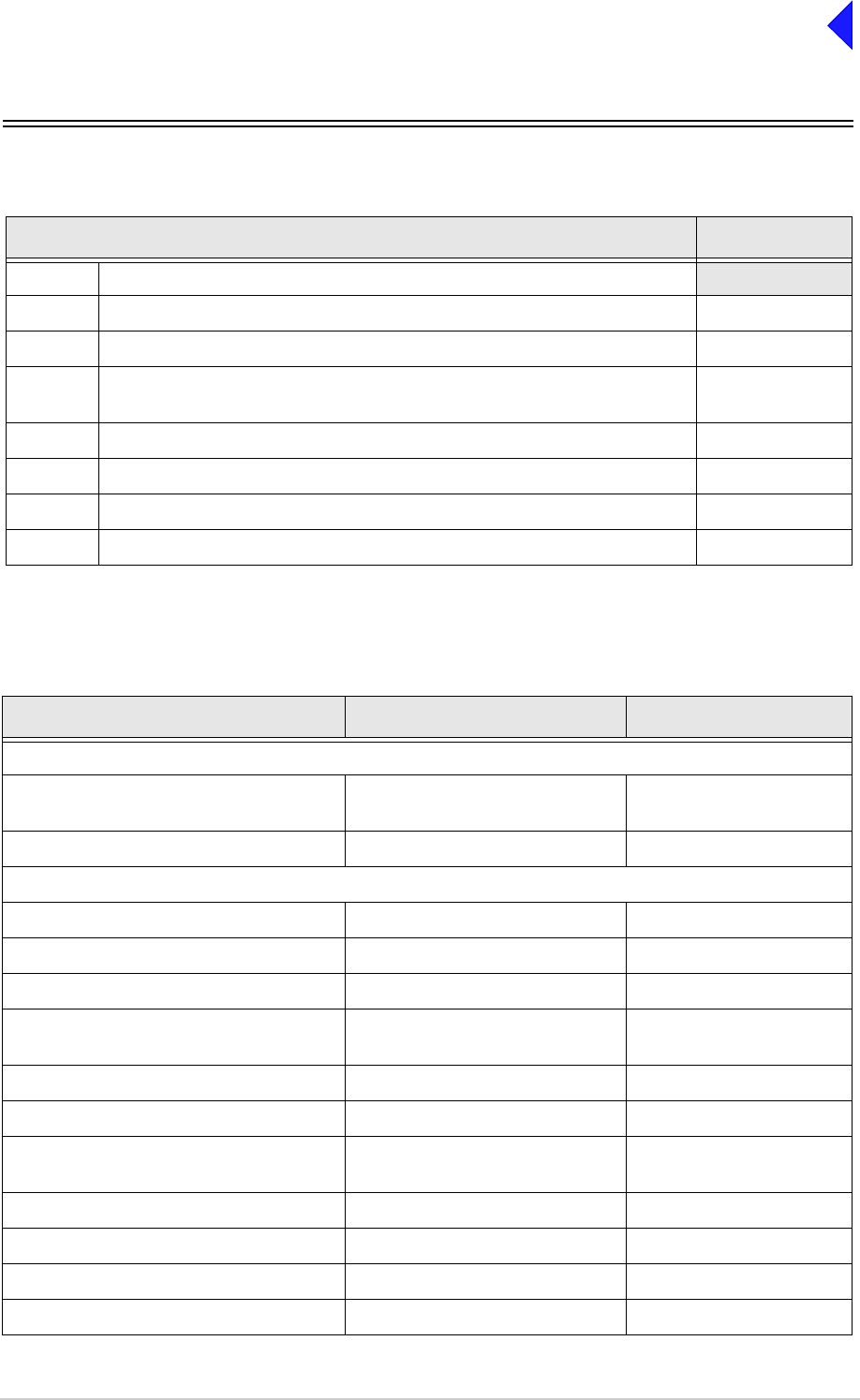

The following table identifies the T6T VHF 100 W transmitters:

Mechanical Installation

The transmitter fits into an industrial standard 19 inch (483 mm) equipment cabinet and occupies 4U of

space.

Description Part Number Frequency Range Channel

Spacing

(AM-Voice)

Special

Applications

T6T 100 W standard

frequency coverage high

stability transmitter

B63100HS/NB 118 to 136.975 MHz 25 kHz or

8.33 kHz Supports 5-offset

carrier operation

T6T VHF 100 W Transmitter Page 3 Introduction

Back to Transmitter

Main Page

Frequency Selection

T6 radios operate with 8.33 kHz and 25 kHz channel spacing. The radios recognize frequencies entered

in ICAO format and automatically adjust to the correct channel spacing. For multichannel operation up

to 100 preset frequency channels can be stored in the radio for immediate recall; any combination of

8.33 kHz and 25 kHz channel spacing can be stored. Any valid operating frequency can be selected from

the radio’s front panel or a compatible remote control equipment.

Operating Parameters

The transmitter’s operating parameters are set using the front panel multi-purpose Scroll/Select switch,

or by using the Park Air Virtual Front Panel (VFP) software in conjunction with a Personal Computer (PC).

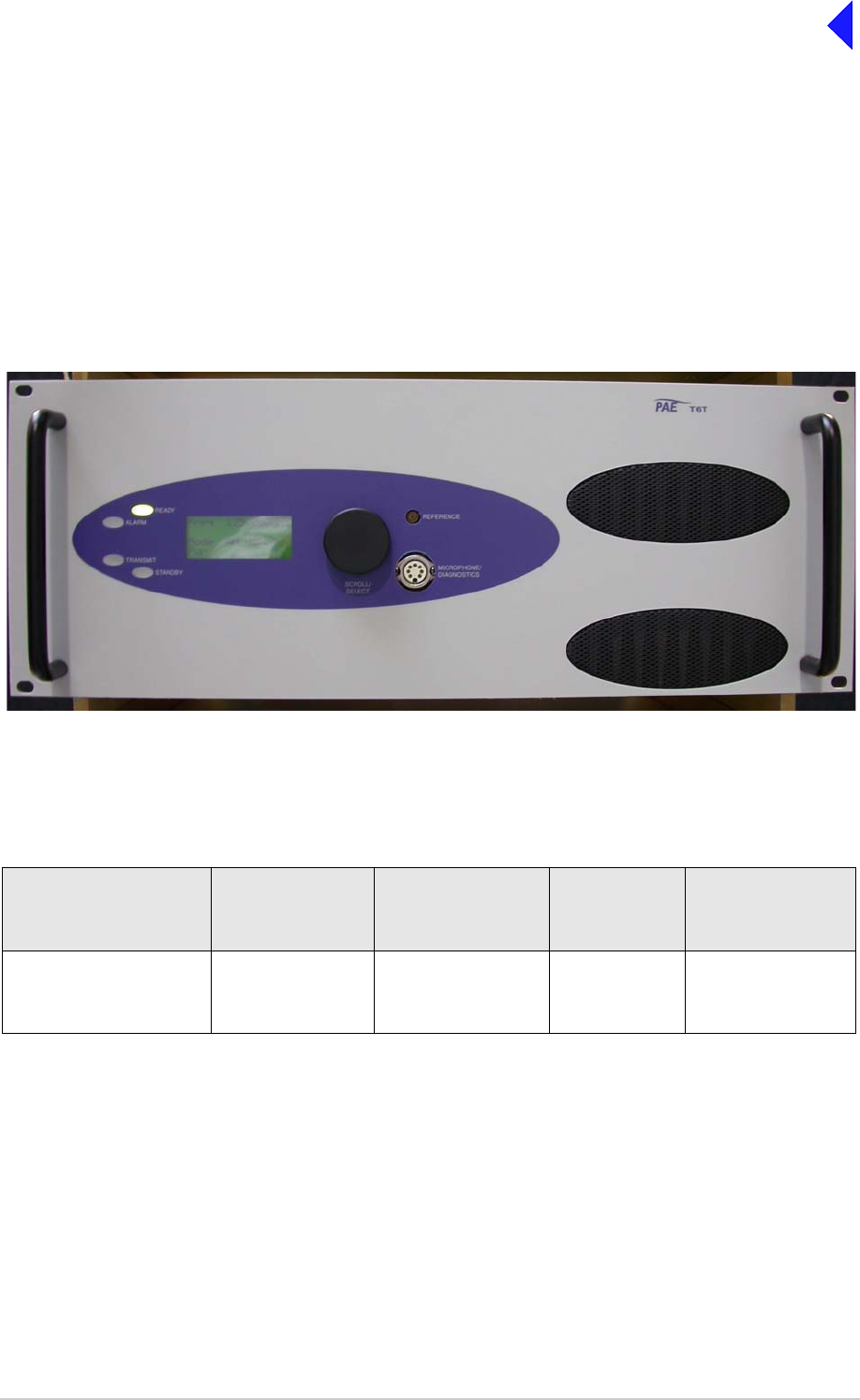

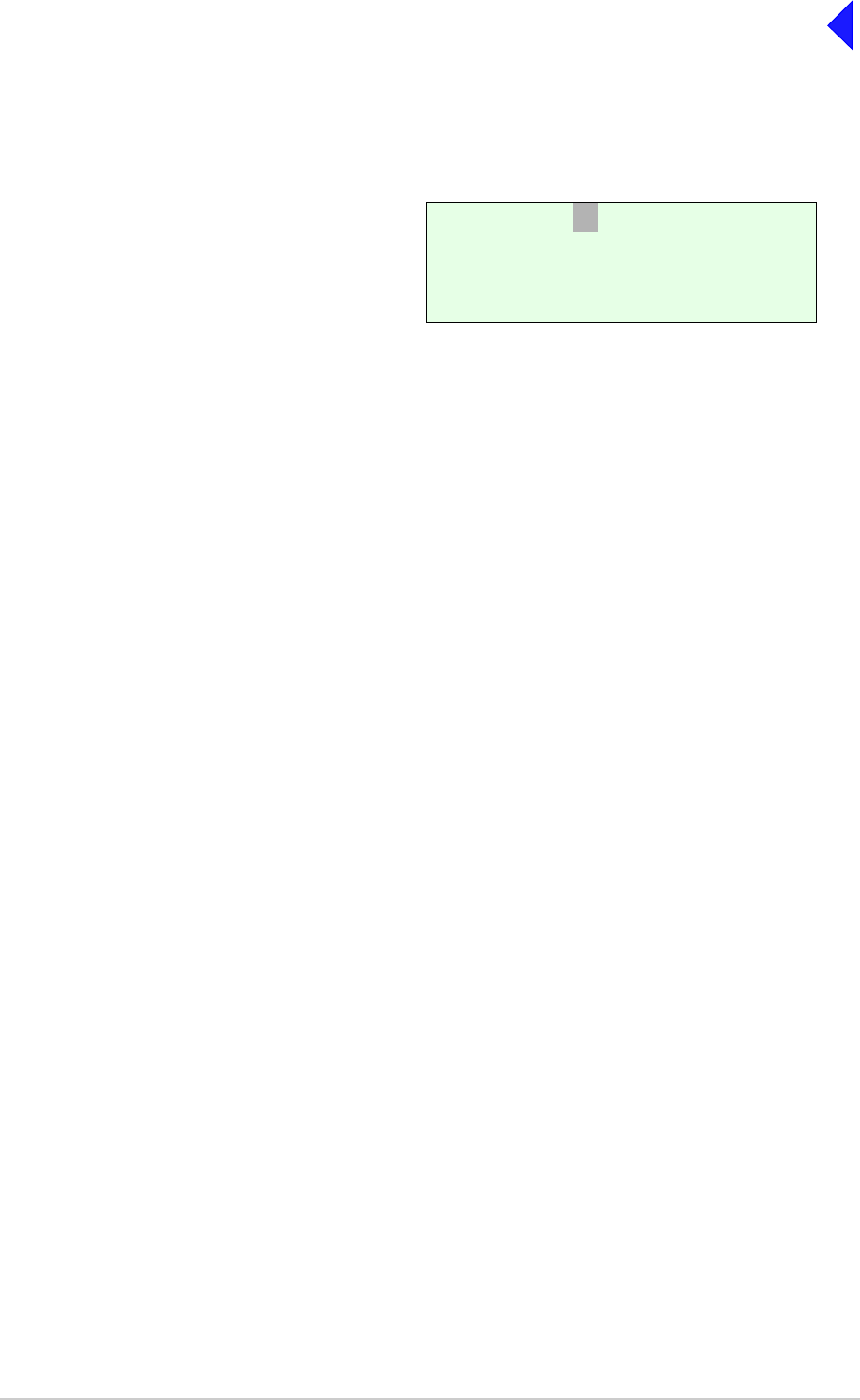

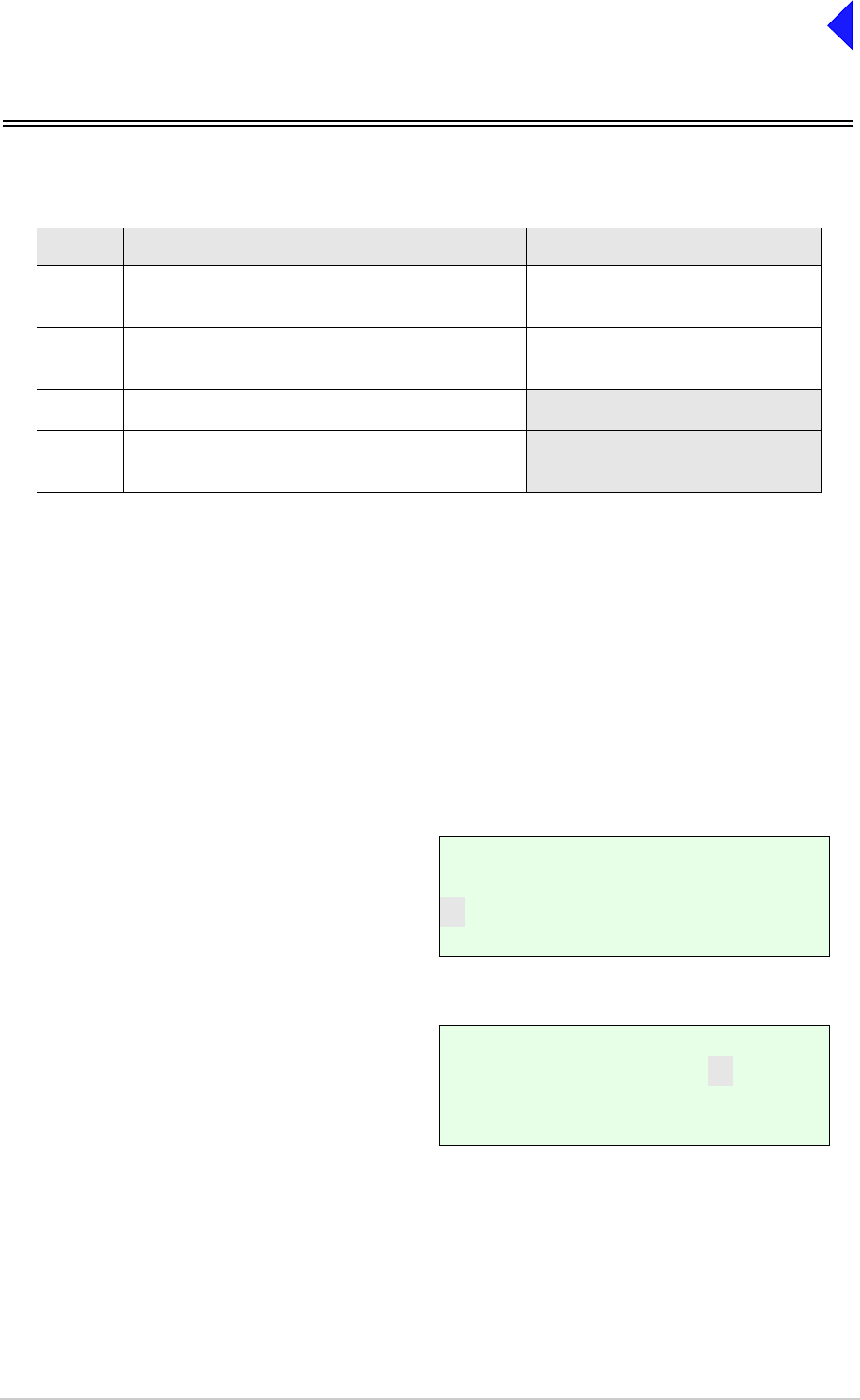

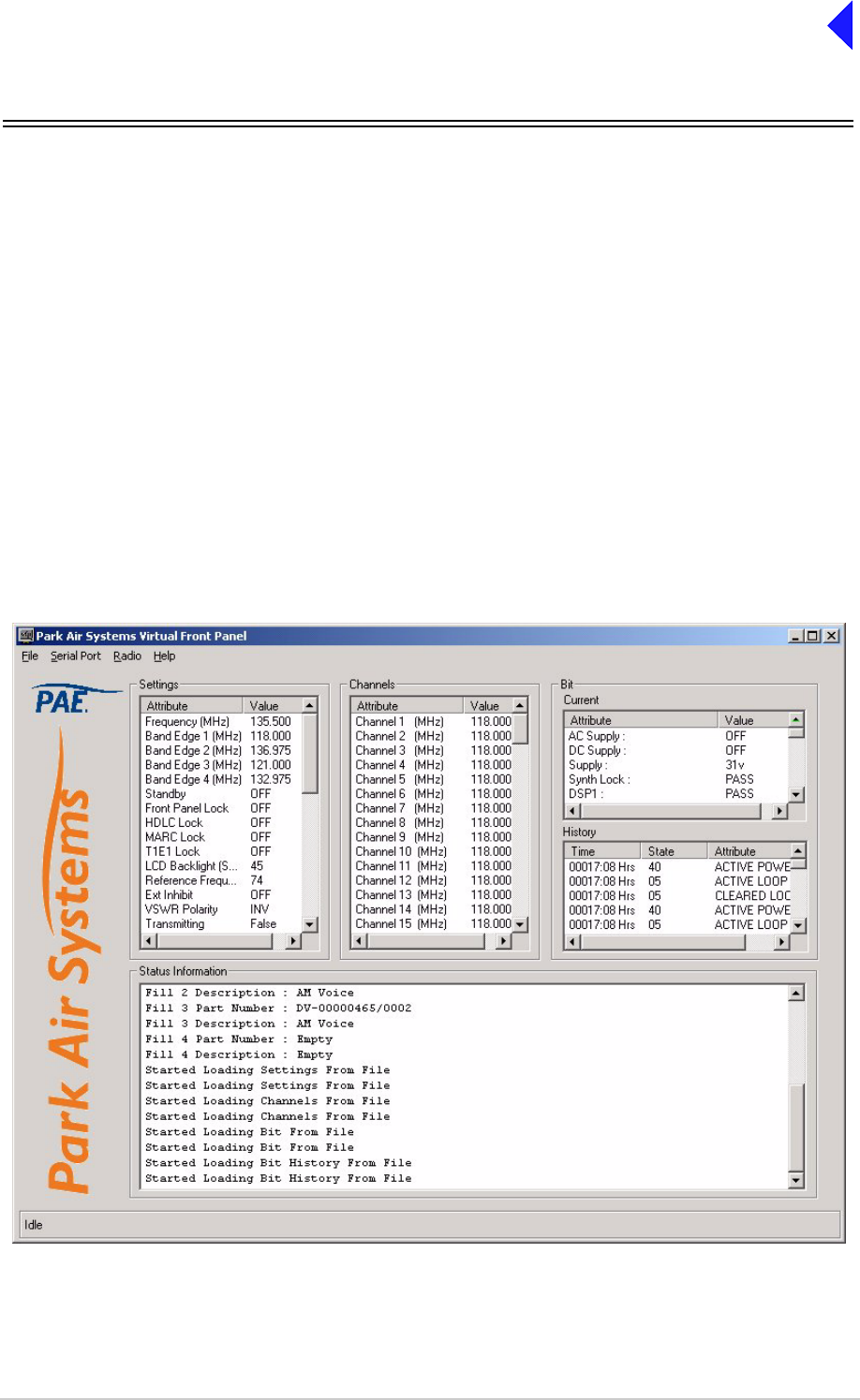

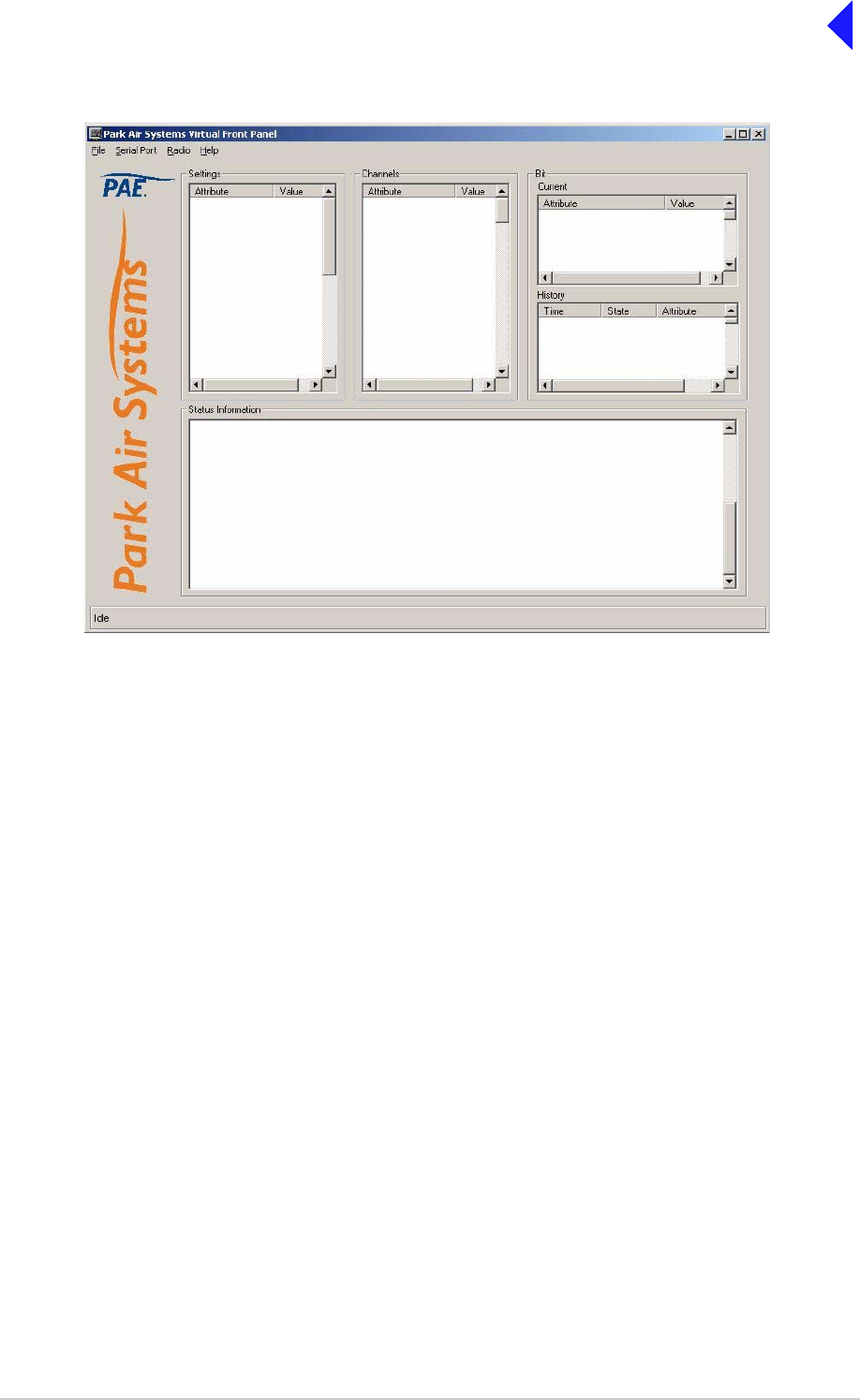

Virtual Front Panel

The Virtual Front Panel (VFP) software supplied on CD with the radio is compatible with any PC or laptop

running Windows 2000™ or Windows XP™. The VFP allows changes to a radio’s settings and channel

information, it displays the current BIT state, displays BIT history, allows security locks to be set, and

provides maintenance facilities. A typical VFP presentation is shown in Fig 2. Using the VFP has several

advantages over setting a radio from the front panel; these are:

❑A profile of the operational settings and channel information can be created, stored on disk, and

then recalled to download into other radios.

❑A print out of the radio’s profile can be made from the VFP.

❑The front panel controls can be locked. Front Panel Lock is available only when using the VFP.

Fig 2 Typical VFP Presentation

Back to Transmitter

Main Page

Intentionally Blank

Back to Transmitter

Main Page

Specification

This section gives the specification applicable to the T6T VHF 100 W Multimode Transmitter

operating in AM modes, Mode 2 and Mode 3.

All radios operate in AM-Voice mode. Additional software must be loaded to allow AM-MSK,

Mode 2 and Mode 3 operation.

T6T VHF 100 W Transmitter Page 2 Specification

Back to Transmitter

Main Page

General Specification

The general specification applies to the T6T 100 watt transmitter irrespective of the selected operating

mode. Separate listings are given for AM modes, Mode 2 and Mode 3. One model of the T6T VHF 100 W

Multimode Transmitter is available as detailed in Table 1.

Frequency accuracy

The frequency accuracy is better than 0.3 ppm.

Number of Channels

The transmitter has a multichannel capability. 100 channels can be stored and recalled.

Power Requirements

The transmitter operates from an ac mains supply, or a dc input supply. When both supplies are

connected, the dc input acts as an automatic backup for the ac mains.

ac input supply The transmitter operates from a 48 to 62 Hz single-phase ac supply

and automatically adjusts to operate from any supply voltage ranging

from 110 Vac to 230 Vac ±10%. The power consumption figures are

given in Table 2.

dc input supply The transmitter operates from a dc input supply between 21.6 and

32 V (measured at the radio’s input). Current loading is given in

Table 2.

Table 1 100 Watt T6 Transmitter

Description Part Number Frequency Range Special Applications

100 watt, high stability, standard

frequency coverage transmitter B63100HS/NB 118 to 136.975 MHz Supports 5-offset carrier

operation

Table 2 Power Consumption

Requirement 100 Watt Transmitter Normal Operation

ac dc

Maximum 1000 VA 24 A

Typical 600 VA 17 A

Not Transmitting 90 VA 1.5 A

T6T VHF 100 W Transmitter Page 3 Specification

Back to Transmitter

Main Page

Dimensions and Weight

The dimensions and weight of the 100 watt transmitter are:

Width 483 mm (19 inches).

Height 177.8 mm (7 inches). The height occupies 4U of equipment cabinet

space.

Depth 430 mm (16.9 inches) measured from front panel to rear panel.

465 mm (18.3 inches) measured from front panel to rear RF

connectors.

Weight 25 kg (55 pounds).

Environmental

Temperature range The transmitter operates to specification across the temperature

range of -20°C to +55°C.

The transmitter can be stored at temperatures ranging from

-30°C to +70°C without causing any damage.

Humidity The transmitter operates to specification at a relative humidity

between 5% and 90% non-condensing.

Altitude The transmitter operates to specification up to 15,000 feet.

Additionally it is capable of storage at altitudes up to 50,000 feet

without damage.

Shock and vibration The transmitter complies with shock and vibration protection

MIL-STD-810E, method 516.4, procedure VI - Bench Handling.

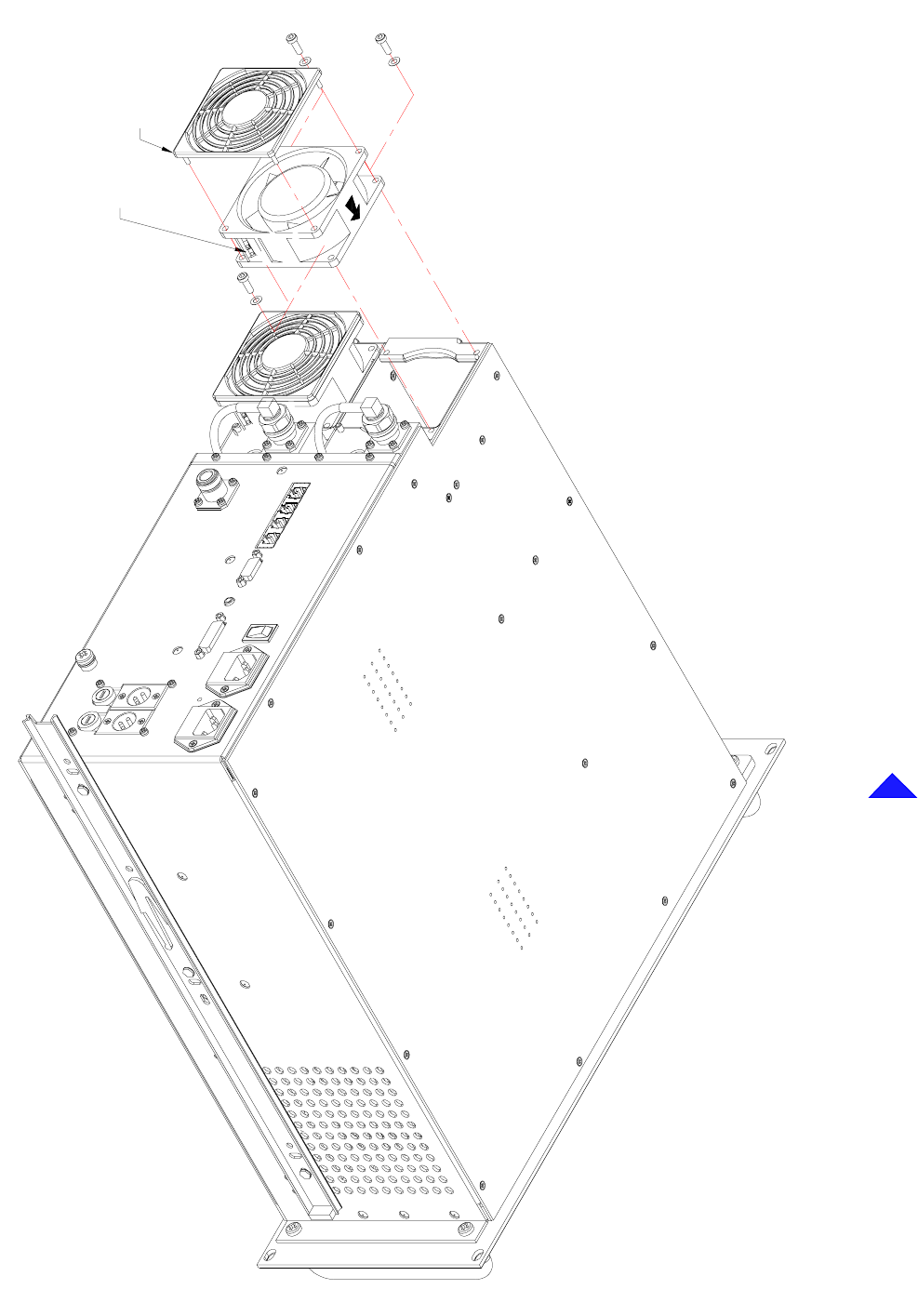

Ventilation The transmitter is cooled by integral fans, which normally runs at half

speed. At an RF PA temperature of 45°C this is increased to full speed

and at 40°C it reduces to half speed again.

