Honeywell Sensing and Control TMS9250FCC TMS9250 User Manual Exhibit D Users Manual per 2 1033 b3

Honeywell Sensing and Control TMS9250 Exhibit D Users Manual per 2 1033 b3

Exhibit D Users Manual per 2 1033 b3

TMS 9250 Product User Manual

V 1.0

May 2011

Release V 1.0

Honeywell Confidential & Proprietary

This work contains valuable, confidential and proprietary information. Disclosure, use or

reproduction outside of Honeywell International Inc. is prohibited except as authorized in writing.

This unpublished work is protected by the laws of the United States and other countries.

V 1.0 TMS 9250 Product User Manual iii

May 2011 Honeywell Confidential & Proprietary

About This Document

Release Information

Document Name Document

ID

Release

Number

Publication

Date

TMS 9250 Product User Manual V 1.0 May 2011

V 1.0 TMS 9250 Product User Manual v

May 2011 Honeywell Confidential & Proprietary

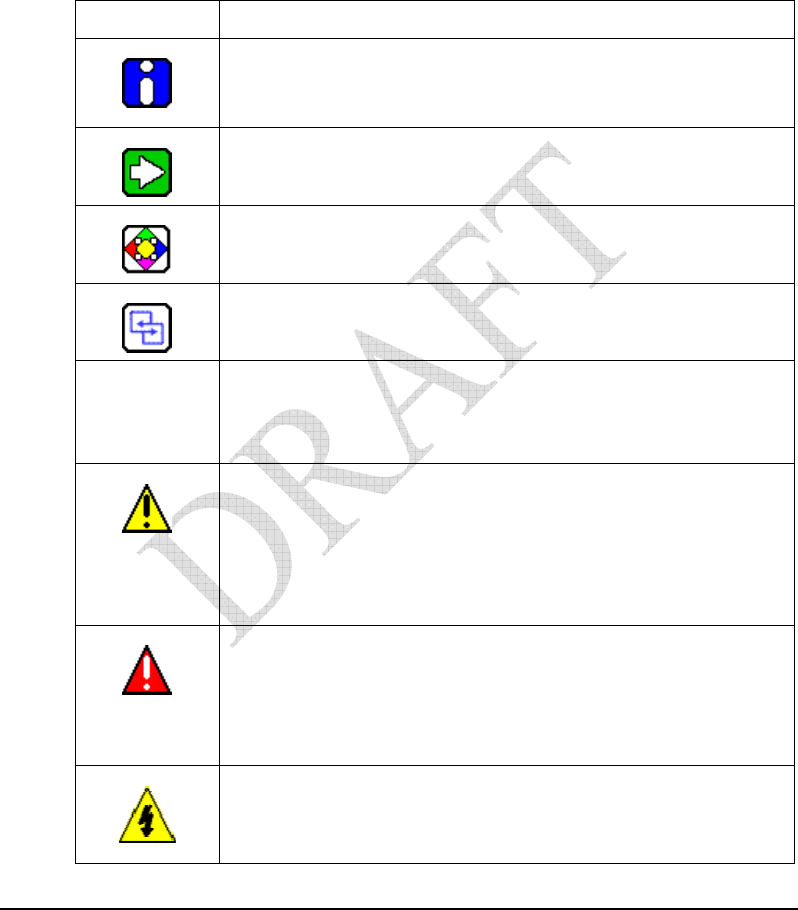

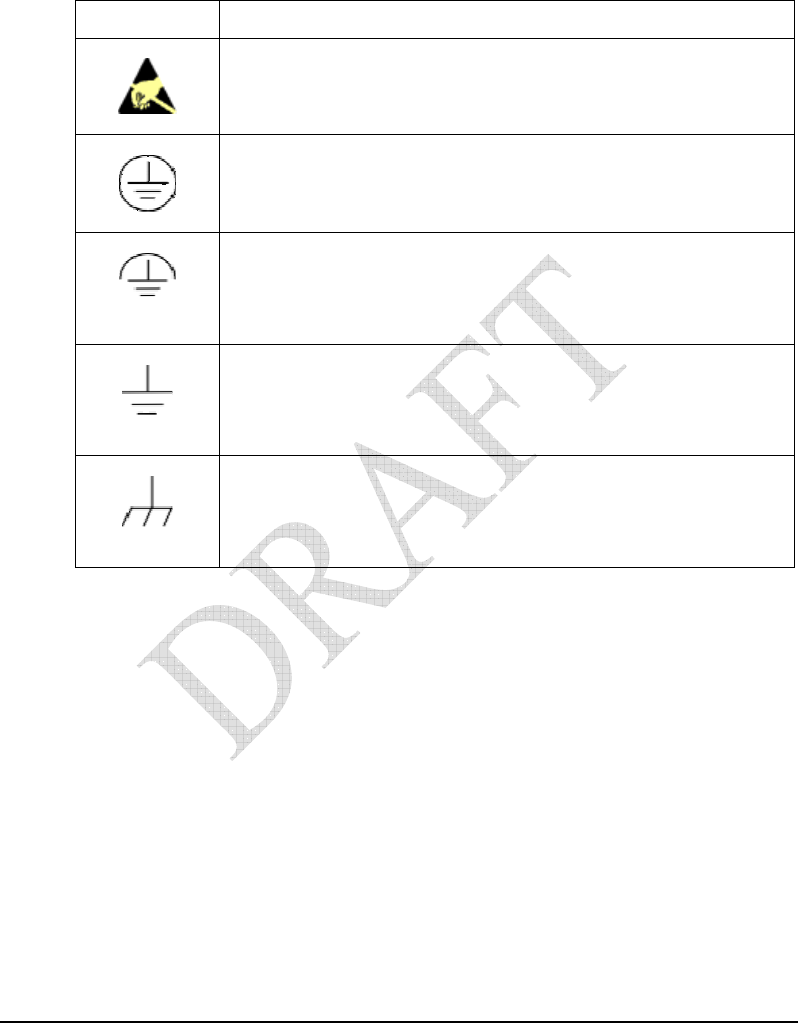

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

Symbol Definition

ATTENTION: Identifies information that requires special

consideration.

TIP: Identifies advice or hints for the user, often in terms of

performing a task.

REFERENCE -EXTERNAL: Identifies an additional source of

information outside of the bookset.

REFERENCE - INTERNAL: Identifies an additional source of

information within the bookset.

CAUTION

Indicates a situation which, if not avoided, may result in equipment

or work (data) on the system being damaged or lost, or may result in

the inability to properly operate the process.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used

to alert against unsafe practices.

CAUTION symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to

required information in the manual.

WARNING: Indicates a potentially hazardous situation, which, if not

avoided, could result in serious injury or death.

WARNING symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to

required information in the manual.

WARNING, Risk of electrical shock: Potential shock hazard where

HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or

60 VDC may be accessible.

vi TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

Symbol Definition

ESD HAZARD: Danger of an electro-static discharge to which

equipment may be sensitive. Observe precautions for handling

electrostatic sensitive devices.

Protective Earth (PE) terminal: Provided for connection of the

protective earth (green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as

noise immunity improvement. NOTE: This connection shall be

bonded to Protective Earth at the source of supply in accordance

with national local electrical code requirements.

Earth Ground: Functional earth connection. NOTE: This

connection shall be bonded to Protective Earth at the source of

supply in accordance with national and local electrical code

requirements.

Chassis Ground: Identifies a connection to the chassis or frame of

the equipment shall be bonded to Protective Earth at the source of

supply in accordance with national and local electrical code

requirements.

V 1.0 TMS 9250 Product User Manual vii

May 2011 Honeywell Confidential & Proprietary

V 1.0 TMS 9250 Product User Manual ix

May 2011 Honeywell Confidential & Proprietary

Contents

1. TMS 9250 TORQUE MEASUREMENT SYSTEM ........................11

1.1

Important safety and certification information .......................................... 11

1.2

In The Box ...................................................................................................... 13

1.3

Intended Use.................................................................................................. 14

Torque Sensor .....................................................................................................................14

Principle of Telemetry ..........................................................................................................14

Usage scenario of TMS 9250...............................................................................................15

1.4

Installation and Setup ................................................................................... 15

2. MODES OF OPERATION ............................................................18

2.1

Normal mode operation detailed description............................................. 18

Normal mode operation........................................................................................................18

2.2

Fast mode operation detailed description.................................................. 21

Fast hmode operation ..........................................................................................................21

2.3

Analog Output characteristics..................................................................... 24

3. CALIBRATION .............................................................................25

3.1

System Calibration Method.......................................................................... 25

3.2

Shunt Calibration .......................................................................................... 26

3.3

Storage and Recalibration............................................................................ 27

4. TROUBLESHOOTING .................................................................28

4.1

“Power On” light is not showing ................................................................. 28

4.2

“Rotor Active” light is not showing ............................................................ 28

4.3

Shunt calibra-tion does not operate............................................................ 28

4.4

Cannot communicate.................................................................................... 29

5. PRODUCT SPECIFICATIONS .....................................................31

Contents

x TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

6. APPENDICES ..............................................................................33

6.1

APPENDIX A...................................................................................................33

Manual Supplement for TMS 9250 SPM Remote Shunt Cal Option.................................... 33

Overview..............................................................................................................................33

Setup ...................................................................................................................................33

6.2

APPENDIX B...................................................................................................34

Manual Supplement for TMS 9250 SPM Digital Filter Settings............................................ 34

Filter Operation General Description ...................................................................................34

Filter Settling Time...............................................................................................................36

Sample Charts.....................................................................................................................37

6.3

APPENDIX C...................................................................................................40

6.4

APPENDIX D...................................................................................................41

6.5

APPENDIX E...................................................................................................42

1. TMS 9250 Torque Measurement System

1.1. Important safety

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 11

May 2011 Honeywell Confidential & Proprietary

1. TMS 9250 Torque Measurement System

1.1 Important safety

Before you work on any electronic equipment, review and follow the safety guidelines to

help protect the system from potential damage and to ensure personal safety.

CAUTION

• For continued protection from electrical shock, all connectors on the SPM

and CCM shall be connected to equipment providing low voltage (not more

than 33Vac rms / 46.7V peak or 70Vdc total) double insulated (SELV)

sources of supply.

• When you are adjusting the CCM to align with the torque sensor, you must

lock out power to the prime mover and ensure that you are trained prior to

accessing these areas of the installation.

CAUTION

• The SPM is intended only for connection to the specific power supply

shipped with the system.

• The system was evaluated for use with a specific SELV power supply of

limited energy output that affords electrical fire and shock hazard protection.

• The use of other power supply with this system is prohibited and may result

in electrical shock or fire hazards.

• The CCM is intended only for connection to the SPM with cables provided

by the manufacturer.

• Refer to the Appendix-E for connecting cables to the SPM.

• This equipment provides only low voltage double insulated signal I/O for

connection to other equipment.

1. TMS 9250 Torque Measurement System

1.2. Certification information

Rev: A

008-0738-00

12 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

ATTENTION

• Ensure that the interface cables are shielded before connecting to the

product.

• Due to the multitude of variations possible for connection of the torque

sensor to the load and prime mover, you must enhance the guarding for the

end application to meet provisions of the machinery directive.

• The equipment is evaluated only with respect to the Low Voltage Directive

and RTTE Directives and is not evaluated to the machinery directive for the

reasons stated. Therefore, you must ensure the compliance of this

equipment with the provisions of the machinery directive in the end

application. This will normally mandate the need for additional guarding at

the mechanical coupling points to the torque sensor.

TIP

• Place the power supply of the system in a place where you can easily

unplug the power cords.

1.2 Certification information

Certification

FCC ID: XJLTMS9250FCC

FCC statement: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including

interference that may cause undesired operation

EMC

Product is meeting EMC/EMI requirement as per following standard

• Class-B FCC § 15.225(a)

• Class B FCC § 15.225(d)

• Class B FCC § 15.207

• Class-B EN 301 489-1

• Class B EN 300 330 -1

Saftey

Product is meeting saftey requirement as per following standard

• EN 60950

• EN 61010

1. TMS 9250 Torque Measurement System

1.3. In The Box

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 13

May 2011 Honeywell Confidential & Proprietary

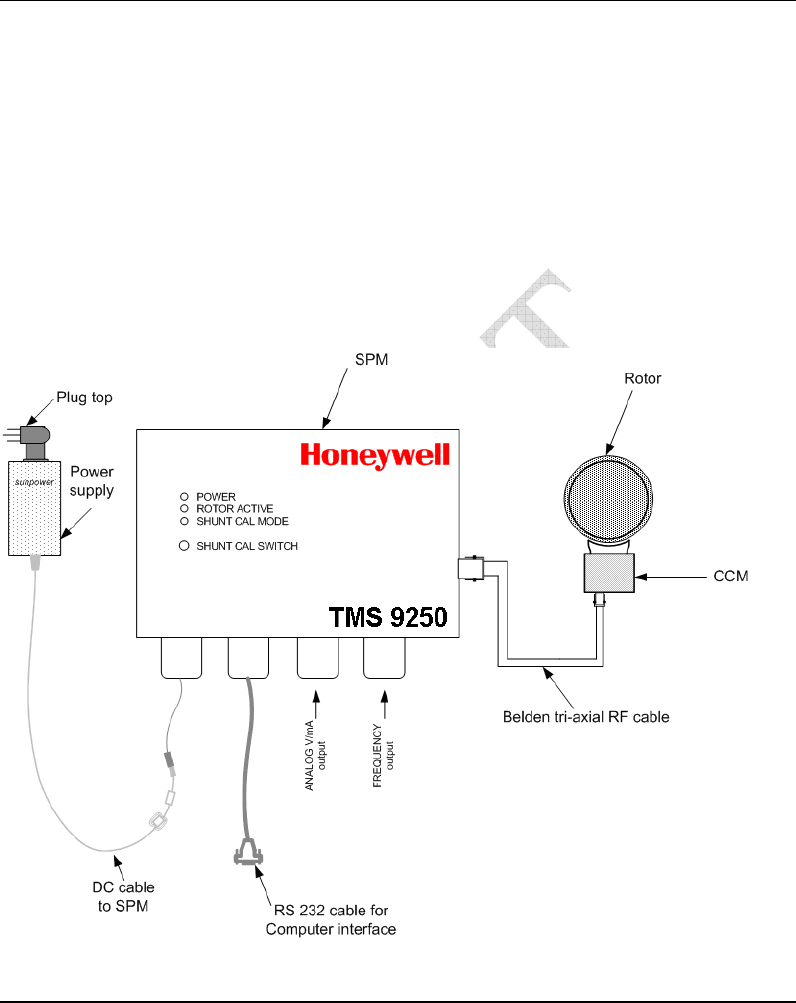

1.3 In The Box

• Plug top

• Power supply

• SPM

• Rotor

• CCM

• RF cable

• RS-232 cable

• Alignment Tool

1. TMS 9250 Torque Measurement System

1.4. Intended Use

Rev: A

008-0738-00

14 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

1.4 Intended Use

Torque Sensor

Lebow Torque Sensors are designed structures that perform in a predictable and

repeatable manner when a torque is applied. This torque is translated into a signal voltage

by the resistance change of strain gages, which are attached to the torque sensor

structure. The change in resistance indicates the degree of deformation, and in turn, the

torque on the structure.

The strain gages are connected in a 4 arm Wheatstone Bridge configuration which acts as

an adding and subtracting electrical network and allows compensation for temperature

effects as well as cancellation of signals caused by extraneous loading.

When the torque sensor is rotating, a means must be provided to transfer an excitation

voltage to the rotational element from a stationary surface, and also to transfer the torque

signal from the rotational element back to the stationary surface. This is accomplished

through the use of digital telemetry.

Principle of Telemetry

The digital telemetry system consists of a receiver-transmitter module, a caliper-style

coupling module, and a signal processing module.

The receiver-transmitter module is an integral part of the torque sensor and is connected

to the strain gauges and to the epoxy glass annular printed circuit board that contains the

rotating antenna system. Within the receiver-transmitter module, the sensor signals are

amplified, digitized, and are then used to modulate the radio frequency carrier wave that

is detected by the antenna after being transmitted across the air gap by the caliper

coupling module. That same carrier wave is rectified to provide power to drive the strain

gauges and the electronic components in the module, which is managed by a miniature

microprocessor.

The caliper coupling module connects to the signal processing module via a Tri-axial

cable. The detector circuitry in the signal processing module recovers the digital

measurement data from the torque sensor and passes it to the second microprocessor for

scaling and linearizing.

The third microprocessor provides the drive to the two analog outputs, as well as the

standard digital interfaces and the optional digital interface modules. Extensive facilities

are provided in software for setup and configuration of the complete system.

1. TMS 9250 Torque Measurement System

1.5. Installation and Setup

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 15

May 2011 Honeywell Confidential & Proprietary

Usage scenario of TMS 9250

This product is used in the controlled environment, not for the intended out door use, and

designed typically for dynamometer test laboratories.

Refer to the cleaning instructions provided in the Appendix D.

1.5 Installation and Setup

To create DSN using EBIDataSource:

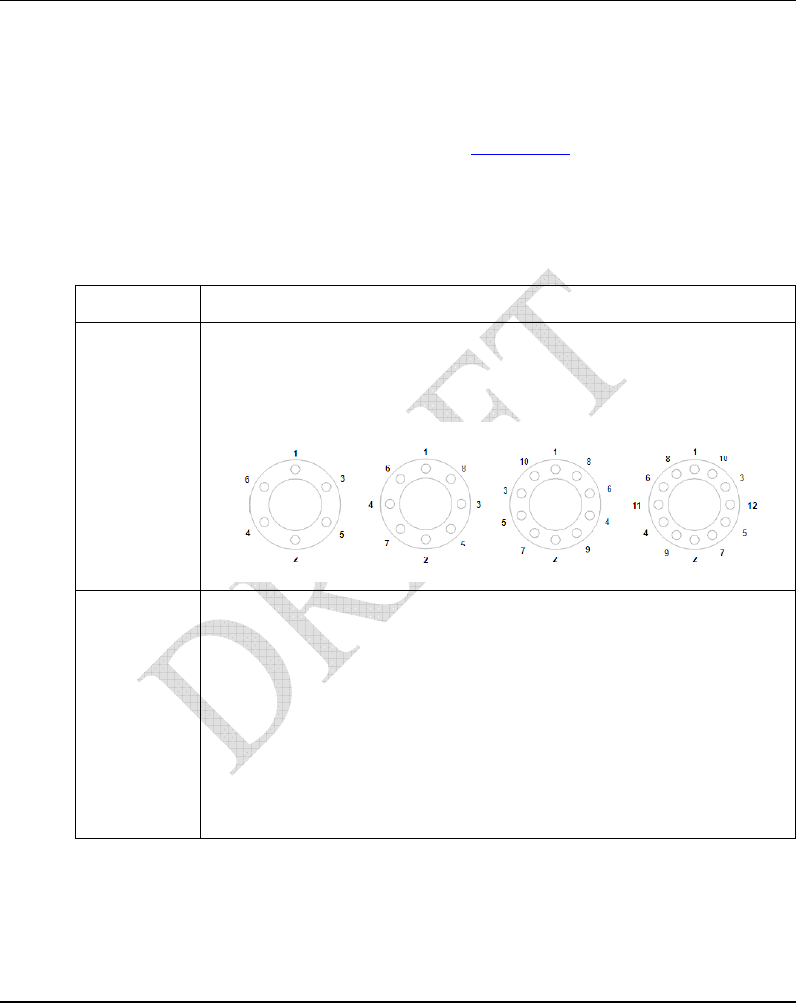

Step Action

Bolting

Information

Tighten all bolts, in incremental steps, to the bolt manufacturers rated

torque specification. Use the respective sequence illustration shown

below depending on the number of bolts the sensor requires. This

bolting sequence applies to both bolt circles of the torque sensor.

Torque

Sensor

The TMS 9250 series torque sensors may be operated horizontally,

vertically, or any angle in between provided the load is applied through

the loading axis.

All torque sensors in this series have bolt patterns that mate directly to

standard industrial couplings. When mounted, one of the flanges

should be mated to a good quality double flex coupling or a driveshaft

arrangement that incorporates universal joints at each end. This is

designed to compensate for angular and parallel misalignment.

Avoid applications that place extraneous loads on the torque sensor.

1. TMS 9250 Torque Measurement System

1.5. Installation and Setup

Rev: A

008-0738-00

16 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

Step Action

Caliper

Coupling

Module

The caliper coupling module must be firmly mounted to a non-rotating

support structure. It must be aligned with the epoxy glass annular

printed circuit board antenna so that the air gap between the caliper

and the antenna is approximately equal on both sides. Care should be

taken to avoid any items touching one another, and consideration

should be given to the effects of vibration as well as the free play in

any driveshaft sliding joints.

To assist in the process of aligning the caliper and the antenna, a

simple plastic alignment tool is provided with each system. The tool is

used to hold the required clearance between the caliper and the

antenna while the caliper fixing bolts are being tightened, and then is

removed before the sensor is rotated.

The tolerances for end-float (axial) are +/-

4.5mm (+/- 3/16”) and for run-out (radial) are +/-

1.0mm (+/- 1/16”). For installations where run- out cannot be

controlled within the specified tolerance, the secondary coupling

position can be used. This is achieved by placing the edge of the

caliper in close proximity to the edge of the antenna. In this position,

the run-out tolerance can be at least doubled, at the expense of a

reduced signal to noise ratio caused by the higher incidence of data

drop outs. The axial tolerance is limited by the distance between the

caliper sections.

The caliper can also be mounted such that only one side is in

proximity to the antenna, if the mounting arrangement does not allow

for placing of the antenna between the two sides of the caliper.

Successful positioning of the caliper can be confirmed by the

quality test of the TMS tool kit returning 100% result.

The length of the RF cable connection between the caliper coupling

module and the signal processing module is critical to system

performance (due to reflections and standing waves). You mustuse

tri-axial cable only of length 14.6 meters (47’11’’ feet) supplied with

the product.

1. TMS 9250 Torque Measurement System

1.5. Installation and Setup

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 17

May 2011 Honeywell Confidential & Proprietary

Step Action

Signal

Processing

Module

The receiver is mounted remotely with the tri-axial cable being the only

connection between it and the caliper coupling module. The receiver

has holes provided for permanent mounting. Request appropriate

certified drawing from Lebow before making fixtures.

When deciding where to locate the signal processing module,

consideration should be given to the type of output that will be

used. If the analog voltage or current output is to be used, then the

signal processing module should be mounted in an area of low

electrical noise and the connection between the module and the data

acquisition equipment should be as short as possible made up of

double screened twisted pair cable. If the frequency output or the

digital output is to be used, then the signal processing module can be

mounted in the electrically noisy area provided that good quality dual

screened twisted pair cables are used.

Electrical

connection

As mentioned in table below.

Refer to Appendix E for SPM IO box connections

Powering of

device

After all the connection are completed then system shall be power and

allowed for 30-45min warm-up time for stable output

2. Modes of Operation

2.1. Normal mode operation detailed description

Rev: A

008-0738-00

18 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

2. Modes of Operation

2.1 Normal mode operation detailed description

Normal mode operation

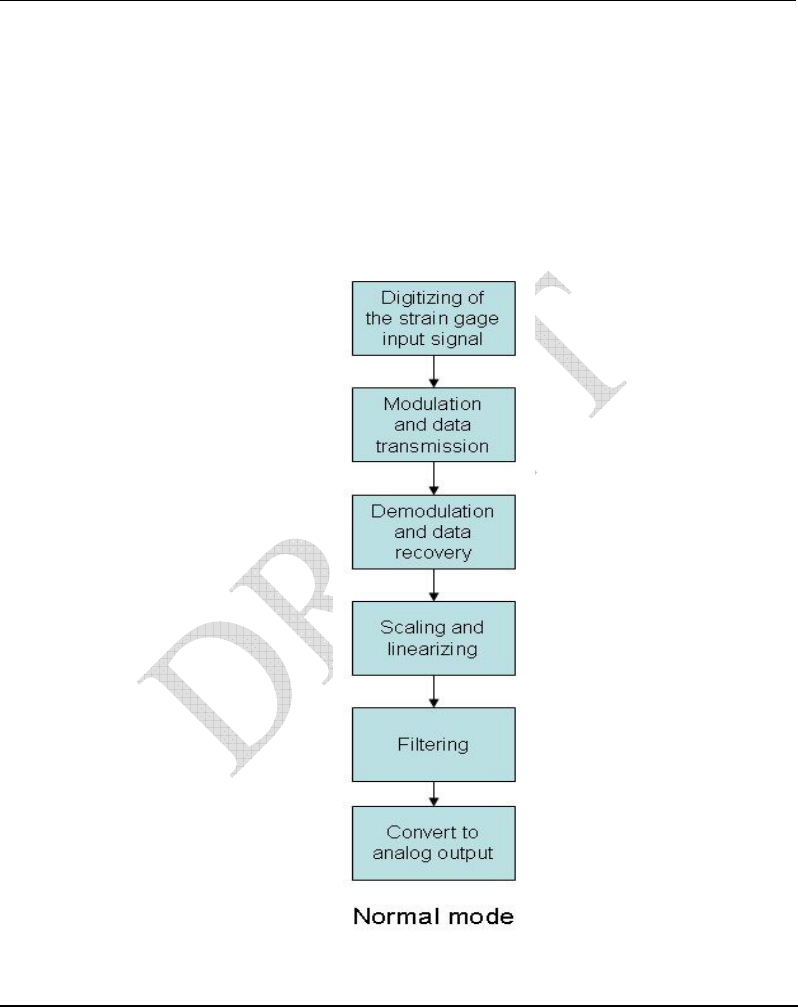

The flow of data in the TMS 9250 is subjected to various forms of processing as it passes

from input to output.