The transmitter power supply units also use internal fans.

Warm up time The transmitter is fully operational within 20 seconds but can take up

to 10 minutes to achieve frequency accuracy for offset carrier.

T6T VHF 100 W Transmitter Page 4 Specification

Back to Transmitter

Main Page

AM Modes

The transmitter can operate in AM-Voice mode (standard) and AM-MSK mode (optional). The following

specifications apply to both modes unless stated otherwise.

Transmitter RF Characteristics

RF Power Output

The RF carrier output power is adjustable in 2 W steps from 10 W to 100 W.As an option, the maximum

selectable power can be limited. Output power is automatically controlled under the following conditions:

Frequency range Variations in power remain within 0 to +1 dB over the operational

frequency range.

Low supply voltage Variations in power remain within ±1 dB for supply voltages between

24 Vdc and 32 Vdc.

High VSWR Loop error can reduce power progressively by up to 3 dB. Variations

in power remain within ±1 dB into a VSWR of up to 2.5:1. At a VSWR

greater than this the output power may be reduced by 10 dB ±1 dB.

High RF PA temperature If the RF PA temperature sensor exceeds 80°C the output power is

reduced by 3 dB ±1 dB. If the RF PA temperature sensor exceeds

90°C the transmitter is de-keyed and automatically re-keyed at 70°C.

PA Module Failure If one of the two PA modules fails, the transmitter will continue to

operate at half power, 50 watts.

Duty Cycle

Both modes 100% continuous operation.

Channel Spacing

AM-Voice mode The transmitter is capable of both 25 kHz channel spacing and

8.33 kHz channel spacing.

AM-MSK mode 25 kHz.

Offset Carrier

AM-Voice mode The transmitter is capable of offsetting the carrier frequency to provide

2, 3, 4 and 5-carrier offset.

AM-MSK mode Offset carrier is not available.

Harmonic Outputs

Both modes Second harmonic outputs are less than -36 dBm, third harmonic

outputs are less than -46 dBm and fourth harmonic outputs and above

up to 4 GHz, are less than -56 dBm.

T6T VHF 100 W Transmitter Page 5 Specification

Back to Transmitter

Main Page

Spurious Outputs

Both modes The spurious outputs are less than -46 dBm for modulation depths up

to 90%, measured at greater than 500 kHz from carrier in the

frequency range 9 kHz to 4 GHz. There are no coherent spurious

outputs above the spectral mask at less than 500 kHz.

Intermodulation

Both modes Intermodulation products, caused by an interfering signal with the

same power as the transmitter isolated by 30 dB, are at least -40 dBc

at ≥±150 kHz and -50 dBc at ≥±500 kHz.

Transmitter Modulation Characteristics

The transmitter modulation characteristics are as follows:

Mode

AM-Voice AM-Voice mode uses Double Sideband (DSB) Amplitude Modulation

(AM) full carrier; emission designator 6K80A3EJN for 25 kHz

channels and 5K00A3EJN for 8.33 kHz channels.

AM-MSK AM-MSK mode uses Double Sideband (DSB) Amplitude Modulation

(AM) full carrier; emission designator 13K0A2DJN.

Modulation Depth

Both modes The transmitter is capable of modulation depths up to 95%.

Hum and Noise

Both modes The hum and noise is more than 45 dB below the signal level for line

input levels <-13 dBm, and more than 50 dB below the signal level for

line input levels ≥-13 dBm, for a carrier modulated by a 1 kHz signal

with a modulation depth of 90%.

Frequency Response

25 kHz channel spacing AM-Voice and AM-MSK: The variation in frequency response with

reference to a 1 kHz signal is within +0.5 dB and -1.5 dB across the

frequency range 300 to 3400 Hz. The response is also less than

-20 dB at 100 Hz and below, and less than -30 dB at 4 kHz and above.

8.33 kHz channel spacing AM-Voice only: The variation in frequency response with reference to

a 1 kHz signal is within +0.5 dB and -1.5 dB across the frequency

range 350 Hz to 2500 Hz. The response is also less than -10 dB at

100 Hz and below, and less than -30 dB at 3200 Hz and above.

Distortion

25 kHz channel spacing The total harmonic distortion is less than 5% due to signals with a

modulation depth of 90%, within the frequency range 300 Hz to

3400 Hz.

8.33 kHz channel spacing AM-Voice only: The total harmonic distortion is less than 5% due to

signals with a modulation depth of 90%, within the frequency range

350 Hz to 2500 Hz.

T6T VHF 100 W Transmitter Page 6 Specification

Back to Transmitter

Main Page

Residual FM

Both modes For a test signal of 1 kHz set at 80% modulation depth applied to the

line input of the transmitter, the unwanted peak frequency modulation

does not exceed ±500 Hz.

VOGAD

AM-Voice The VOGAD has an operational range of 30 dB. The VOGAD can be

disabled.

AM-MSK The VOGAD is disabled.

Mute

AM-Voice The mute level is set at 15 dB below the average speech line level

setting. The mute can be disabled.

AM-MSK The mute is disabled.

Differential Group Delay

AM-MSK There is less than 60 µs differential group delay for signals in the

range 1200 to 2400 Hz.

Transmitter Control

Transmitter control characteristics are as follows:

Audio Inputs

Voice can be connected to the transmitter via the front panel microphone connector. Voice can also be

connected via the line inputs. Line level setting from -30 to +10 dBm.

PTT Time Out

The time out period is adjustable from 2 to 510 seconds in 2 second steps or it can be disabled.

T6T VHF 100 W Transmitter Page 7 Specification

Back to Transmitter

Main Page

Mode 2

This section gives the transmitter specification applicable to Mode 2 operation. Mode 2 parameters are

identical to AM-Voice mode parameters with the following exceptions:

RF Power Rise Time

The transmitter produces more than 90% of full power output within the first 2 symbols of the power

stabilization segment, which is the first segment of the training sequence and consists of 4 symbols each

representing 000.

RF Power Decay Time

The output power decays by more than 20 dB within 2.5 symbols of the middle of the final symbol.

Channel Spacing

25 kHz channel spacing only.

Transmitter Modulation Characteristics

Mode 2 uses Carrier Sense Multiple Access (CSMA) differentially encoded 8-phase shift keying

(D8PSK), using a raised cosine filter with α=0.6 (nominal value), emission designator 14K0G1DE.

Information is differentially encoded with 3 bits per symbol transmitted as changes in phase rather than

absolute phase. The data stream is divided into groups of 3 consecutive data bits, least significant bit

first. Zeros are padded to the end of transmissions if needed for the final channel symbol.

Modulation Rate

The symbol rate is 10,500 symbols/second (±0.005%), resulting in a nominal bit rate of 31,500 bits/s.

RMS Phase Error

The RMS phase error is less than 3°. The error vector magnitude is less than 6%.

Phase Acceleration

The total frequency change during the transmission of the unique word is less than 10 Hz. After this, the

phase acceleration is less than 500 Hz/s.

T6T VHF 100 W Transmitter Page 8 Specification

Back to Transmitter

Main Page

Mode 3

This section gives the transmitter specification applicable to Mode 3 operation. Mode 3 parameters are

identical to AM-Voice mode parameters with the following exceptions:

RF Power Rise Time

The transmitter produces more than 90% of full power output within the first 2 symbols of the power

stabilization segment, which is the first segment of the training sequence and consists of 4 symbols each

representing 000.

RF Power Decay Time

The output power decays by more than 20 dB within 2.5 symbols of the middle of the final symbol.

Channel Spacing

25 kHz channel spacing only.

Transmitter Modulation Characteristics

Mode 3 uses Time Division Multiple Access (TDMA) differentially encoded 8-phase shift keying (D8PSK),

using a raised cosine filter with α=0.6 (nominal value), emission designator 14K0G7WET. Information is

differentially encoded with 3 bits per symbol transmitted as changes in phase rather than absolute phase.

The data stream is divided into groups of 3 consecutive data bits, least significant bit first. Zeros are

padded to the end of transmissions if needed for the final channel symbol.

Modulation Rate

The symbol rate is 10,500 symbols/second (±0.005%), resulting in a nominal bit rate of 31,500 bits/s.

RMS Phase Error

The RMS phase error is less than 3°. The error vector magnitude is less than 6%.

Phase Acceleration

The total frequency change during the transmission of the unique word is less than 10 Hz. After this, the

phase acceleration is less than 500 Hz/s.

Back to Transmitter

Main Page

Operation

This topic describes the transmitter’s operating controls and indicators.

It also details how to set up the transmitter’s operating parameters.

T6T VHF 100 W Transmitter Page 2 Operation

Back to Transmitter

Main Page

Controls, Indicators and Front Panel Connectors

This section describes the transmitter’s controls, indicators and front panel connectors.

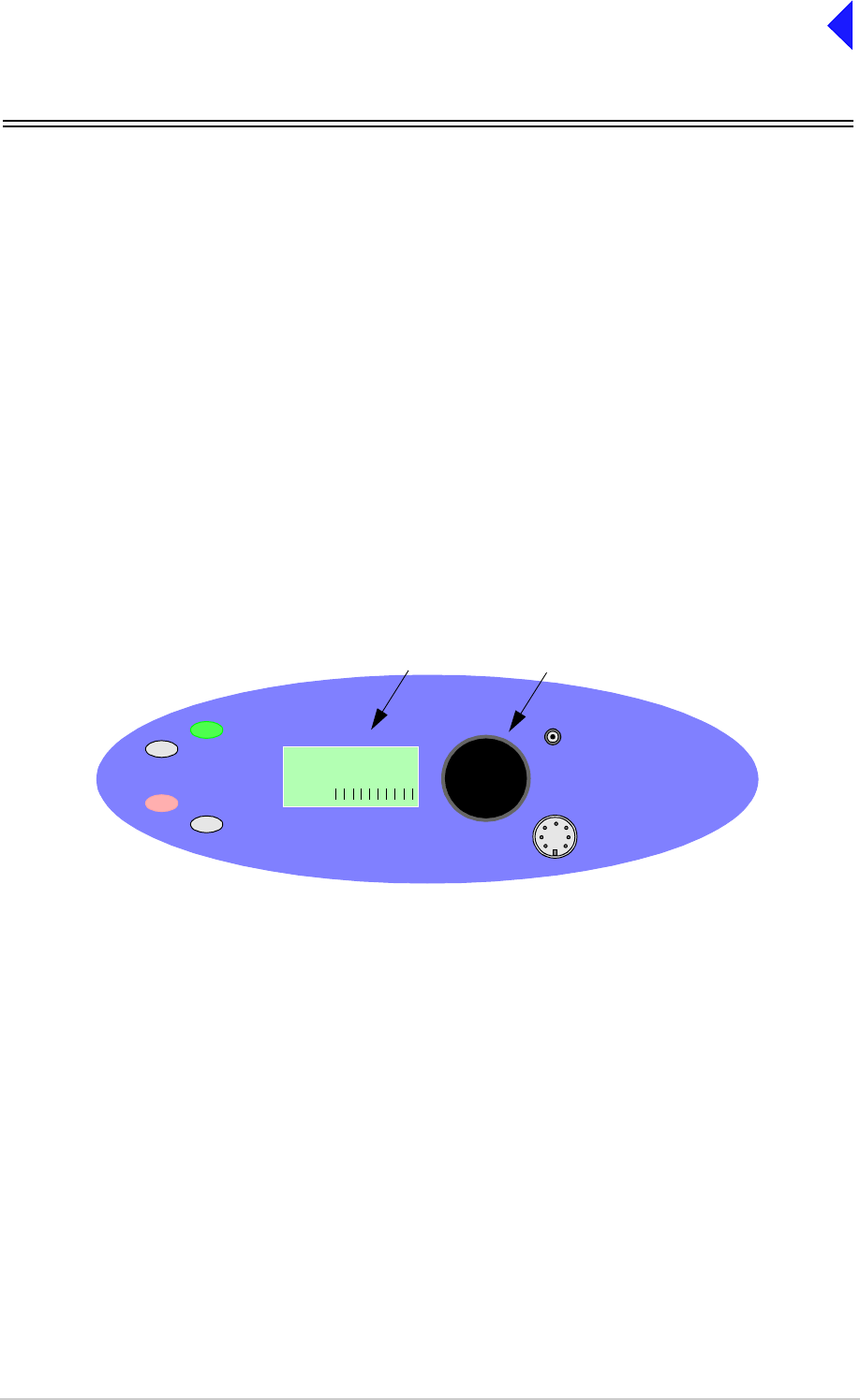

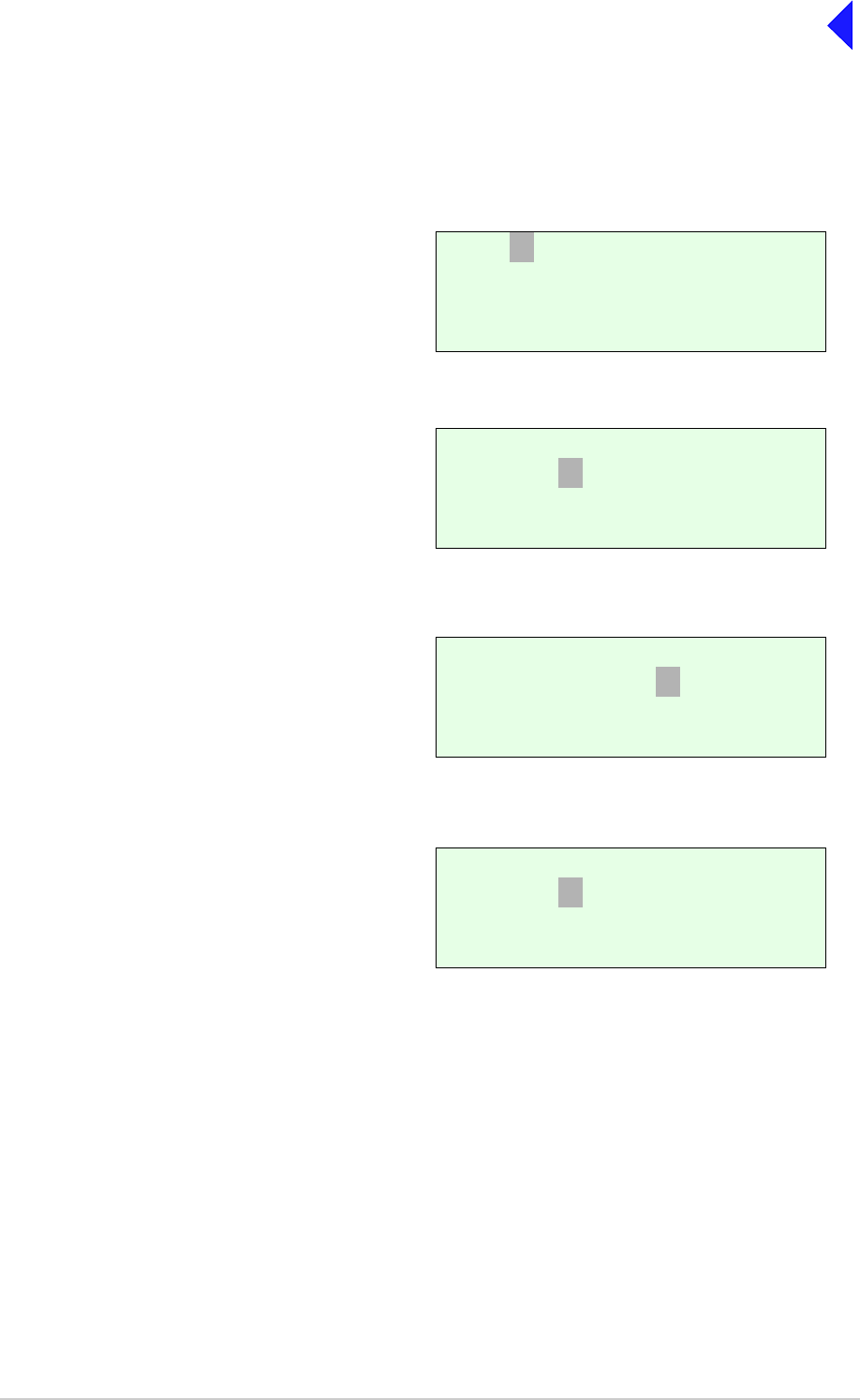

Front Panel

The transmitter’s front panel is illustrated below.

Scroll/Select Switch and LCD

The Scroll/Select switch is used in conjunction with the LCD to select most of the transmitter's operational

settings. During normal operation, the LCD shows the operating frequency, the channel number (if the

channel store facility is used), the carrier offset (if used), and displays a graphical representation of

instantaneous peak power.

The example LCD screen above shows the transmitter operating on 118.000 MHz; the frequency has

been preset as channel 100 and offset at +7.3 kHz.

Ready Indicator

A green indicator that lights when the transmitter is ready for use and no BIT faults have been detected.

Transmit Indicator

An amber indicator that lights when the transmit circuit is keyed and producing output power.

Alarm Indicator

A red indicator that either flashes, or lights, when a BIT fault has been detected. BIT indications are

classified as either Alarms or Alerts.

If an ‘alert’ condition is detected, the Alarm indicator flashes, the Ready indicator remains lit, and the

transmitter remains operational. A BIT ‘alert’ is indicated if:

❑The transmitter RF output power has reduced from its setting by more than 1 dB but not more than

3 dB.

❑The supply volts falls below a pre-defined level.

Any other BIT condition results in an alarm. When detected, the Alarm indicator lights and the Ready

indicator becomes unlit; the transmitter cannot be used.

READY

ALARM

TRANSMIT

STANDBY SCROLL/

SELECT

MICROPHONE/

DIAGNOSTICS

REFERENCE

F r e q 1 1 8 .0 0 0 M H z

C h 1 0 0 + 7 . 3 k H z

P w r

Scroll/Select SwitchLCD

M o d e A M V o i c e 1

T6T VHF 100 W Transmitter Page 3 Operation

Back to Transmitter

Main Page

Standby Indicator

A red indicator that lights when the transmitter is in standby mode. When in standby mode, most of the

radio's circuits are inactive, the front panel LCD is blanked, and the transmitter cannot be keyed.

Standby mode is selected and deselected using the front panel Scroll/Select switch and LCD, by initiating

an instruction through a MARC system, through a T6 controller or through the VFP. For details of front

panel selection and deselection see page 14.

Reference Connector

An SMB jack socket that allows a frequency counter to monitor the transmitter's reference frequency.

This connector is used only for maintenance purposes. The instructions for checking and adjusting the

reference frequency are given in the Maintenance section.

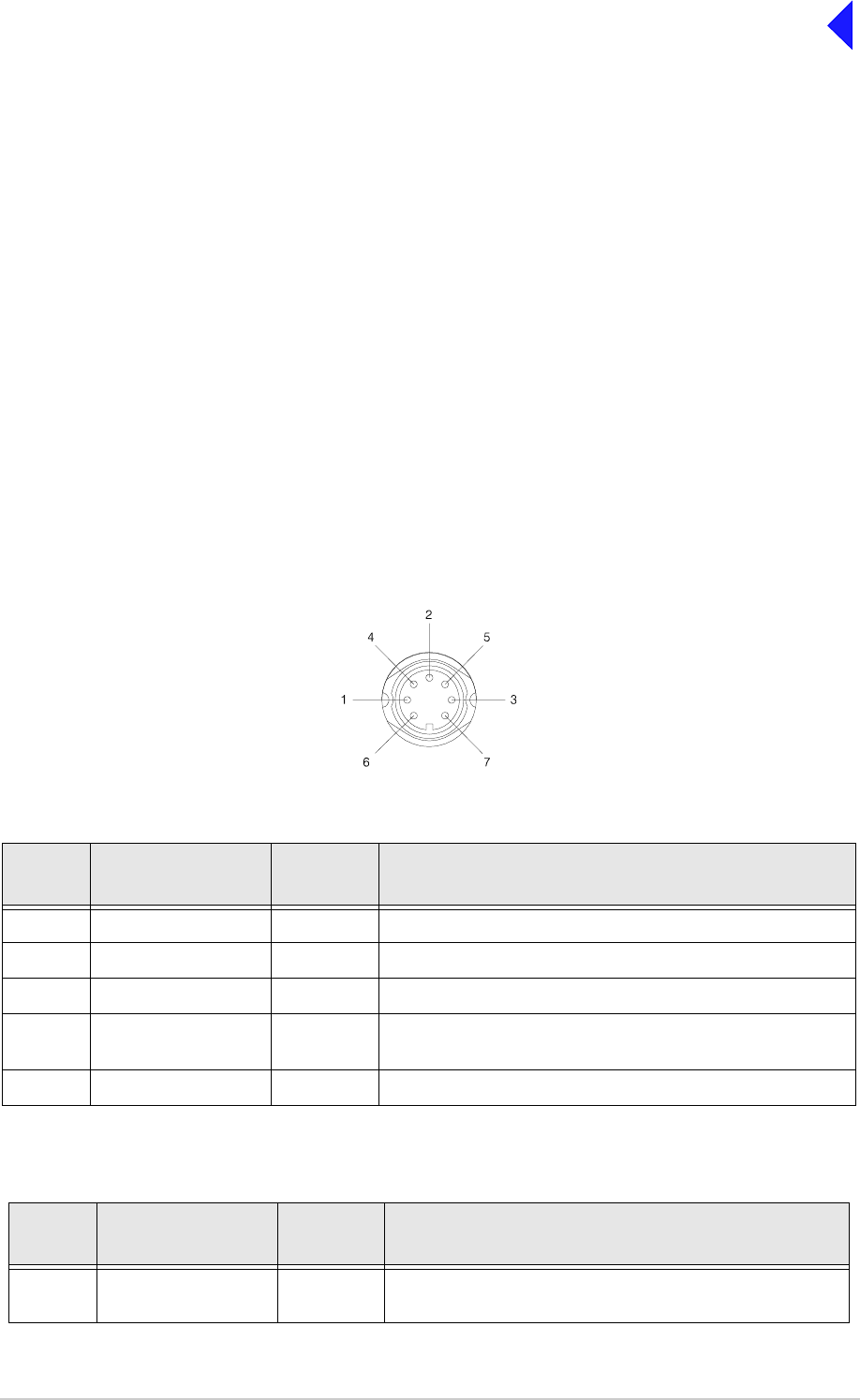

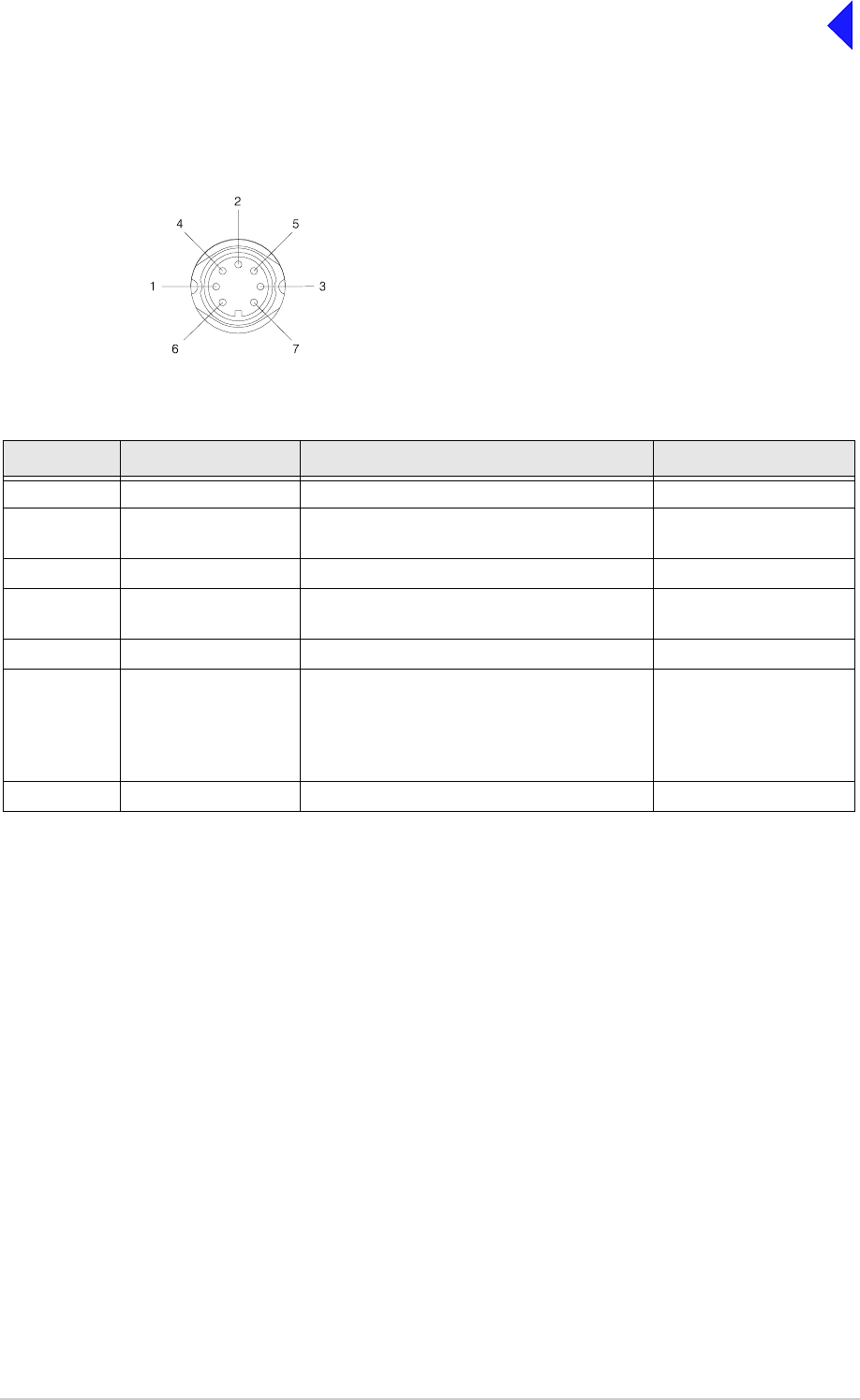

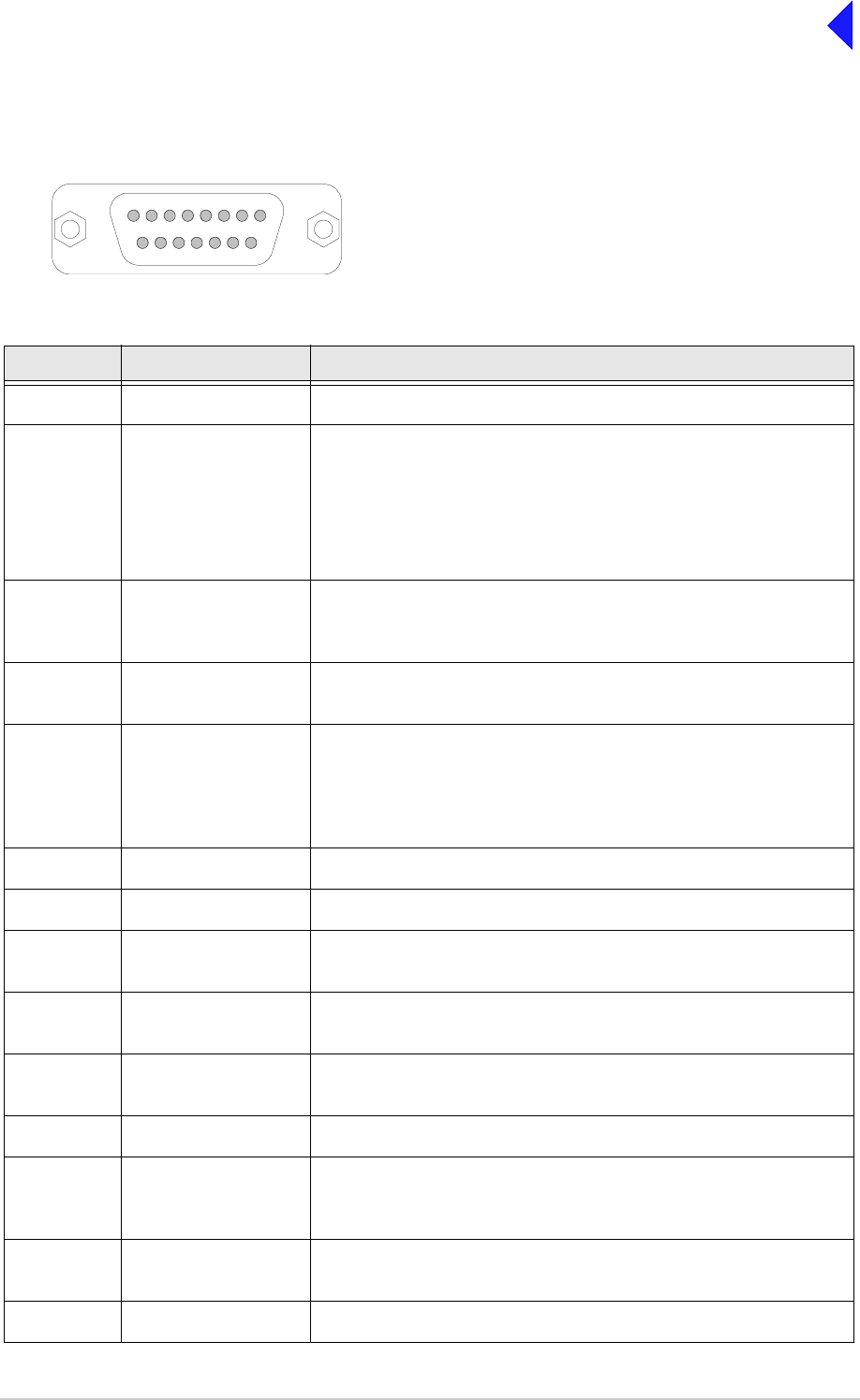

Microphone/Diagnostics Connector

A dual purpose connector that allows either a microphone, or a PC, to be connected to the transmitter.