This process is best described by use of a flow chart as follows:

2. Modes of Operation

2.1. Normal mode operation detailed description

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 19

May 2011 Honeywell Confidential & Proprietary

The data is transmitted from the rotor at the maximum data rate but the rate has to be

slowed down for linearizing and scaling due to

the amount of processing required – the TMS 9250 features independent scaling of the

input and output, using floating point values for convenience of the user, and the

linearizing routine can use up to 9 data points (user selectable), so a significant amount of

processor power is consumed during these floating point calculations.

The next process is digital filtering, using a parameter driven recursive algorithm that

performs output smoothing but also provides a separate parameter that controls a filter

bypass in the event of a significant change in input being required to be reflected through

to the output without delay.

The filtered data is then converted to the required analog output format or formats (the

TMS 9250 can drive the voltage or current loop output at the same time as providing a

frequency output) using the output scaling parameters that are independent from the input

calibration.

The rate at which the microprocessor can perform the separate linearizing and scaling

calculations is the limiting factor in determining the available bandwidth of the TMS

9250.

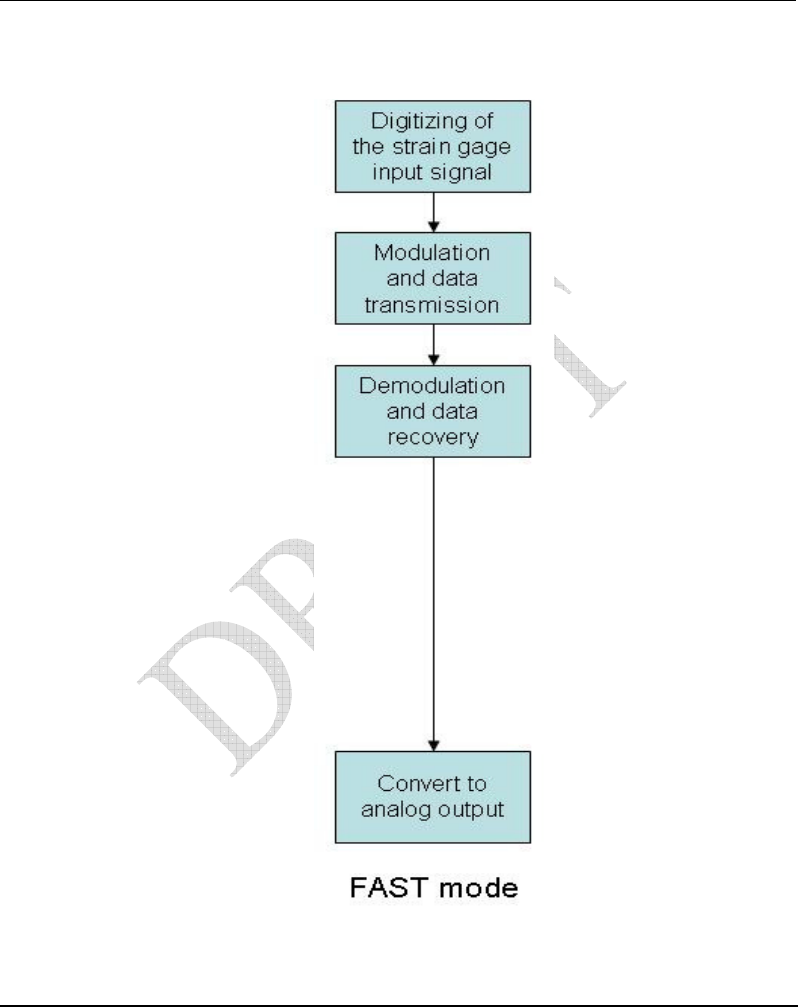

To provide a faster response for users that want to analyze the dynamic data, a

FASTMODE is provided, and in this mode, the data is “piped” directly from the rotor to

the analog voltage output.

The benefit of this mode is that the analog voltage output is updated at the maximum data

rate, which is eight times faster than the normal mode rate.

The penalty of using fastmode is that the scaling and linearizing stages are bypassed, so

the relationship between input and output becomes fixed, and the only way to calibrate

the output against the input is to calculate the expected change in output value (by

reference to the calibration data stored in the TMS 9250), or perform a physical system

calibration or to use the SHUNT CAL feature.

2. Modes of Operation

2.1. Normal mode operation detailed description

Rev: A

008-0738-00

20 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

The following diagram shows the change in data flow when using FASTMODE.

2. Modes of Operation

2.2. Fast mode operation detailed description

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 21

May 2011 Honeywell Confidential & Proprietary

Because of the significant change in output characteristics that takes place when

FASTMODE is selected, it is implemented as a VOLATILE setting, therefore recycling

the power or performing a soft reset will return the TMS 9250 to NORMAL mode.

As an indication to the user that FASTMODE is in operation, the ROTOR ACTIVE light

on the lid of the TMS 9250 Signal processing Modules (SPM) is de-activated.

2.2 Fast mode operation detailed description

Fast hmode operation

The strain gage input value is digitized at a rate of 17,656 samples per second with 24-

bit resolution, but this amount of data is in excess of the capacity of the telemetry link,

so it is reduced by the simple averaging of every pair of A-D results at the rotor

electronics module. The data that is transmitted across the telemetry gap consists of 8,828

results per second at a resolution of 16-bit, and it is this data that is then piped directly to

the analog voltage output whenever FASTMODE is turned on.

The analog voltage output channel is a 16-bit digital-to-analog converter with a

bandwidth of greater than 3 kHz, therefore the expected analog output voltage for a full

scale torque measurement can be calculated by reference to the calibration data tables

held in the TMS 9250.

Assuming that the factory calibrated (or user re- calibrated) data tables can be accessed

using the CAL user mode of the TMS Toolkit, the

Output calibration can be determined using this theoretical method, an example of which

will be given later.

When the TMS Toolkit is not available, the user will need to perform a physical system

calibration by placing a known torque on the sensor and measuring the change in the

analog output voltage.

In cases where the shunt calibration value is known, the change in output due to shunt

calibration can be measured and the result extrapolated to give a full scale equivalent.

Note that this result will need to be adjusted when the shunt cal scaling feature has been

used (#SCSCALE is something other than 1). An example of calculating the analog

output voltage by using shunt cal and the #SCSCALE parameter is also given later.

2. Modes of Operation

2.2. Fast mode operation detailed description

Rev: A

008-0738-00

22 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

Normal mode and FASTMODE data update rates

Mode Data rate

NORMAL When FILTSTEPS>1, data rate is 1104 results per second

NORMAL When FILTSTEPS=1, data rate is 2207 results per second

FASTMODE 8828 results per second

Note

Note that the analog voltage output channel should be only channel

is use for any data rate above 1104 results per second. Therefore

OPTYPE should be set to 1.

Note that any traffic on the RS-232 port caused by TMS Toolkit or

any other communications package will disrupt the flow of data due

to the interrupts that are generated by the external software.

Examples

The following examples assume that either the TMS Toolkit is available and running in

CAL user mode, or that a hard copy of the parameters list is available and valid.

Example 1 – Theoretical determination of analog output value

The relationship between torque and digital counts can be determined by reference to

the parameters held in the TMS 9250. When in FASTMODE, the digital counts received

from the rotor are simply piped through to the analog voltage output channel, so the

counts values can be used to determine the expected analog output values (actual

values may vary within the calibration accuracy of the analog output channel, usually

within 0.1%FS).

Consider a sensor with a 2000Nm full scale torque measuring range

Calibration values most likely to have been used will be (approximately) -2000, 0 and

+2000 Nm

The actual values used may have been adjusted to take account of local gravity and

buoyancy and can be seen from the parameters #CALVALUE1, 2 and 3

Make a note of the actual values used and compare them to the values of #CALCNTS1, 2

and 3

The #CALCNTSx values store the digital counts values that were output by the rotor for

the load conditions given by the relevant #CALVALUEx

2. Modes of Operation

2.2. Fast mode operation detailed description

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 23

May 2011 Honeywell Confidential & Proprietary

The analog voltage output channel is 16-bit and it will generate an output of -10V when

it is driven by a counts value of 0, and will generate an output of +10V when driven by a

COUNTS value of 65535. Therefore each count generates 0.0003052V starting from a

base of -10V.

The analog voltage output will be generated in direct relationship to the statement above.

Therefore, using the following data, the analog voltage output will be:

#CALVALUE1=-1998.699 #CALCNTS1=21553

Therefore at a load of -1998.699 Nm, the analog Voltage will be (21553*0.0003052)-

10V = -3.422V

#CALVALUE2=0.000000 #CALCNTS2=32700

Therefore at a load of 0 Nm, the analog Voltage will be (32700*0.0003052)-10V = -

0.020V

#CALVALUE3=1998.500 #CALCNTS3=43842

Therefore at a load of +1998.500 Nm, the analog Voltage will be (43842*0.0003052)-

10V = +3.381V

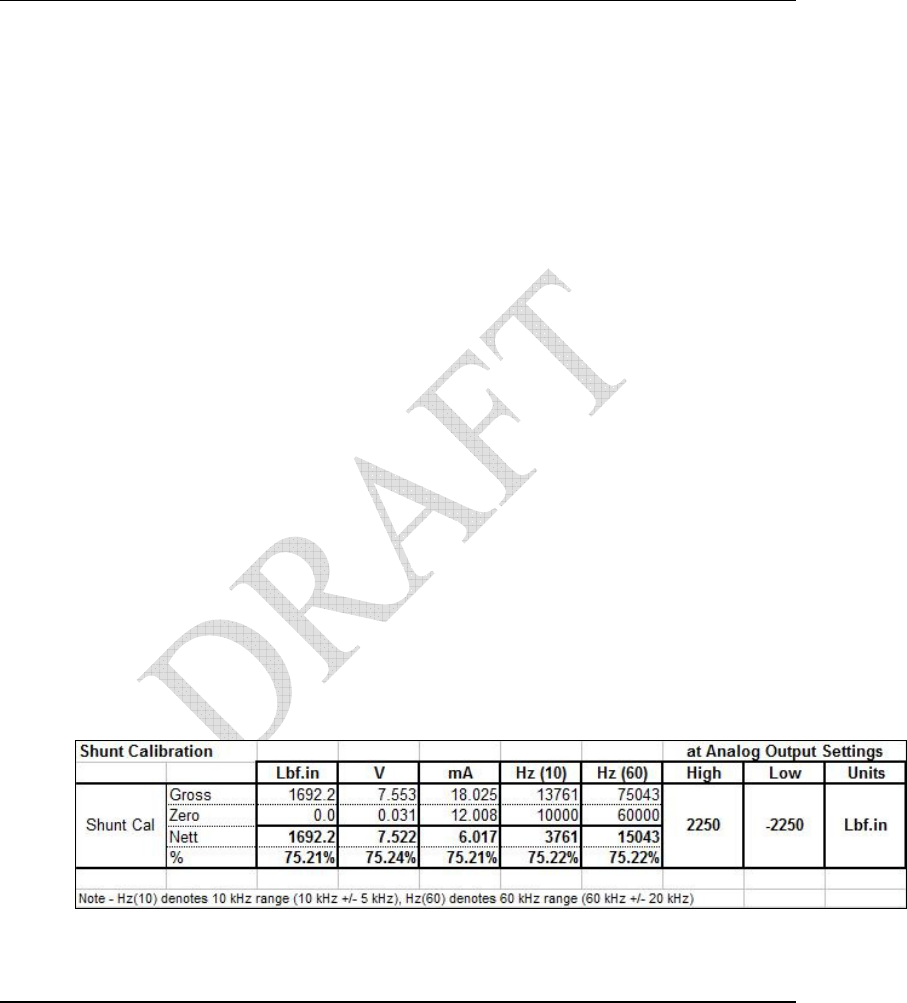

Example 2 - Using the SHUNT CALIBRATION feature

The shunt cal feature operates by switching-in a high precision shunt resistor across

one of the arms of the strain gage bride on the rotor. The change in output that occurs

due to this shunting is repeatable and is often used as a means of calibration. During

factory calibration, the apparent change in torque output due to shunt cal will have been

recorded, and this value can be used to re-calibrate the analog voltage output when in

FASTMODE.

Consider a sensor with a 2250 Lbf.in measuring range. The factory calibration certificate

will include the changes due to shunt cal as a list of effects such as follows :

When in FASTMODE, the shunt cal values for voltage, current and frequency are invalid

because the scaling module is bypassed, so the only piece of information that remains

2. Modes of Operation

2.3. Analog Output characteristics

Rev: A

008-0738-00

24 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

valid and that we need to use from this data table is the apparent change in TORQUE due

to shunt cal, and in the case of this example, it is 1692.2 Lbf.in

It follows that the change in analog voltage output when in FASTMODE will represent

1692.2 Lbf.in

The exception to this case will be when a value has been set for #SCSCALE. This

parameter allows the effect of shunt cal to be varied, according to the value set. The

default is 1 and any other value acts as a multiplier – but only when the scaling module is

operating.

For FASTMODE operation, the scaling module is bypassed so the effect of shunt cal will

be the original effect, as manufactured, and may be significantly different from the

calibration certificate value.

To compensate for any value of #SCSCALE, calculate as follows : Certificated change in

torque due to shunt cal is 1692.2 Lbf.in Value set for #SCSCALE is 1.5

Actual change due to shunt cal is 1692.2/1.5 = 1128.13 Lbf.in

If #SCSCALE is 1, then no calculation is necessary.

2.3 Analog Output characteristics

The analog output channel is specified for a bandwidth of 3 kHz so there is no output

filtering that follows the digital-to-analog converter (DAC). This can lead to a

“staircasing” effect when the DAC is being updated at a relatively slow rate such as

1104Hz.

For users that do not require wide bandwidth, this staircasing will not be a problem and

can be eliminated from the measurement by applying a suitable sampling rate at the

data acquisition end. Typically, a sampling rate of one quarter of the TMS 9250 DAC

update rate (or less) would be sufficient to solve this problem.

For applications where the fidelity of the output waveform is of prime importance, the

solution to staircasing is to add a filter network across the analog voltage output

terminals.

When using FASTMODE, the DAC is being updated at a rate of 8828 Hz therefore

staircasing is reduced as a result of the much faster update rate.

3. Calibration

3.1. System Calibration Method

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 25

May 2011 Honeywell Confidential & Proprietary

3. Calibration

3.1 System Calibration Method

The TMS 9250 features nine-point linearization and all calibration are achieved using the

following parameters:

#CalSteps

#CalReset

#CalValue1

#CalValue2

#CalValue3

#CalValue4

#CalValue5

#CalValue6

#CalValue7

#CalValue8

#CalValue9

The minimum number of calibration points is 2. Calibration points can be created in any

order provided that the values they contain are in ascending order starting with

#CalValue1. Therefore, the lowest or the most negative (counter-clockwise) calibration

point should be designated as #CalValue1.

The number of calibration points that are in use is set by the parameter “#CalPoints”.

Any change to the value of #CalPoints should be followed by the issuance of a

“#CalReset” command, to clear the old calibration values from the EEPROM memories.

Calibration is achieved by applying known loads at each of the calibration points that are

selected for use and then writing the engineering units value to the appropriate

#CalValuex parameter.

The analog outs are precalibrated in the factory, so calibration of the input to the required

output range is automatic and is dependent on the values entered for the parameters

#AnOutHigh

#AnOutLow

#AnOutHigh and #AnOutLow are written-to using the engineering units value at which

the analog outputs are required to give the maximum and minimum outputs.

3. Calibration

3.2. Shunt Calibration

Rev: A

008-0738-00

26 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

Available analog outputs are: Voltage range is –10 to +10 volts.

Current output range is 4 to 20 mA. Frequency range is 5 kHz to 15 kHz or alternatively,

40 kHz to 80 kHz

Calibration Example:

To calibrate from –100 to +100 Nm in five steps of –100, -50, 0, +50 and +100 Nm:

Set #CalSteps=5

#CalReset

Apply –100 Nm and set #CalValue1=-100,

Apply –50 Nm and set #CalValue2=-50

Apply 0 Nm and set #CalValue3=0

Apply +50 Nm and set #CalValue4=50

Apply 100 Nm and set #CalValue5=100

To obtain a frequency output of 5 kHz at 10 Nm and 15 kHz at 80 Nm then the

parameters would be #AnOutLow=10 and #AnOutHigh=80.

The device will then be fully calibrated. Note that for best results and to conform to

accepted calibration practice, the unit under test should be exercised three times at the

full load in the direction of loading prior to the setting of calibration points. This is

especially important when calibrating in both the clockwise and the counterclockwise

directions. Please contact the factory for a detailed description of calibration practice and

procedure.

If an alternative analog output is selected at a later date, or if different settings are chosen

for the #AnOutHigh/Low parameters later, it is not necessary to repeat the loading

calibration because all analog outputs are digitally driven.

3.2 Shunt Calibration

An electrical signal equivalent to that produced by a known load can be obtained by

activating the shunt calibration function. The shunt calibration function is built in to the

sensor itself, and it is therefore necessary for the Rotor Active light to be showing before

the function can be operated. By design, the caliper coupling module is more sensitive to

receiving data than it is to transmitting data, therefore it may be necessary to adjust the

caliper coupling module position to ensure good two-way communications, prior to

using the shunt cal function.

The shunt calibration function is achieved by connecting a high-precision resistor of

know value, in parallel (shunt) with one arm of the strain gage Wheatstone bridge. The

connection is made by a solid state switch, under the control of the microprocessor on the

rotating sensor, when commanded by the remote Signal Processing Module. This switch

3. Calibration

3.3. Storage and Recalibration

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 27

May 2011 Honeywell Confidential & Proprietary

can be activated via the pushbutton on the face of the signal processing module. The

shunt calibration value is determined during factory calibration of the torque sensor.

The shunt calibration function is a very useful aid when setting up the system or when

fault finding. This function can be used as an alternative in applications where it is neither

possible nor practical to perform dead weight system calibration. However, there can be

some loss of calibration accuracy. To provide for this eventuality, the shunt calibration

value is factory-set to represent between 50% and 95% of full scale. This is achieved using

high grade resistors that exhibit very low thermal sensitivity.

3.3 Storage and Recalibration

This torque measurement system may be stored for an indefinite period in a dry place at

room temperature. Recalibration should follow normal instrumentation certification

schedule.

4. Troubleshooting

4.1. “Power On” light is not showing

Rev: A

008-0738-00

28 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

4. Troubleshooting

The following is the sequence in which a typical installation should proceed:

4.1 “Power On” light is not showing

• Check that 12VDC is being applied to the correct terminals (J1) and at the correct polarity.

• In certain cases, for example where the caliper coupling module has been left in direct contact

with a metal surface for some time, the internal thermal protection circuit may have activated.

•

To reset this condition, remove power and wait ten minutes before restoring power.

4.2 “Rotor Active” light is not showing

• Check that the RF cable is in good condition and is of the correct length (look for damage to

the outer sheath that may indicate that the cable has been crushed at some time).

• Check that the caliper coupling module has been correctly positioned in close proximity to the

rotating antenna. Use the positioning guide that was supplied with the system to confirm the

position. Move the caliper coupling module to try and achieve coupling in an alternative

position.

• Check that there are no metal parts (flanges, covers, etc), within one and a half inches

(40mm) of the caliper coupling surfaces.

• Check that the power supply is actually 12 VDC when the caliper coupling module is in the

appropriate position (some power supplies have built-in protection circuits that cause a

reduction in supply voltage when current demands increase.

4.3 Shunt calibra-tion does not operate

• Check that the “Rotor Active” light is showing, prior to using the shunt calibration function.

• Check that the RF cable is in good condition and is of the correct length (look for damage to

the outer sheath that may indicate that the cable has been crushed at some time).

• Check that the caliper coupling module has been correctly positioned in close proximity to the

rotating antenna. Use the positioning guide that was supplied with the system to confirm the

4. Troubleshooting

4.4. Cannot communicate.

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 29

May 2011 Honeywell Confidential & Proprietary

position. Move the caliper coupling module to try and achieve coupling and shunt cal

functionality in an alternative position.

• Check that there are no metal parts (flanges, covers, etc), within one and a half inches (40mm)

of the caliper coupling surfaces.

• Check that the power supply is actually 12 VDC when the caliper coupling module is in the

appropriate position (some power supplies have built-in protection circuits that cause a

reduction in supply voltage when current demand increase).

Make sure “scon” shunt cal on command is not given in software tool kit. Which will

make shunt cal on always. Type in scoff in the tool kit to switch off shunt cal. Refer to

the TMS Tool kit User Manual for more information.

4.4 Cannot communicate.

• Check all wiring.

• If using the RS232 port, check that the Rx pin of the host computer is connected to the Tx pin

of the TMS 9250 and vice versa.

• Check that the communications cable being used is of high quality or try a shorter length of

cable (RS232 is sensitive to cable length and grounding issues, especially when used with

laptop computers where grounding is uncertain).

• Check that the correct serial port is selected in the software or TMS Toolkit. When using

Windows, the serial port in use can be found by using the CONTROL PANEL, SYSTEM,

HARDWARE, DEVICE MANAGER, COM ports functions.

• On older desktop PC’s, the COM1 port is already in use for the mouse, so a different COM

port should be selected.

• If using a USB to Serial adapter, Windows assigns the COM port designations dynamically so

they may change whenever the system is rebooted.

• The serial port settings are automatically modified by TMS Toolkit so there is no need to

change any of the settings in Windows.

• The baud rate setting in TMS Toolkit should always be 38400 because that is the default baud

rate of the TMS 9250.

• The “TMS ID” should be left blank because TMS Toolkit will search the connected port for

any TMS device and will commence the communication automatically if present.

• Refer to the TMS Toolkit User Manual for more information

5. Product Specifications

4.4. Cannot communicate.

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 31

May 2011 Honeywell Confidential & Proprietary

5. Product Specifications

Product Feature Product Specification

Power supply

•

90~264V AC 47~63 Hz

Protection

•

Short Circuit and over voltage protection

Pollution degree

•

3

Analog output signals

•

4-20 mA (zero torque = 12 mA)

•

+/- 10 VDC (zero torque = 0 V)

•

10 kHz +/- 5 kHz (zero torque = 10 kHz)

•

60 kHz +/- 20 kHz (zero torque = 60 kHz)

Output drives capability

•

4-20 mA 400 Ohms max including cable

resistance

•

+/- 10 VDC 2 k Ohms min

•

Frequency 4 V p-p for 100 k Ohms 2.3 V

p-p for min load of 1k Ohms

Digital resolution

•

Normal mode 16-bit ( 0.01 %FS)

•

Hi-res mode 19-bit (0.001 %FS) RF

carrier frequency 13.56 MHz

Accuracy

•

System 0.050% FS typical*

•

*4-20mA Current output drifts with input

power supply change around the nominal

12V

Temperature Range

•

Operating, Sensor and CCM Only

•

40 to 85 C (-40 to 185 F)

•

Operating, SPM and Power Supply

•

0 to 40 C (32 to 104 F)

•

Compensated

•

10 to +50 C (14 to 122 F)

•

008-0738-00

Frequency response

•

Input sampling rate 17,656 samples/sec

•

Anti-aliasing

5. Product Specifications

4.4. Cannot communicate.

Rev: A

008-0738-00

32 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

•

filter fixed) 4.1kHz

•

Telemetry update rate 8.828 kHz

•

Fast mode data

•

throughput rate 8.828 kHz

•

Normal mode data

•

throughput rate 1.104 kHz

•

Analog output

•

bandwidth (max) 3 kHz @ -3 db

•

Group delay (typical,

•

normal mode) 2.5ms

•

Group delay (typical,

•

fast mode) 1.2ms

Digital filtering

•

FIR mode 0.1 through 1000 Hz

•

IIR mode recursive algorithm

6. Appendices

6.1. APPENDIX A

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 33

May 2011 Honeywell Confidential & Proprietary

6. Appendices

The following section describes about different appendices related to the TMS 9250

Torque Measurement System.

The following section describes about different appendices related to the TMS 9250

Torque

Measurement System.