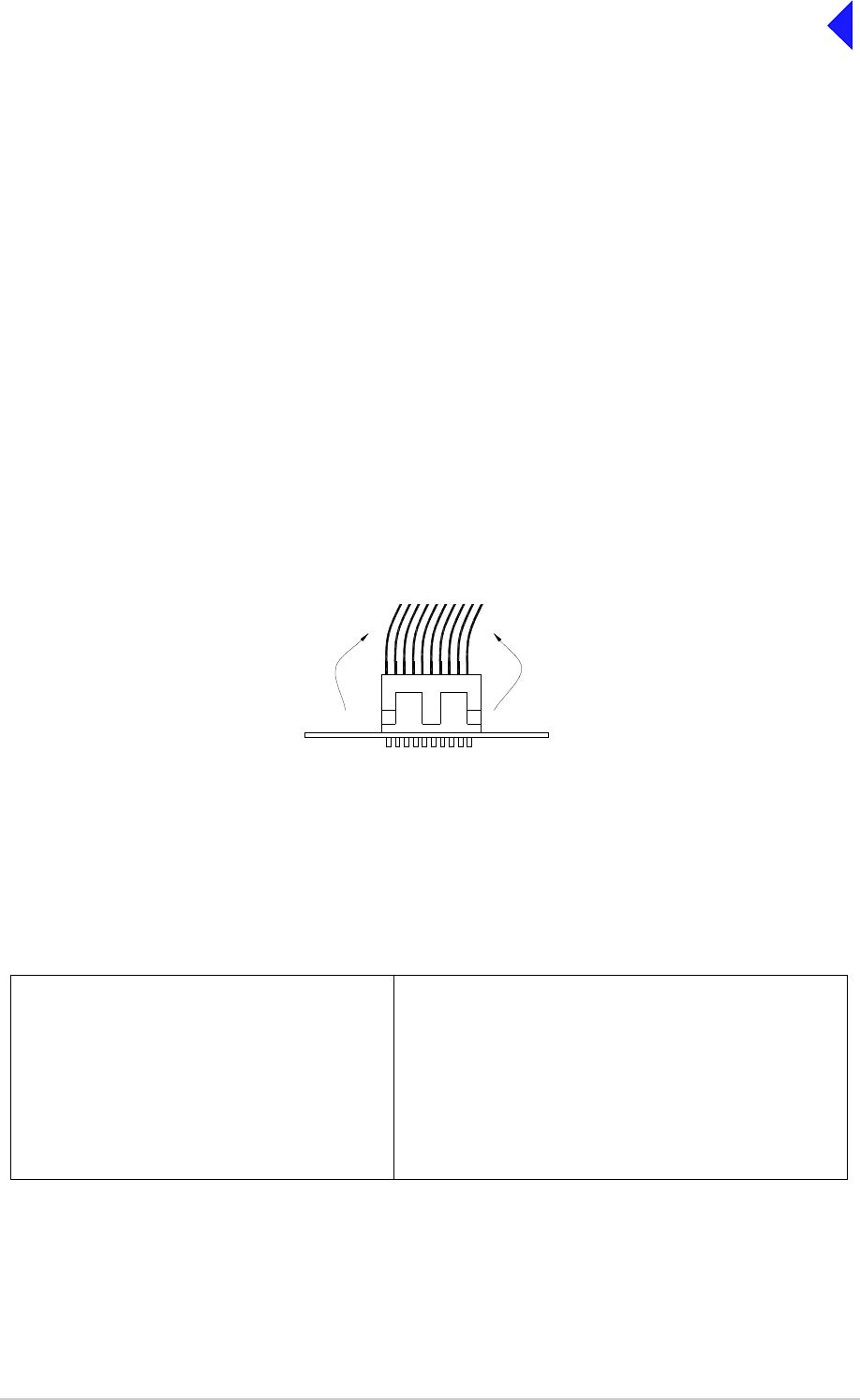

The connector is a 7-pin self-locking DIN socket; the pin-out is shown in Table 1.

A microphone is fitted to this connector to enable the transmitter to be operated in AM local mode. The

connections are detailed in Table 1. A PC can also be connected to allow the VFP to be displayed. Using

the VFP is detailed in the Maintenance section. The PC connections at the transmitter are shown in

Table 2 on the following page.

Table 1 Microphone/Diagnostics Connector - Audio Connections

Pin

Number Signal Input or

Output Description

1 Microphone ground - 0 V.

3 Microphone PTT Input 0 V to PTT.

5 Sidetone Output 0 to 3 V pk-pk.

6 Microphone input Input 2 to 35 mV rms on Passive setting and 8 to 140 mV rms on

Active setting to remain in VOGAD range.

7Ground - 0V.

Table 2 Microphone/Diagnostics Connector - PC Connections

Pin

Number Signal Input or

Output Description

2 Transmit data Output RS232, 115200 baud, 8 data bits, 1 stop bit, no parity, no

handshaking.

Viewed from front

T6T VHF 100 W Transmitter Page 4 Operation

Back to Transmitter

Main Page

Rear Panel Power Switch

The rear panel power switch is a 2-way rocker switch used to select between power on, and standby.

When the Power switch is set to the Standby position, dangerous voltages are still present

in the transmitter's internal power supply circuitry. To ensure safe working, the transmitter

must be isolated from the ac and dc input supplies.

4 Receive data Input RS232, 115200 baud, 8 data bits, 1 stop bit, no parity, no

handshaking.

7 Ground - 0 V.

Table 2 Microphone/Diagnostics Connector - PC Connections

Pin

Number Signal Input or

Output Description

WARNING Dangerous Voltages

= Standby= On

T6T VHF 100 W Transmitter Page 5 Operation

Back to Transmitter

Main Page

Setting Up and Operation

Introduction

Setting up the transmitter involves using the front panel Scroll/Select switch to specify the operating

parameters.

Operating parameters can also be set using the Virtual Front Panel (VFP), through a Multi-Access

Remote Control (MARC) system, from an associated T6 controller. VFP operation is described on this

disk under Maintenance; MARC and T6 controller functionality is described in separate handbooks.

Table 9 on page 32 details the functions and parameters that can be set from all sources.

No attempt to set up the transmitter should be made until the installation procedures, given in the

Installation topic, are completed.

Normal Operation

During normal operation, the LCD displays the Main screen. This screen shows the operating frequency,

the channel number (if the channel store facility is used), the carrier offset (if used), and displays a

graphical representation of output power when the transmitter is keyed. If the transmitter has been set to

Standby mode, which is shown by the front panel Standby indicator being lit, the LCD is blanked.

Using the Scroll/Select Switch

The Scroll/Select switch (referred to throughout this section as the ‘Switch’) is used to leave the Main

screen and display the Control screen (see page 8). Further use of the Switch displays various selection

menus and allows the required parameters to be set. The switch has three actions: it can be turned

clockwise, anti-clockwise, or momentarily pushed in.

READY

ALARM

TRANSMIT

STANDBY SCROLL/

SELECT

MICROPHONE/

DIAGNOSTICS

REFERENCE

F r e q 1 1 8 .0 0 0 M H z

C h 1 0 0 + 7 . 3 k H z

P w r

Scroll/Select SwitchLCD

M o d e A M V o i c e 1

T6T VHF 100 W Transmitter Page 6 Operation

Back to Transmitter

Main Page

Screen Protocol

The following protocol is applicable to all screens described in this document.

Main Screen During normal operation, the Main screen (an example of which is shown below

whilst the transmitter is transmitting) is displayed.

Switch Refers to the front panel Scroll/Select switch. The switch is turned clockwise to scroll

through fields from left to right, and from top to bottom. The switch is turned

anti-clockwise to scroll through fields from right to left, and from bottom to top. The

switch is pressed to make a selection.

Time out If during any setting up procedure the Scroll/Select switch is not operated for

30 seconds, the display returns to the Main screen. If editing any parameter has not

been completed, the transmitter stays on the original setting.

>> Indicates more fields are available other than those currently displayed. To access

those fields, turn the switch clockwise through the last displayed field.

<< Indicates more fields are available other than those currently displayed. To access

those fields, turn the switch anti-clockwise through the first displayed field.

Back When Back is selected, you are returned to the previous menu.

Exit When Exit is selected, you are returned to the Main screen.

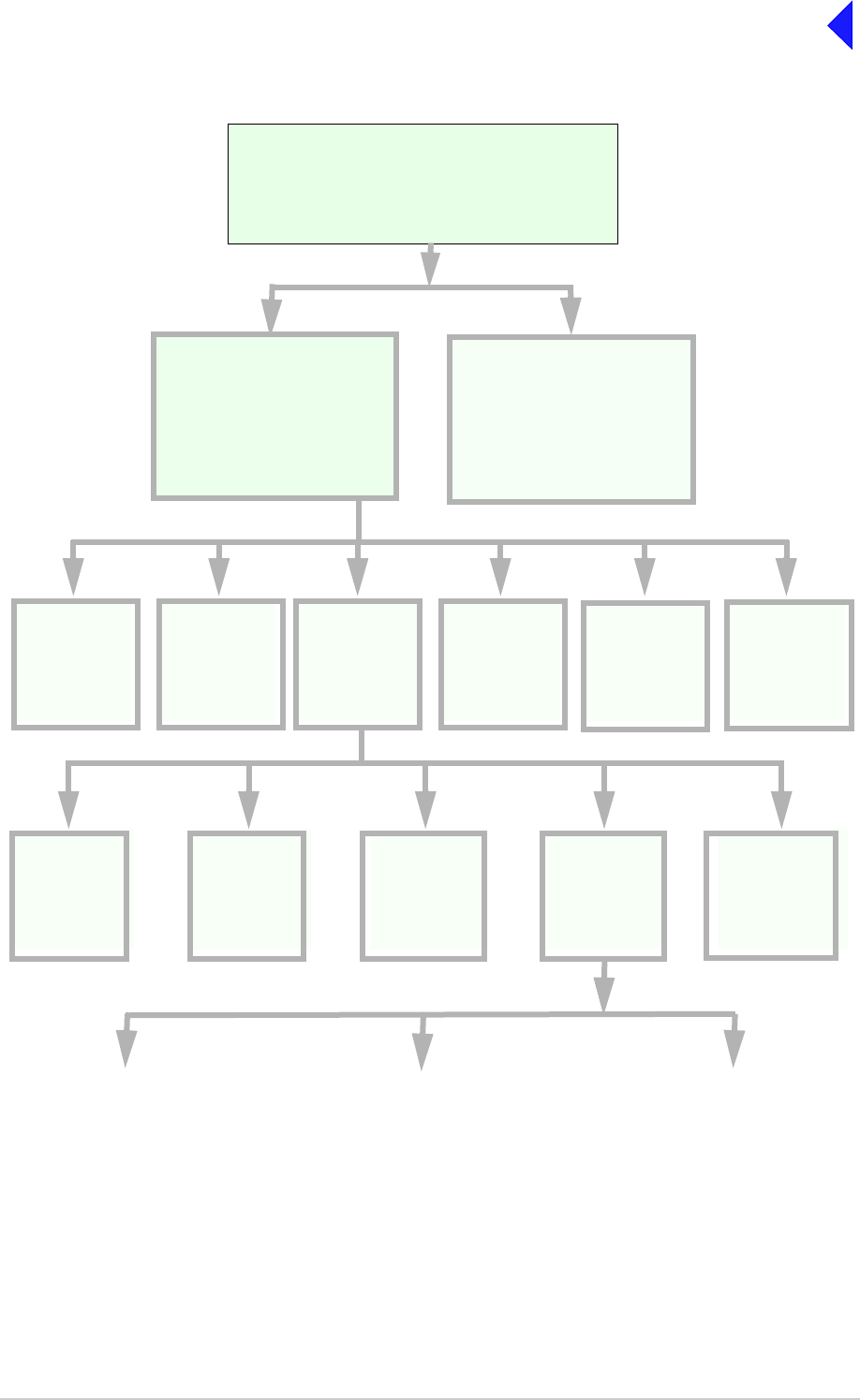

Menu System

The front panel control of the radio is implemented through a hierarchical menu system as shown on the

following page.

F r e q 1 1 8 . 0 0 0 M H z

C h 1 0 0 + 7 . 3 k H z

M o d e A M V o i c e

P w r I I I I I I I I I I

T6T VHF 100 W Transmitter Page 7 Operation

Back to Transmitter

Main Page

Menu System

F r e q 1 1 8 . 0 0 0 M H z

C h 1 0 0

M o d e A M V o i c e

P w r I I I I I I I I I I

Settings

Set the

transmitter

operational

settings

BIT

Initiate a BIT

test and view

results

Standby

Enter or Exit

standby mode

Ref Freq

Adjust the

transmitter

reference

frequency

Band Edges

Set up the

transmitter

band edges

Polarities

Set the active

polarity for

certain hardwire

connections

Backlight

Adjust the

display’s

backlight

AM-Voice Mode

Settings

(see page 17)

AM-MSK Mode

Settings

(see page 19)

Digital Modes

(see page 20)

Mode and

Mode

Settings

Select Mode

Menu Lock Screen

Main Screen

(Example)

Displayed during normal

transmitter operation

Frequency

Set the

transmitter

operating

frequency

Channel

Set or recall up

to 100 preset

frequency

channels

Control Screen

Configure the transmitter

operating parameters, access

the BIT facility or view the

software configuration.

S/W Config

View the

transmitter

software

configuration

T6T VHF 100 W Transmitter Page 8 Operation

Back to Transmitter

Main Page

Menu Lock Screen

A security facility available only from the VFP allows the transmitter front panel to be ‘locked’. When this

facility is active, no operational settings can be made from the front panel until an ‘unlock’ command is

sent from the VFP.

The following screen is displayed when ‘lock’ is active, and the front panel switch is pressed.

To exit the system lock screen:

❑Select OK, then press the switch. You are returned to the Main screen.

or,

❑Wait for the 30 second time out to expire. You are returned to the Main screen.

Control Screen

The Control screen is entered from the Main screen by pressing the switch. The following screen is

displayed:

S E C U R I T Y M E S S A G E

F r o n t P a n e l

L o c k e d

O K

F r e q u e n c y

C h a n n e l

S e t t i n g s

E x i t > >

B I T

S / W C o n f i g

S t a n d b y

E x i t < <

Change the transmitter operating frequency.

Store or recall preset channel frequencies.

Select operating mode and mode settings.

Initiate a BIT test and view results.

View software configuration.

Enter or exit standby mode.

T6T VHF 100 W Transmitter Page 9 Operation

Back to Transmitter

Main Page

Notes for Setting Up the Transmitter

The following notes should be read before setting up the transmitter. They advise on the special

frequency display when using 8.33 kHz channel spacing, and give guidance on the optimum line level

settings. Note that for operation in the United States of America, this equipment is certified only for

operation using 25 kHz channel spacing.

Front Panel Display for 25 kHz and 8.33 kHz Channel Spacing

When setting the operating frequency of the transmitter and 8.33 kHz channel spacing is required, the

displayed frequency differs from the actual channel frequency. Table 3 shows the pattern used for

25 kHz and 8.33 kHz spaced channel frequencies from 118.000 MHz to 118.141 MHz. The pattern is the

same for any frequency within the transmitter's frequency range. The display conforms to ICAO

convention for 8.33 kHz operation.

Table 3 25 kHz and 8.33 kHz Channel Spacing Displays

Actual Frequency

(to 4 decimal places) Channel Spacing Displayed Frequency

at Transmitter's Front Panel

118.0000 MHz

118.0000 MHz

118.0083 MHz

118.0166 MHz

118.0250 MHz

118.0250 MHz

118.0333 MHz

118.0416 MHz

118.0500 MHz

118.0500 MHz

118.0583 MHz

118.0666 MHz

118.0750 MHz

118.0750 MHz

118.0833 MHz

118.0916 MHz

118.1000 MHz

118.1000 MHz

118.1083 MHz

118.1166 MHz

118.1250 MHz

118.1250 MHz

118.1333 MHz

118.1416 MHz

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

118.000 MHz

118.005 MHz

118.010 MHz

118.015 MHz

118.025 MHz

118.030 MHz

118.035 MHz

118.040 MHz

118.050 MHz

118.055 MHz

118.060 MHz

118.065 MHz

118.075 MHz

118.080 MHz

118.085 MHz

118.090 MHz

118.100 MHz

118.105 MHz

118.110 MHz

118.115 MHz

118.125 MHz

118.130 MHz

118.135 MHz

118.140 MHz

T6T VHF 100 W Transmitter Page 10 Operation

Back to Transmitter

Main Page

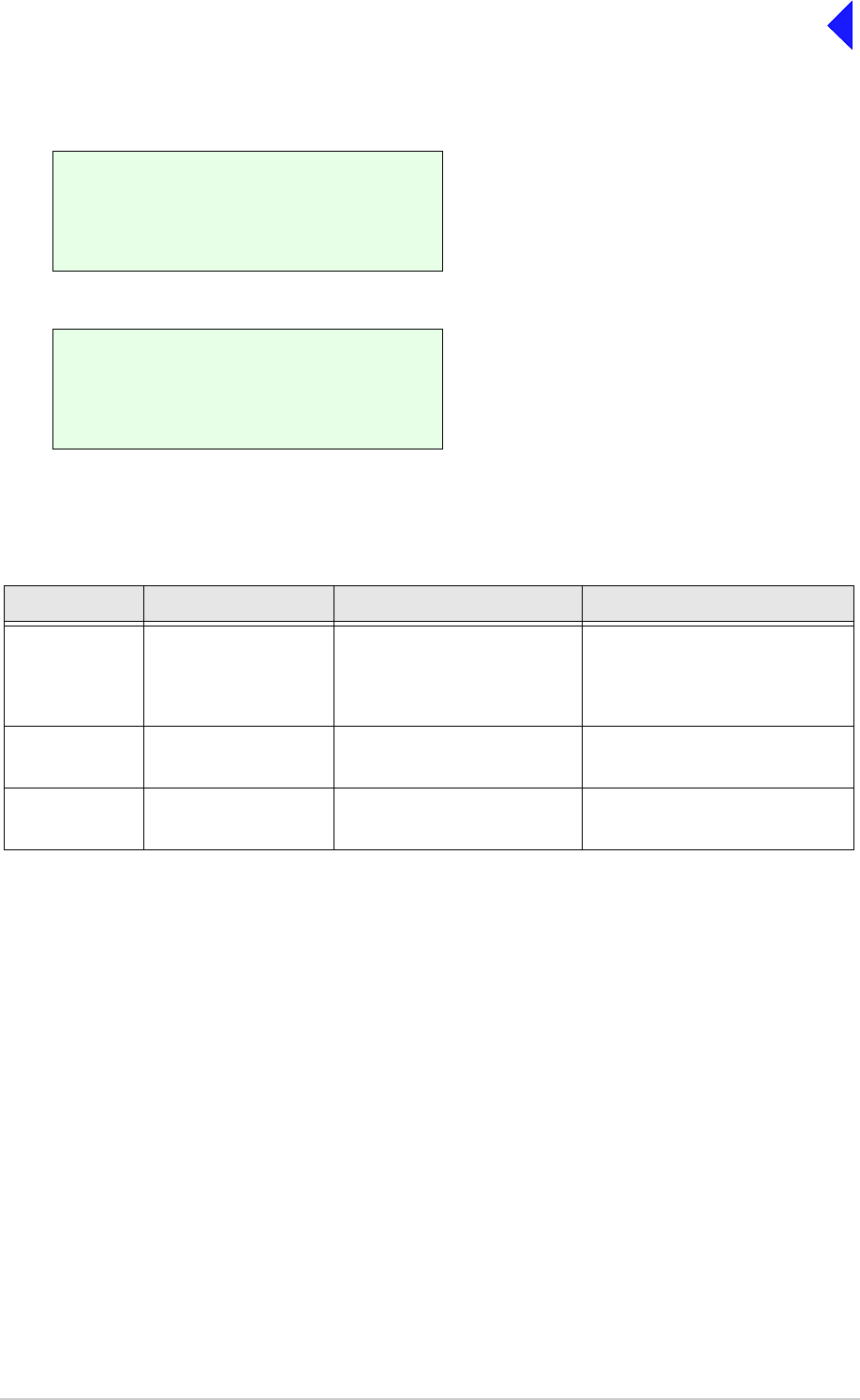

Line Level Setting

The input line level setting displayed on the front panel is equivalent to the average speech level with a

peak-to-average ratio of 13 dB. This corresponds to the level specified for the lines.

When testing the transmitter using a sine wave, the line input level should be set to 10 dB above the line

level setting. The VOGAD and mute thresholds are preset at 10 dB and 15 dB respectively below the line

level setting.

Table 4 shows the relationship between the input line level, VOGAD threshold and mute threshold.

Table 4 Relationship Between Line Level, VOGAD Threshold and Mute Threshold

Line Level Setting

(dBm) Average Speech

Level (dBm) Sine Wave Level

(dBm) VOGAD Threshold

(dBm) Mute Threshold

(dBm)

+10 +10 +20 0 -5

+5 +5 +15 -5 -10

00+10-10-15

-5 -5 +5 -15 -20

-10 -10 0 -20 -25

-15 -15 -5 -25 -30

-20 -20 -10 -30 -35

-25 -25 -15 -35 -40

-30 -30 -20 -40 -45

T6T VHF 100 W Transmitter Page 11 Operation

Back to Transmitter

Main Page

Changing the Transmitter Operating Frequency

The transmitter frequency can be changed in two ways: either from the frequency screen, or by recalling

a preset channel. This procedure details the use of the Frequency screen.

F r e q 1 1 8 . 0 0 0 M H z

C a n c e l O K

(1) From the Control screen, select

frequency to display the Frequency

screen.

(2) Turn the switch to highlight the digit to

be changed, then press the switch.

(3) Turn the switch until the required digit

is shown, then press the switch.

(4) Repeat until the required frequency is

shown, then highlight OK and press the

switch.

(5) Only frequencies that fall between the

band edge settings can be selected.

T6T VHF 100 W Transmitter Page 12 Operation

Back to Transmitter

Main Page

To Store and Recall Frequency Channels

Up to 100 frequency channels can be stored in the transmitter.

C h 1 0 0

F r e q 1 2 1 . 5 0 0 M H z

R e c a l l

B a c k E x i t

C h 1 0 0

F r e q 1 1 8 . 0 0 0 M H z

S t o r e

B a c k E x i t

C h 1 0 0

F r e q 1 1 8 . 0 0 0 M H z

I n v a l i d f o r M o d e

B a c k E x i t

C h 1 0 0

F r e q 1 1 8 . 0 0 0 M H z

O u t s i d e B a n d E d g e

B a c k E x i t

To store a Channel Frequency:

(1) From the Control screen, select

Channel to display the Channel

screen. Highlight Channel, press the

switch and then turn it until the required

channel number is displayed; press the

switch.

(2) Highlight the MHz frequency value

(see Example 2) press the switch and

then turn it until the required MHz value

is shown. Press the switch.

(3) Highlight the kHz frequency value (see

Example 3), press the switch and then

turn it until the required kHz value is

shown. Press the switch.

(4) Highlight Store and press the switch.

The new frequency is now stored in the

selected channel number.

To recall a Stored Frequency Channel:

(1) From the Control screen, select

Channel to display the Channel

screen.

(2) To make the transmitter operate on

any preset channel frequency,

highlight Channel and press the switch.

Turn the switch until the required

channel number/frequency is

displayed, then press the switch.

(3) Turn the switch to highlight Recall, then

press the switch. Exit the screen. The

transmitter now operates on the

recalled channel frequency.

Notes:

If a frequency outside the band edge limits is

entered, a message (see Channel Screen -

Example 3) is displayed.

If a frequency not valid for the mode of

operation is entered, a message (see Channel

Screen - Example 4) is displayed.

Channel Screen - Example 1

Channel Screen - Example 2

Channel Screen - Example 3

Channel Screen - Example 4

T6T VHF 100 W Transmitter Page 13 Operation

Back to Transmitter

Main Page

To Initiate a BIT Test

Use the following procedure to initiate an interruptive BIT test from the transmitter front panel. A BIT test

cannot be initiated while the transmitter is keyed. After a BIT test has been run, the BIT screen is

displayed (see AM-Voice and AM-MSK BIT Screen on page 25). An interruptive BIT test cannot be

initiated in Mode 2 or Mode 3.

(1) From the Main screen, press the switch to display the Control screen. Turn the switch until BIT

is highlighted. Press the switch.

(2) Ensure the BIT menu is displayed. Turn the switch until BIT Initiate is highlighted. Press the

switch.

(3) During the test, which takes approximately two seconds, the Testing screen is displayed.

B I T I n i t i a t e

E T I 0 0 0 0 0 : 0 0 h r s

A C S u p p l y O N

E x i t > >

T e s t i n g

P l e a s e W a i t

During an interruptive BIT test, the transmitter radiates modulated carrier waves at the set power.

Users should therefore obtain the necessary authority before initiating a test.

If the test is to be carried out with the antenna disconnected, ensure a load is fitted to the

transmitter's antenna connector.

In order to test the line input stages, an internally generated 1 kHz tone is injected into the line input

circuit. Any other audio present on the line input will cause the test to be inaccurate. Therefore the

transmitter must not be keyed during the test.

B I T

S / W C o n f i g

S t a n d b y

E x i t < <

T6T VHF 100 W Transmitter Page 14 Operation

Back to Transmitter

Main Page

(4) On completion, and if the interruptive test was initiated from the front panel, one of the following

screens will be shown.

(5) Selecting OK takes the user back to the BIT screen.

(6) Selecting OK takes the user back to the BIT screen. The user can then scroll through the screen

to check out transmitter parameters for failure.

Standby Mode

Standby mode is a power saving feature that can be used for non-operational transmitters. When in

standby mode, most of the transmitter's circuits are inactive, the LCD is blanked, and the transmitter

cannot be keyed. To put the transmitter into standby mode, use the following procedure.

When the transmitter is in Standby mode, the red front panel Standby indicator is lit.

To Enter Standby Mode

To Exit Standby Mode

T e s t S t a t u s

P A S S

O K

T e s t S t a t u s

F A I L

O K

E n t e r S t a n d b y ?

Y e s N o

(1) From the Control screen select

Standby.

(2) At the Standby screen, select Yes.

(3) Check that the display blanks and

the front panel Standby indicator is

lit.

E x i t S t a n d b y ?

Y e s N o

(1) Press the Switch.

(2) Select Yes.

(3) Check that the Main screen is

displayed and that the front panel

Standby indicator is unlit.

T6T VHF 100 W Transmitter Page 15 Operation

Back to Transmitter

Main Page

Settings

Operational settings for the T6T 100 W VHF transmitter are configured at the front panel, through the

VFP, and through an associated MARC system (or compatible control system). Some settings can also

be made remotely via a T6 controller. The Settings screen is entered from the Control screen.

The settings that can be selected at the front panel Settings screen are:

❑Mode - either AM-Voice, AM-MSK, Mode 2 or Mode 3

❑Mode settings - allows the selected mode parameters to be set

❑Polarities

❑Band edges

❑Backlight

❑Reference frequency.

Note that the mode selection, reference frequency and backlight are set from this screen. When mode

settings, polarities and band edges are selected the user is taken to other screens.

General and mode specific settings, showing default values, are referenced in Table 5 on the following

page. Click on any required parameter by page number for further references.

M o d e A M V o i c e

M o d e S e t t i n g s

P o l a r i t i e s

E x i t > >

B a n d E d g e s

R e f F r e q 5 0 . 0 %

B a c k l i g h t 0 3 0 s

E x i t < < > >

B a c k

E x i t

Select between AM-Voice, AM-MSK, Mode 2 or Mode 3.

Select to take you to the mode specific Settings menu.

Select to take you to the Polarities menu.

Set the transmitter’s frequency band edges.

Align the transmitter’s reference frequency (Note 1).

Adjust the LCD’s backlight time out (Note 2).

Notes:

1. Setting the transmitter reference frequency is a maintenance operation. The current value

should not be reset unless the correct test equipment is connected. See the Maintenance

section.

2. The LCD backlight can be set for permanently on, off, or timed to stay on for a period between

15 and 120 seconds.