Appendix A – Supplement for TMS 9250 SPM Remote Shunt Cal Option.

Appendix B – Supplement for TMS 9250 SPM Digital Filter Settings.

Appendix C – Supplement for Conversion table.

Appendix D – Supplement for power supply positioning, product grounding and cleaning

instructions.

Appendix E - Setting up the Cables for the Signal Processing Module (SPM).

6.1 APPENDIX A

Manual Supplement for TMS 9250 SPM Remote Shunt Cal Option

This supplement provides information on the operation and specifications of the TMS

9250 SPM with the Remote Shunt Cal Option, P/N 064-LW37039.

Overview

The TMS 9250 SPM with Remote Shunt Cal option allows the user to remotely activate

and deactivate the shunt cal mode via an external switch and cable.

Setup

The Remote Shunt Cal option is installed and tested at the factory. A six-pin circular

connector is mounted to the front panel of the SPM box as a connection point for the

remote shunt cal switch. A mating connector (023-LW181-034) is provided so the user

can attach a cable between the SPM and the customer supplied switch.

Step Action

a Connect a two-conductor cable between the remote switch and the

mating connector. Solder one conductor to pin A of the mating

connector and the other conductor to pin B. Attach the strain relief

to the connector.

6. Appendices

6.2. APPENDIX B

Rev: A

008-0738-00

34 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

Step Action

b Attach the mating connector to the six pin connector on the SPM

c After setting up the sensor and caliper module, power on the SPM

and verify the Power LED and the Rotor Active LED is lit on the top

of the SPM. Turn on the remote shunt cal switch and verify the

Shunt Cal Mode LED is lit on the top of the SPM. Turn off the remote

shunt cal switch and verify the Shunt Cal Mode LED turns off.

d Setup of the Remote Shunt Cal Option is complete.

6.2 APPENDIX B

Manual Supplement for TMS 9250 SPM Digital Filter Settings

This supplement provides information on the operation and specifications of the TMS

9250 SPM with the Digital Filter Settings, as they relate to v1.38 software.

Intended Use

This supplement is intended for the purpose of describing the function and operation of

the digital filtering algorithms that are included in the TMS 9250 version 1.38 firmware.

It should be used in conjunction with the TMS 9250 User Manual and the TMS Toolkit

User Manual, both of which are supplied with a TMS 9250 Torque Measuring System.

Filter Operation General Description

The digital filter algorithm in the v1.30 and later firmware versions of the TMS 9250 is

basically a recursive filter that behaves like an “RC” circuit.

It has two user settings, the first being a “level” set by the parameter FiltLevel, and the

second being a filter “weight”, set by the parameter FiltSteps.

The “level” works as a threshold, above which the filter is reset to allow a fast response

to a event that exceeded the threshold. This is useful in the case when well-damped

steady state data is required, but when significant fast transients and disturbances should

not be filtered out.

The “weight” of the filter is set by increasing the number of filter steps, which in turn

increases the time constant of the RC filter, increasing the damping effect.

The settings of any of the TMS 9250 parameters can be changed at any time via the

RS232 communications link. Changing parameters while the system is running will take

effect immediately, and in the case of filter setting changes, will become effective as

soon as the filter flushes through.

6. Appendices

6.2. APPENDIX B

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 35

May 2011 Honeywell Confidential & Proprietary

The TMS Toolkit software, supplied with the TMS 9250 system, simplifies the task of

changing settings, although any character-based communications software could be used

instead (e.g. HyperTerminal).

Filter Operation Detailed Description

Consider the input signal as being V

i

and the output signal being V

o

In a steady state situation, V

o

will equal V

i

When V

i

changes, the extent of the change is compared with the threshold, which is set

as a proportion of the full scale sensitivity, by the parameter FiltLevel.

If the change exceeds the threshold, then the new input value is passed immediately to the

output, thereby resetting the filter.

If the change does not exceed the threshold, then the output value V

o

is updated by a

fractional amount of the new value V

i

until the output value equals the input value

again. The number of steps set by FiltSteps determines the number of fractional steps

that are taken to increment the output value, according to the following series :

1 / 2, 1 / 3, 1 / 4, 1 / 5 ….etc

The output characteristic is therefore exponential and behaves in a predictable manne.

To determine the settling time of the filter (the time taken to reach the V

o

= V

i

condition), it is necessary to know both the filter update rate and the number of

fractional steps. The filter update rate is fixed at 1000 Hz in the firmware v1.30 and

above, although other filter update rates can be made available upon request to the

factory.

The cut-off point (in Hz) is given by the expression

Frequency (-3dB)=

(Update rate/number of steps)/6.3

The table below provides a quick reference to determine the filter characteristic

Note that this filter operates only when the cha Consider the input signal as being

V

i

and the output signal being V

o

In a steady state situation, V

o

will equal V

i

When V

i

changes, the extent of the change is compared with the threshold, which is set

as a proportion of the full scale sensitivity, by the parameter FiltLevel.

If the change exceeds the threshold, then the new input value is passed immediately to the

output, thereby resetting the filter.

6. Appendices

6.2. APPENDIX B

Rev: A

008-0738-00

36 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

If the change does not exceed the threshold, then the output value V

o

is updated by a

fractional amount of the new value V

i

until the output value equals the input value

again. The number of steps set by FiltSteps determines the number of fractional steps

that are taken to increment the output value, according to the following series :

1 / 2, 1 / 3, 1 / 4, 1 / 5 ….etc

The output characteristic is therefore exponential and behaves in a predictable manne.

To determine the settling time of the filter (the time taken to reach the V

o

= V

i

condition), it is necessary to know both the filter update rate and the number of

fractional steps. The filter update rate is fixed at 1000 Hz in the firmware v1.30 and

above, although other filter update rates can be made available upon request to the

factory.

The cut-off point (in Hz) is given by the expression

Frequency (-3dB)=(update rate/number of steps)/6.3

The table below provides a quick reference to determine the filter characteristic

Note that this filter operates only when the change in the input is below the threshold set

by FiltLevel.

The time required for the output to settle following a step change in input level is

given by the following table.

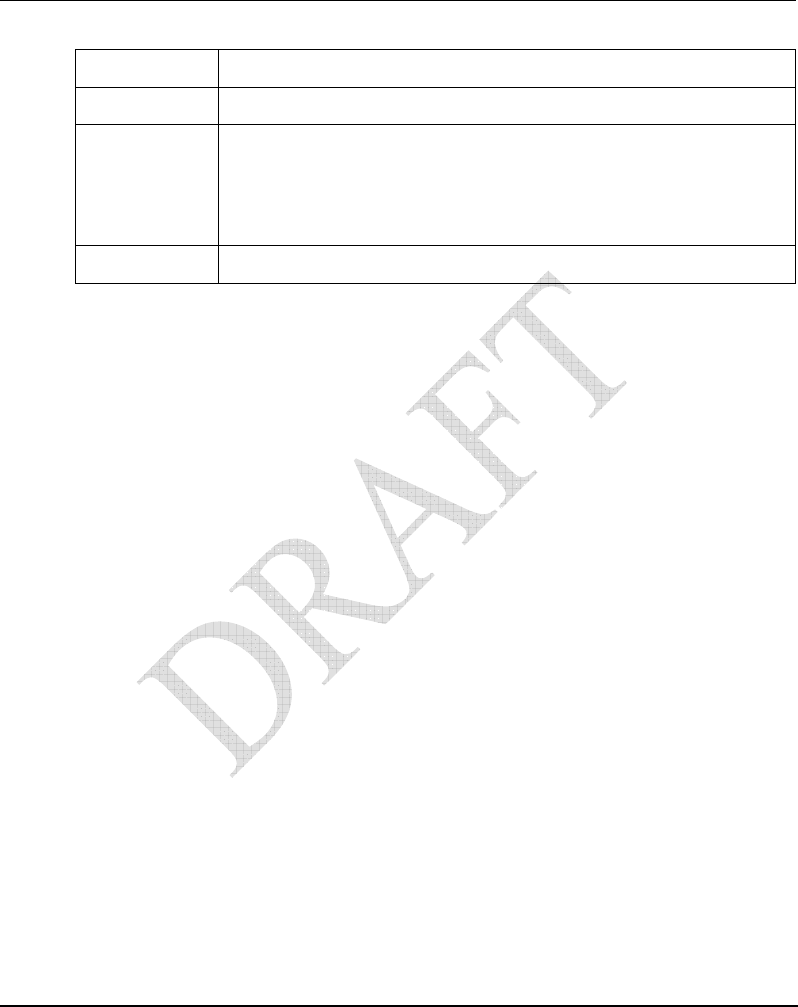

Filter Settling Time

The time required for the output to settle following a step change in input level is

given by the following table.