T6T VHF 100 W Transmitter Page 16 Operation

Back to Transmitter

Main Page

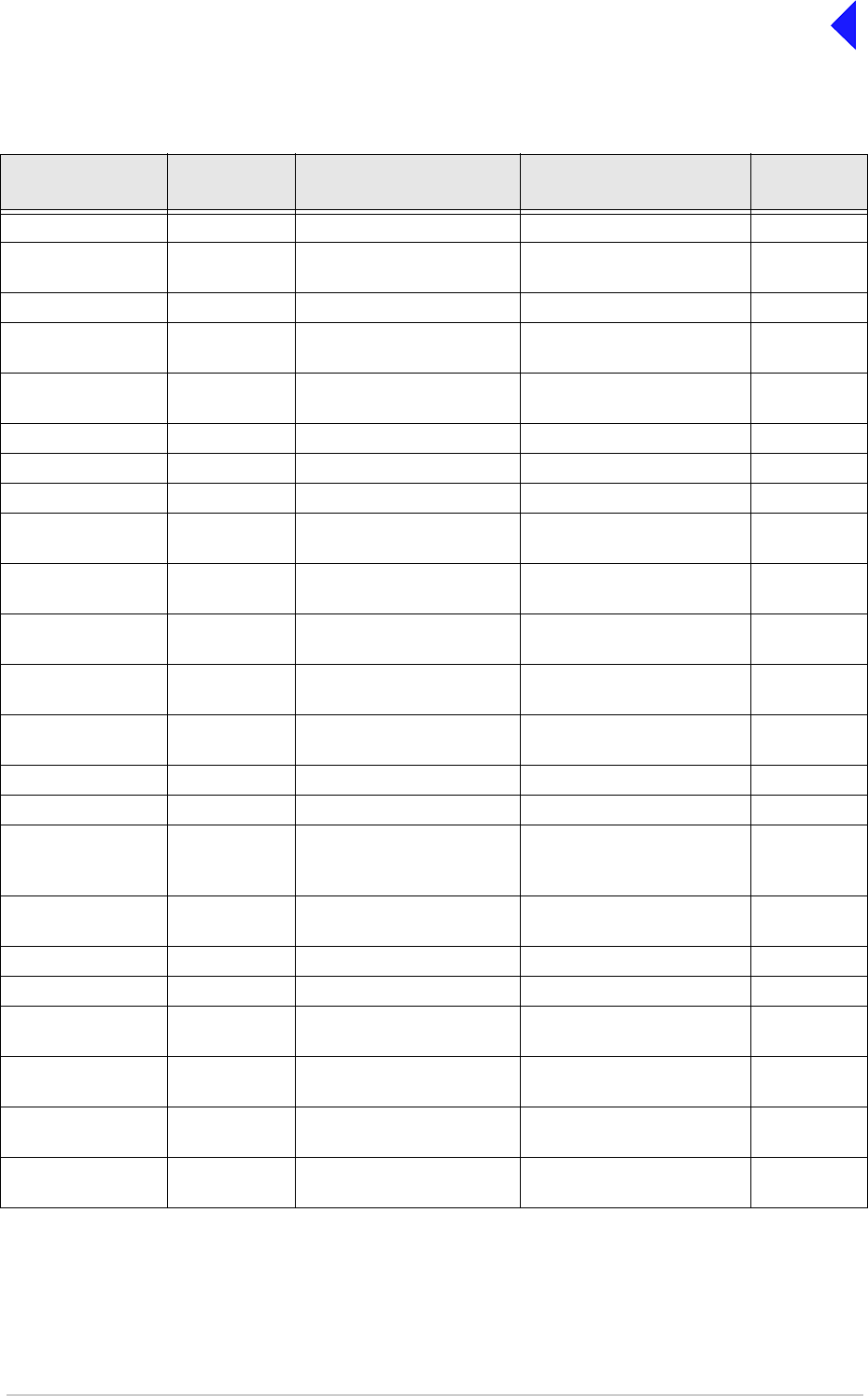

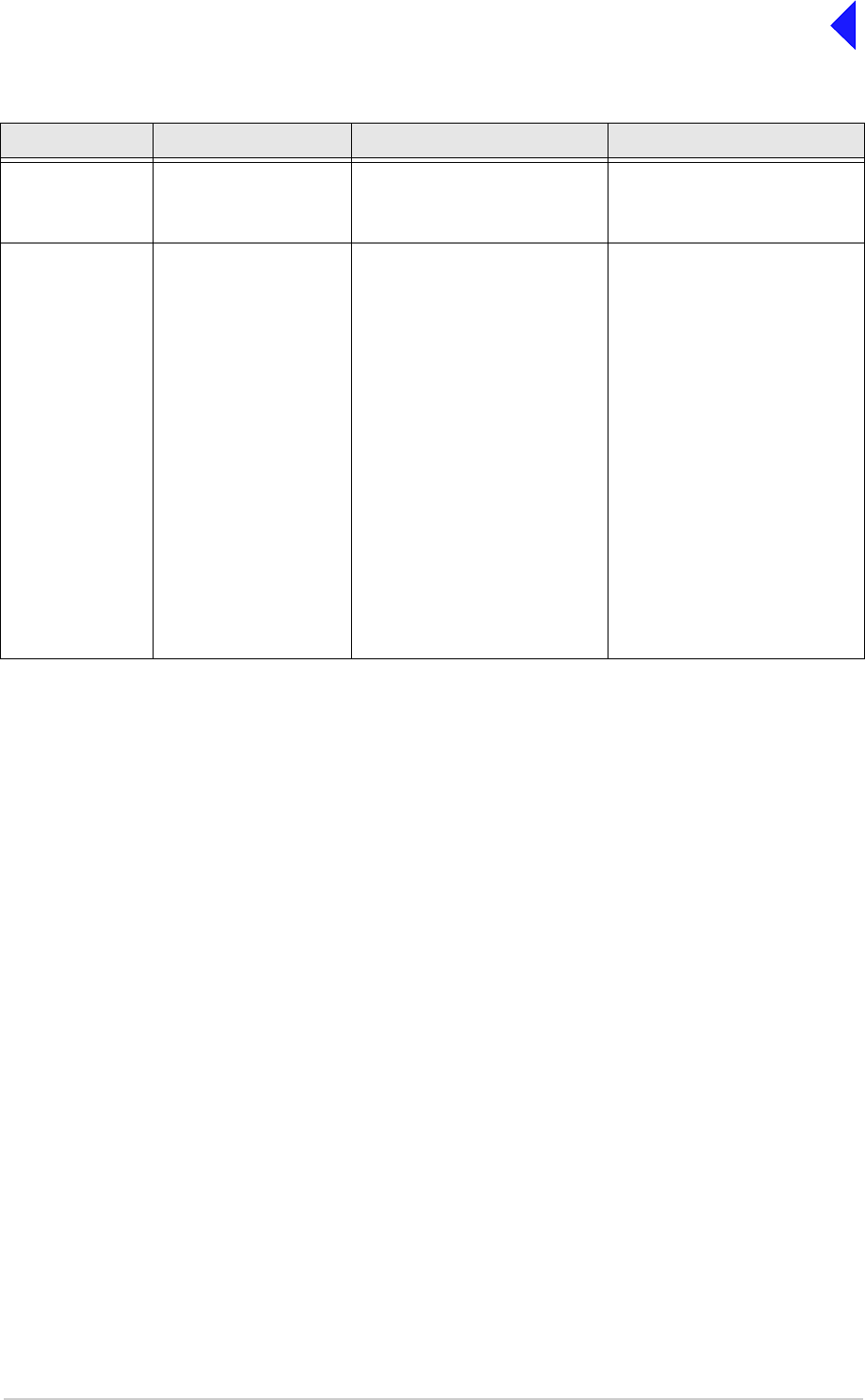

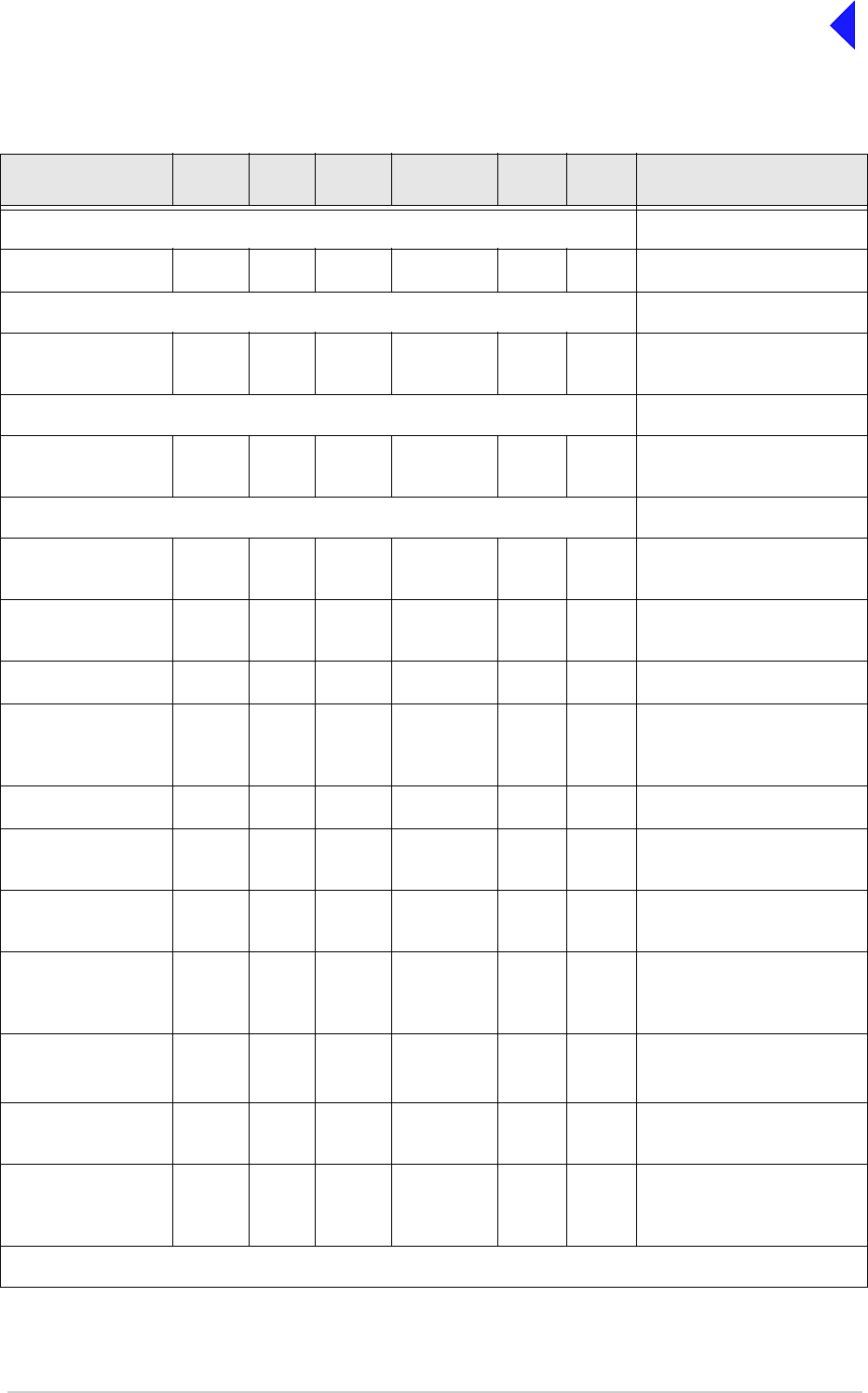

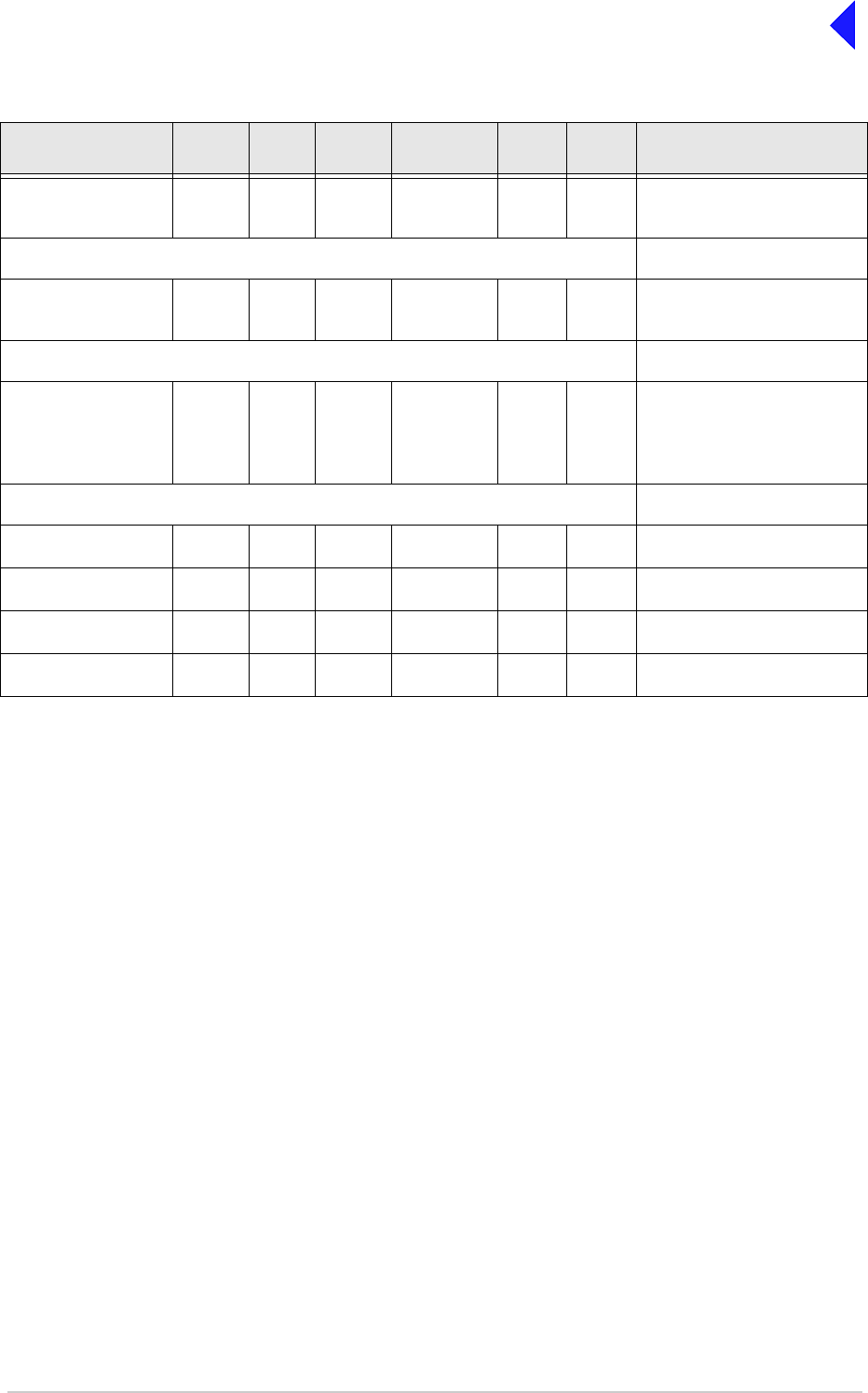

Table 5 Operational Settings from the Front Panel

Parameter Mode Adjustment Range Factory Default Setting Further

Reference

Menu lock screen All Locked or unlocked Unlocked page 8

Enter standby

mode All Yes or No - page 14

Exit standby mode All Yes or No - page 14

Set mode of

operation All AM-Voice, AM-MSK, Mode

2 or Mode 3 AM-Voice page 15

Set polarities AM-Voice,

AM-MSK STD or INV STD page 21

Band edges All 118.000 to 136.975 MHz 118.000 and 136.975 MHz page 29

LCD backlight All 15 to 120 s, On or Off 30 s page 15

RF power All 10 to 100 W 100 W page 17

Audio line in level AM-Voice,

AM-MSK -30 to +10 dBm -13 dBm page 17 and

page 19

Inhibit AM-Voice,

AM-MSK On or Off Off page 17 and

page 19

PTT (key) AM-Voice,

AM-MSK On (key), Off (de-key) Off page 17 and

page 19

Tx time out AM-Voice,

AM-MSK 2 to 510 s or Off 180 s page 17 and

page 19

Modulation depth AM-Voice,

AM-MSK 5 to 95% 85% page 17 and

page 19

Mute AM-Voice On or Off On page 17

VOGAD AM-Voice On or Off On page 17

Antenna C/O delay AM-Voice

AM-MSK On or Off On

Off

page 17

page 19

Offset AM-Voice 0, ±2.5, ±4, ±5, ±7.3, ±7.5,

±8 kHz 0 (No offset) page 18

Step AM-Voice 8.33 kHz, 25 kHz or both 25 kHz page 18

Mic AM-Voice Active or Passive Passive page 18

Key priority AM-Voice,

AM-MSK Local-Remote or

Remote-Local Local-Remote page 18 and

page 19

Local PTT AM-Voice,

AM-MSK Enabled or Disabled Enabled page 18 and

page 19

Remote PTT AM-Voice,

AM-MSK Enabled or Disabled Enabled page 18 and

page 19

Remote phantom

PTT AM-Voice,

AM-MSK Enabled or Disabled Enabled page 18 and

page 19

T6T VHF 100 W Transmitter Page 17 Operation

Back to Transmitter

Main Page

AM-Voice Settings Procedure

During this procedure, the following parameters, applicable to AM-Voice operation, can be set:

❑RF power output

❑Audio line input level

❑Inhibit

❑PTT on (key) or off (de-key)

❑Transmitter time out

❑Modulation depth

❑Mute (on or off)

❑VOGAD (on or off)

❑Antenna c/o delay (on or off)

❑Offset

❑Step

❑Mic

❑Key priority (local or remote)

❑Enable or disable local PTT

❑Enable or disable remote PTT

❑Enable or disable remote phantom PTT.

AM-Voice Mode Settings Screen

The AM-Voice mode setting screen is accessed from the Settings screen. Use the Scroll/Select switch

to select the parameter, then enter the required setting(s).

P o w e r 1 0 0 W

L i n e I n - 1 3 d B m

I n h i b i t O F F

E x i t > >

P T T O F F

T X T i m e o u t 1 8 0 s

M o d D e p t h 8 5 %

E x i t < < > >

M u t e O N

V O G A D O N

A n t C / O D e l O N

E x i t < < > >

Adjustments

RF power between 10 W to 100 W.

Audio line in level between -30 to +10 dBm.

On or Off.

On (key), Off (de-key).

2 to 510 s.

5 to 95%.

On or Off.

On or Off.

On or Off.

T6T VHF 100 W Transmitter Page 18 Operation

Back to Transmitter

Main Page

O f f s e t 0 . 0 k H z

S t e p 2 5 k H z

M i c P A S S I V E

E x i t < < > >

K e y P r i o r i t y L - R

L o c a l P T T E N

R e m o t e P T T E N

E x i t < < > >

R e m P h a n P T T E N

B a c k

E x i t < <

Adjustments

0, ±2.5, ±4, ±5, ±7.3, ±7.5, ±8 kHz.

25 kHz, 8.33 kHz or both.

Active or Passive.

Local-remote or Remote-local.

Enabled or Disabled.

Enabled or Disabled.

Enabled or Disabled.

Return to Settings screen.

T6T VHF 100 W Transmitter Page 19 Operation

Back to Transmitter

Main Page

AM-MSK Mode Settings Procedure

During this procedure, the following parameters, applicable to AM-MSK operation, can be set:

❑RF power output

❑Audio line input level

❑Inhibit

❑PTT on (key) or off (de-key)

❑Transmitter time out

❑Modulation depth

❑Antenna c/o delay (on or off)

❑Key priority (local or remote)

❑Enable or disable local PTT

❑Enable or disable remote PTT

❑Enable or disable remote phantom PTT.

AM-MSK Mode Settings Screens

The AM-MSK mode setting screen is accessed from the Settings screen. Use the Scroll/Select switch to

select the parameter, then enter the required setting(s).

P o w e r 1 0 0 W

L i n e I n - 1 3 d B m

I n h i b i t O F F

E x i t > >

P T T O F F

T X T i m e o u t 1 8 0 s

M o d D e p t h 8 5 %

E x i t < < > >

A n t C / O D e l O N

K e y P r i o r i t y L - R

L o c a l P T T E N

E x i t < < > >

R e m o t e P T T E N

R e m P h a n P T T E N

B a c k

E x i t < <

Adjustments

RF power between 10 W to 100 W.

Audio line in level between -30 to +10 dBm.

On or Off.

On (key), Off (de-key).

2 to 510 s.

5 to 95%.

On or Off.

Local-remote or Remote-local.

Enabled or Disabled.

Enabled or Disabled.

Enabled or Disabled.

T6T VHF 100 W Transmitter Page 20 Operation

Back to Transmitter

Main Page

Mode 2 Settings Screen

This is an advisory screen. Pressing OK returns the user to the Main screen.

Mode 3 Settings Screen

This is an advisory screen. Pressing OK returns the user to the Main screen.

M o d e 2 p a r a m e t e r s

a r e s e t v i a t h e

H L D C i n t e r f a c e

O K

M o d e 3 p a r a m e t e r s

a r e s e t v i a t h e

T 1 / E 1 i n t e r f a c e

O K

T6T VHF 100 W Transmitter Page 21 Operation

Back to Transmitter

Main Page

Polarities Screens AM-Voice and AM-MSK

A number of remote indication and control signals can be hardwire connected to the transmitter. These

signals include a transmitter ready indication, a PTT control signal, a phantom PTT control signal, a PTT

out indication, a transmitter inhibit control signal, an E-BIT input, a BIT test initiation control signal, an

external VSWR fault indication and antenna C/O. The following paragraphs detail the signals applicable

to the operational mode of the transmitter.

The Polarities screen is accessed from the Settings screen.

AM-Voice and AM-MSK Polarity Settings

Each of ten polarity settings applicable to AM-Voice and AM-MSK can be set to the default STD

(standard) setting or INV (inverted).

The signal connections are shown in Table 6 along with the conditions when STD or INV is selected.

The settings for the PTT Reference voltage are also shown in Table 6.

R e a d y O u t S T D

E - B I T I n S T D

I n h i b i t I n S T D

E x i t > >

B I T S t a r t I n S T D

P T T R e f + 1 4 V

P T T I n S T D

E x i t > >

P h a n P T T I n S T D

P T T O u t S T D

F a s t P T T O u t S T D

E x i t < < > >

E x t V S W R I n S T D

A n t C / O O u t S T D

B a c k

E x i t < <

T6T VHF 100 W Transmitter Page 22 Operation

Back to Transmitter

Main Page

Table 6 AM-Voice and AM-MSK Polarity Settings

Signal Connector Polarity set to STD Polarity set to INV

Ready Out Facilities, pin 13 An open collector grounded

output when the radio is ready

to transmit and no BIT faults

are detected.

An open collector high

impedance output when the

radio is ready to transmit and

no BIT faults are detected.

E-BIT In Facilities, pin 2 TTL input. 0 V indicates an

external fault. TTL input. 5 V indicates an

external fault.

Inhibit In Facilities, pin 10 TTL input. 0 V inhibits

transmitter operation. TTL input. 5 V inhibits

transmitter operation.

BIT Start In Facilities, pin 11 TTL input. 0 V initiates an

interruptive BIT test. TTL input. 5 V initiates an

interruptive BIT test.

PTT In MARC, pin 4

MARC Audio, pin 6 Active when input differs from

reference by more than 10 V.

Inactive when input differs from

reference by less than 1 V.

Maximum input level ±60 V

with respect to reference. Input

will draw no more than 6 mA,

requires at least 1 mA to

operate.

Active when input differs from

reference by less than 1 V.

Inactive when input differs from

reference by more than 10 V.

Maximum input level ±60 V

with respect to reference. Input

will draw no more than 6 mA,

requires at least 1 mA to

operate.

Phantom PTT In

(Phan PTT In)

MARC or

MARC Audio, pin 2 Active when input differs from

reference by more than 10 V.

Inactive when input differs from

reference by less than 1 V.

Maximum input level ±60 V

with respect to reference. Input

will draw no more than 6 mA,

requires at least 1 mA to

operate.

Active when input differs from

reference by less than 1 V.

Inactive when input differs from

reference by more than 10 V.

Maximum input level +60 V

with respect to reference. Input

will draw no more than 6 mA,

requires at least 1 mA to

operate.

PTT Out Facilities, pin 3 Grounding solid state relay.

+60 to -60 V, ac or dc, 100 mA

max, n/o. Activated 20 ms

(±1 ms) before the start of the

power ramp up to allow for the

antenna relay to pull-in time.

Grounding solid state relay.

+60 to -60 V, ac or dc, 100 mA

max, n/c. Activated 20 ms

(±1 ms) before the start of the

power ramp up to allow for the

antenna relay to pull-in time

External VSWR

Input

(Ext VSWR In)

Facilities, pin 4 TTL input. 0 V active. TTL input. 5 V active.

Antenna

Changeover

(Ant c/o out)

Facilities, pin 5

(Common pin 6) Solid state relay. +60 to -60V,

ac or dc, 100 mA max, n/o.

Activated 35 ms (±1 ms) before

the start of the power ramp up

to allow for the antenna relay

pull-in time.

Solid state relay. +60 to -60V,

ac or dc, 100 mA max, n/c.

Activated 35 ms (±1 ms) before

the start of the power ramp up

to allow for the antenna relay

pull-in time.

Continued >>

T6T VHF 100 W Transmitter Page 23 Operation

Back to Transmitter

Main Page

Fast PTT Output

(antenna

change-over)

MARC Audio, pin 3 Open collector NPN transistor

grounding output, 200 mA max,

n/o.

Open collector NPN transistor

grounding output, 200 mA max,

n/c.

PTT Ref - PTT Ref can be set to +14 V,

0 V or -14 V. PTT. Maximum

input level ±60 V with respect

to PTT reference. Input will

draw no more than 6 mA, and

requires at least 1 mA to

operate.

When the input PTT signal and

the PTT reference differ by

more than 10 V the radio keys.

When the input PTT signal and

the PTT reference are within

1 V, the radio dekeys.

Other conditions are

indeterminable.

PTT Ref can be set to +14 V,

0 V or -14 V. PTT. Maximum

input level ±60 V with respect

to PTT reference. Input will

draw no more than 6 mA, and

requires at least 1 mA to

operate.

When the input PTT signal and

the PTT reference differ by

more than 10 V the radio

dekeys.

When the input PTT signal and

the PTT reference are within

1 V, the radio keys.

Other conditions are

indeterminable.

Table 6 AM-Voice and AM-MSK Polarity Settings (Continued)

Signal Connector Polarity set to STD Polarity set to INV

T6T VHF 100 W Transmitter Page 24 Operation

Back to Transmitter

Main Page

Mode 2 and Mode 3 Polarity Settings

Table 7 Mode 2 and Mode 3 Polarity Settings

Signal Connector Polarity set to STD Polarity set to INV

Ready Out Facilities, pin 13 An open collector grounded

output when the radio is ready

to transmit and no BIT faults

are detected.

An open collector high

impedance output when the radio

is ready to transmit and no BIT

faults are detected.

E-BIT In Facilities, pin 2 TTL input. 0 V indicates an

external fault. TTL input. 5 V indicates an

external fault.

External VSWR

Input Facilities, pin 4 TTL input. 0 V active. TTL input. 5 V active.

R e a d y O u t S T D

E - B I T I n S T D

E x t V S W R I n S T D

E x i t > >

B a c k

E x i t

< <

Each of the three polarity settings applicable to

Mode 2 and Mode 3 can be set to the default STD

(standard) setting or INV (inverted).

The signal connections are detailed in Table 7

along with the conditions when STD or INV is

selected.

T6T VHF 100 W Transmitter Page 25 Operation

Back to Transmitter

Main Page

AM-Voice and AM-MSK BIT Screen

The AM-Voice and AM-MSK BIT screen is accessed from the Control screen.

B I T I n i t i a t e

E T I 0 0 0 0 0 : 0 0 h r s

A C S u p p l y O N

E x i t > >

D C S u p p l y O N

S u p p l y 2 8 V

S y n t h L o c k P A S S

E x i t < < > >

P A T e m p 5 0 d e g C

P A C o o l i n g P A S S

B a s e b a n d P A S S

E x i t < < > >

R F D r i v e P A S S

P A O u t p u t P A S S

P A L o o p P A S S

E x i t < < > >

M o d D e p t h P A S S

R F F i l t e r s P A S S

V S W R P A S S

E x i t < < > >

L o o p E r r o r P A S S

A u d i o I n P A S S

D S P 1 P A S S

E x i t < < > >

Select to initiate BIT test.

Shows elapsed time 0:00 to 99999:59 (Hrs:Min).

Shows state of ac supply (On or Off).

PA temperature -20°C to +150°C.

Pass or Fail.

Pass, Fail or Not Tested.

Pass, Fail or Not Tested.

Pass, Fail or Not Tested.

Pass, Fail or Not Tested.

Shows state of dc supply (On or Off).

dc supply 0 to 40 V, <21.6 V Alert, <19 V Alarm.

Pass or Fail (Out-of-Lock).

Pass, Fail or Not Tested.

Pass, Fail or Not Tested.

Pass, Fail or Not Tested.

Pass or Fail.

Pass, Fail or Not Tested.

Pass or Fail.

T6T VHF 100 W Transmitter Page 26 Operation

Back to Transmitter

Main Page

D S P 2 P A S S

X i l i n x 1 P A S S

X i l i n x 2 P A S S

E x i t < < > >

E E P R O M P A S S

S t a r t U p P A S S

C a l i b r a t i o n P A S S

E x i t < < > >

U n k e y e d P w r P A S S

E - B I T P A S S

M A R C A C T I V E

E x i t < < > >

H D L C I N A C T I V E

T 1 / E 1 I N A C T I V E

B a c k

E x i t < <

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Active or Inactive.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Active or Inactive.

Active or Inactive.

T6T VHF 100 W Transmitter Page 27 Operation

Back to Transmitter

Main Page

Mode 2 and Mode 3 BIT Screen

The Mode 2 and Mode 3 BIT screen is accessed from the Control screen.

E T I 0 0 0 0 0 : 0 0 h r s

A C S u p p l y O N

D C S u p p l y O N

E x i t > >

S u p p l y 2 8 V

S y n t h L o c k P A S S

P A T e m p 5 0 d e g C

E x i t < < > >

P A C o o l i n g P A S S

V S W R P A S S

L o o p E r r o r P A S S

E x i t < < > >

D S P 1 P A S S

D S P 2 P A S S

X i l i n x 1 P A S S

E x i t < < > >

X i l i n x 2 P A S S

E E P R O M P A S S

S t a r t U p P A S S

E x i t < < > >

C a l i b r a t i o n P A S S

E - B I T P A S S

M A R C A C T I V E

E x i t < < > >

Shows elapsed time 0:00 to 99999:59 (Hrs:Min).

Shows state of ac supply (On or Off).

Shows state of dc supply (On or Off).

Shows value of dc supply.

Synth lock (Pass or Fail).

Indicates the PA temperature.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass, Fail or Not Tested.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Active or Inactive.

H D L C I N A C T I V E

T 1 / E 1 I N A C T I V E

B a c k

E x i t < <

Active or Inactive.

Active or Inactive.

T6T VHF 100 W Transmitter Page 28 Operation

Back to Transmitter

Main Page

Software Configuration Screens

Software configuration screens are as follows:

T 6 V H F 1 0 0 W T X

1 1 8 - 1 3 6 . 9 7 5 M H z

H i g h S t a b i l i t y

E x i t > >

B o o t S o f t w a r e

6 5 - x x x x x x x x / v v

E x i t < < > >

B a s e S o f t w a r e

6 5 - x x x x x x x x / v v

E x i t < < > >

M o d e S o f t w a r e

6 5 - x x x x x x x x / v v

E x i t < < > >

F i l l 1 S o f t w a r e

6 5 - x x x x x x x x / v v

[ D e s c r i p t i o n ]

E x i t < < > >

F i l l 2 S o f t w a r e

6 5 - x x x x x x x x / v v

[ D e s c r i p t i o n ]

E x i t < < > >

The first screen defines the radio.

65-xxxxxxxx represents the software part

number and /v v represents its version.

65-xxxxxxxx represents the software part

number and /v v represents its version.

Current mode running. 65-xxxxxxxx

represents the software part number and /v v

represents its version.

65-xxxxxxxx represents the software part

number and /v v represents its version.

65-xxxxxxxx represents the software part

number and /v v represents its version.

T6T VHF 100 W Transmitter Page 29 Operation

Back to Transmitter

Main Page

F i l l 3 S o f t w a r e

6 5 - x x x x x x x x / v v

[ D e s c r i p t i o n ]

F i l l 4 S o f t w a r e

6 5 - x x x x x x x x / v v

[ D e s c r i p t i o n ]

65-xxxxxxxx represents the software part number

and /v v represents its version.

65-xxxxxxxx represents the software part number

and /v v represents its version.

T6T VHF 100 W Transmitter Page 30 Operation

Back to Transmitter

Main Page

Band Edges

The frequency range of the T6 100 W transmitter is 118 to 136.975 MHz. If required, transmission can

be limited to either one or two smaller parts of the frequency band by setting the band edges, BE1 to

BE4. Transmission is possible between BE1 and BE2 frequencies, and between BE3 and BE4

frequencies.

Table 8 Band Edge Settings

BE1 BE2 BE3 BE4

B63100HS/NB set so that the full frequency range can be

transmitted. 118.000 136.975 118.000 136.975

Example: Transmitter set to transmit only those frequencies

in the range 120 to 130 MHz. 120.000 130.000 120.000 130.000

Example: Transmitter set to transmit only those frequencies

in the ranges 120 to 125 MHz and 130 to 135 MHz. 120.000 125.000 130.000 135.000

B E 1 1 1 8 . 0 0 0 M H z

B E 2 1 3 6 . 9 7 5 M H z

B E 3 1 1 8 . 0 0 0 M H z

E x i t > >

B E 4 1 3 6 . 9 7 5 M H z

E x i t < <

The Band Edge screen is accessed from the

Control screen.

Band edge frequencies can be set only in

increments of 25 kHz.

If the transmitter is required to operate over the

full range, the band edge parameters must be set

to the lowest and highest values in the range (see

Table 8).

T6T VHF 100 W Transmitter Page 31 Operation

Back to Transmitter

Main Page

BIT Status Warning Screens

The following shows some example BIT screens. These screens alternate with the Main screen when an

alert or alarm condition is present. Only the parameters causing the alert or alarm are displayed, and if

both an alert and alarm condition exists simultaneously only the alarm information is displayed. If multiple

parameters are signalling an alert or alarm condition, multiple screens are used to display the status

alternating with the Main screen.

A L E R T

S u p p l y 2 1 V

A L E R T

R F P o w e r R e d u c e d

L o o p E r r o r

S u p p l y 2 1 V

A L E R T

R F P o w e r R e d u c e d

P A T e m p 8 5 d e g C

A L A R M

R F P o w e r R e d u c e d

V S W R F A I L

A L A R M

R F P o w e r R e m o v e d

L o o p E r r o r F A I L

S u p p l y 1 8 V

A L A R M

R F P o w e r R e m o v e d

P A T e m p 9 5 d e g C

Alert:

There is no RF power reduction. The Alarm

indicator is flashing.

Alert:

The RF output power is reduced between 1 and

3 dB. The Alarm indicator is flashing.

Alert:

The RF output power is reduced between 1 and

3 dB. The Alarm indicator flashing

Alarm:

The RF output power reduced by more than 3

dB. The Alarm indicator is lit.

Alarm:

The RF output power is shut down. The Alarm

indicator is lit.

Alarm:

The RF output power is shut down. The Alarm

indicator is lit.

T6T VHF 100 W Transmitter Page 32 Operation

Back to Transmitter

Main Page

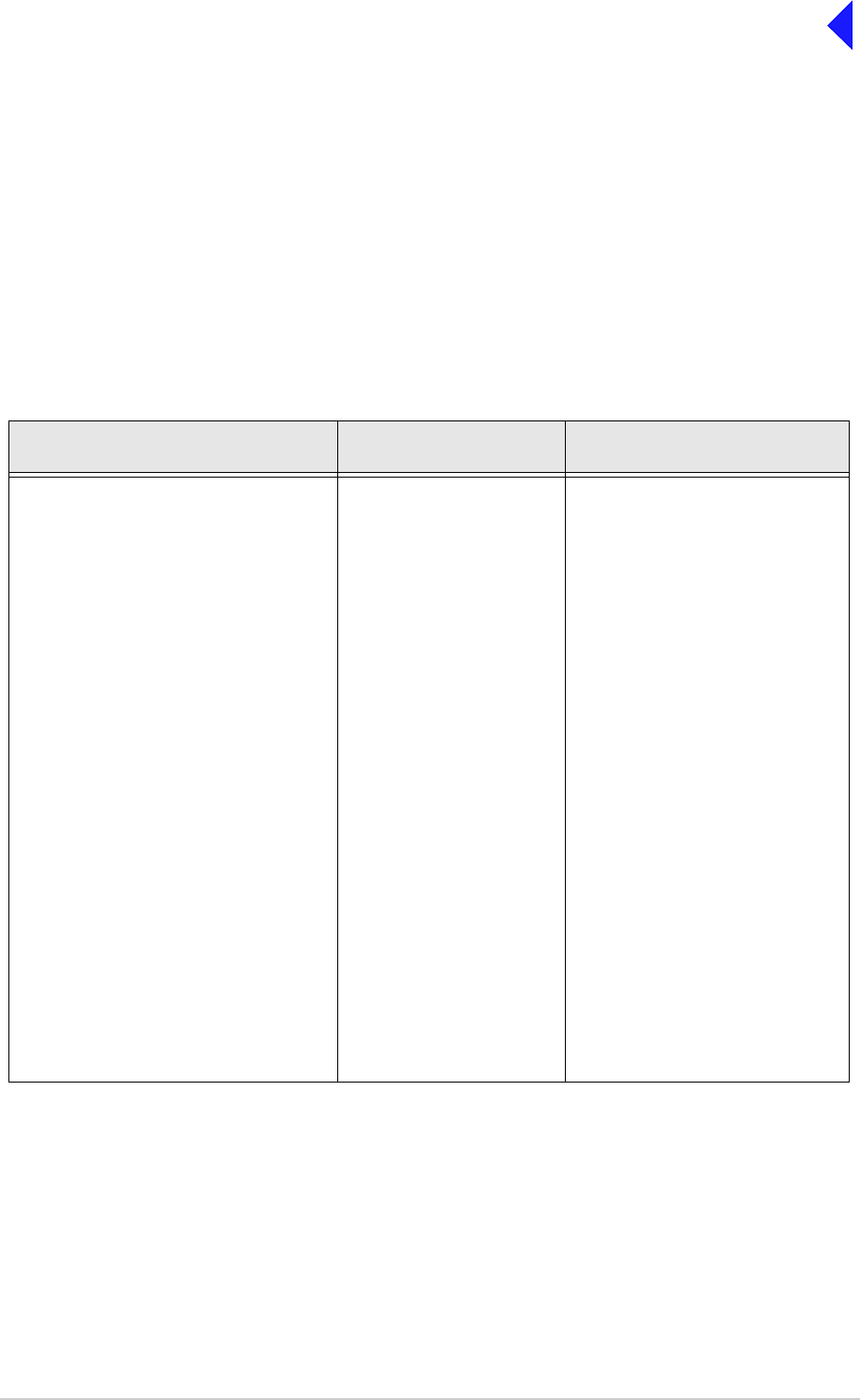

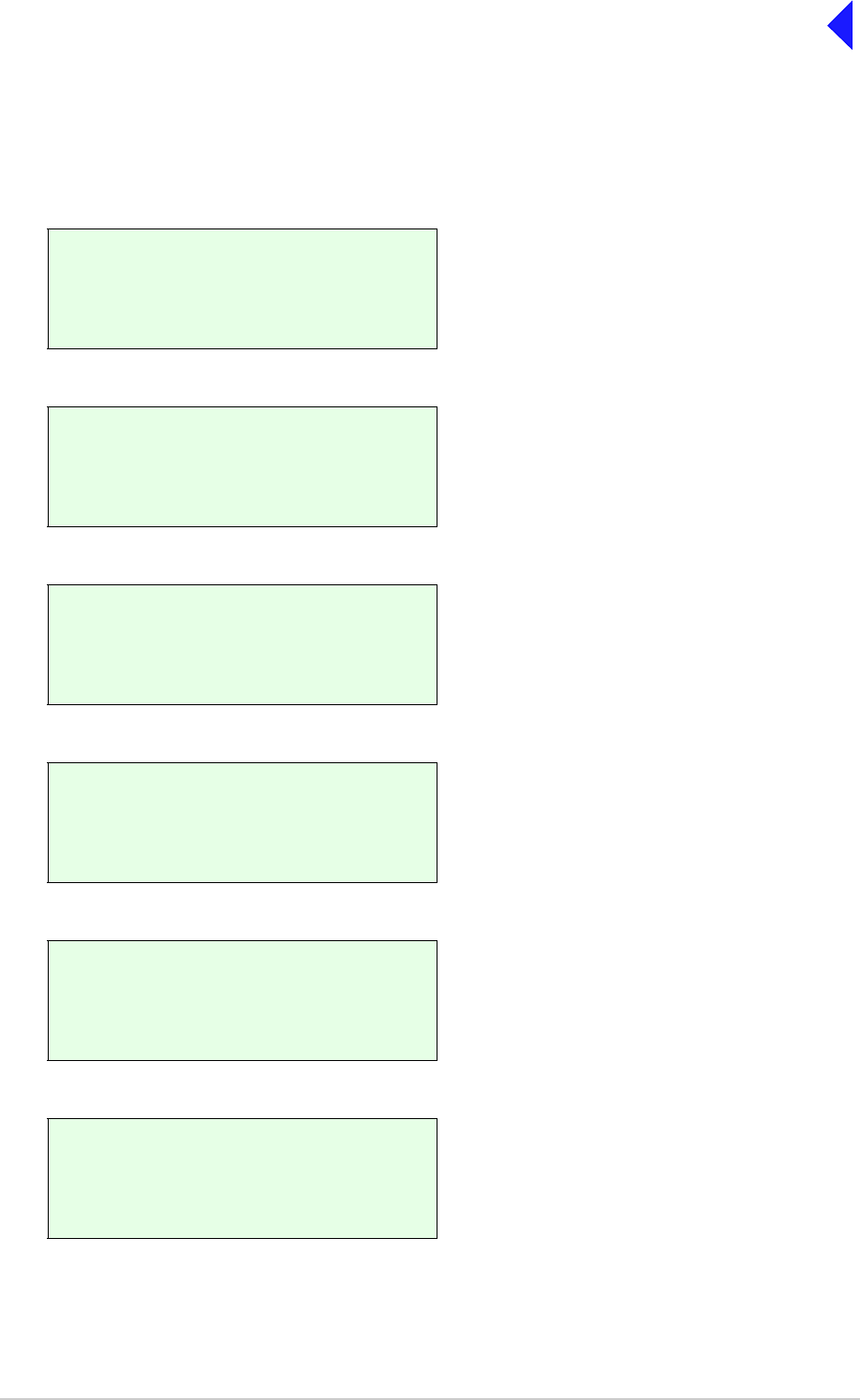

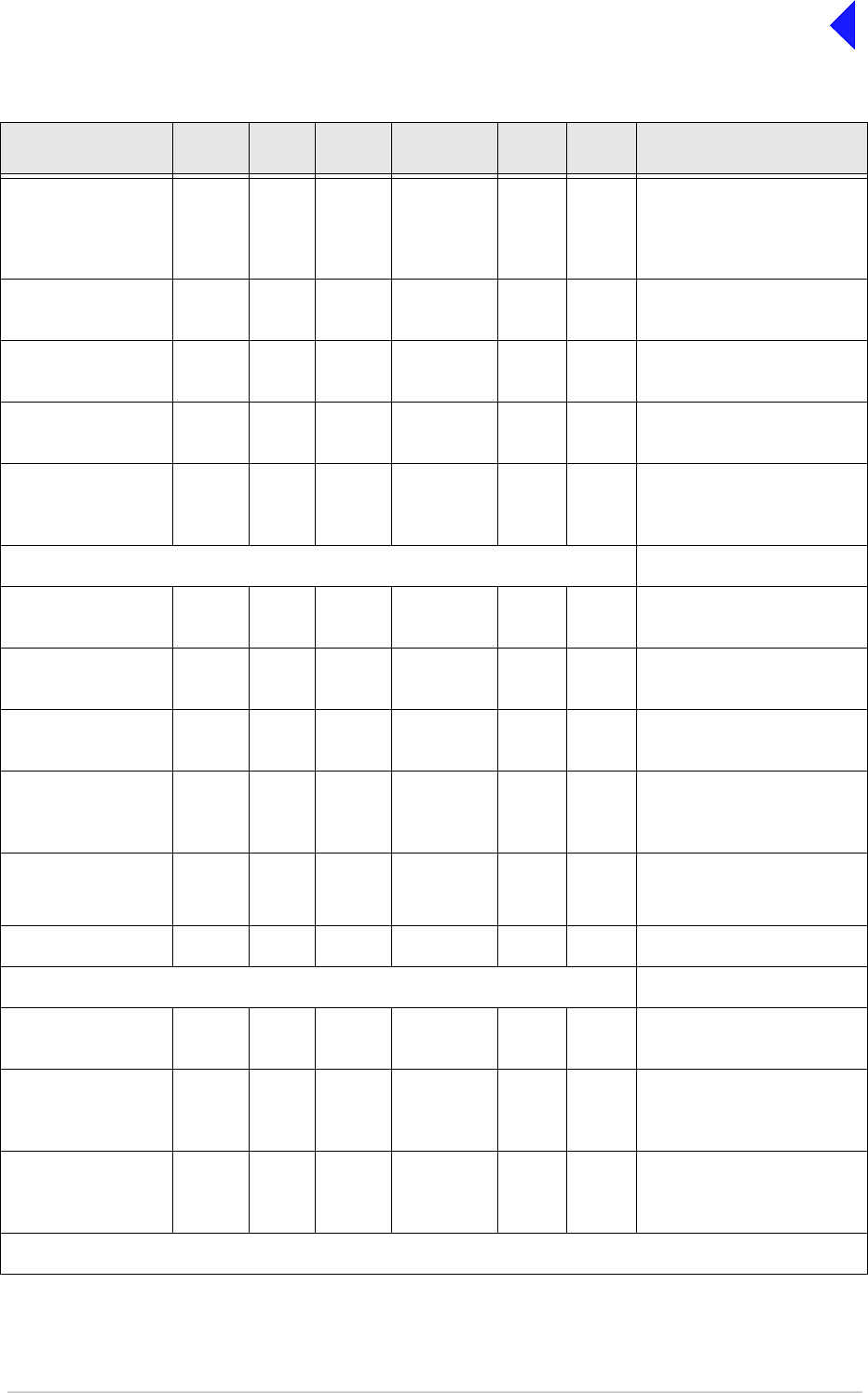

Table 9 Functions and Parameters

Function Front

Panel VFP MARC T6

Controller T1/E1 HDLC Default Setting

FREQUENCY

Change frequency 118.000 MHz

FREQUENCY CHANNELS

Store/Recall preset

frequency channels -

SETTINGS

Set modulation

mode AM-Voice

Radio Settings (AM Modes)

Set RF output

power 100 W

Set audio input line

level -13 dBm

Set inhibit on or off Off

PTT test facility

on (key), off (de-

key)

View

state Off

Set Tx time out 180 s

Set modulation

depth 85%

Set mute on or off

(AM-Voice only) On

Set VOGAD on

or off

(AM-Voice only)

On

Set antenna C/O

delay on or off AM-Voice - On

AM-MSK - Off

Set frequency offset

(AM-Voice only) 0 (No offset)

Set frequency step

size

(AM-Voice only)

25 kHz

Continued >>

T6T VHF 100 W Transmitter Page 33 Operation

Back to Transmitter

Main Page

Set microphone

type

(active or passive)

(AM-Voice only)

Passive

Set keying priority

(local or remote) Local-Remote

Enable or disable

local PTT Enabled

Enable or disable

remote PTT Enabled

Enable or disable

remote phantom

PTT

Enabled

Radio Settings (Digital Modes)

MAC TM1 (inter

access delay) 2.5 ms

MAC TM2 (channel

busy) 60 s

MAC p

(persistance) 13/256

MAC M1 (maximum

number of access

attempts)

135

Scramble vector 4D4B

19787

Tx enable On

Polarities

Ready out

View

state STD

Set PTT input

polarity

(AM modes only)

View

state STD

Set phantom PTT

input polarity

(AM modes only)

View

state STD

Continued >>

Table 9 Functions and Parameters (Continued)

Function Front

Panel VFP MARC T6

Controller T1/E1 HDLC Default Setting

T6T VHF 100 W Transmitter Page 34 Operation

Back to Transmitter

Main Page

Set PTT reference

voltage

(AM modes only)

View

state +14 V

Set PTT output

polarity

(AM modes only)

View

state STD

Set fast PTT

antenna change-

over output polarity

(AM modes only)

View

state STD

Set antenna

change-over output

polarity

(AM modes only)

View

state STD

Set external VSWR

input polarity

(All modes)

View

state STD

Set inhibit input

polarity

(AM modes only)

View

state STD

BIT interruptive test

input polarity

(AM modes only)

View

state STD (active low)

E-bit input polarity

(All modes)

View

state STD (active low)

Band Edges

Set band edges

118.000 and 136.975 MHz

Reference Frequency

Adjust transmitter’s

reference frequency -

LCD Backlight

Adjust LCD

backlight 30 s

Continued >>

BIT

Table 9 Functions and Parameters (Continued)

Function Front

Panel VFP MARC T6

Controller T1/E1 HDLC Default Setting

T6T VHF 100 W Transmitter Page 35 Operation

Back to Transmitter

Main Page

Initiate BIT

interruptive test -

STANDBY

Enter and exit

standby facility Not in Standby

SOFTWARE CONFIGURATION

View the

transmitter’s

software

configuration

-

LOCK FACILITIES

Front panel lock Off

MARC lock Off

T1/E1 lock Off

HDLC lock Off

Table 9 Functions and Parameters (Continued)

Function Front

Panel VFP MARC T6

Controller T1/E1 HDLC Default Setting

Back to Transmitter

Main Page

Intentionally Blank

Back to Transmitter

Main Page

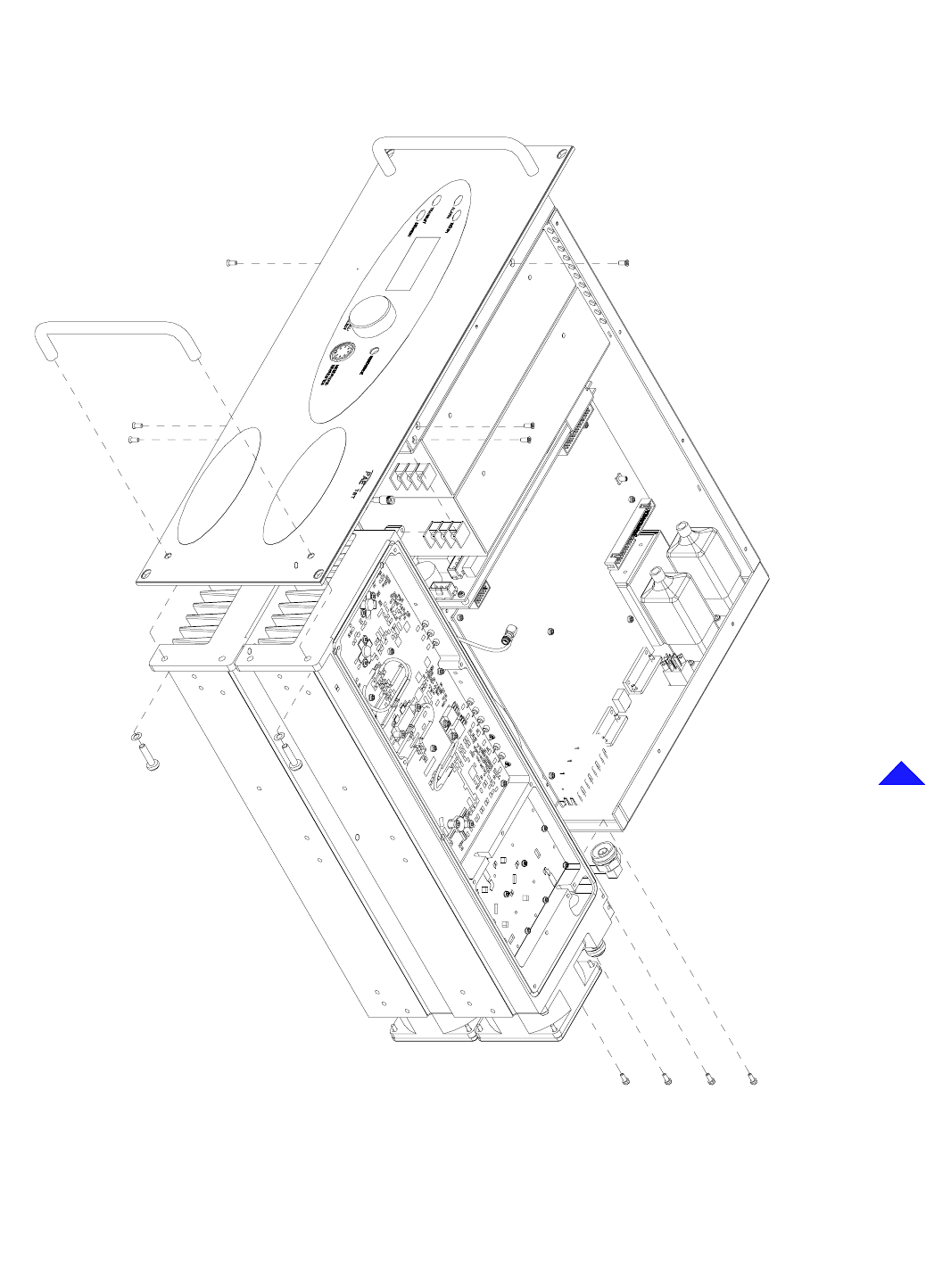

Installation

This topic gives the information required to install a T6T VHF 100 W Multimode Transmitter.

T6T VHF 100 W Transmitter Page 2 Installation

Back to Transmitter

Main Page

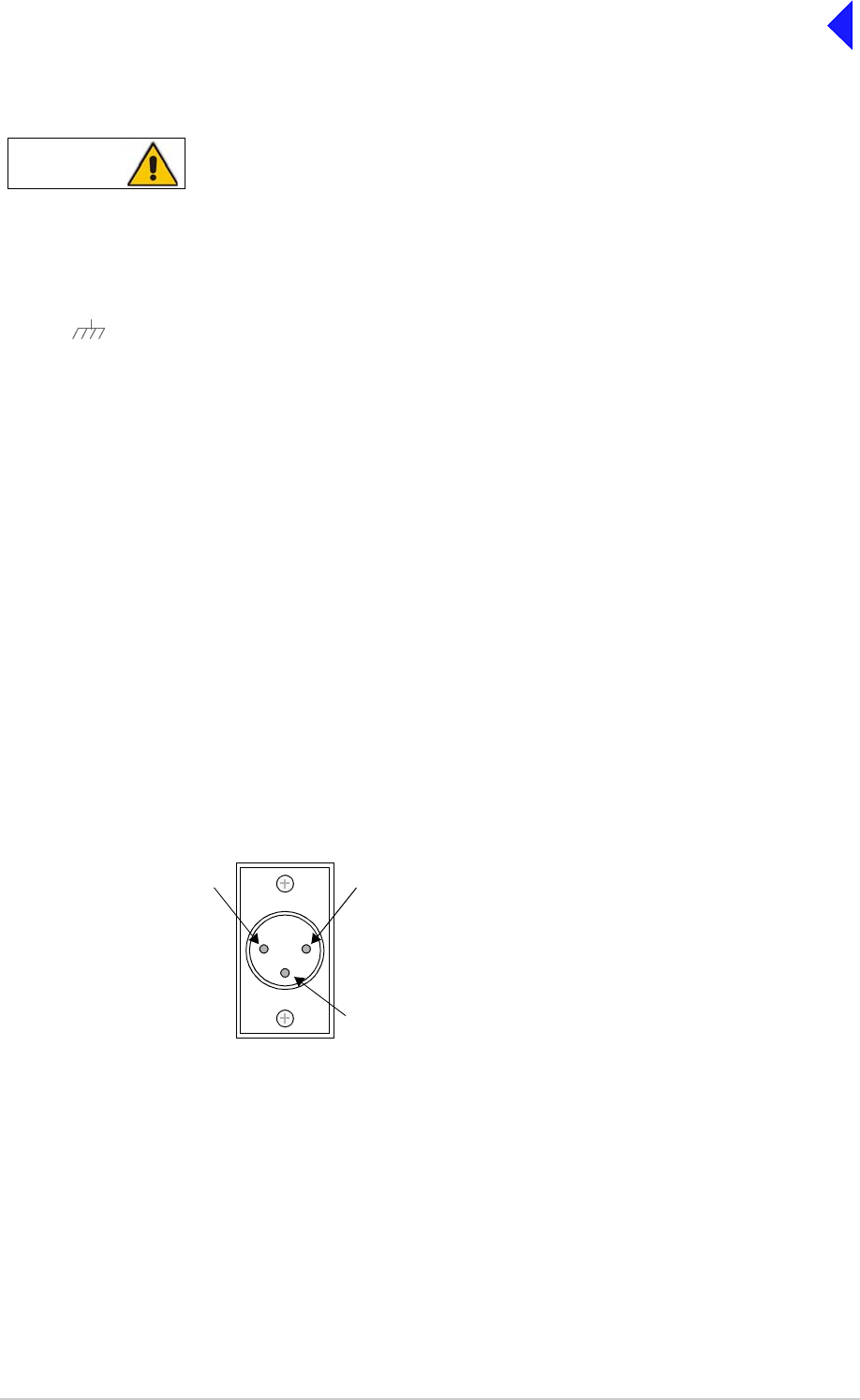

Warnings and Cautions

The instructions given in this topic involve connecting dangerous voltages to the transmitter

and should be carried out only by suitably qualified personnel.

The equipment is permanently connected to the mains supply when the mains connector is

attached. Switching the rear panel Power switch to off does not isolate all internal circuits

from the mains supply. For this reason, a mains isolating switch should be fitted close to,

and easily accessible from, the transmitter's position. The isolation switch should isolate

both live and neutral supplies, be clearly labelled, and adequately rated to protect the

equipment.

The antenna used with the transmitter must be installed such that the resultant radiated field

strength is below 10 W/m² in areas normally accessible to personnel.

The T6T transmitter's circuitry contains Electrostatic Sensitive Devices (ESSDs). Personnel

must be aware of the precautions necessary to prevent damage to such devices. During

installation all precautions necessary to prevent ESSD damage must be taken.

Changes or modifications made to this equipment that are not expressly approved by

Park Air, or parties authorized by Park Air, could void the user’s authority to operate the

equipment.

WARNING Dangerous Voltages

WARNING Dangerous Voltages

WARNING Antenna Radiation

Caution ESSDs

Caution Unauthorized Modifications

T6T VHF 100 W Transmitter Page 3 Installation

Back to Transmitter

Main Page

Introduction

The procedures necessary to install a transmitter are listed in Table 1.