6. Appendices

6.2. APPENDIX B

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 37

May 2011 Honeywell Confidential & Proprietary

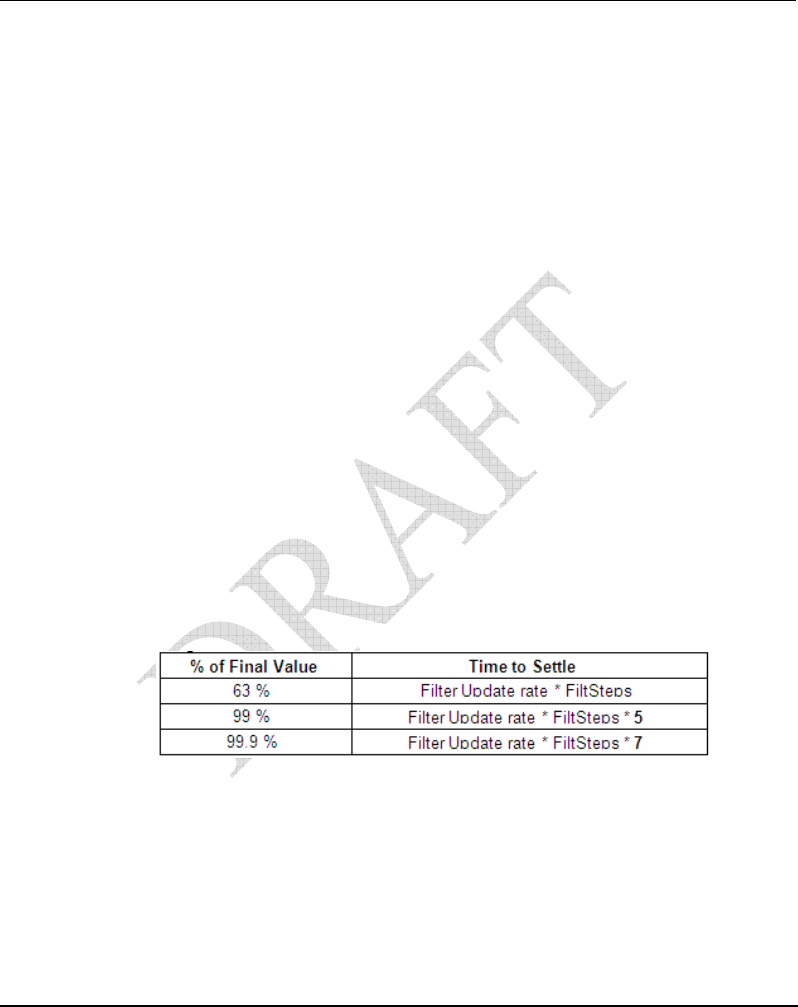

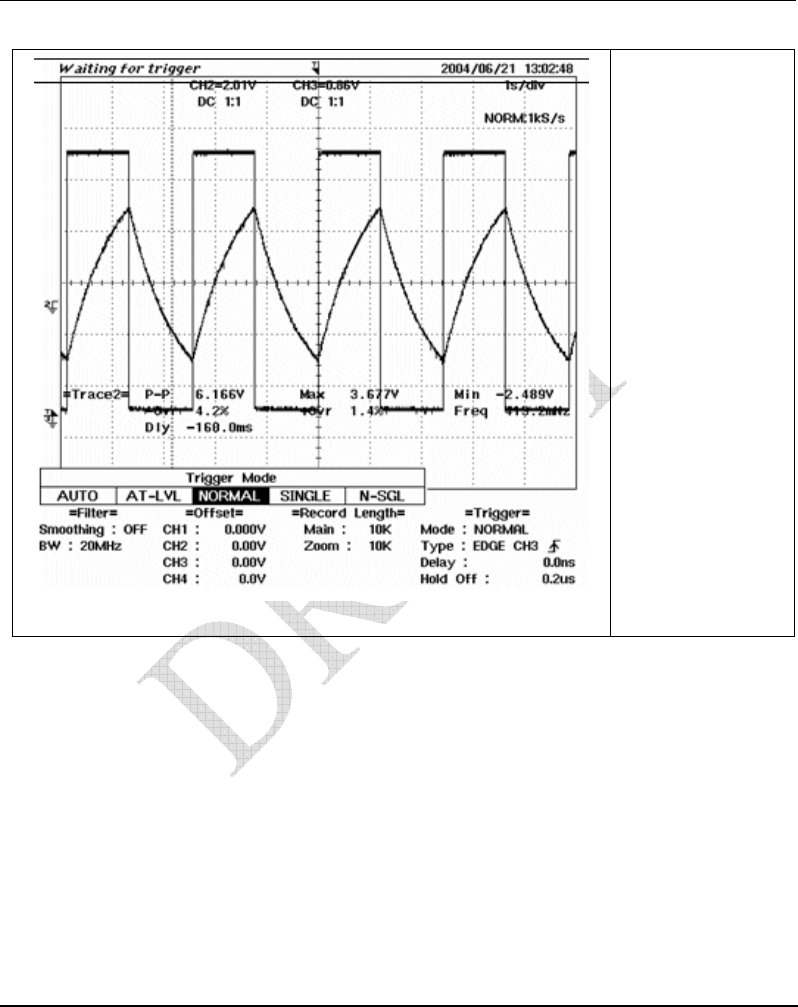

Sample Charts

INPUT : Square

Wave, 0.1 Hz

OUPUT : Analog

Voltage

FiltLevel=10000

FiltSteps=1000

Settling time to 99%

is given by

5 * 0.001 * 1000 = 5

seconds

6. Appendices

6.2. APPENDIX B

Rev: A

008-0738-00

38 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

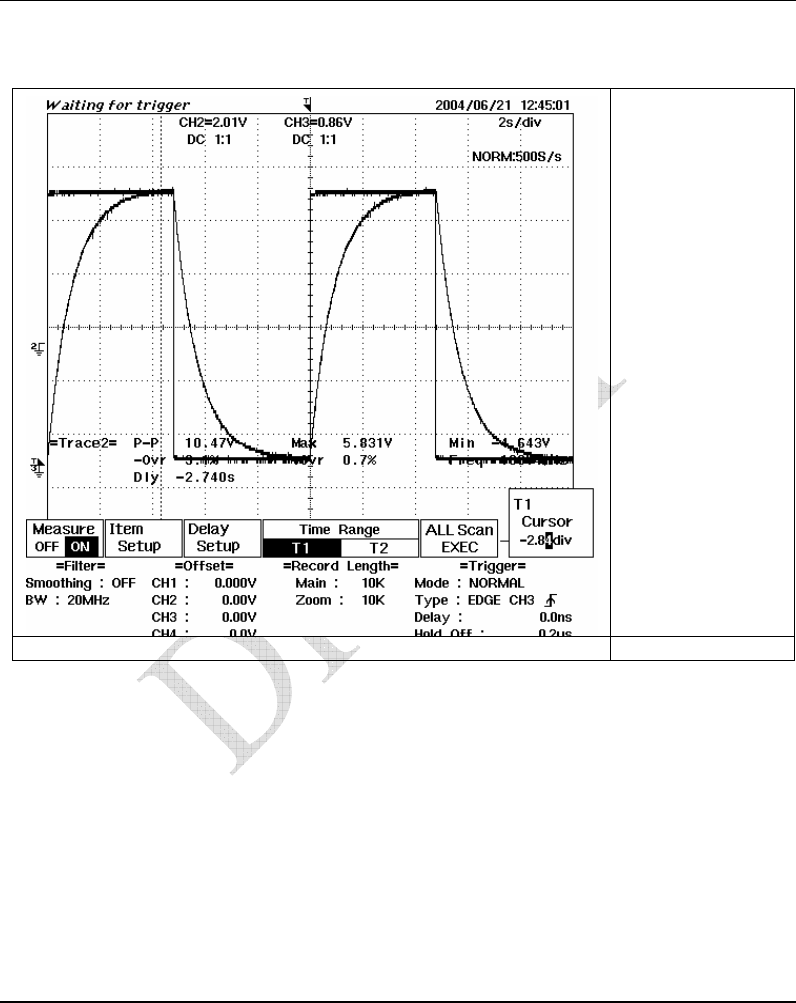

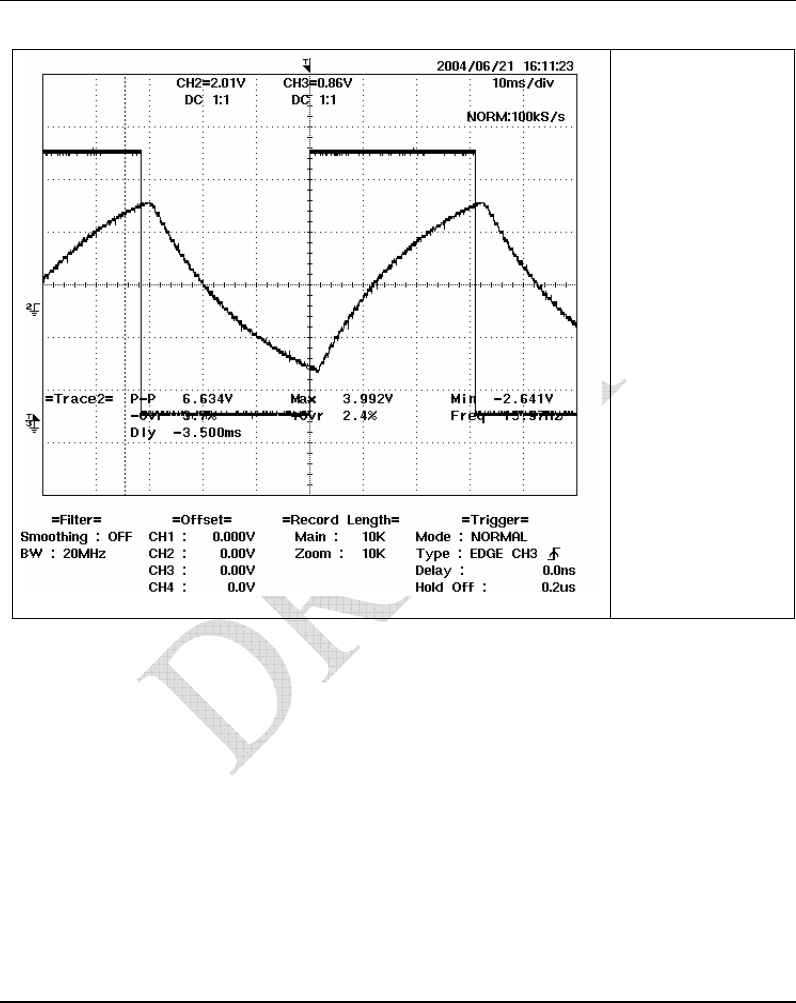

INPUT : Square

Wave, 0.4 Hz

OUPUT : Analog

Voltage

FiltLevel=10000

FiltSteps=1000

Settling time to 99%

is given by

5 * 0.001 * 1000 = 5

seconds

Therefore

overdamped

response, only

reaching 60% of full

scale p-p value

6. Appendices

6.2. APPENDIX B

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 39

May 2011 Honeywell Confidential & Proprietary

INPUT : Square

Wave, 16 Hz OUPUT

: Analog Voltage

FiltLevel=10000

FiltSteps=38

Settling time to 63%

is given by

0.001 * 38 = 0.038

seconds

Therefore

overdamped

response

6. Appendices

6.3. APPENDIX C

Rev: A

008-0738-00

40 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

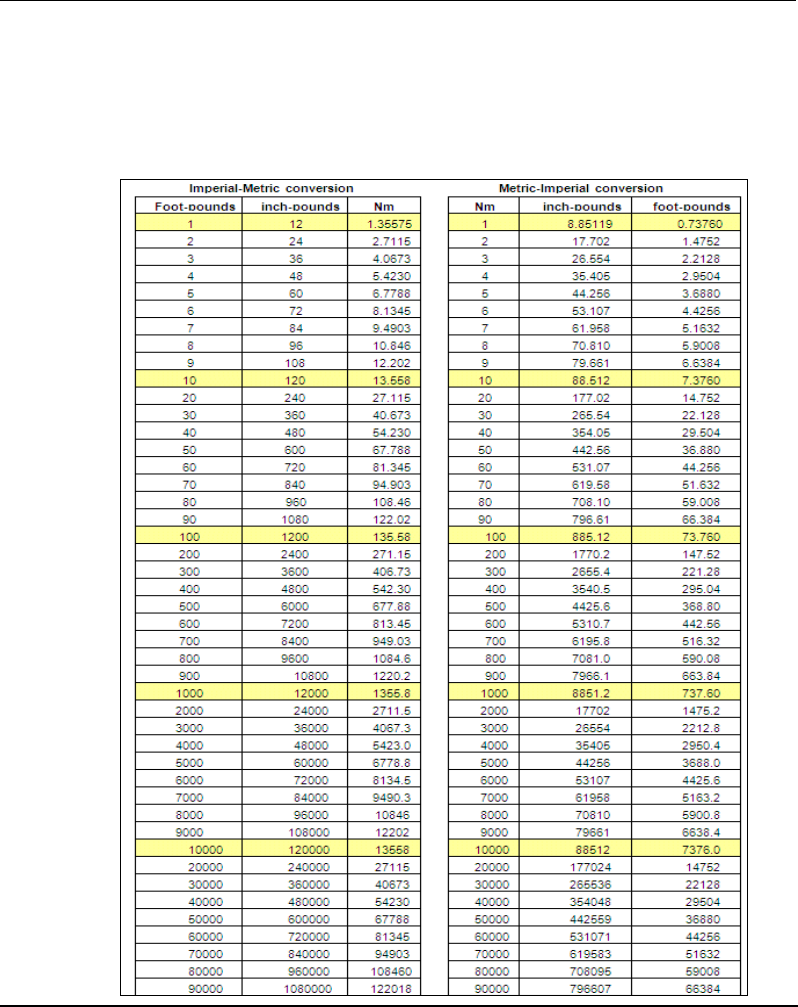

6.3 APPENDIX C

Conversion Table

6. Appendices

6.4. APPENDIX D

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 41

May 2011 Honeywell Confidential & Proprietary

6.4 APPENDIX D

This supplement provides information on positioning the power supply and cleaning instructions.

Step Action

Positioning

the power

supply

Place the power supply of the system in a place where you can

easily unplug the power cords.

Cleaning the system

Step Action

a Disconnect the power supply from the system.

b Clean the SPM, Shroud, CCM and Rotor with dry cloth.

ATTENTION

Do not use any chemicals to clean the system.

Product

Grounding

•

Shield of all the output signal shall be connected to SPM side (refer

to step 4.c of Appendix-E)

and let floating on data acquisition side

•

Third pin of power supply adapter must and shall be connected to

earth.

•

CCM shall be left floating.

6. Appendices

6.5. APPENDIX E

Rev: A

008-0738-00

42 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

6.5 APPENDIX E

Setting up the Cables for the Signal Processing Module (SPM)

Setting up the cables involves the following steps.

ATTENTION

The interface cables must be shielded type and connected to product

end only.