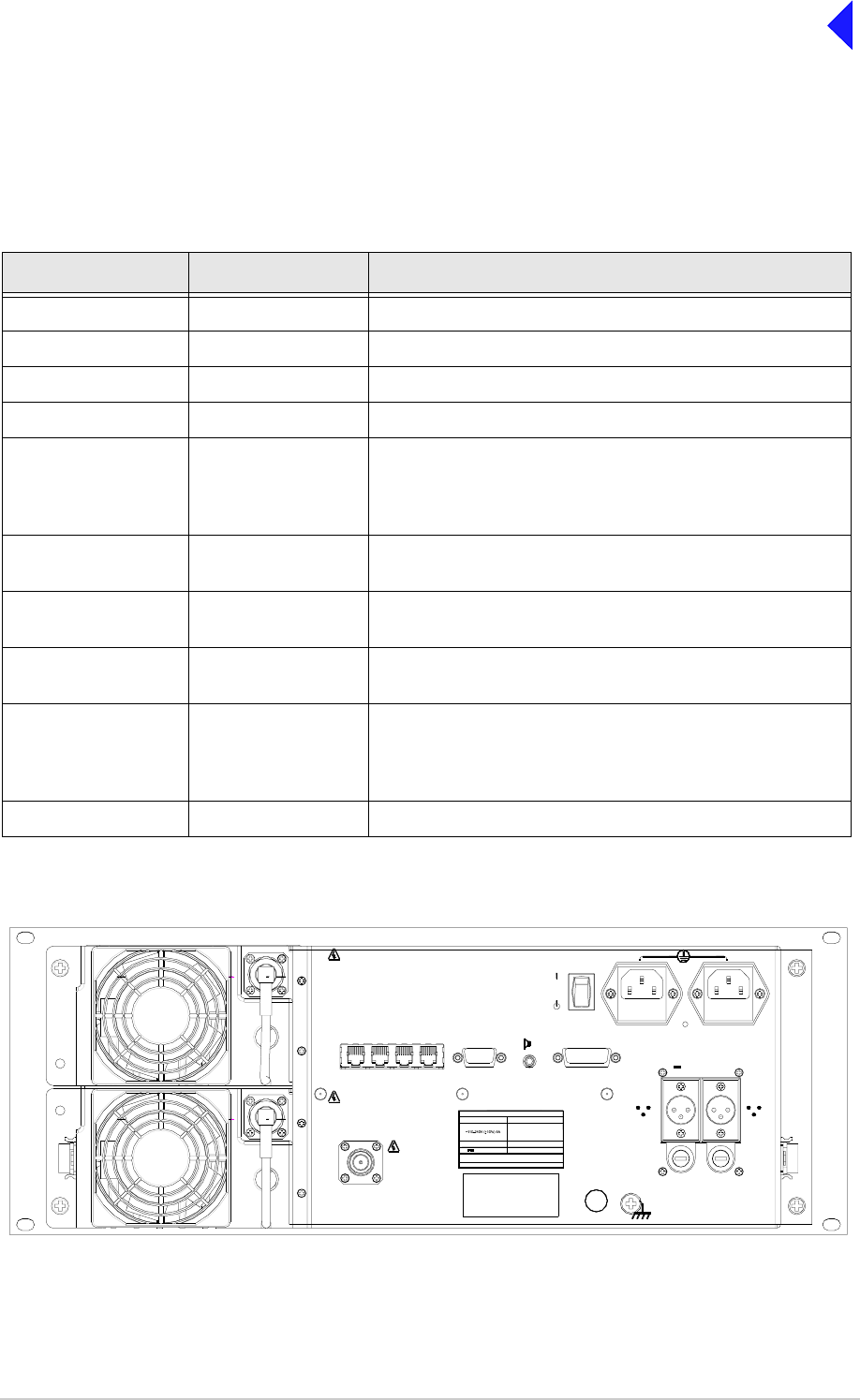

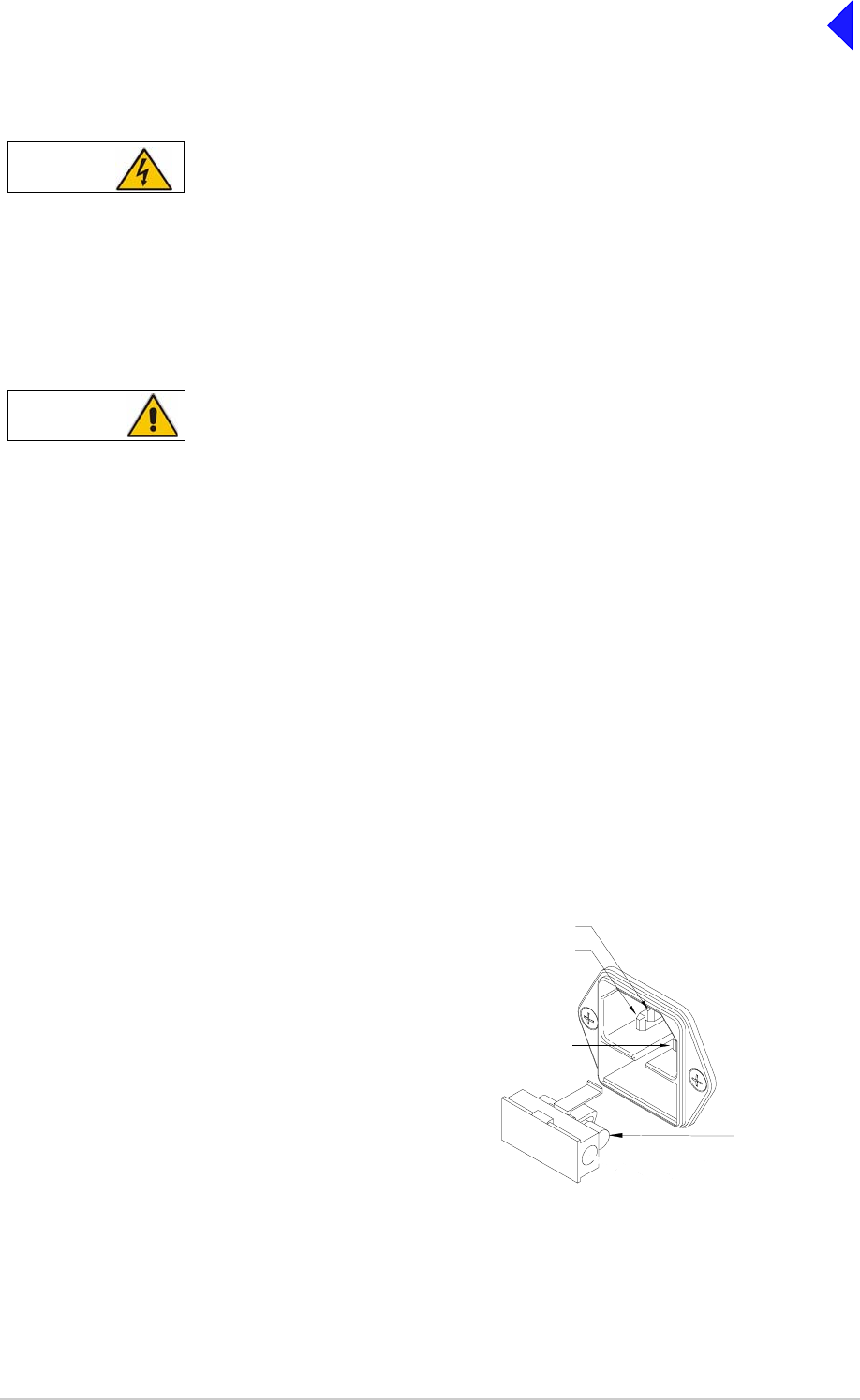

Fuses and Connectors

The following list details the radio’s supply fuses and connectors. Some of the connectors (depending on

your particular configuration) are required during installation.

Table 1 Installation Procedures

Procedure Reference

1 Read and understand the warnings and cautions given on page 2.

2 Perform an initial inspection of the transmitter and fit the correct ac input fuse. page 9

3 Fit the transmitter into an equipment cabinet. page 9

4 Make external signal connections. See Fig 1 to Fig 5 to determine which

external connections are required for the particular configuration. page 10

5 Connect the chassis stud to the cabinet or system earth. page 22

6 Connect the antenna. page 22

7 Connect the dc input supply (if required). page 22

8 Connect the ac input supply (if required). page 23

Table 2 Fuses and Connectors

Component Type Park Air Part Number

Fuses:

AC input fuses, F3, F4 for 110/120 V input

AC input fuses, F3, F4 for 220/230 V input T4A, 125V, UL

T4A, 250V, IEC 29C11120102S

29E01120108S

DC input fuses, F1, F2 15A size 0 29-01350201

Connectors:

AC supply connectors IEC 20-02030102

DC supply connectors XLR 3-pin 20-01030106

Antenna connector N-type plug 19-01030301

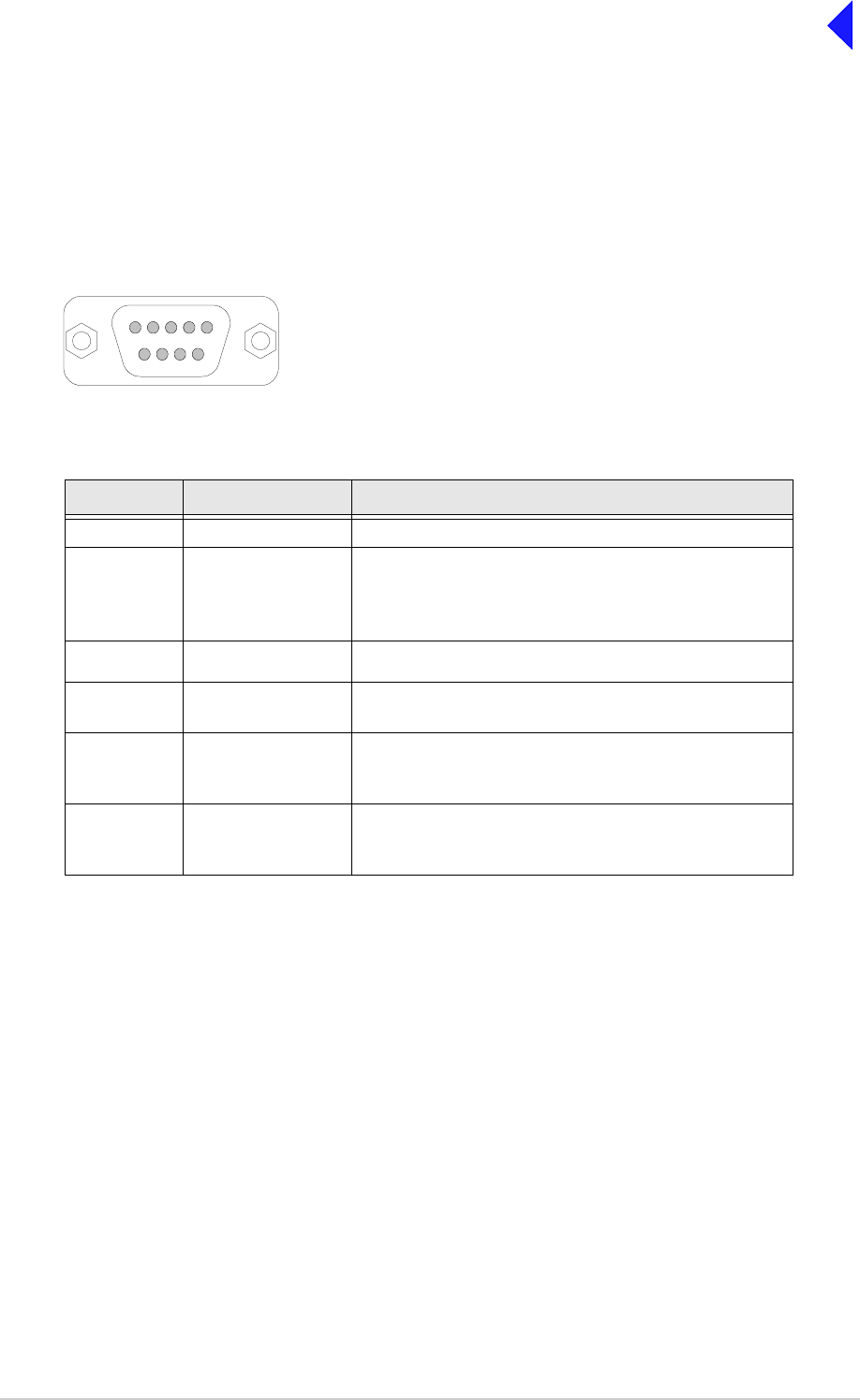

MARC connector 9-way D-type plug Plug: 20-01090100

Cover: 20-09090101

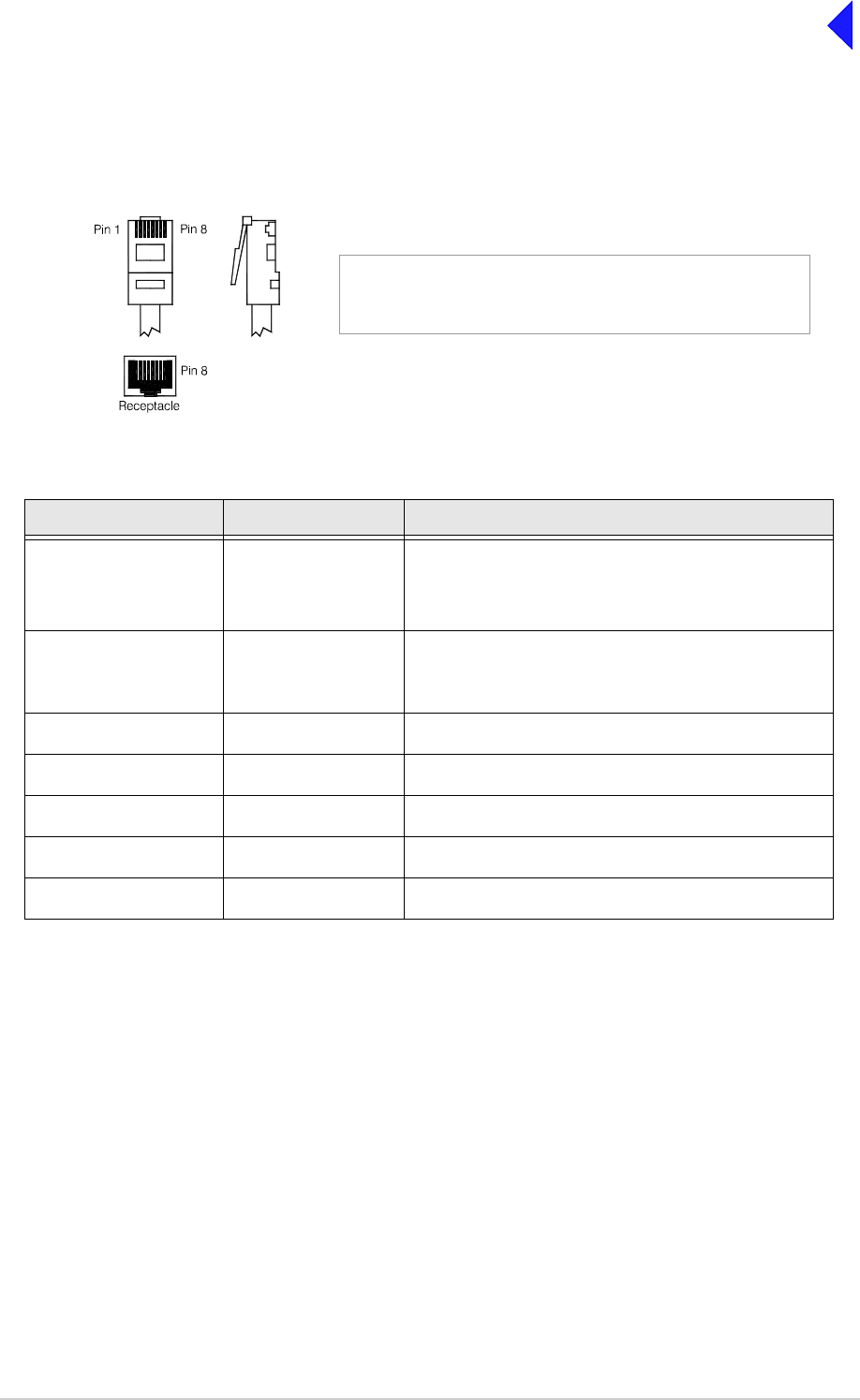

MARC audio RJ48 plug 20K01080100

MARC data RJ48 plug 20K01080100

Facilities connector 15-way D-type plug Plug: 20-01150100

Cover: 20-09150101

HDLC connector RJ48 plug 20K01080100

T1/E1 connector RJ48 plug 20K01080100

Reference connector SMB connector 19C01050300

Microphone/Diagnostics connector 7-pin DIN plug 20-01070101

T6T VHF 100 W Transmitter Page 4 Installation

Back to Transmitter

Main Page

Configuration

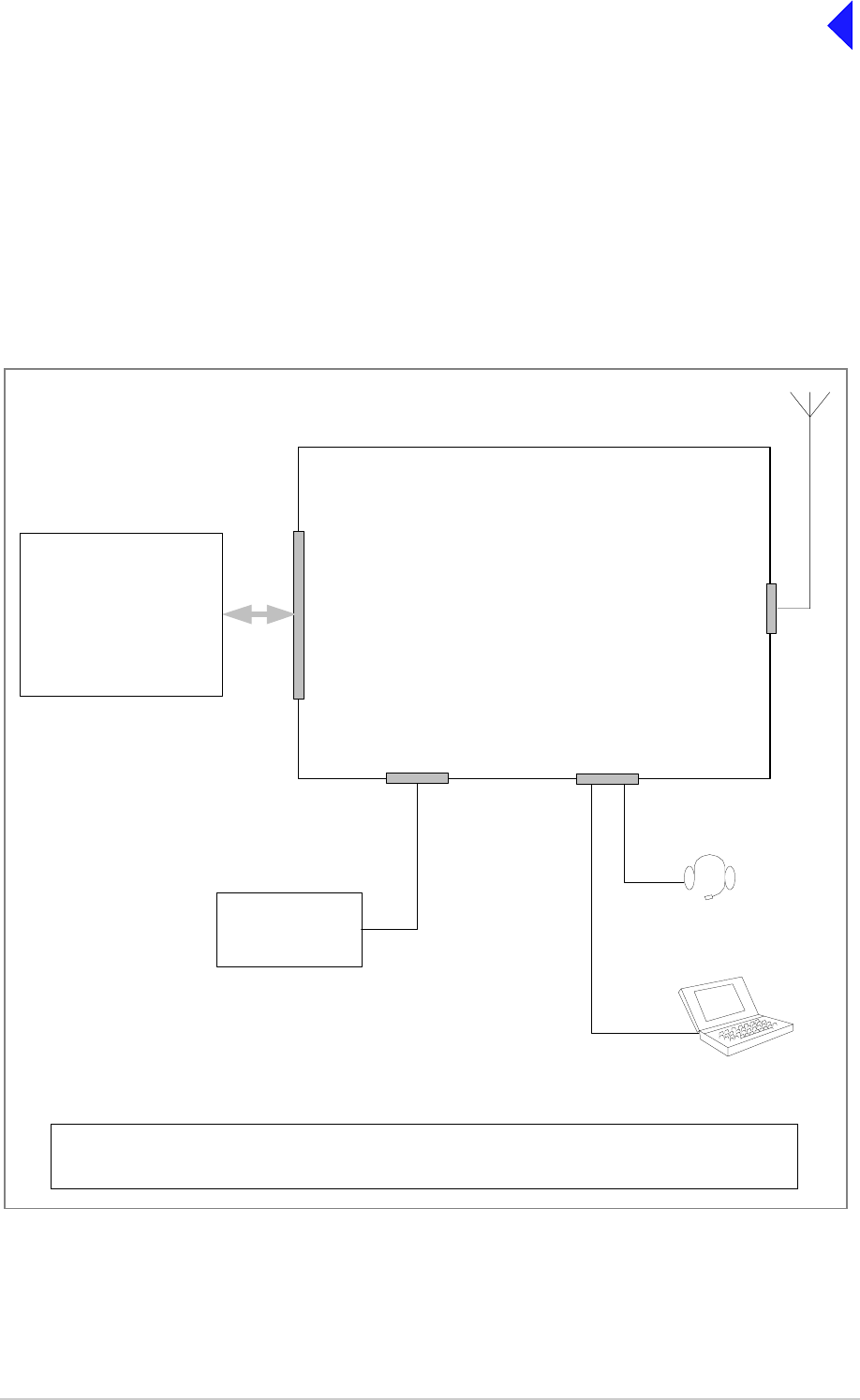

Connection of external equipment depends on the configuration required. Possible configurations are:

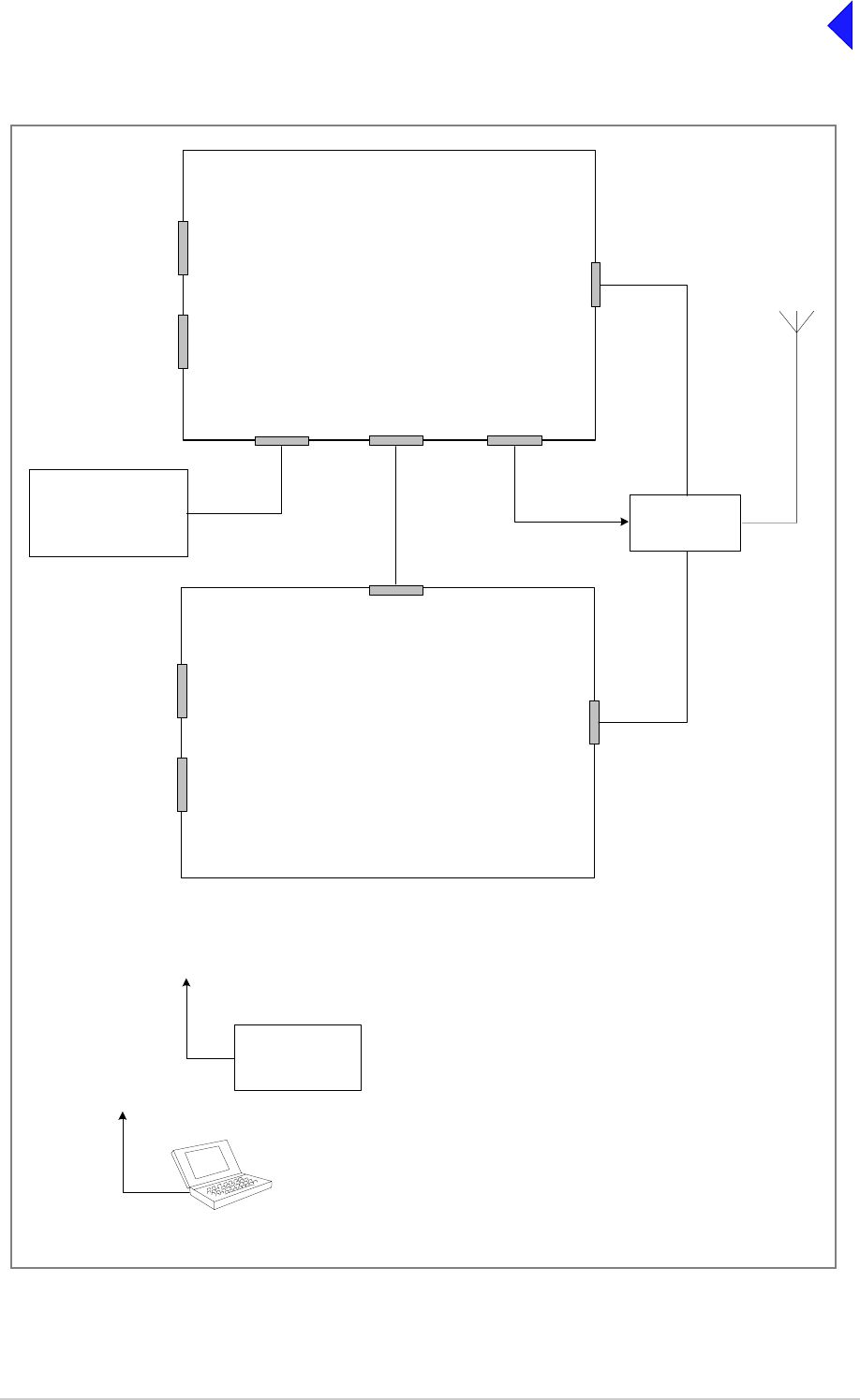

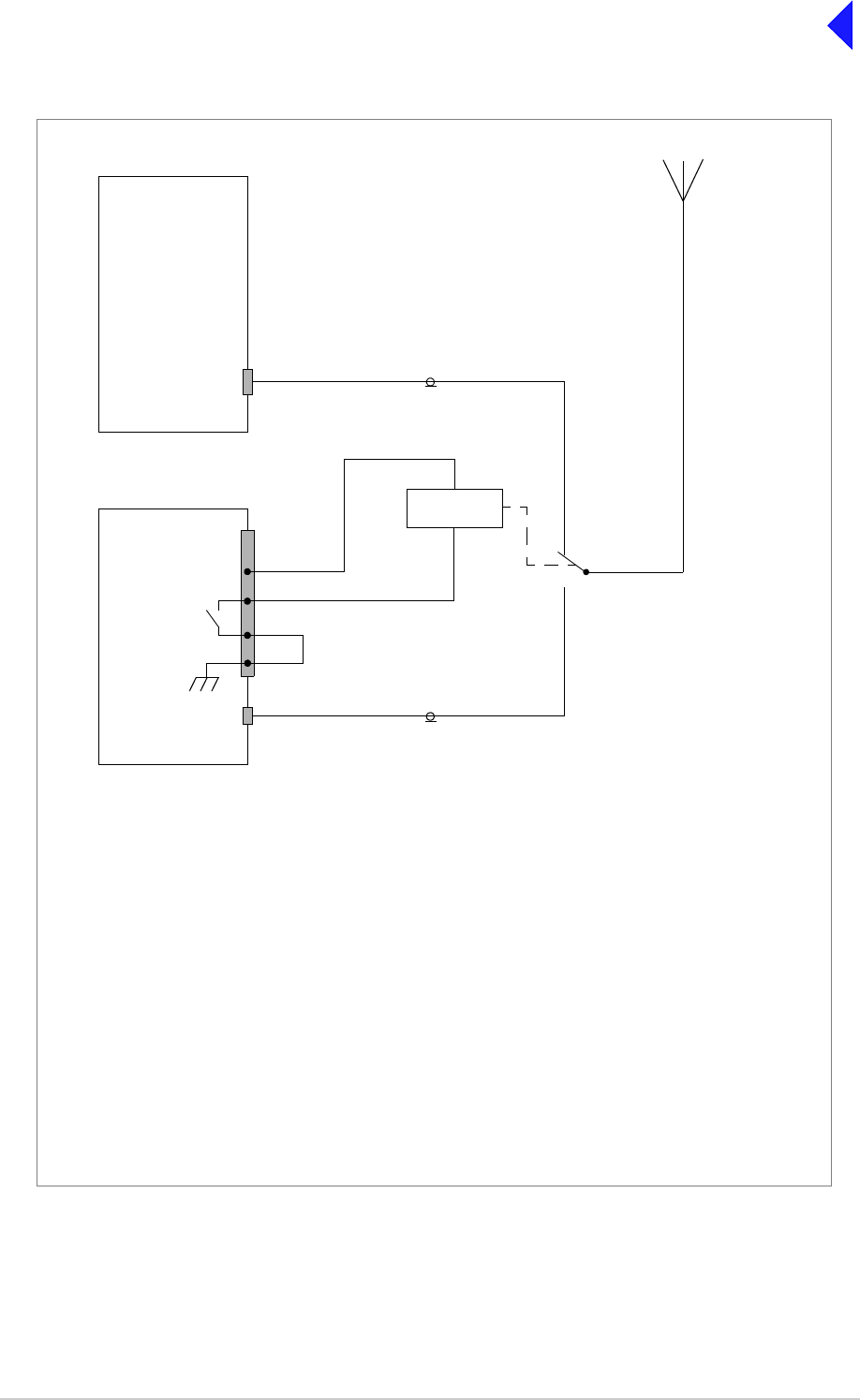

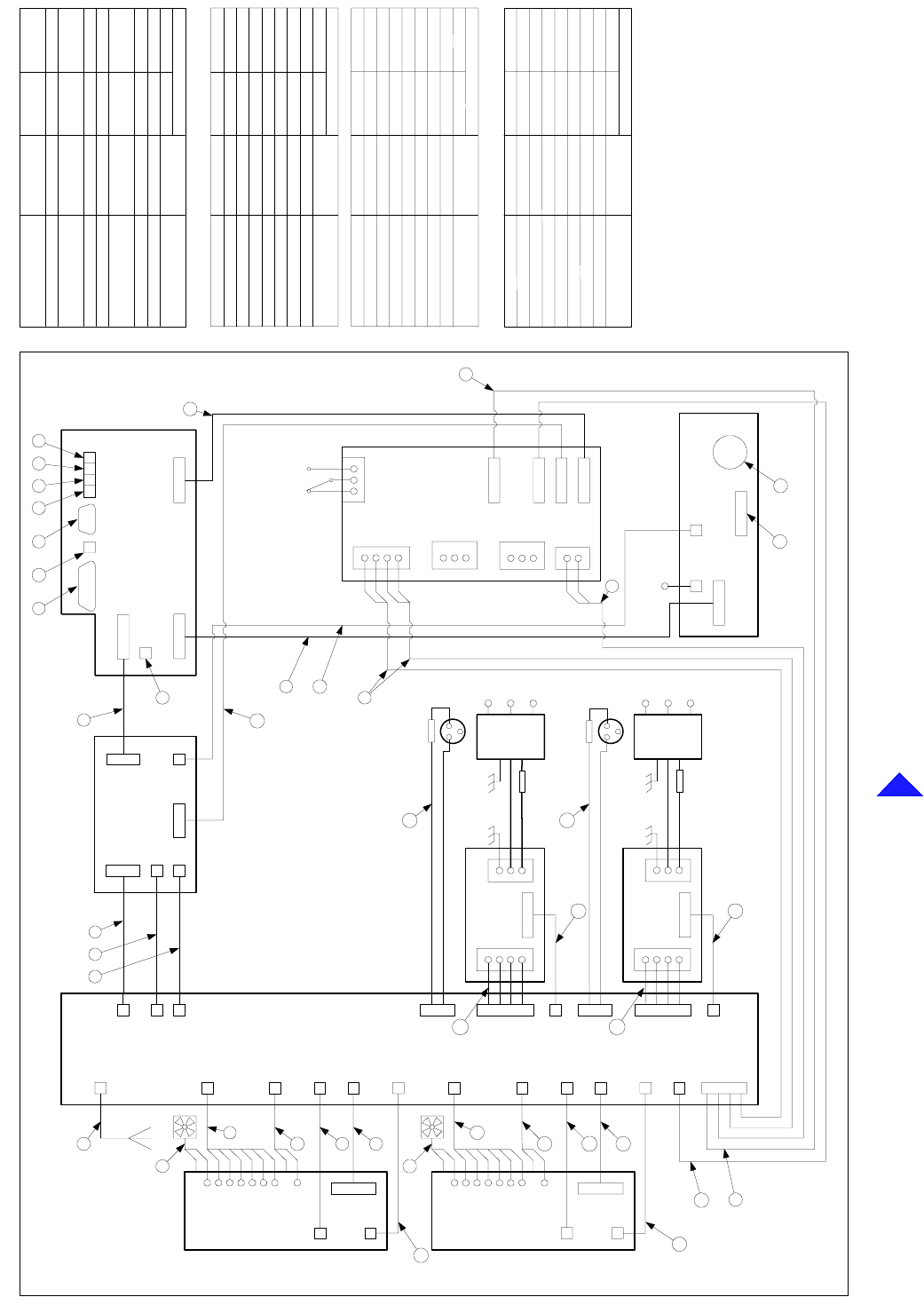

❑T6T transmitter configured for local operation (see Fig 1).

❑T6T transmitter configured for remote operation (see Fig 2).

❑T6T transmitter configured for use with MARC (see Fig 3).

❑T6T Mode 2 configuration (see Fig 4).

❑T6T Mode 3 configuration. (see Fig 5).

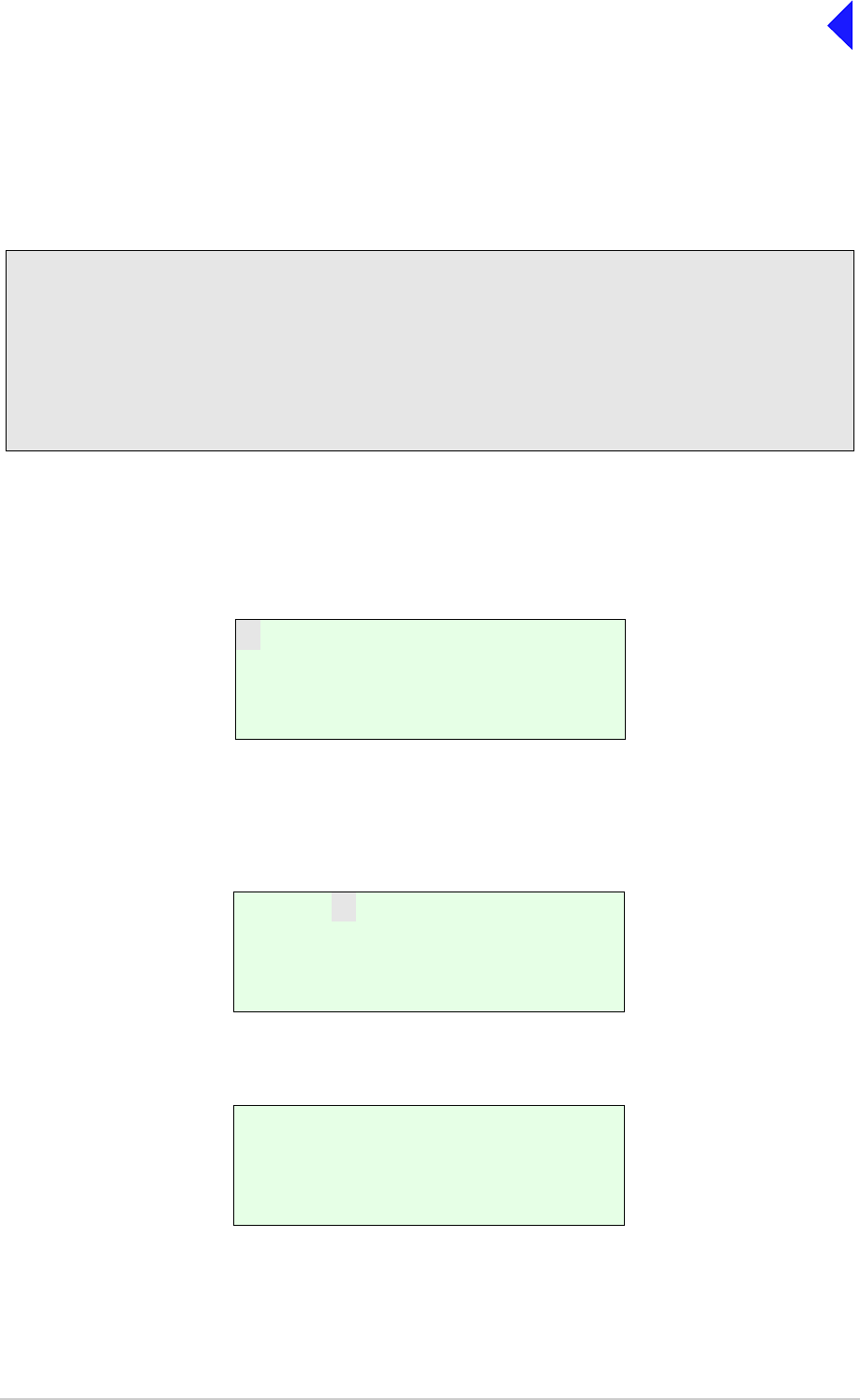

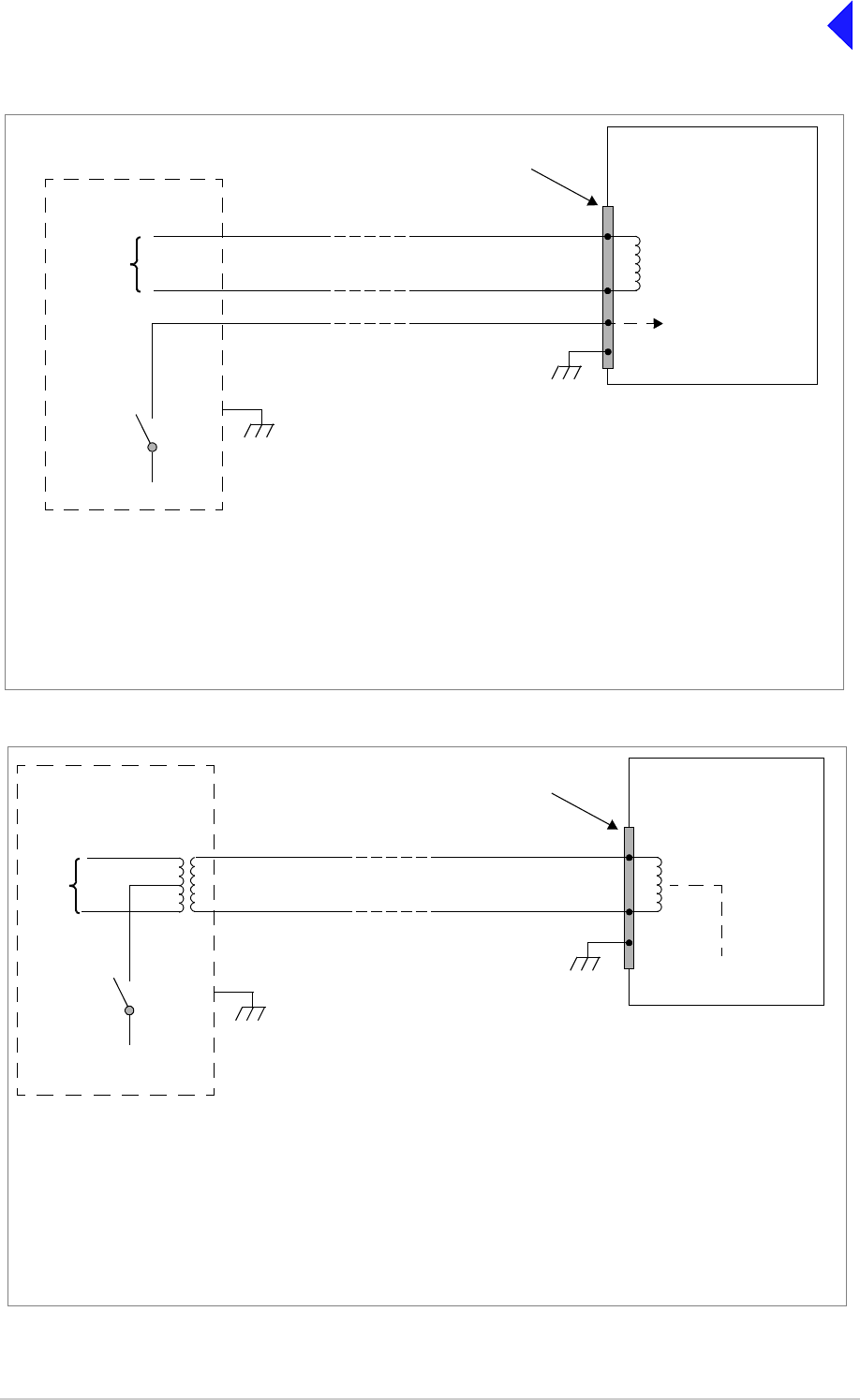

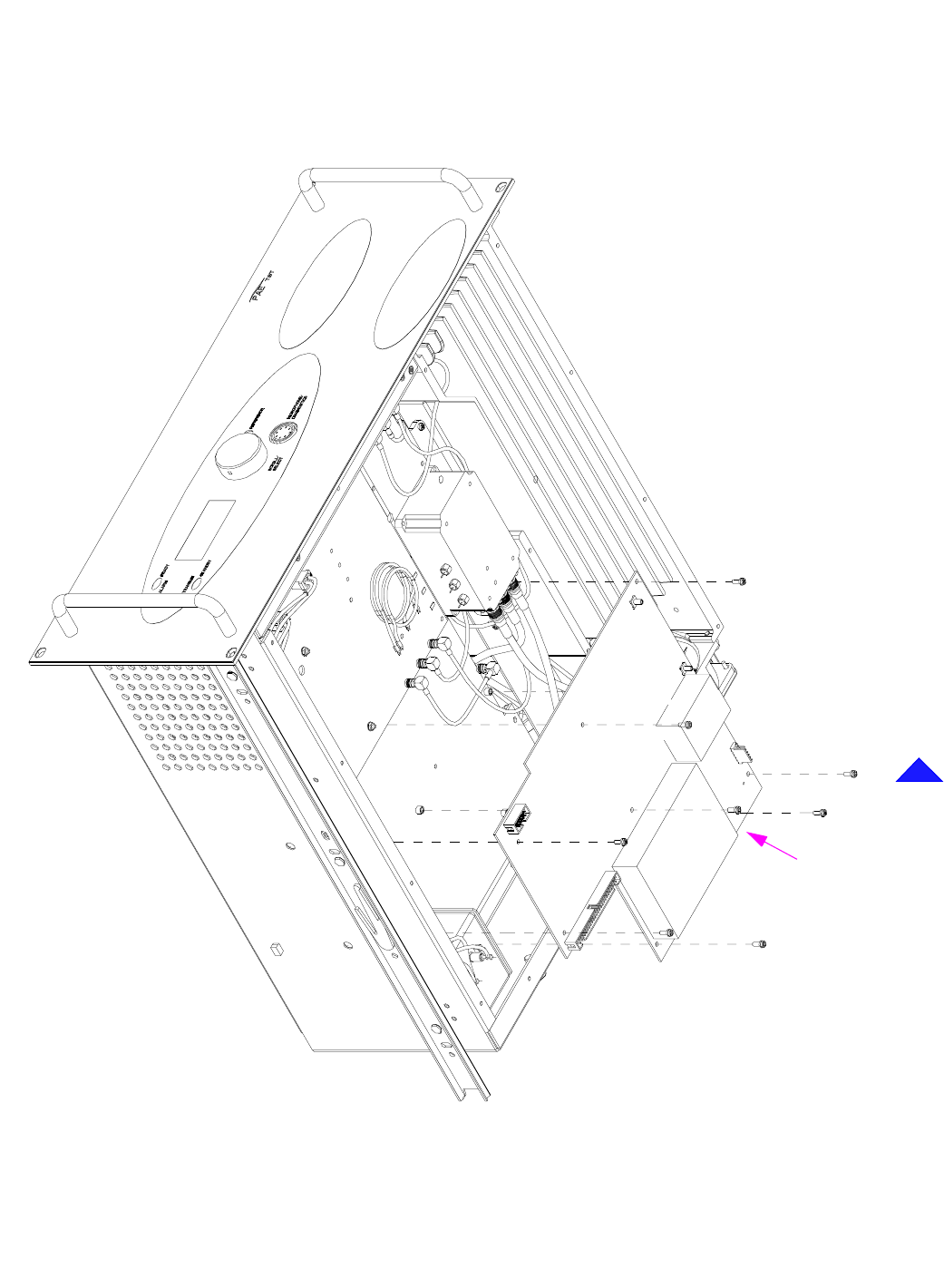

Fig 1 T6T Transmitter Configured for Local Operation

For local operation, the transmitter is operated from the front panel using a microphone/headset.

Any of the optional facilities may be connected.

Antenna

Connector

Reference

Connector Microphone/Diagnostics

Connector

Frequency Counter

required only for

maintenance

Facilities

Connector

T6T Transmitter

E-BIT input

PTT relay output

External VSWR input

dc supply output

Inhibit input

BIT interruptive test input

Antenna change-over output

Ready output

Tape output

Optional Facilities that

can be used if required

Laptop (or PC) required

only for maintenance

Mic/Headset for

local operation

T6T VHF 100 W Transmitter Page 5 Installation

Back to Transmitter

Main Page

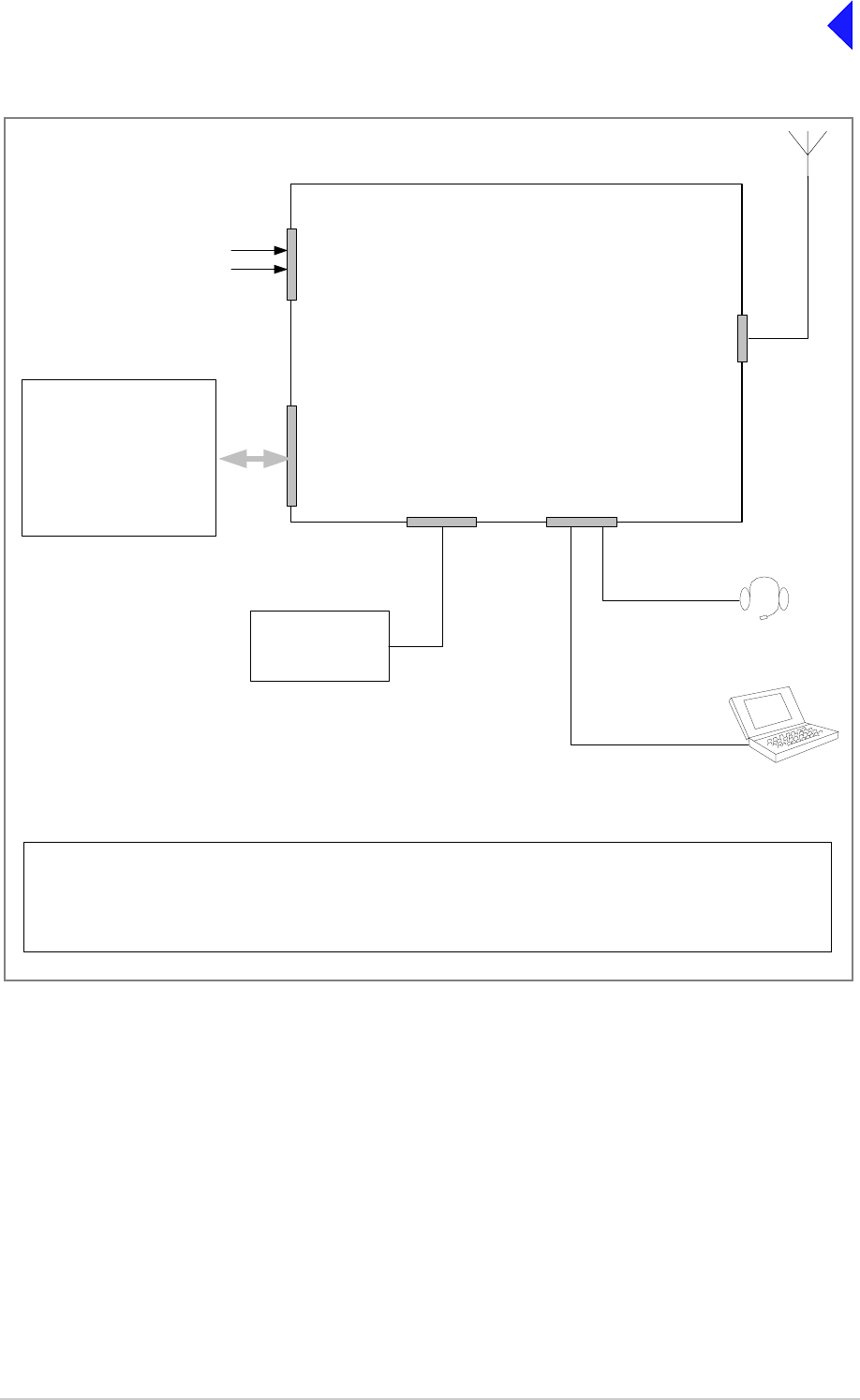

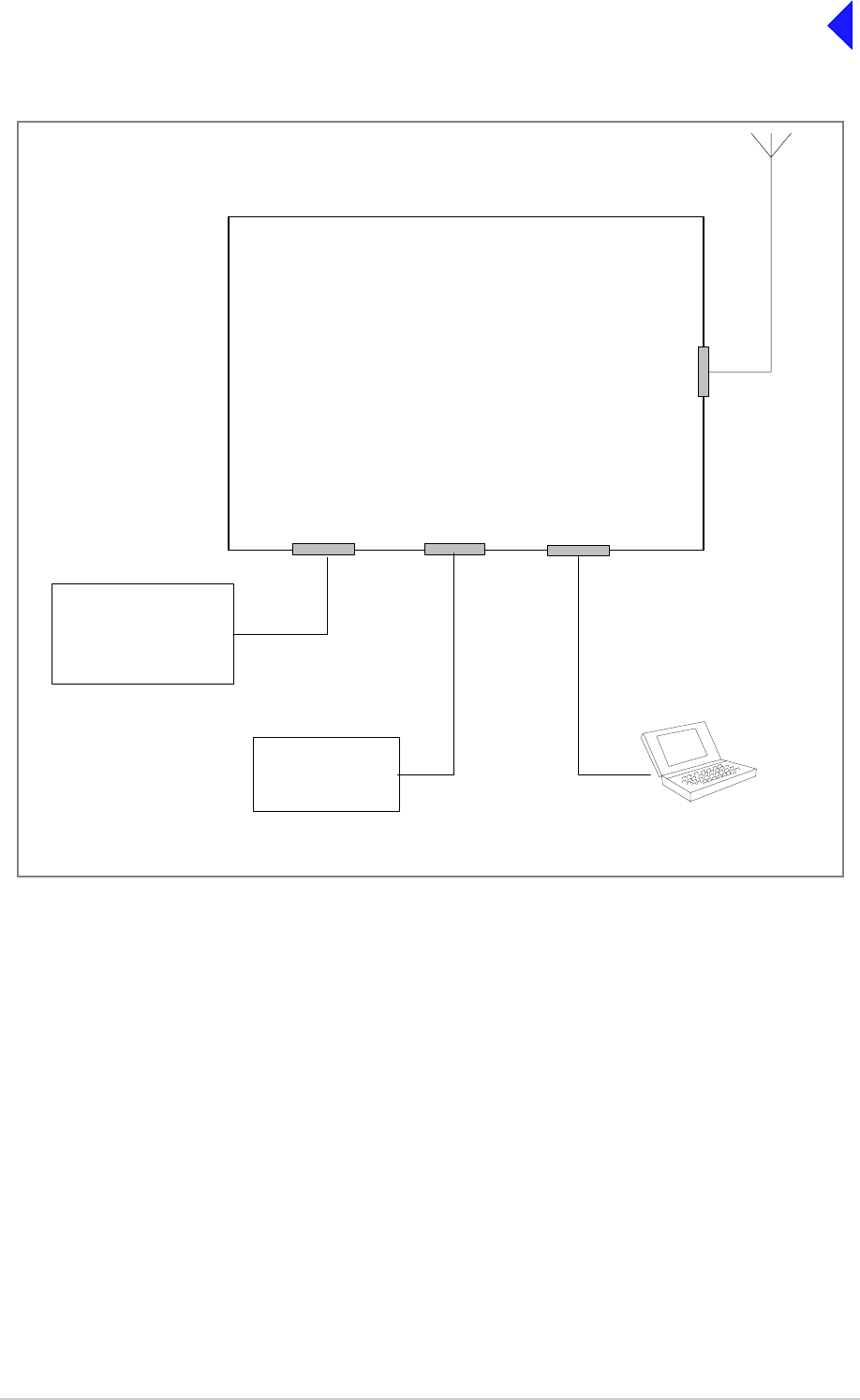

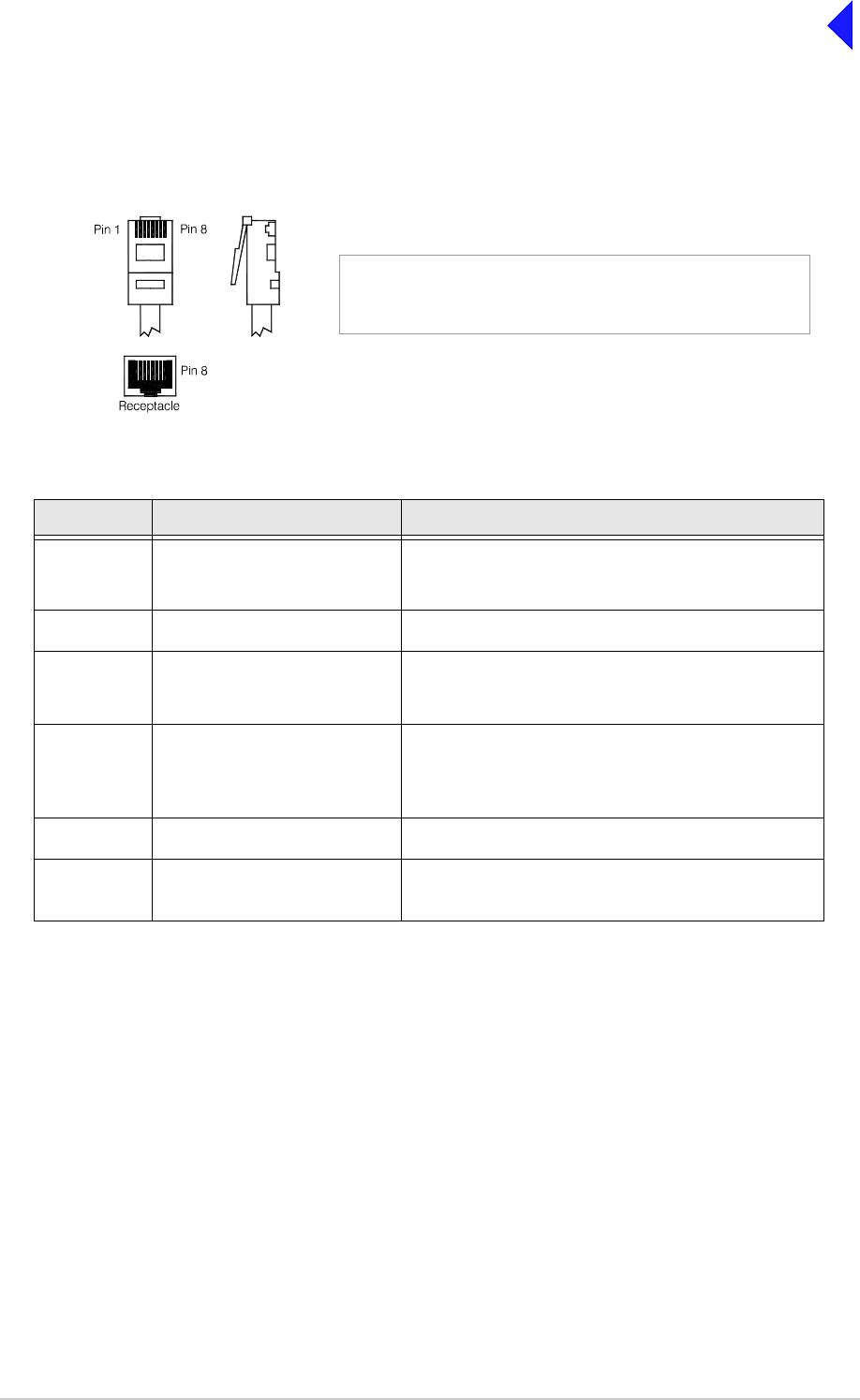

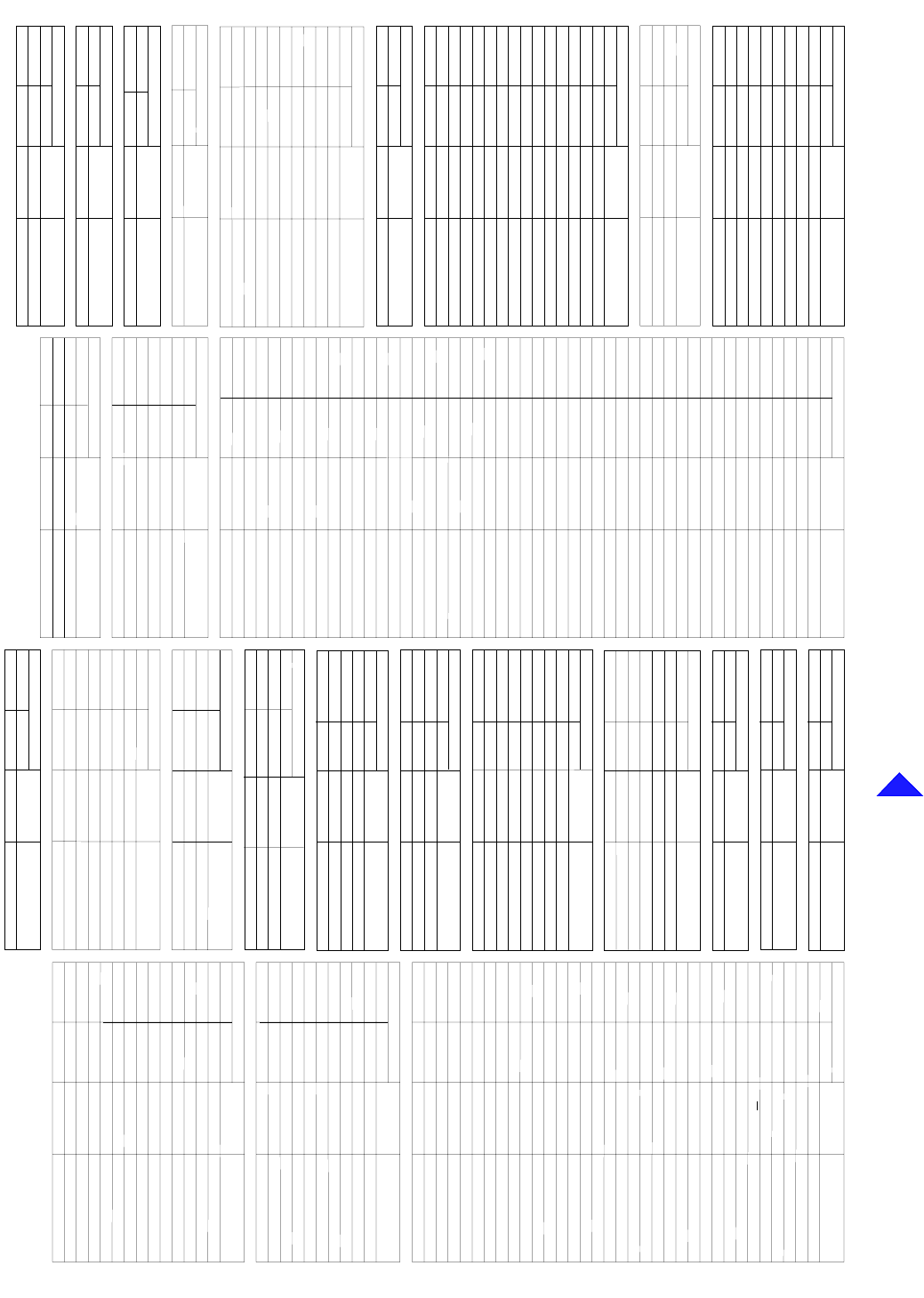

Fig 2 T6T Transmitter Configured for Remote Operation

For remote operation, Audio and PTT signals from the control equipment terminate on the MARC

connector, or alternatively on the MARC Audio connector. If data is required by a compatible data system,

the RS422 data lines terminate on the MARC connector, or alternatively on the MARC Data connector.

Any of the optional facilities may be connected.