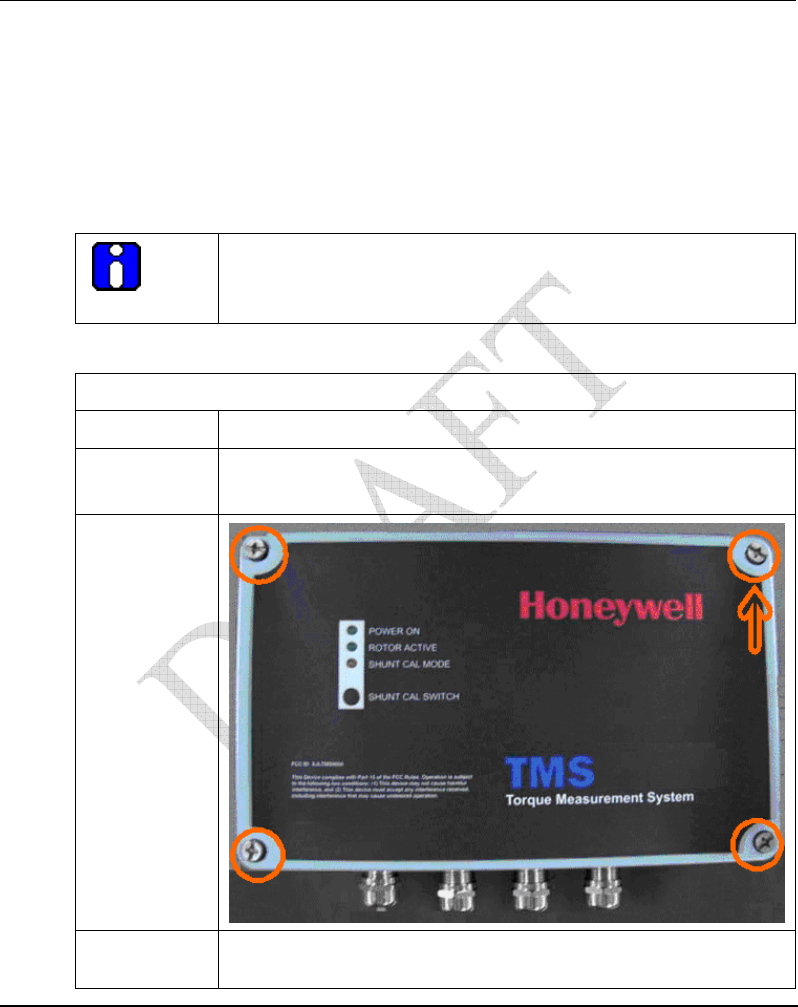

Step 1: Removing the Cover of the SPM Box

Step Action

a Keep the SPM on table with ESD plane, and wear the ESD strap.

Open the cover of the SPM box by removing the screws.

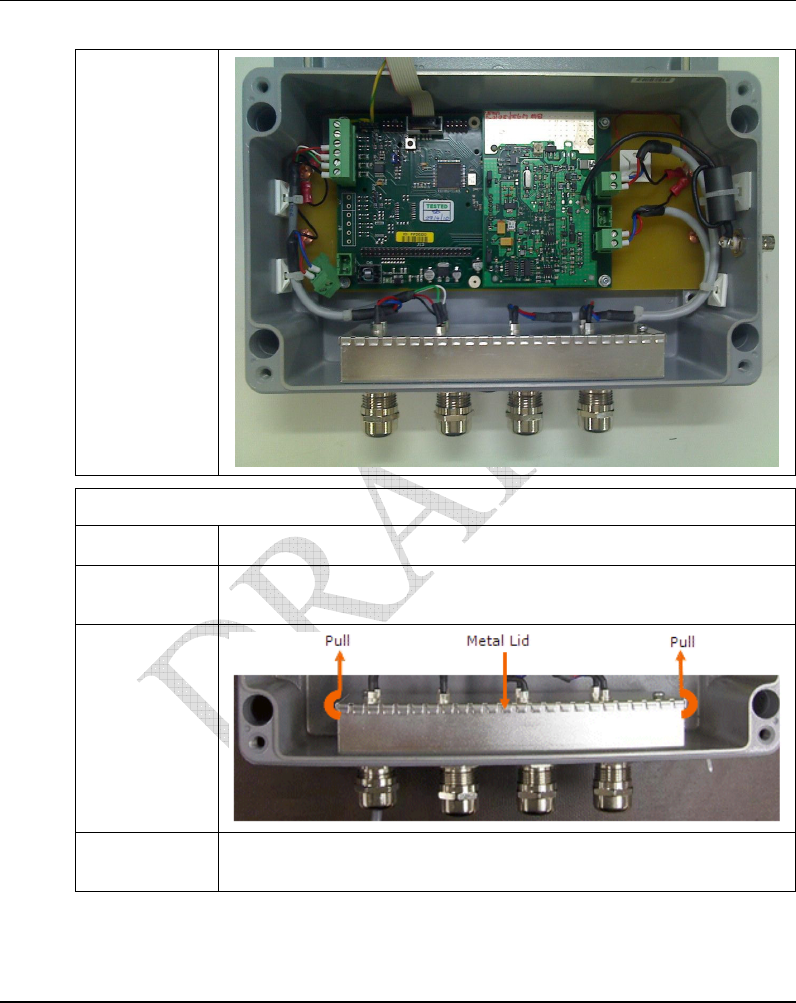

b After removing the cover, you can see the base unit of the SPM in

the following figure.

6. Appendices

6.5. APPENDIX E

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 43

May 2011 Honeywell Confidential & Proprietary

Step 2: Removing the Metal Lid in the SPM Box

Step

Action

a Hold the metal lid at the end and then remove as shown in the

following figure.

b After removing the metal lid, you can see the printed circuit board as

shown in the following figure.

6. Appendices

6.5. APPENDIX E

Rev: A

008-0738-00

44 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

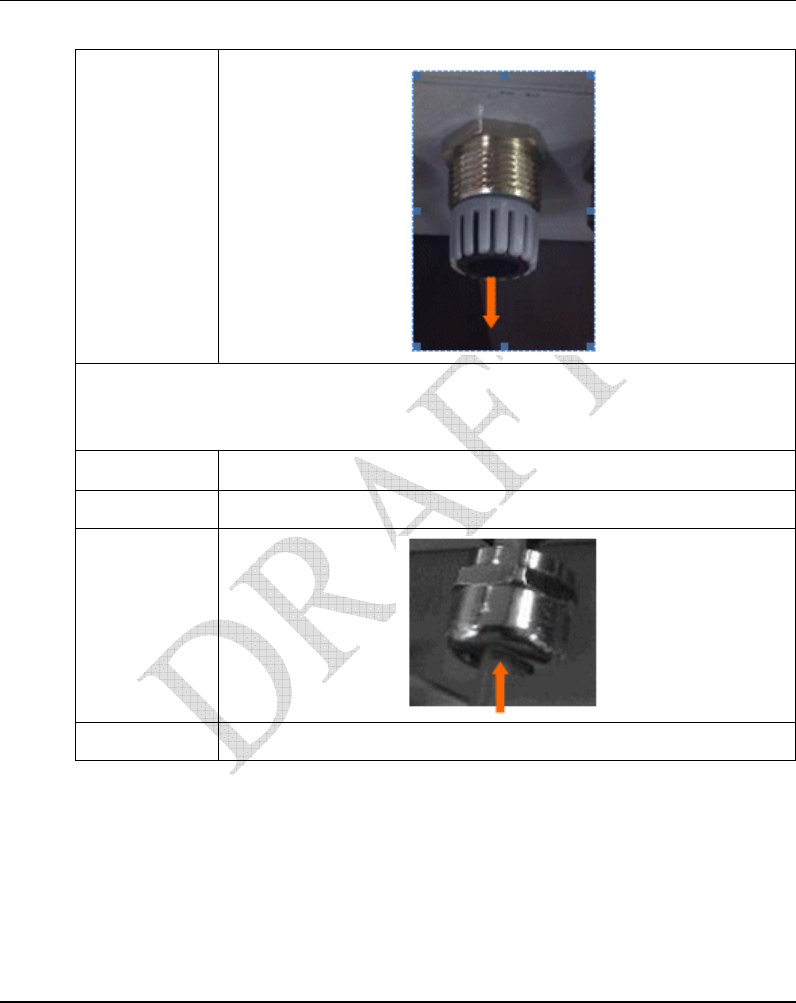

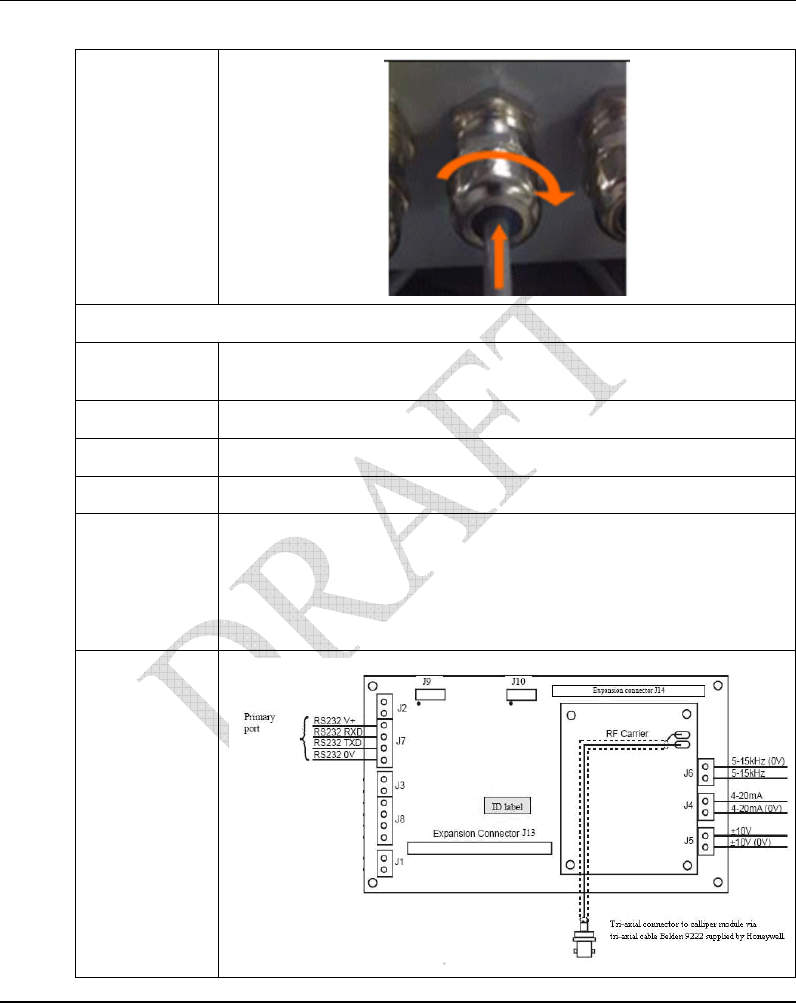

Step 3: Removing the Glands

You must remove the glands before connecting the wires to the printed circuit board.

Step

Action

a Turn the screws of the metal glands in the counter clockwise

direction using the pliers and remove it as shown in the following

figure

b Remove the plastic cover as show in the following figure.

6. Appendices

6.5. APPENDIX E

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 45

May 2011 Honeywell Confidential & Proprietary

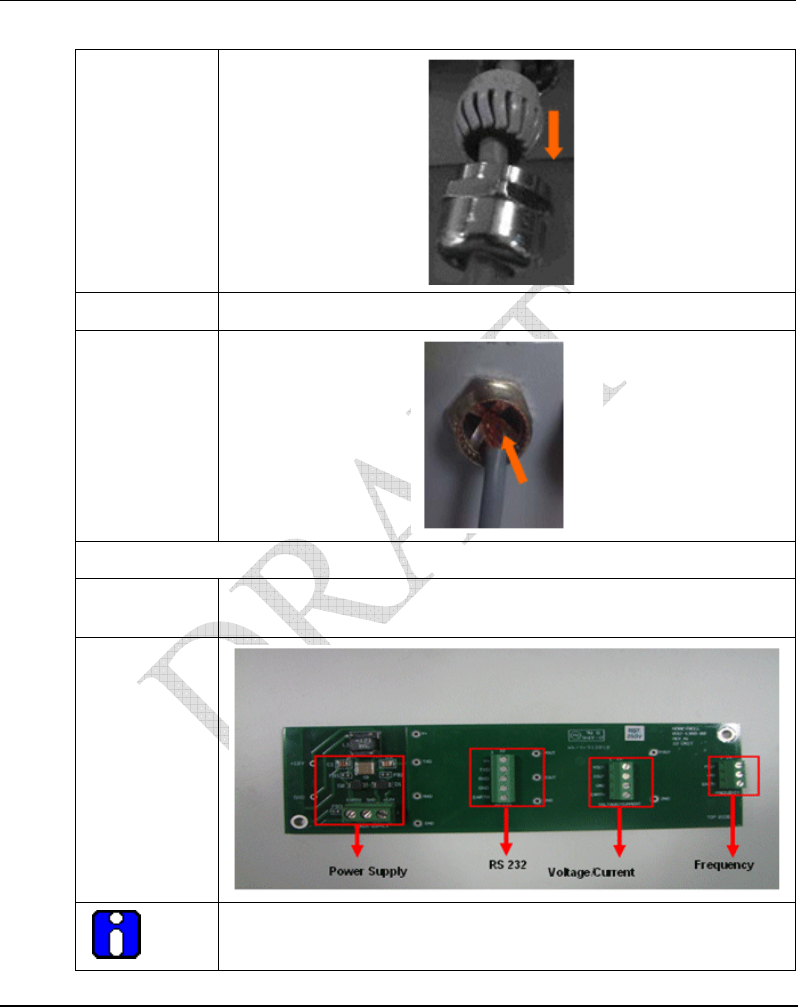

Step 4: Inserting the Cables

You must insert the cables into connectors such as Analog Voltage/ Current, and

Frequency.