Antenna

Connector

Microphone/Diagnostics

Connector

MARC Connector

or,

MARC Audio Connector

Mic/Headset for

engineering use

Laptop (or PC) required

only for maintenance

T6T Transmitter

Optional Facilities that

can be used if required

E-BIT input

PTT relay output

External VSWR input

dc supply output

Inhibit input

BIT interruptive test input

Antenna change-over output

Ready output

Tape output

Reference

Connector

Frequency Counter

required only for

maintenance

Facilities

Connector

Audio

PTT

T6T VHF 100 W Transmitter Page 6 Installation

Back to Transmitter

Main Page

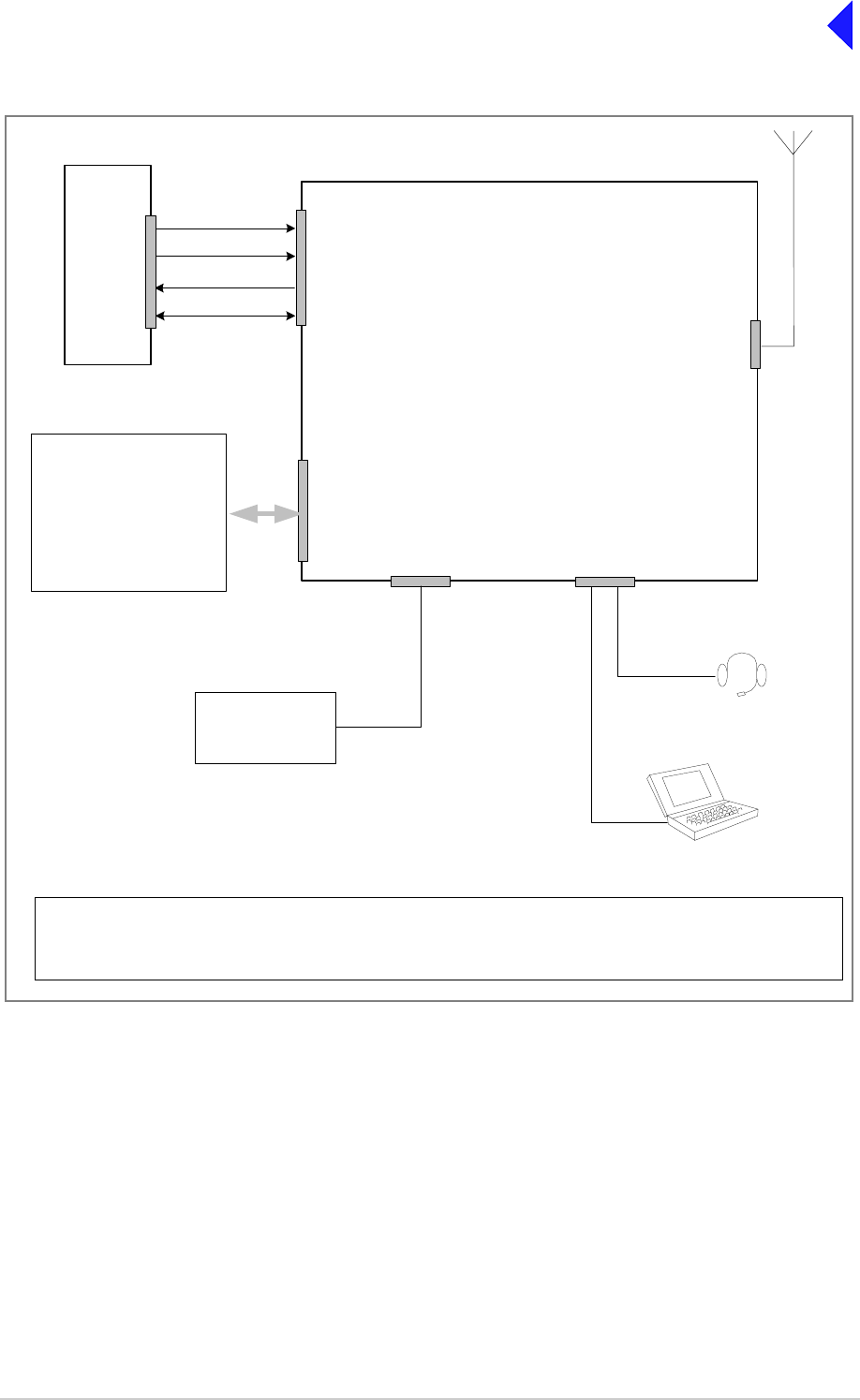

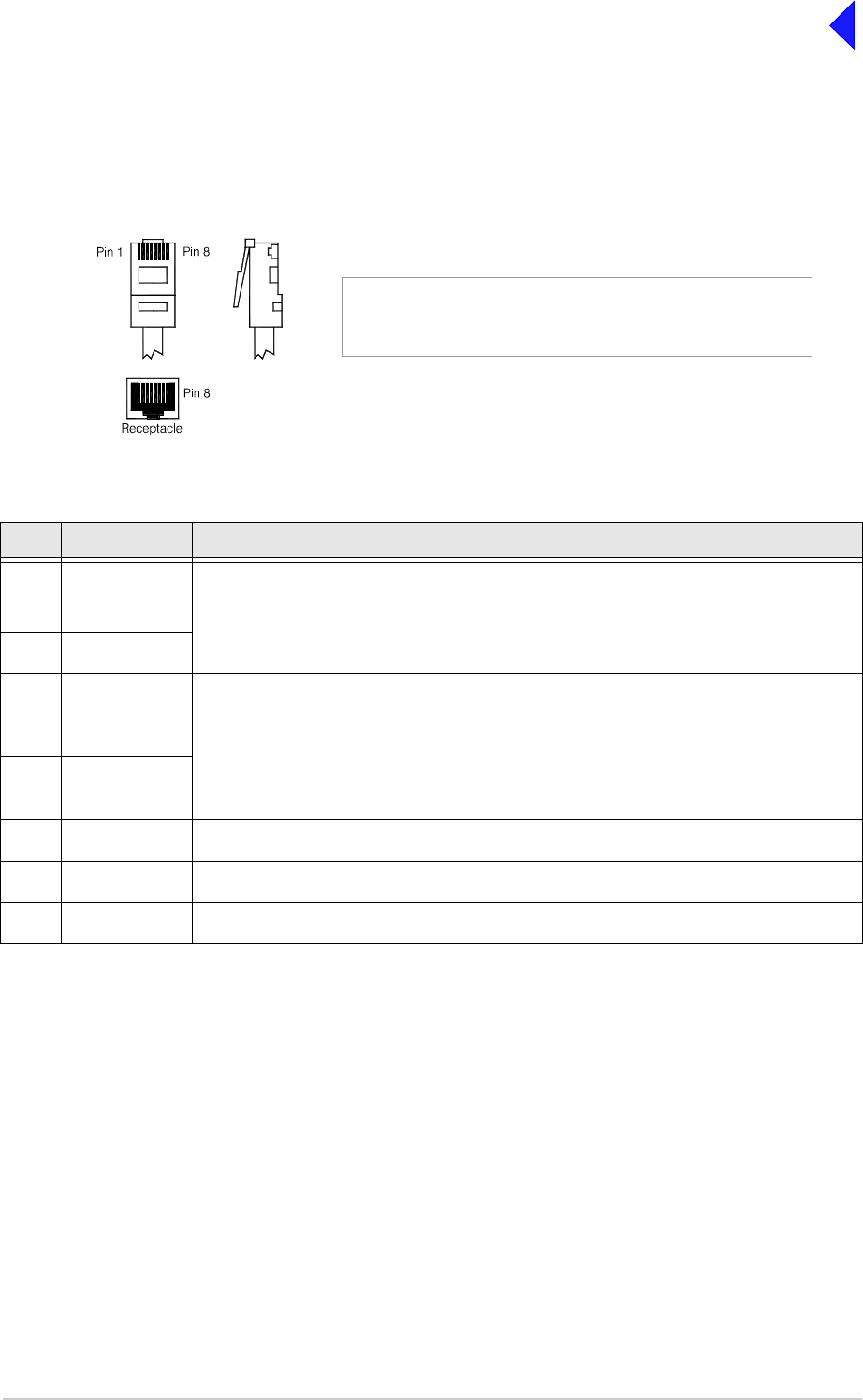

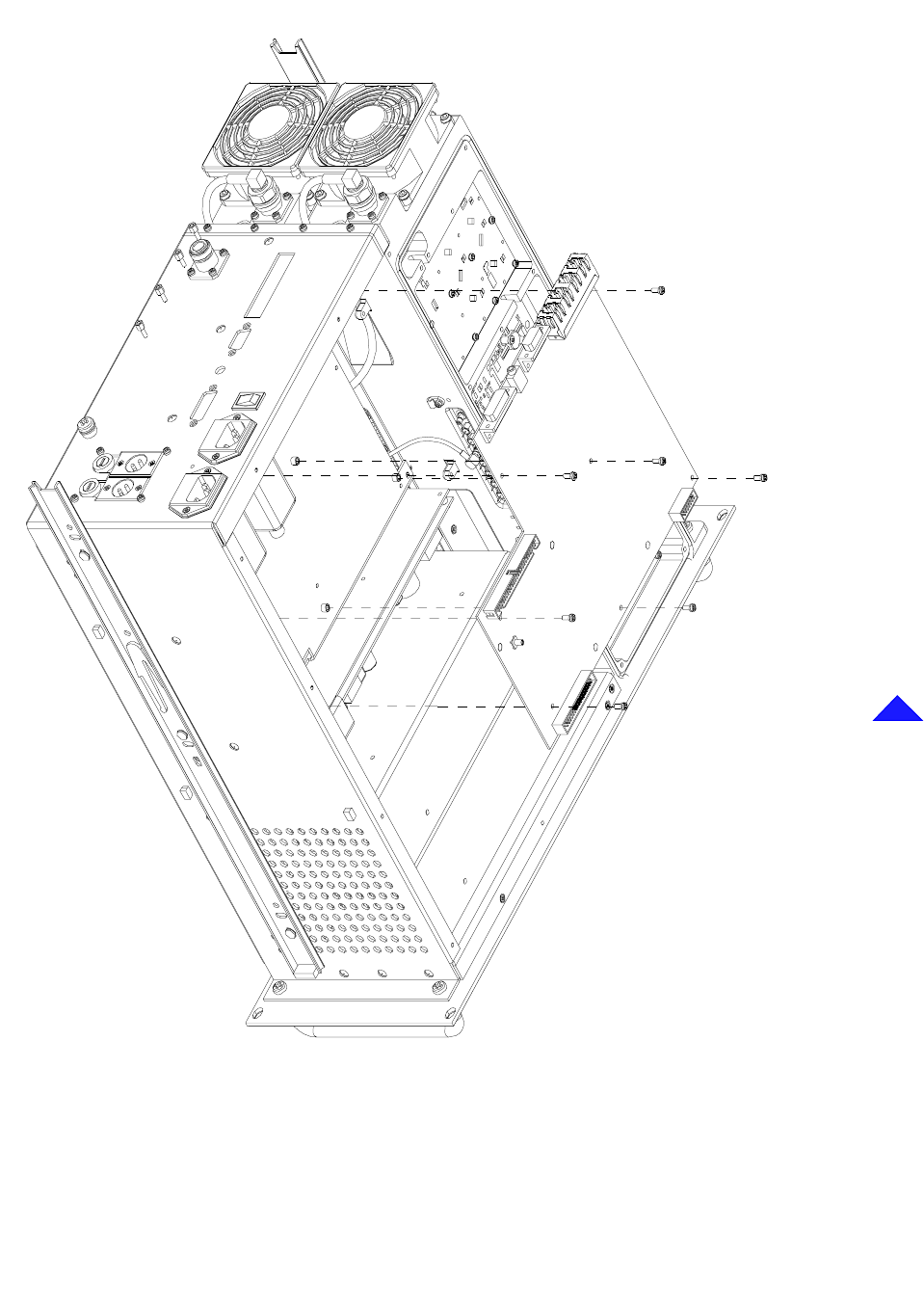

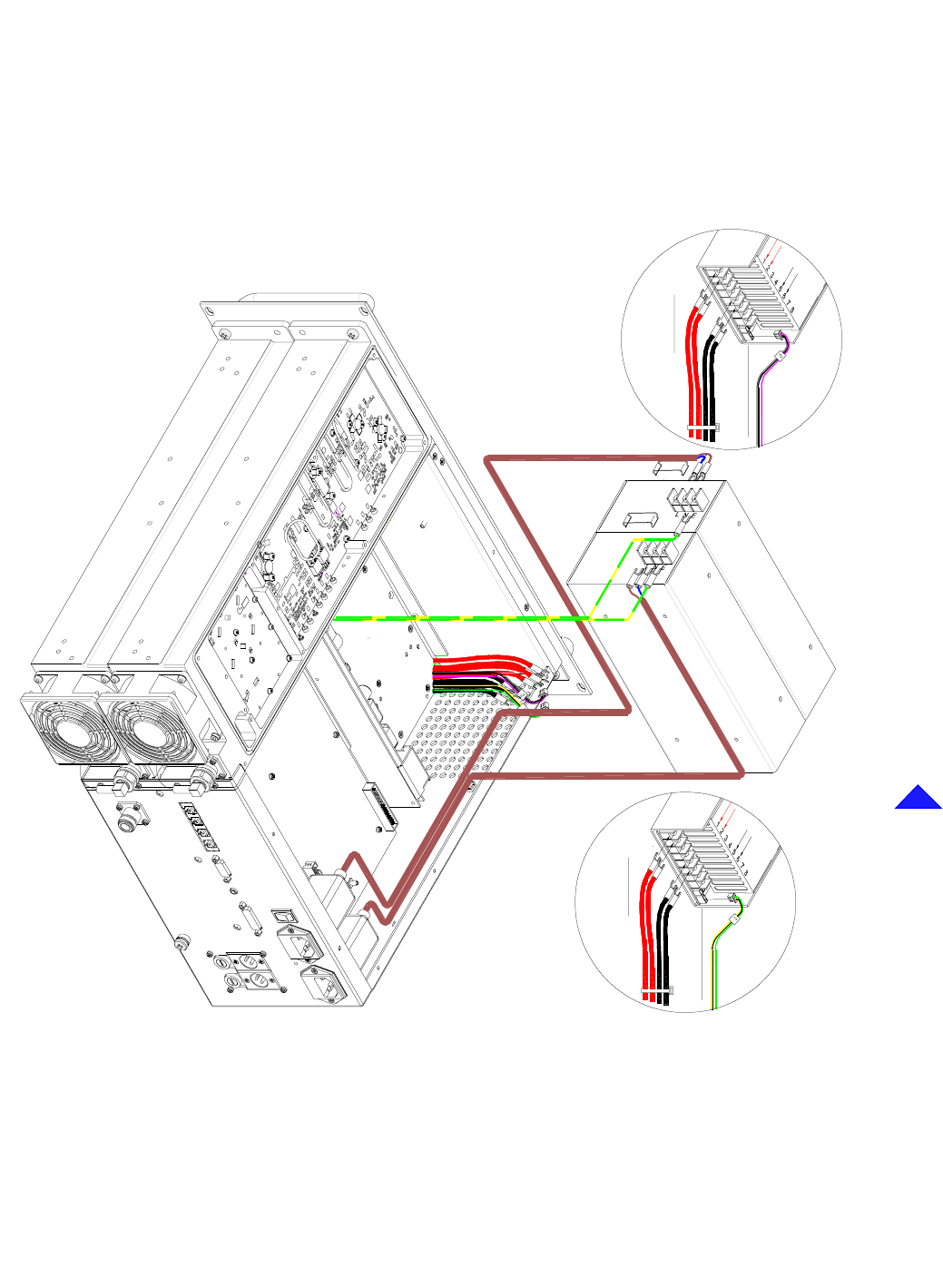

Fig 3 T6T Transmitter Configured for use with MARC

When using a T6T transmitter with a MARC Remote Site Equipment (RSE2) the transmitter MARC

connector is pin-to-pin wired to one of the RSE2 Equipment connectors.

Any of the optional facilities may be connected.

Antenna

Connector

Reference

Connector Microphone/Diagnostics

Connector

T6T Transmitter

Equipment

Connector

RSE2

MARC

Connector

Audio

PTT

RS422 data

dc supply output

E-BIT input

PTT relay output

External VSWR input

Unregulated supply output

Inhibit input

BIT interruptive test input

Antenna change-over output

Ready output

Tape output

Facilities

Connector

Frequency Counter

required only for

maintenance

Mic/Headset for

engineering use

Laptop (or PC) required

only for maintenance

Optional Facilities that

can be used if required

T6T VHF 100 W Transmitter Page 7 Installation

Back to Transmitter

Main Page

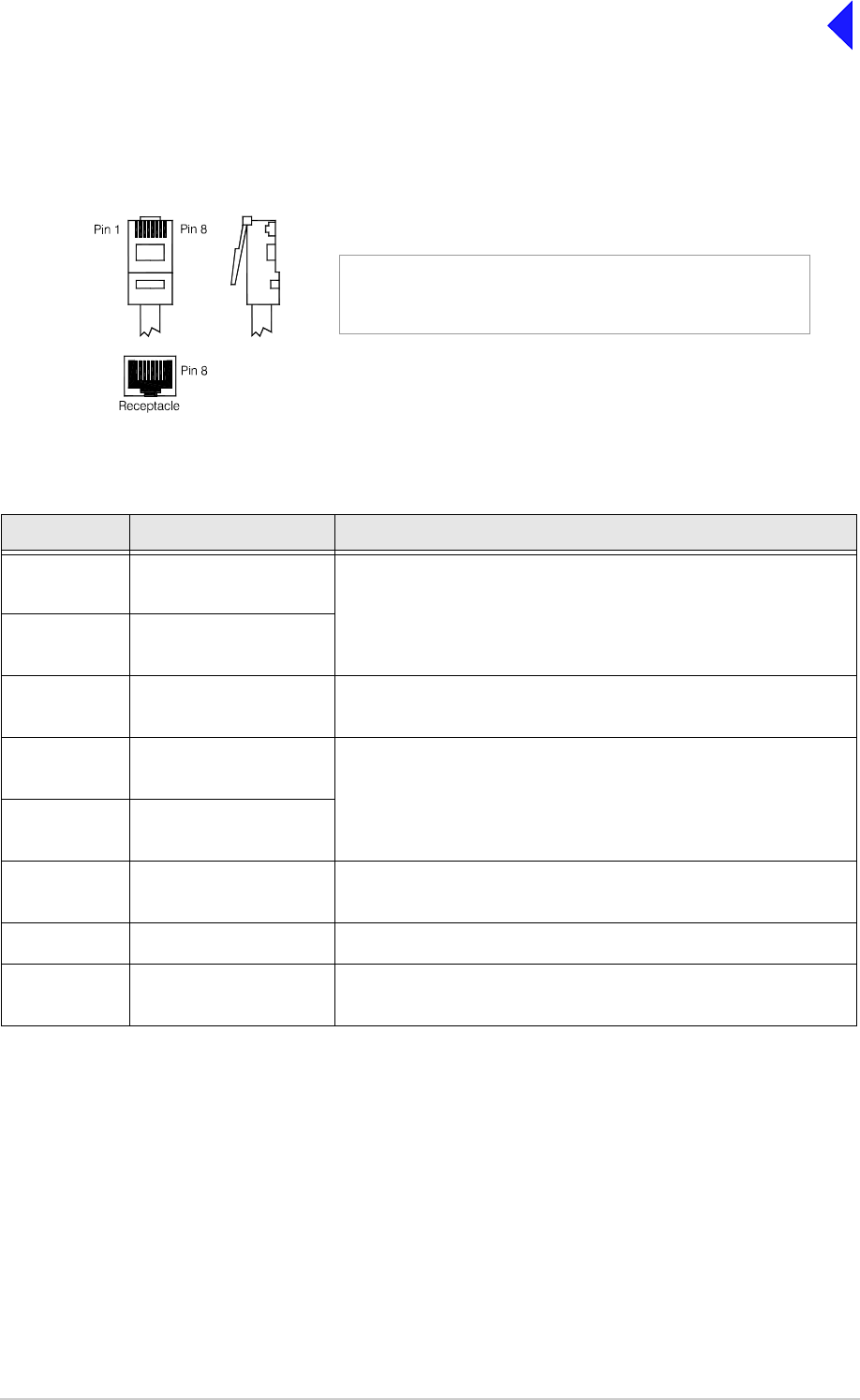

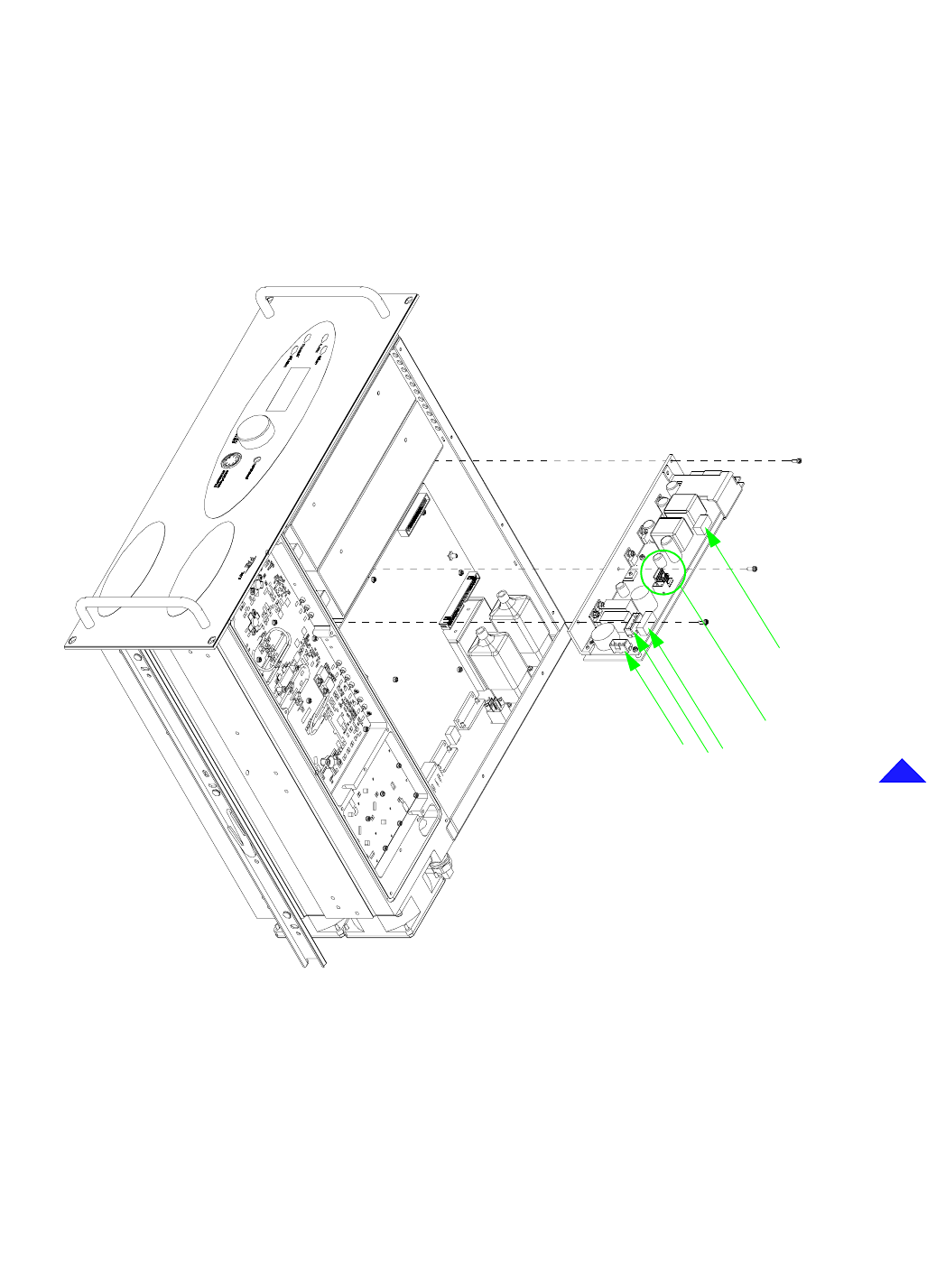

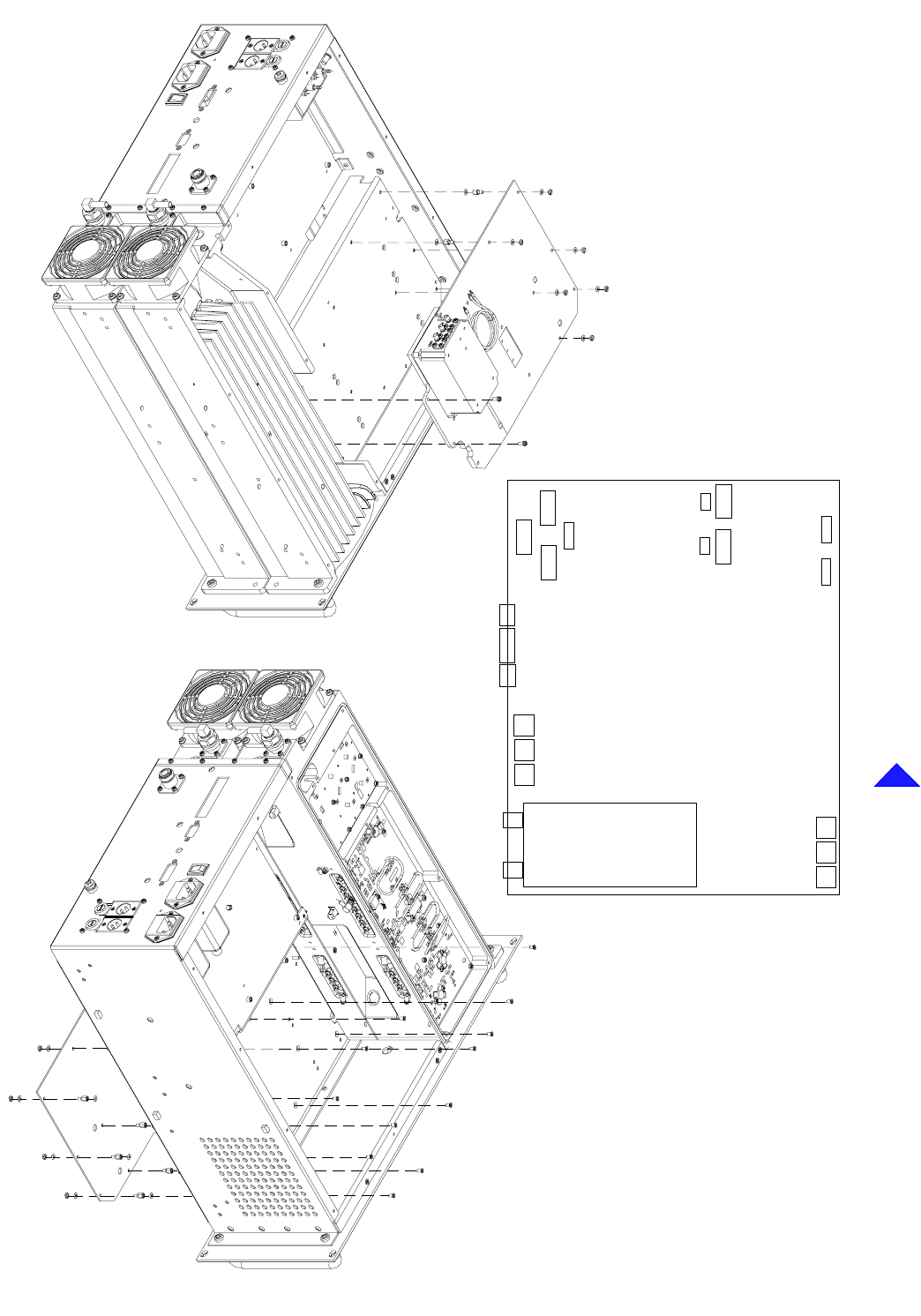

Fig 4 T6T Transmitter Mode 2 Configuration

Antenna

Connector

T6R Receiver

Antenna

Connector

T6T Transmitter

HDLC

Connector T1/E1

Connector Facilities

Connector

Reference

Connector

Microphone/Diagnostics

Connector

Reference

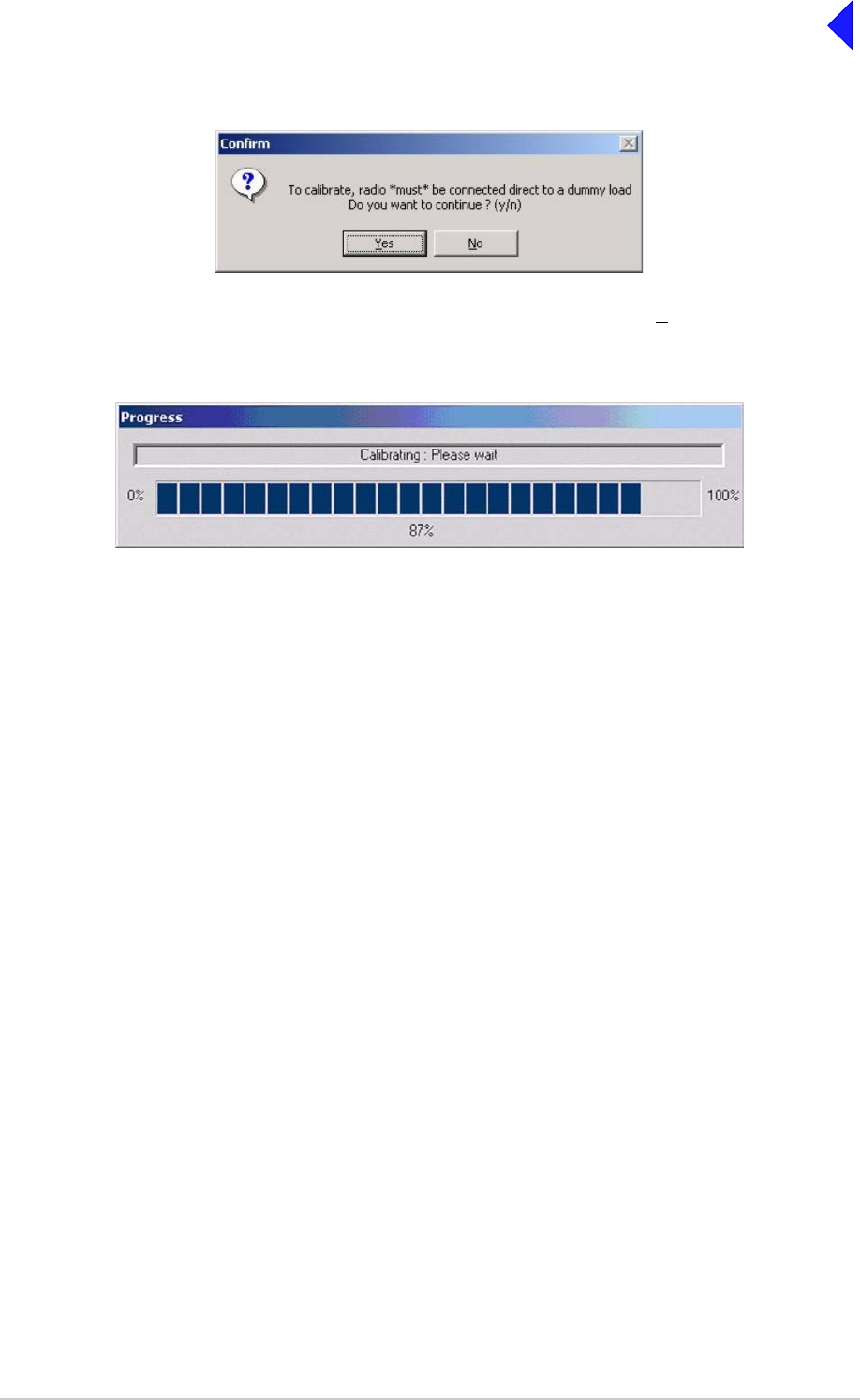

Connector