Step

Action

a Insert the cable into the metal gland as show in the following figure.

b Insert the cable into the plastic cover as show in the following figure.

6. Appendices

6.5. APPENDIX E

Rev: A

008-0738-00

46 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

c Connect the wire to the metal gland as show in the following figure.

Step 5: Connecting the wires to the Printed Circuit Board (PCB)

After inserting the cables into glands, you must connect the wires to

the respective connectors, inside the printed circuit board as shown.

ATTENTION

RS 232 is the only cable supplied with the product.

6. Appendices

6.5. APPENDIX E

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 47

May 2011 Honeywell Confidential & Proprietary

Step

Action

a Loosen the screws of the connectors on the PCB and connect the

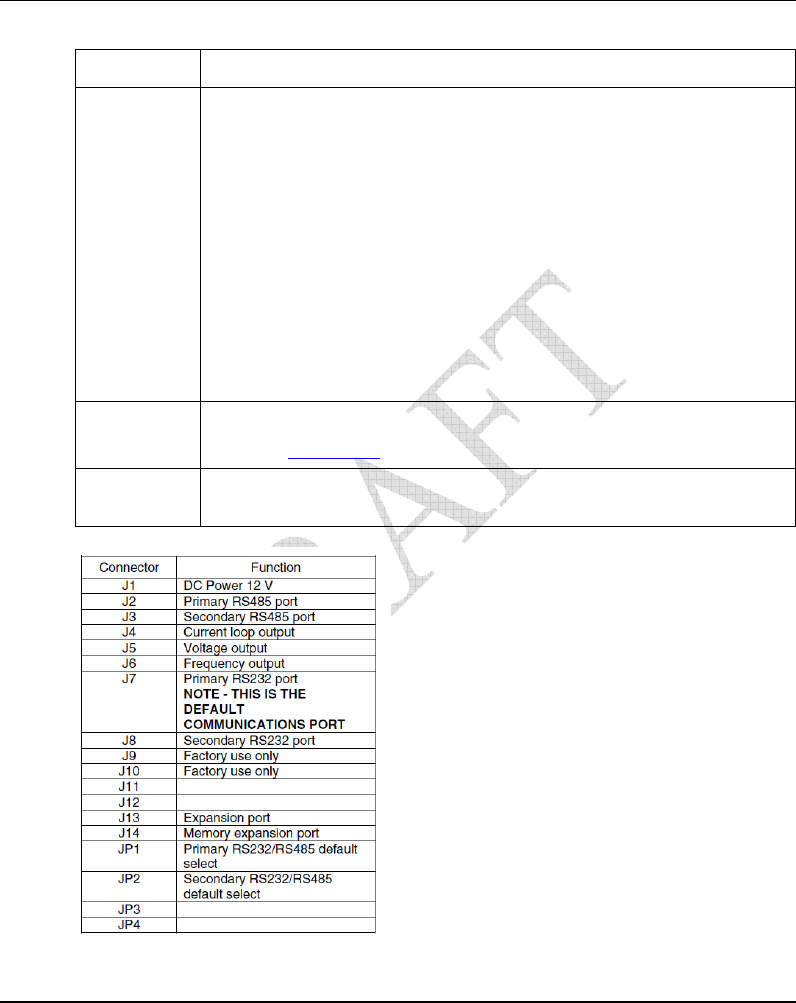

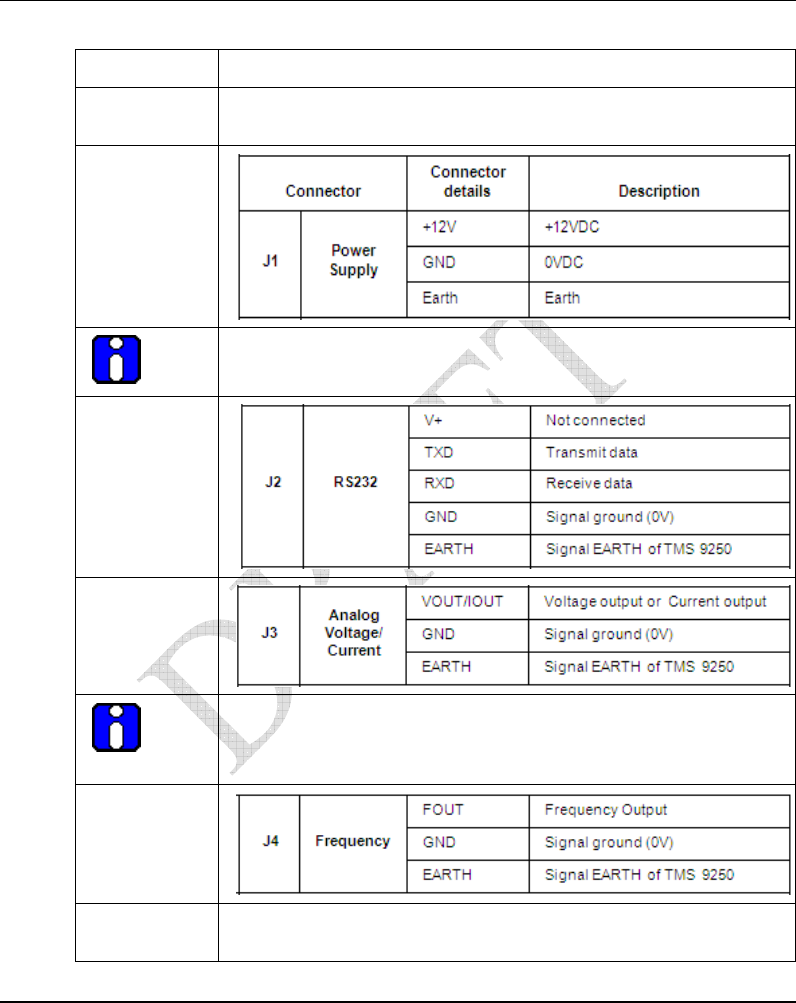

respective wires to the connectors by referring to the below table.

ATTENTION

By default, the power supply cable is connected.

ATTENTION

The output depends on OPTYPE value configured using TMS tool

kit for TMS 9250.

b After connecting the wires to respective connectors, tighten the

screws.

6. Appendices

6.5. APPENDIX E

Rev: A

008-0738-00

48 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

ATTENTION

The output depends on OPTYPE value configured using TMS tool

kit for TMS 9250. Refer to the TMS Toolkit User Manual for more

information

.

Step 6: Closing the Metal Lid inside the SPM Box

a Hold the metal lid at the end and push the LID then close it as

shown in the figure.

Step 7: Closing the Glands

After closing the metal lid inside the SPM box, you must tighten the

glands.

Step

Action

a Put the plastic cover as show in the figure.

b Put the metal gland and tighten in the clock wise as show in the

figure.

6. Appendices

6.5. APPENDIX E

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 49

May 2011 Honeywell Confidential & Proprietary

Step 8: Closing the Metal Cover of the SPM Box

After closing the glands, you must close the metal cover of the SPM

box.

Step

Action

a Replace the cover on the base of the SPM box.

b Insert the screws into the screw holes and tighten it.

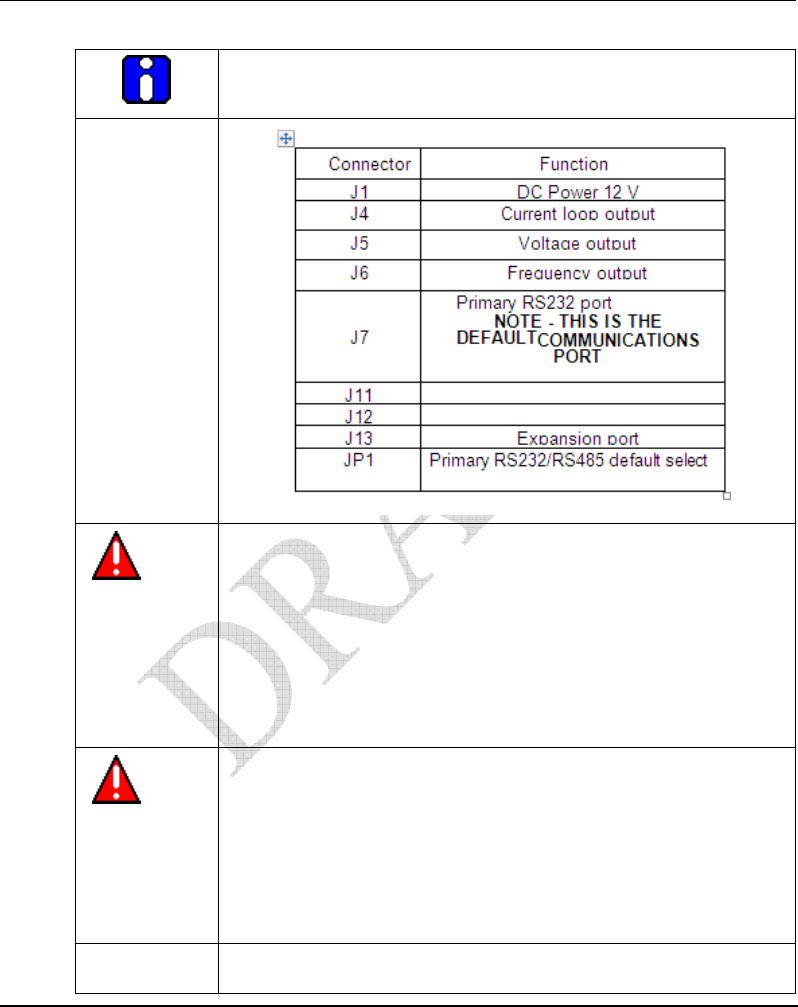

Electrical

Connections

The signal-processing module features two-part plug and socket

connectors and the connection details are shown in figure 2. All

cable connections should pass through the cable glands, and shield

to be connected to metal glands,as described in the Appendix-E.

6. Appendices

6.5. APPENDIX E

Rev: A

008-0738-00

50 TMS 9250 Product User Manual V 1.0

Honeywell Confidential & Proprietary May 2011

Note

Make sure J4/J5 are not swapped with J6

Connector

and Jumper

Functions

WARNING

MISUSE OF D

O

C

U

MEN

T

ATI

O

N

•

The information presented in this product sheet is for reference

only. Do not use this document as product installation guide.

•

Complete installation, operation, and maintenance information is

provided in the instructions supplied with each product.

Failure to c

o

mply with t

h

ese instru

ct

ions could result in

death or serious injury.

WARNING

PERSONAL INJURY

DO NOT USE these products as safety or emergency stop devices

or in any other application where failure of the product could result in

personal injury.

Failure to c

o

mply with t

h

ese instru

ct

ions could result in

death or serious injury.

WARRANTY/ Honeywell warrants goods of its manufacture as being free of

defective materials and faulty workmanship. Honeywell’s standard

6. Appendices

6.5. APPENDIX E

Rev: A

008-0738-00

V 1.0 TMS 9250 Product User Manual 51

May 2011 Honeywell Confidential & Proprietary

REMEDY

product warranty applies unless agreed to otherwise by Honeywell in

writing; please refer to your order acknowledgement or consult your

local sales office for specific warranty details. If warranted goods are

returned to Honeywell during the period of coverage, Honeywell will

repair or replace, at its option, without charge those items it finds

defective.

The foregoing is buyer’s sole

r

e

medy and is in

lieu of

a

ll other

w

arr

an

ties, exp

r

es

s

ed or implied,

including tho

s

e of me

r

cha

n

tability

and fit

n

ess for a

particu

l

ar purpo

s

e. In

no eve

n

t sh

a

ll Honeywell be liable

for conseque

n

tial, special, or indirect damages.

While we provide application assistance personally, through our

literature and the Honeywell web site, it is up to the customer to

determine the suitability of the product in the application.

Specifications may change without notice. The information we

supply is believed to be accurate and reliable as of this printing.

However, we assume no responsibility for its use.

SALES AND

SERVICE

Honeywell serves its customers through a worldwide network of

sales offices, representatives and distributors. For application

assistance, current specifications, pricing or name of the nearest

Authorized Distributor, contact your local sales office or:

E-mail:

sales@sensotec.com

Internet:

www.honeywell.com/sensotec

Phone and

F

ax:

Tel: 614-850-5000

Fax: 614-850-1111

V 1.0 TMS 9250 Product User Manual 53

May 2011 Honeywell Confidential & Proprietary